Casting mold and casting method for large-size disc type complicated-structure part

A technology of complex structure and parts, applied in the field of casting and casting of large-scale disc-type complex structure parts, can solve the problems of slag inclusion, shrinkage porosity, etc., and achieve the effect of stable iron feeding, prevention of shrinkage porosity, and prevention of lifting the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1GE

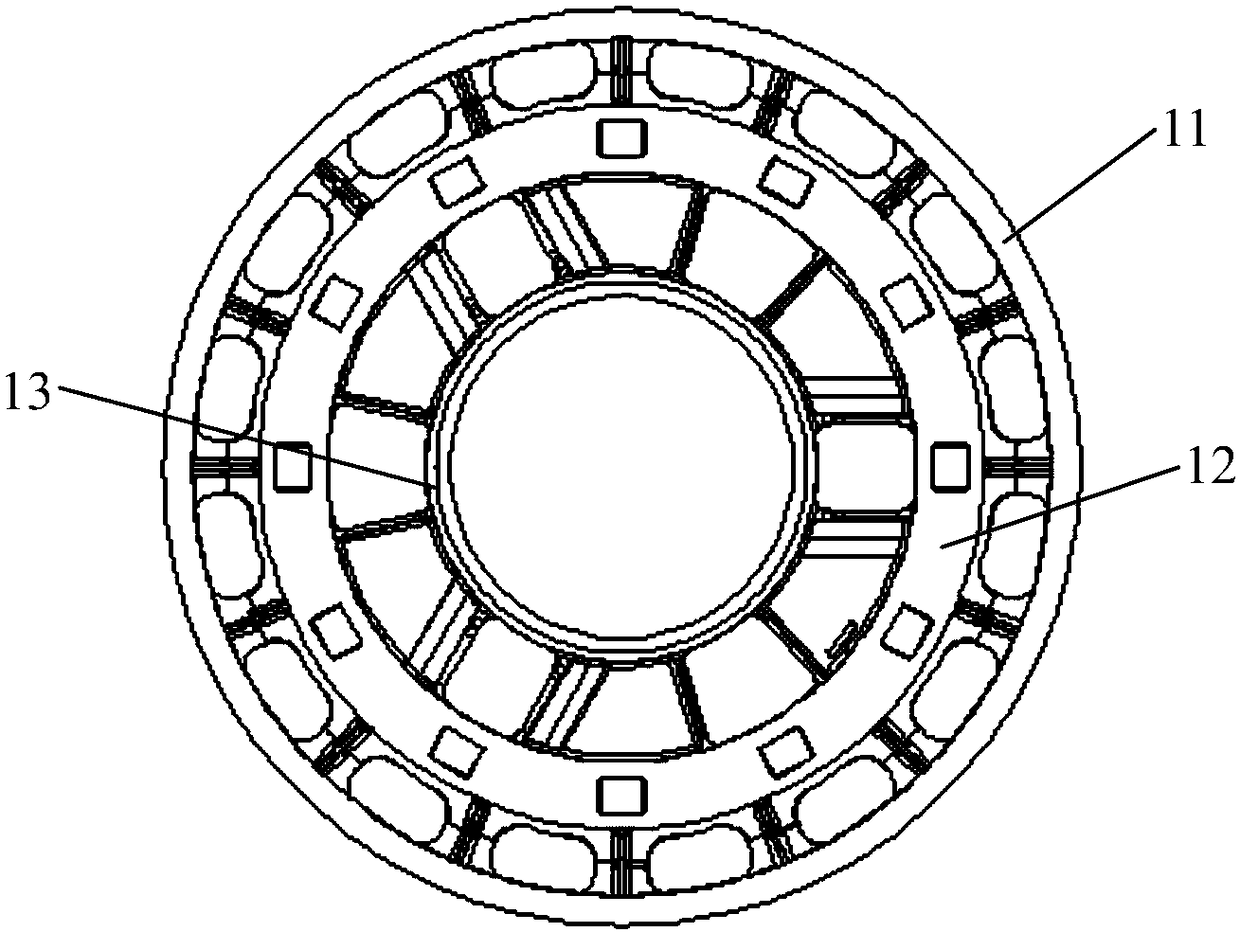

[0025] Embodiment 1 The casting mold of GE6MW rotor

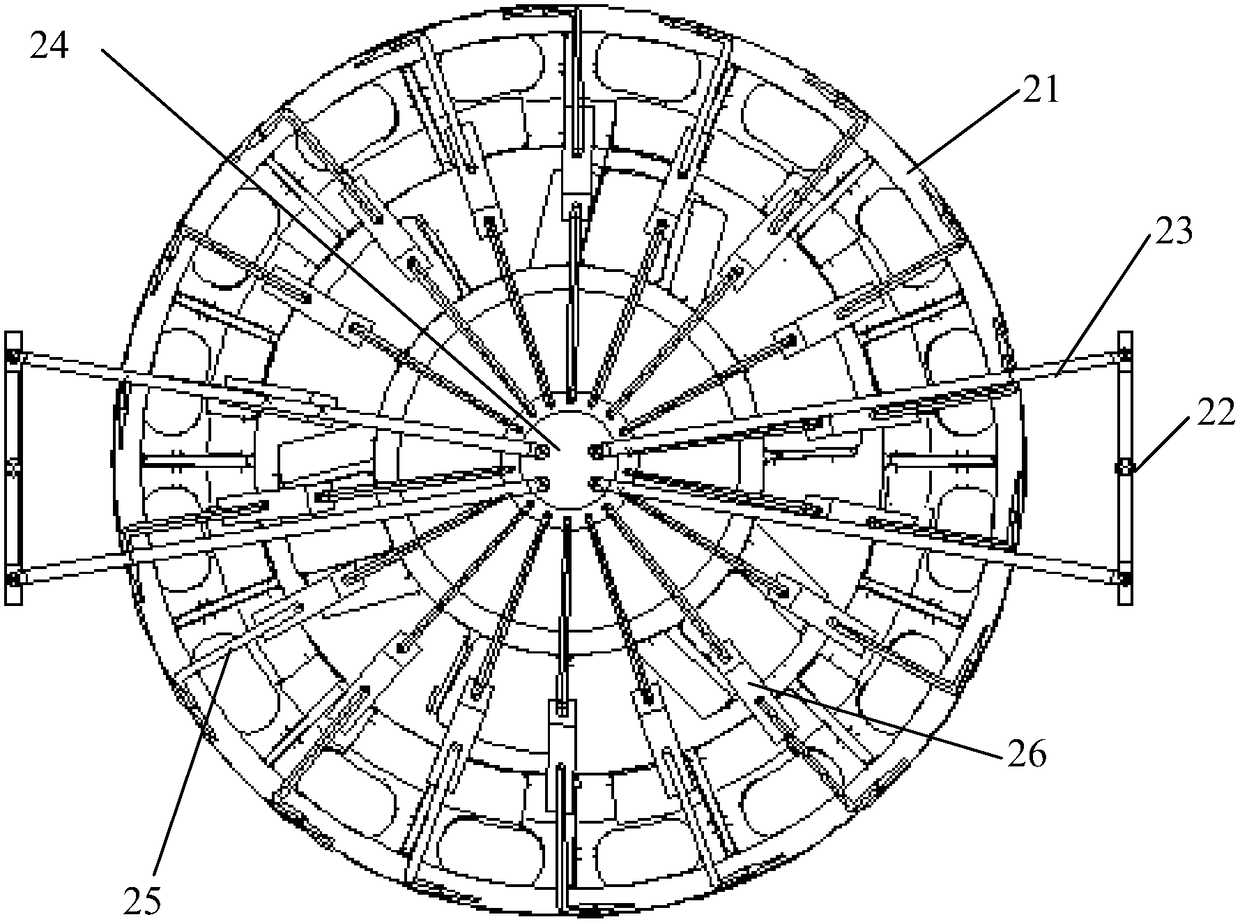

[0026] The casting mold of the large-scale disk-like complex structure part (GE6MW rotor) of the preferred embodiment of the present invention includes an upper mold and a lower mold, and the manufacture of the upper mold and the lower mold can refer to the ordinary mold manufacturing method, and the sand is shaken to the sand box for molding. The cavity structure formed by clamping mold is as follows figure 2 As shown, it includes part cavity 21, riser cavity, air outlet and casting system. The shape of the component cavity 21 fits the shape of the wind power rotor (see the background technology for the specific structure). The casting system includes 2 iron inlets 22, 4 molten iron main channels 23, a central distribution cavity 24 and 18 molten iron flow channels 25. The two iron inlets are respectively arranged on both sides of the mold, and each iron inlet is correspondingly connected with two molten iron main channe...

