Patents

Literature

49results about How to "No local high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zisha ware ceramal non-cooking fume non-stick pan and preparation method thereof

InactiveCN101190097AGood non-stickAvoid direct contactCooking-vessel materialsHardnessWear resistance

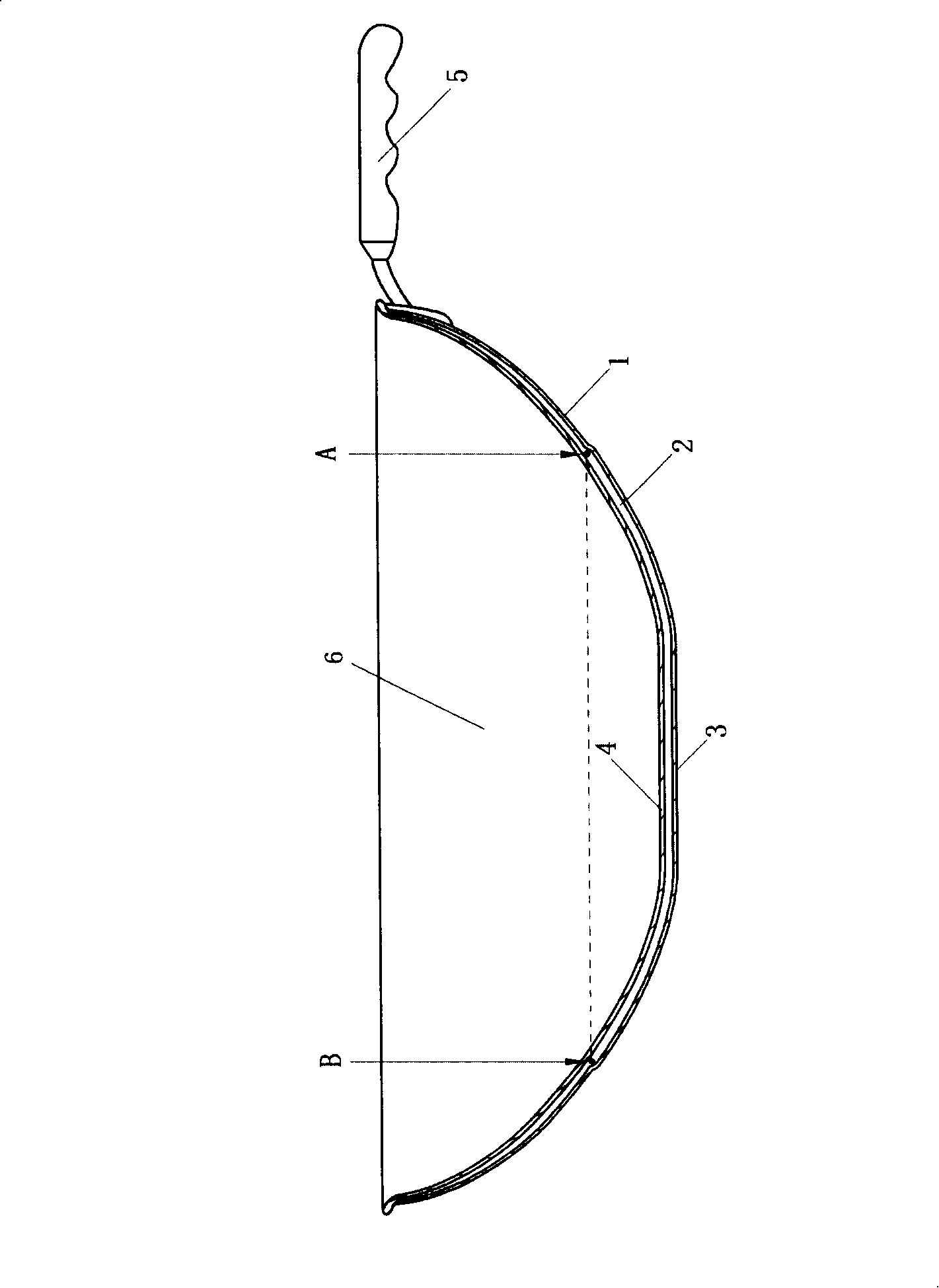

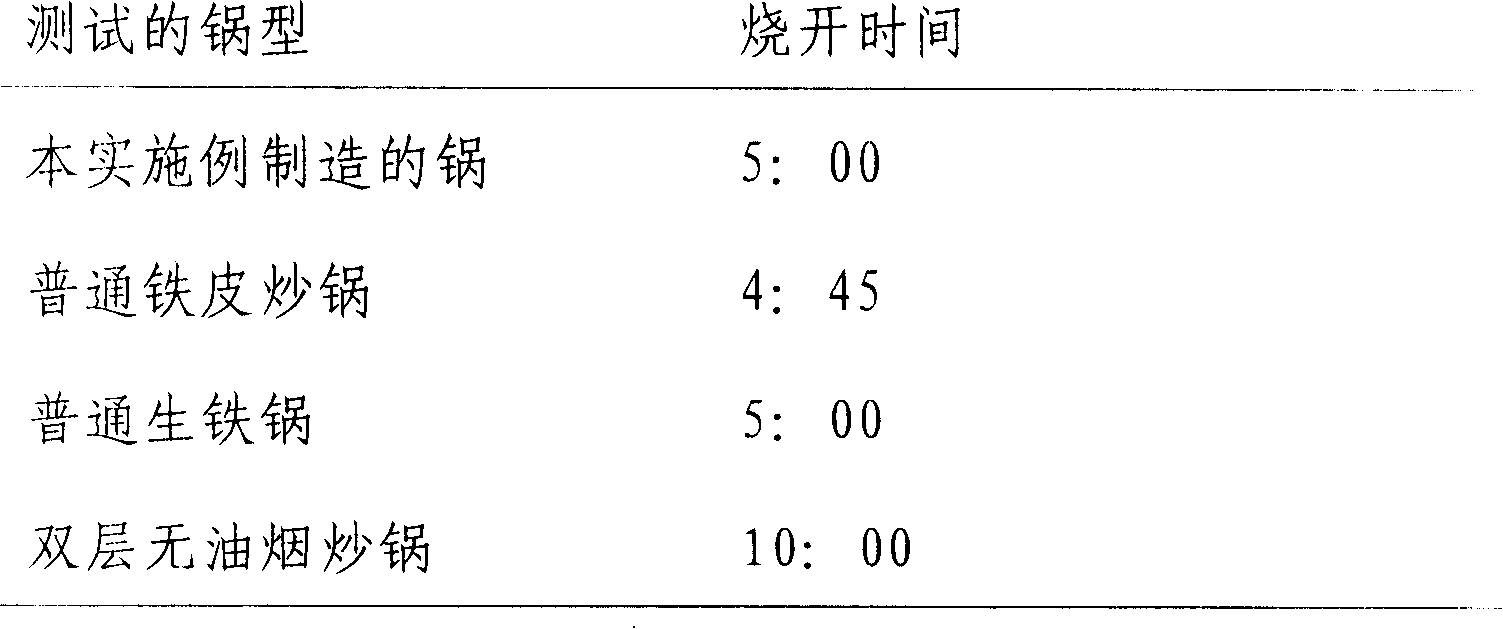

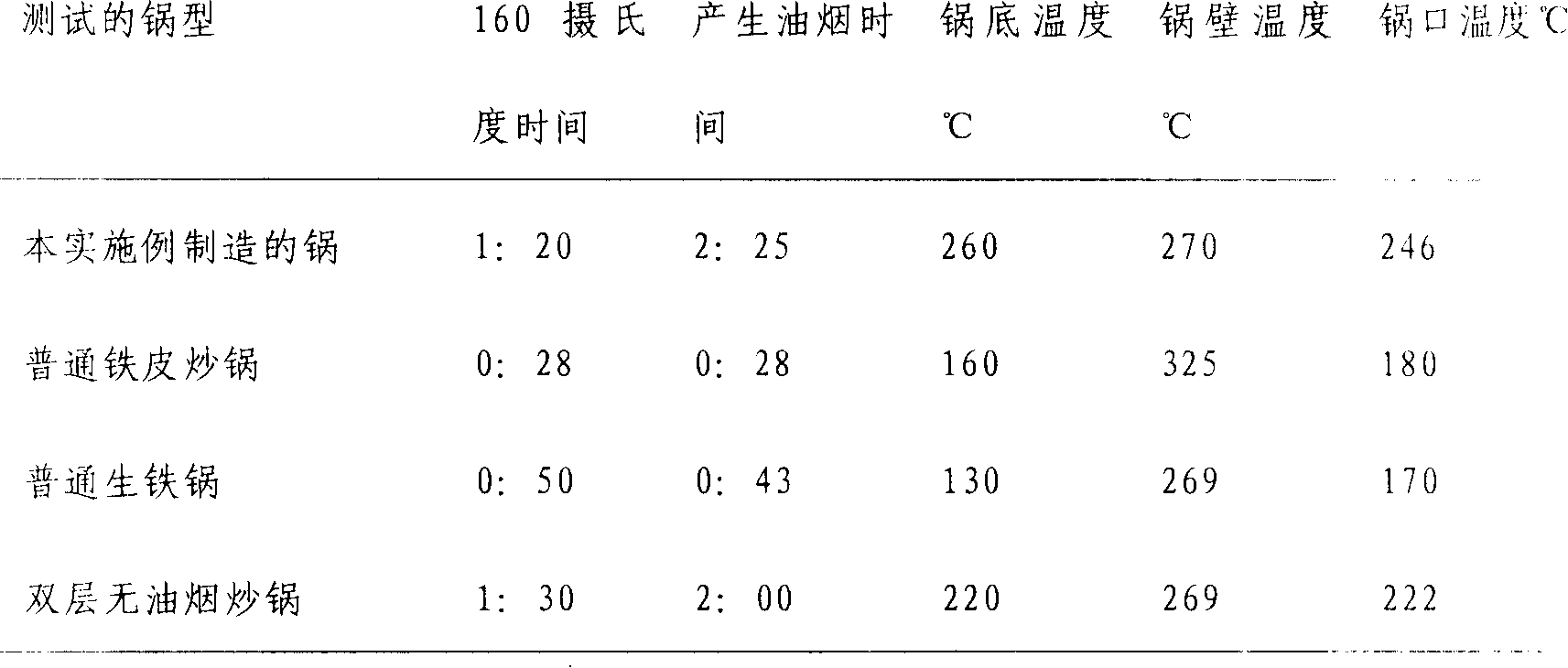

The invention relates to a purple clay pottery alloy non-stick cookware without oil smoke and a preparation method thereof. The purple clay pottery alloy non-stick cookware without oil smoke comprises a cookware body and a cookware handle, wherein, the cookware body takes aluminium alloy as a substrate, the outer surface of the substrate of the cookware body is provided with a pottery crystal layer, and the inner surface of the substrate is provided with a purple clay pottery layer. The purple clay pottery alloy non-stick cookware without oil smoke of the invention consists of the non-stick purple clay pottery layer, the substrate of the cookware body and the pottery crystal layer, so the cookware is heated uniformly and does not generate partial high temperature when in use, thus generating no oil smoke when cooking dishes; in addition, the purple clay pottery layer avoids the direct contact between food and the aluminium alloy substrate, and improves surface hardness considerably, thus leading the cookware body to have more wear resistance and adhesion resistance, resist high temperature and be safe and non-toxic to the human body.

