Carbon dioxide capturing compression system using flue gas and multistage compressing waste heat

A technology of carbon dioxide and compression system, applied in the direction of direct carbon dioxide emission reduction, gas treatment, climate sustainability, etc. discharge capacity, maintain industrial production capacity, and ensure the effect of gas production continuity and gas production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

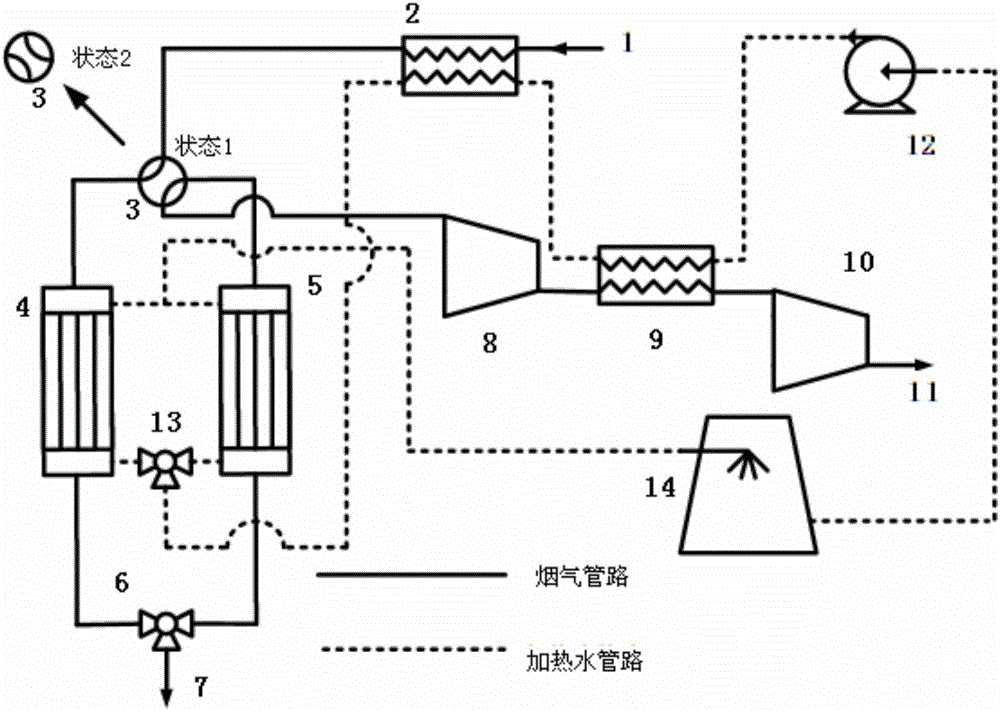

[0028] A carbon dioxide capture and compression system using flue gas and multi-stage compression waste heat in the present invention uses multi-stage compression, intercooling technology, low-grade heat energy and flue gas waste heat to realize temperature-swing adsorption carbon capture and treatment of power plant boiler flue gas, and at the same time reduces compressed carbon dioxide The energy consumption system for transportation is centered on the combination of low-grade heat energy utilization and temperature swing adsorption carbon capture technology, while using multi-stage compression and intercooling technology to meet the needs of low-energy capture of carbon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com