Embodiment 2

[0028] Embodiment 2 Using the casting mold of Embodiment 1 to cast GE6MW rotor

[0029] Using the casting mold of Example 1, pour molten iron into the casting mold through the iron inlet, the casting weight is about 60T, and the casting is completed in about 200S. During the casting process, graphite chill irons are placed at positions prone to shrinkage defects, and the graphite chill iron placement positions include the outer side of the outer ring flange, the inner side of the inner ring flange, and both sides of the sheet metal. After the castings are boxed together, 18 pieces of 15T pressed iron are placed on the surface of the sand box, and the total weight of the pressed irons is about 5.7 times the weight of the casting.

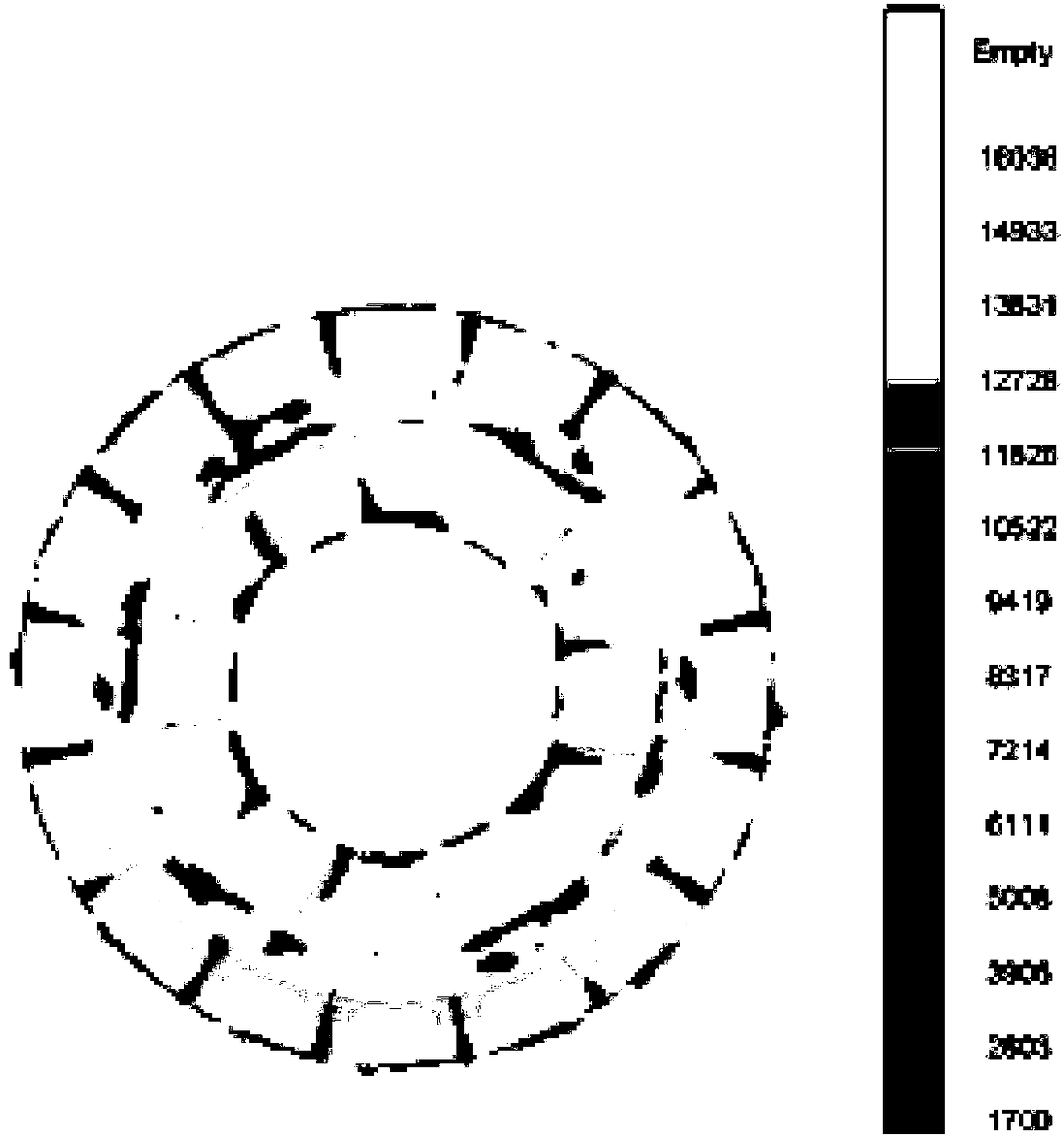

[0030] The simulation test, the steps are: use the 3D drawing software to draw the gating system, cold iron, riser, gas outlet, etc. on the casting, import it into the simulation software MAGMA, set the chemical composition, pouring temperature and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com