Owner:胡金高

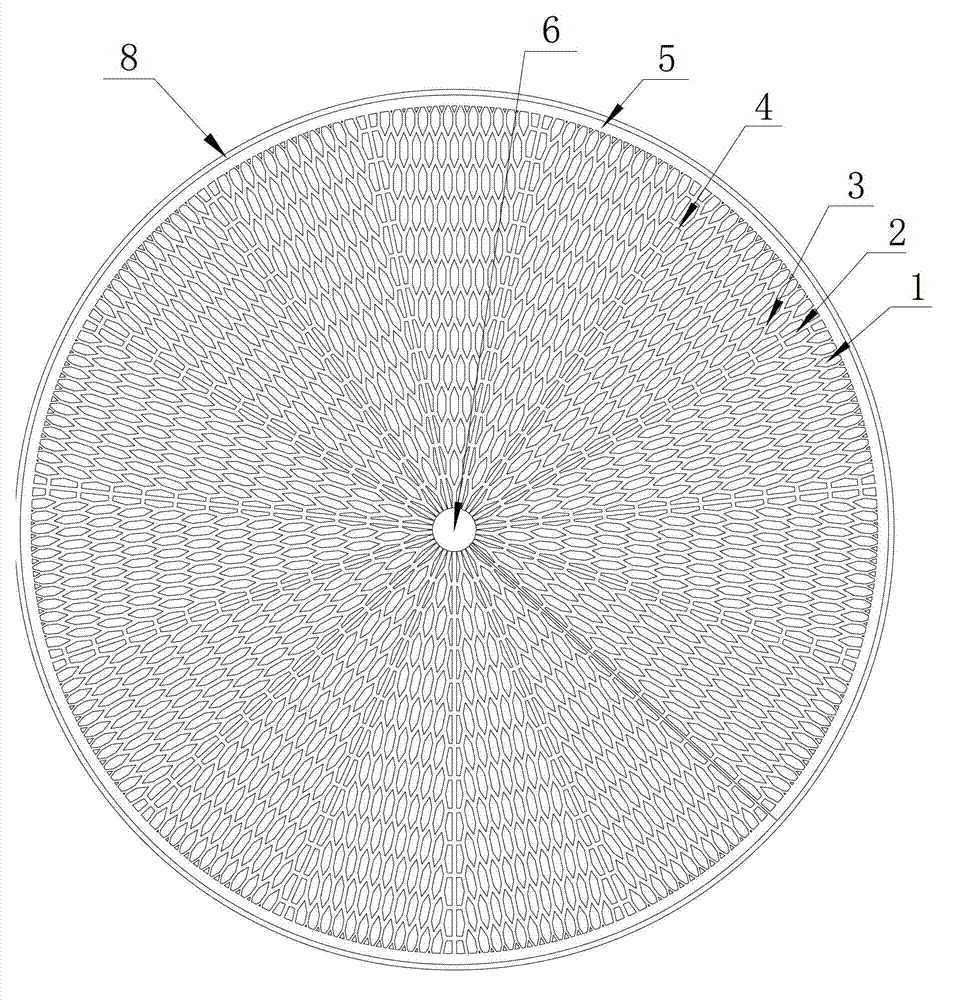

