High-voltage-dropout-type fuse cutout

A drop-out fuse and high-voltage technology, applied in the field of fuses and high-voltage drop-out fuses, can solve problems such as arc extinguishing cover damage, achieve reliable arc extinguishing, prolong service life, and strengthen arc extinguishing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

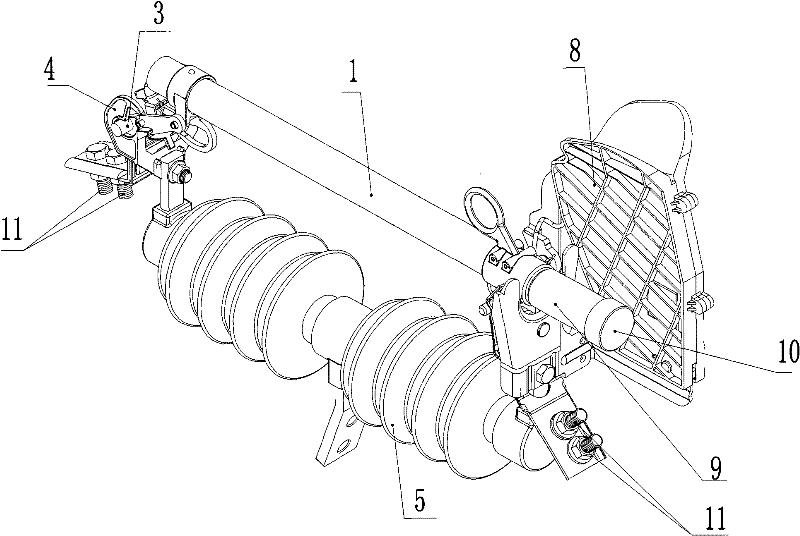

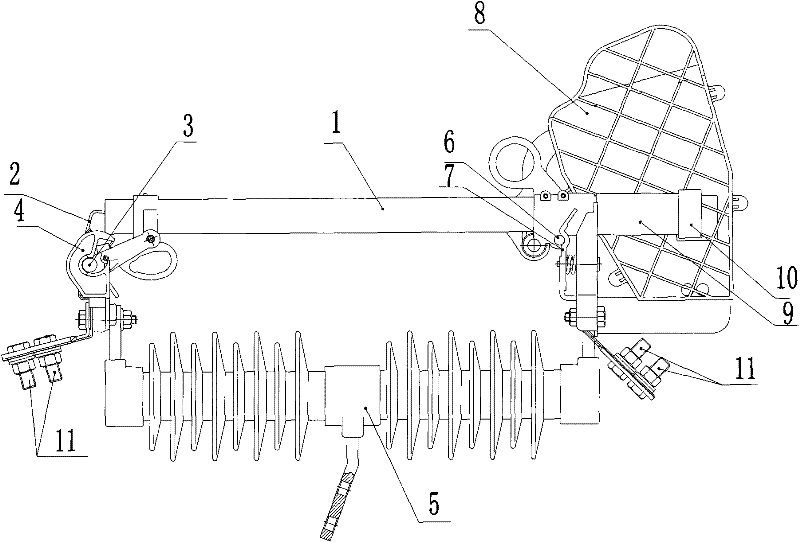

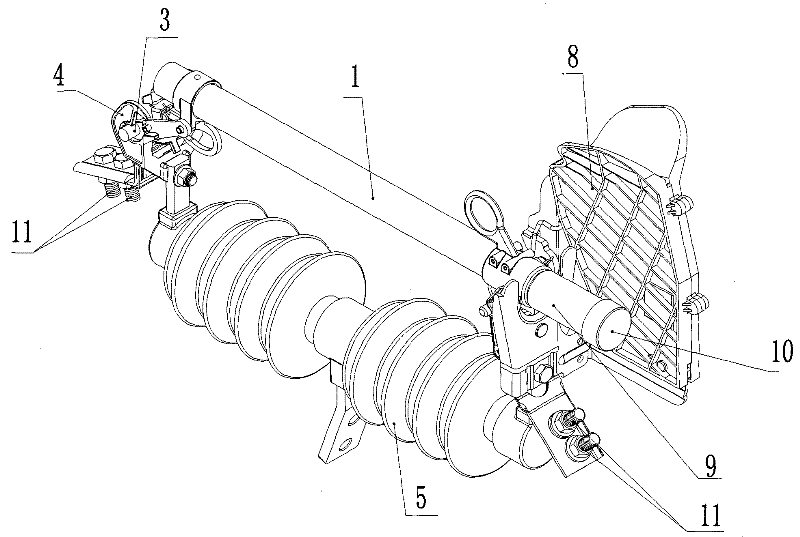

[0014] as attached figure 1 , 2 Shown is a high-voltage drop-out fuse of the present invention, including a melting tube 1, a fuse 2, a static contact 3, a static contact bracket 4, a post insulator 5, a moving contact 6, a moving contact bracket 7, a Arc cover 8; the static contact 3 is arranged on the melting tube 1, the static contact bracket 4 is arranged on one end of the post insulator 5; the moving contact 6 is arranged on the other end of the post insulator 5; the moving contact The contact bracket 7 is set on the melting tube 1; the moving contact 6 is also provided with an arc extinguishing cover 8; the fuse 2 tightens the moving contact 6 on the moving contact bracket 7, and the static contact The head bracket 4 and the moving contact 6 are provided with wiring bolts 11; the end of the moving contact bracket of the melting tube 1 is also provided with a diversion tube 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com