A shale gas production stimulation method based on the combination of explosive fracturing and hydraulic fracturing

A technology of explosion fracturing and hydraulic fracturing, which is used in earth-moving drilling, wellbore/well components, measurement, etc., and can solve the problems of scrapped wellbore, vulnerable wellbore, and high explosion power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

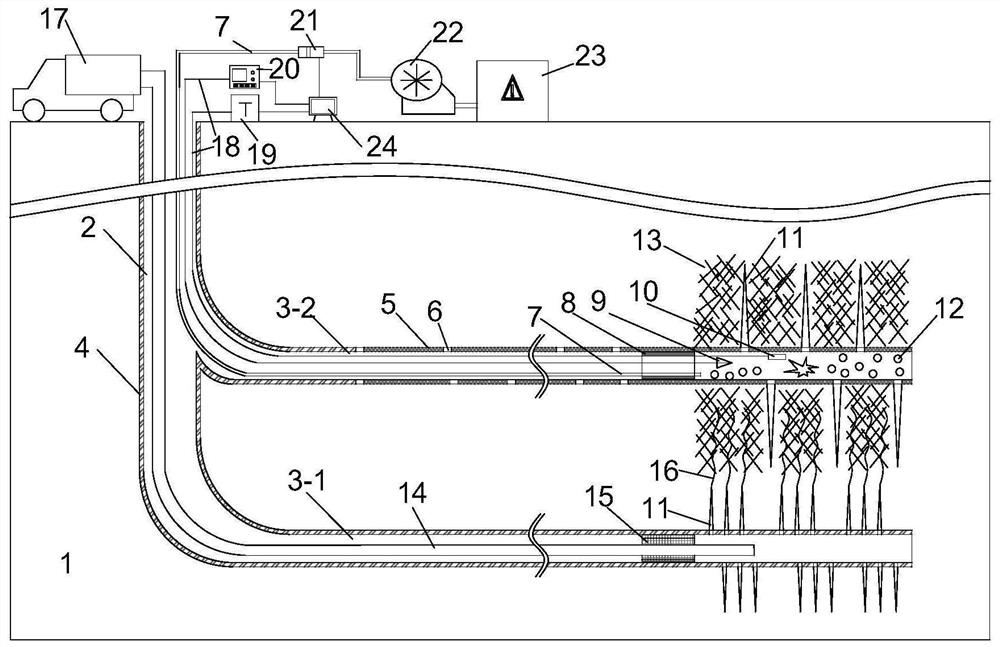

[0024]Embodiment 1: through geological exploration, it is found that there is a shale reservoir 1 with mining value in the stratum of a certain area, and the thickness of this shale reservoir 1 is about 200m, such as figure 1 Shown, adopt the method of the present invention to carry out shale gas exploitation, concrete steps are:

[0025] A. Drill a shaft from the ground to the shale reservoir 1 to be extracted until the shaft 2 reaches a depth of 20m in the shale reservoir 1 and stop, and install the casing 4 to the shaft during the drilling of the shaft 2 2, complete the setting work of shaft 2;

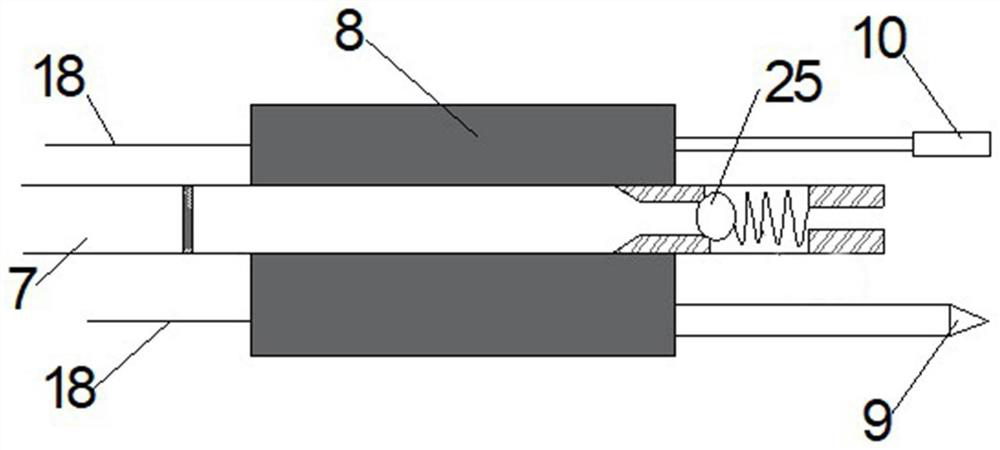

[0026] B. Use a directional drilling rig to extend into the vertical shaft 2 and reach the location of the shale reservoir 1, drill an explosion fracturing horizontal well 3-2 from the vertical shaft 2 to the shale reservoir 1, and perform explosion fracturing in the shaft 2 The horizontal well 3-2 is supported by a combination of casing 4 and screen 5, wherein one end of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com