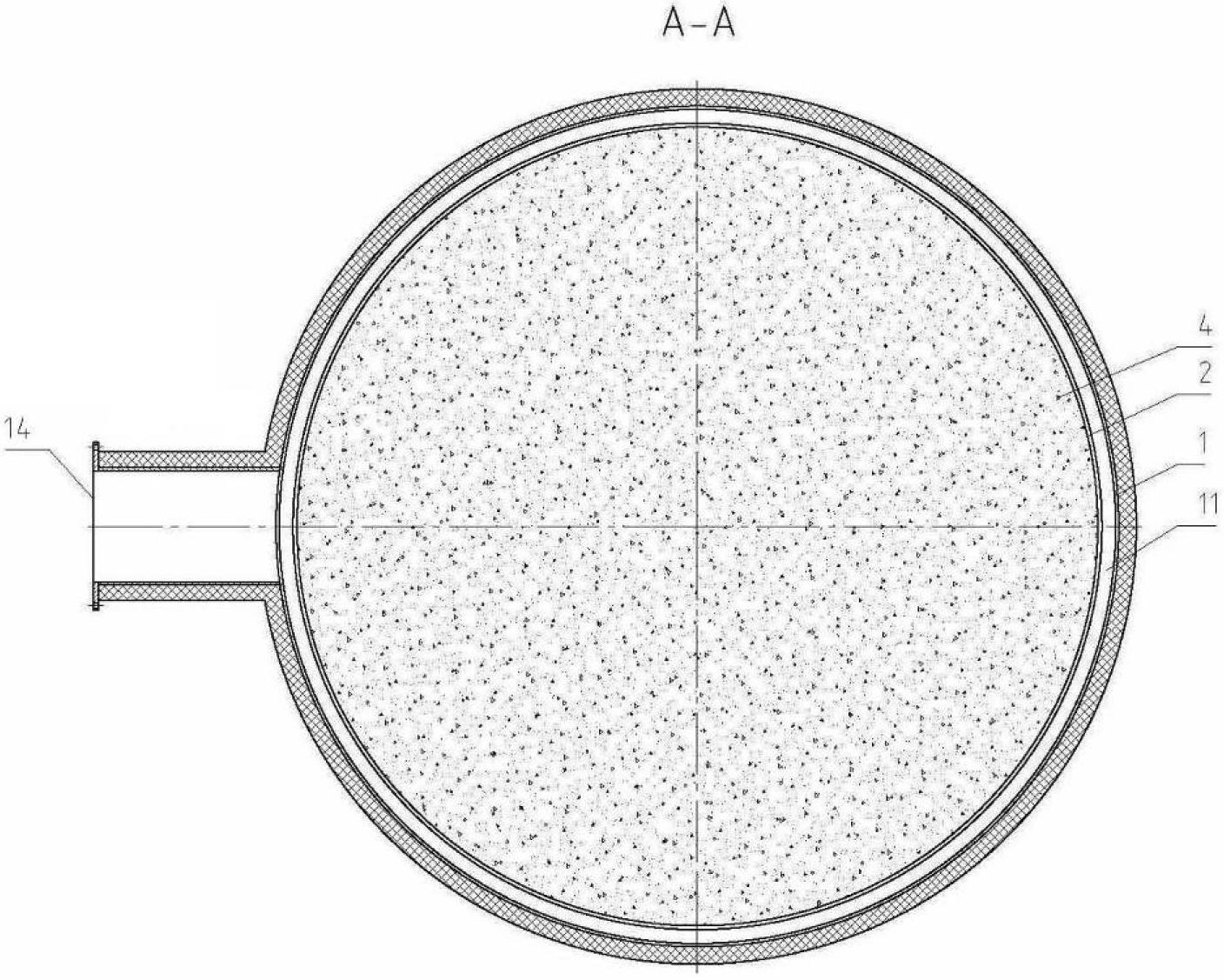

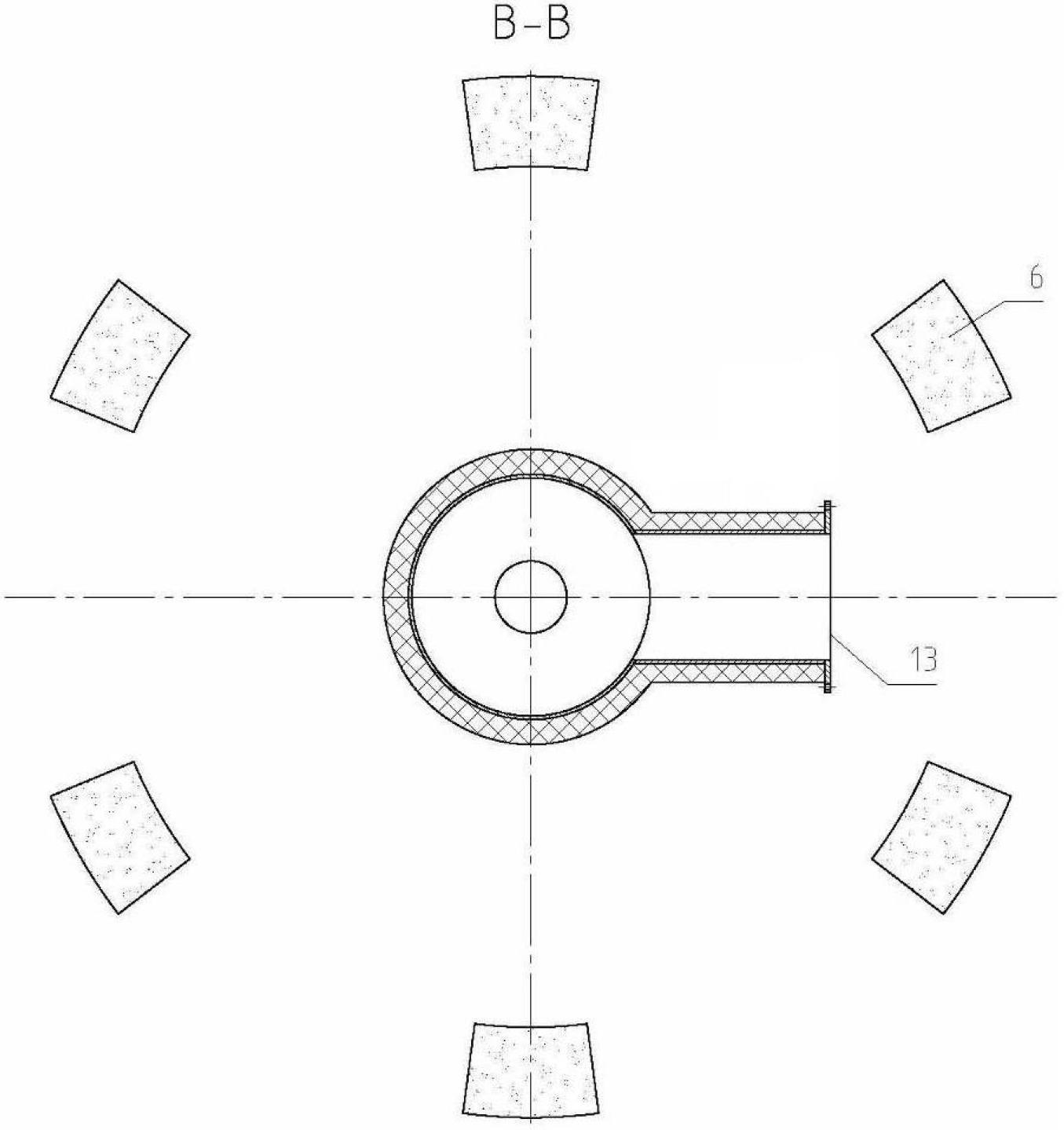

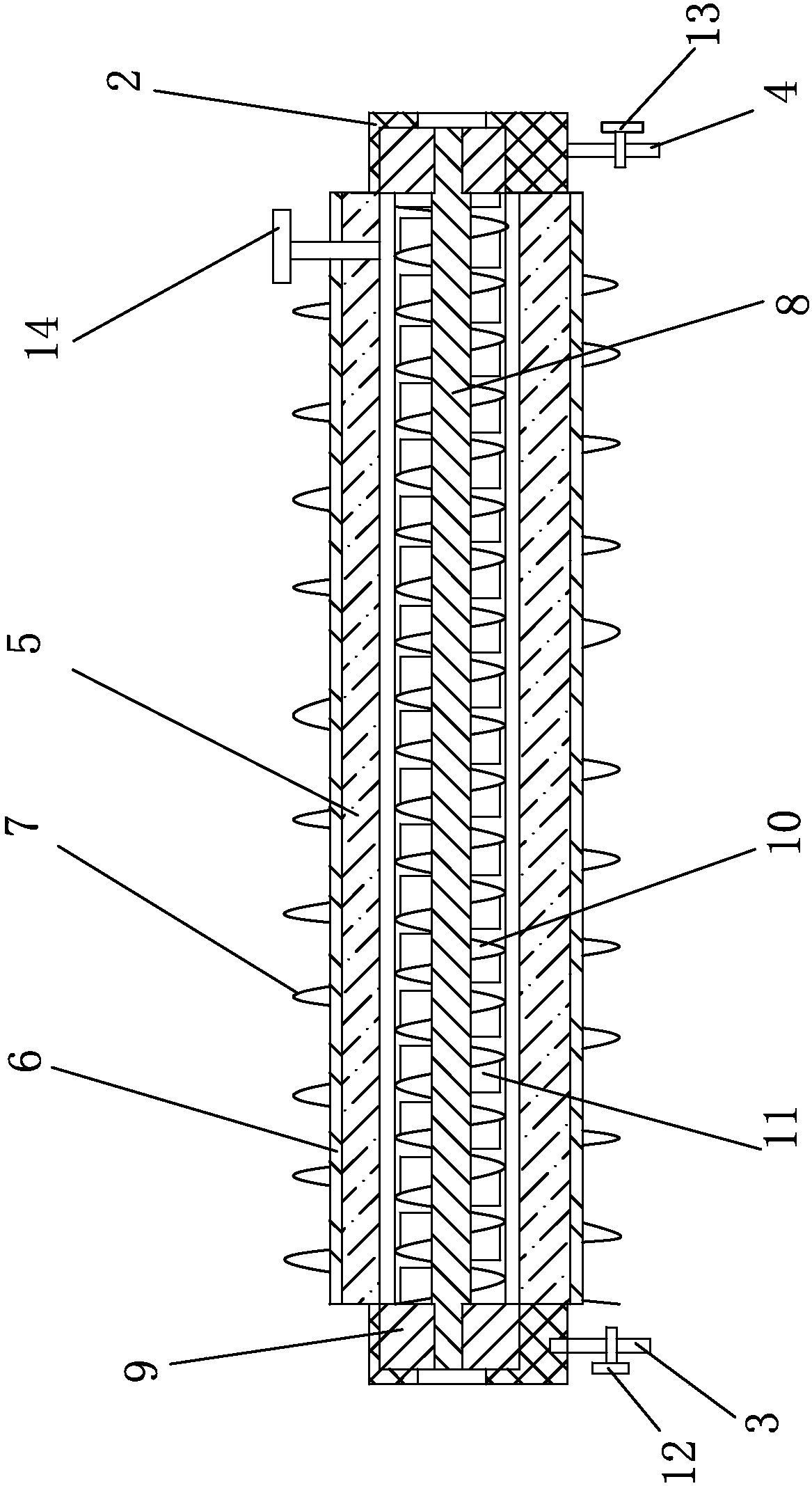

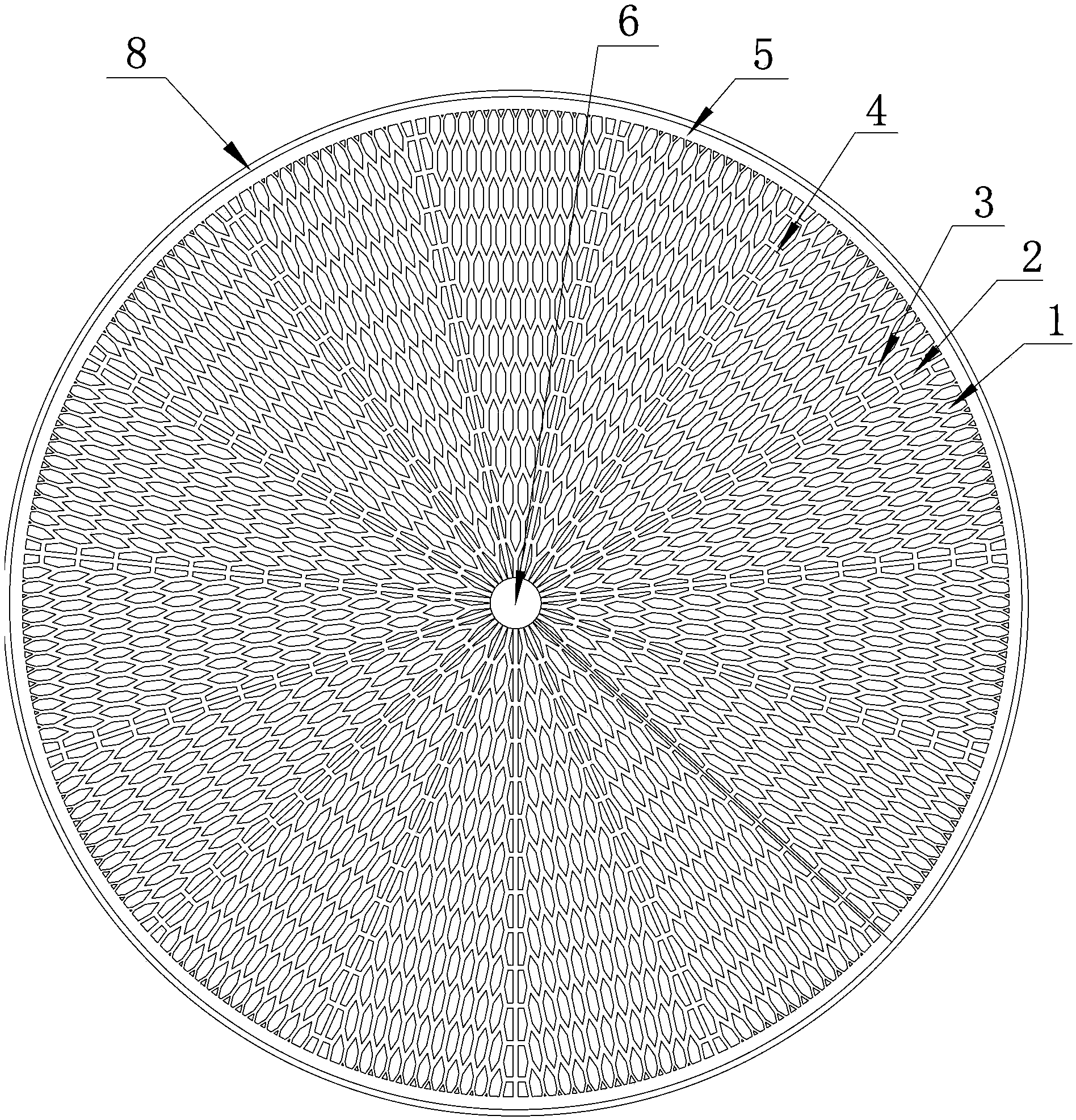

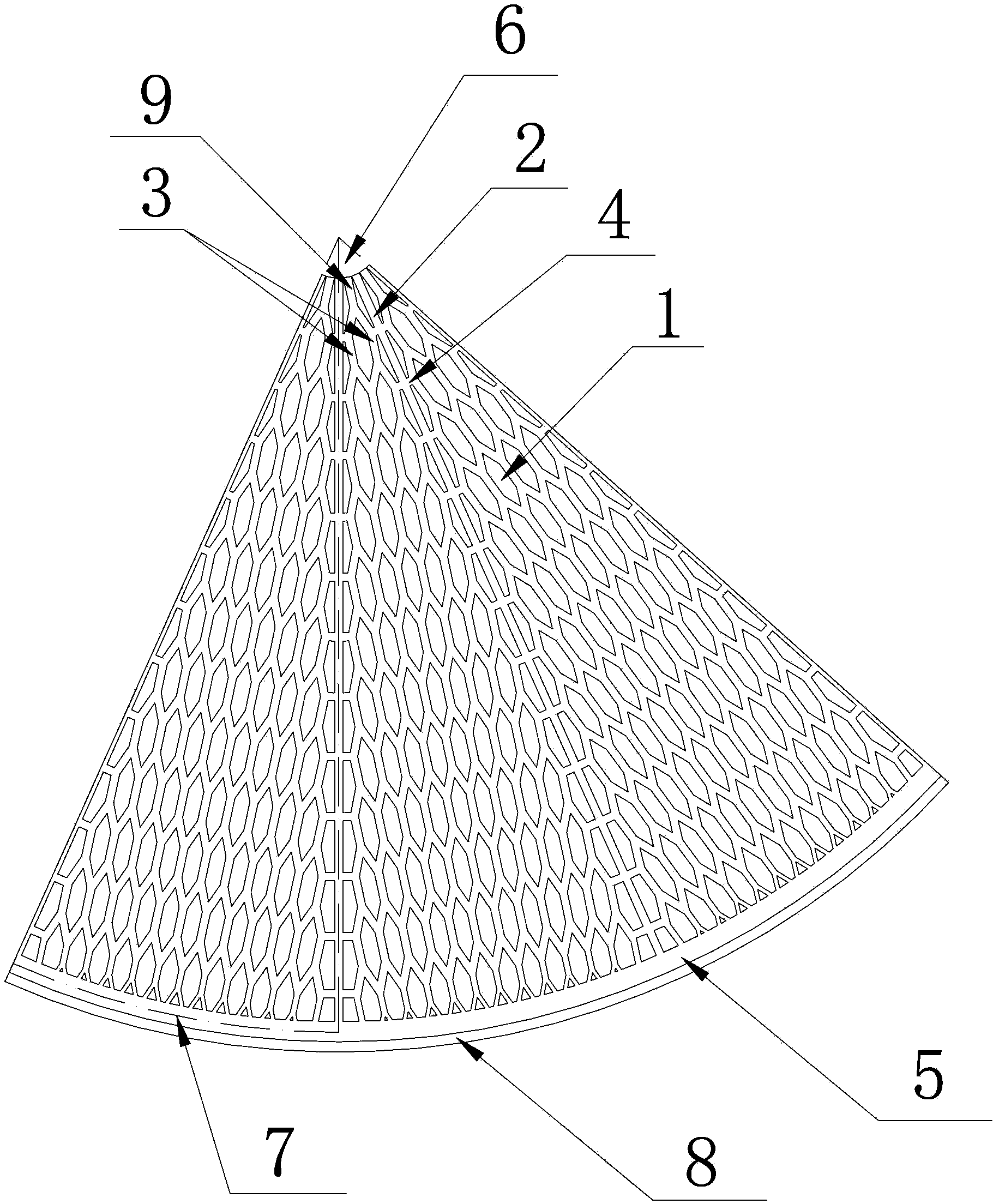

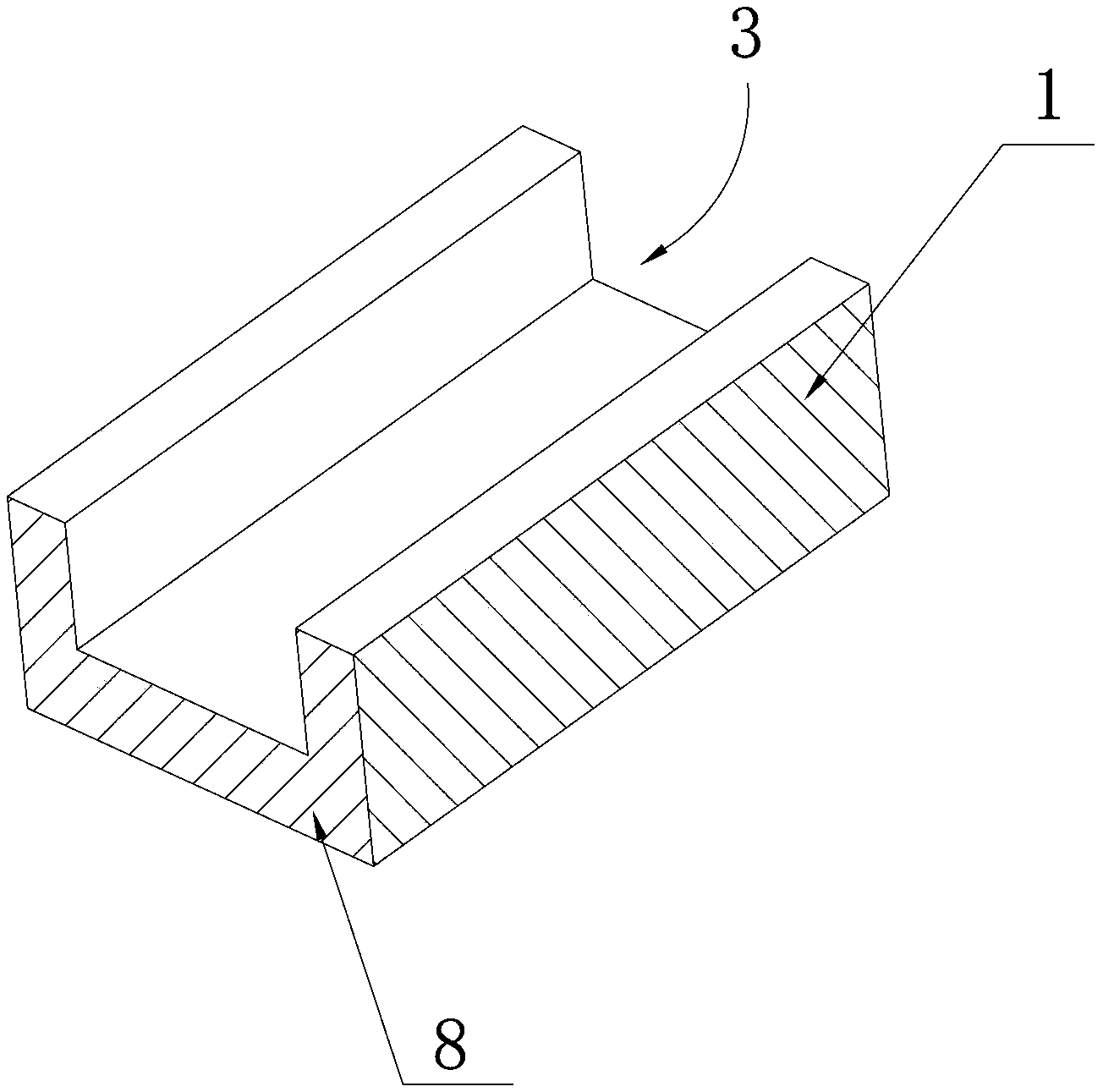

Wick structure for vapor chamber

ActiveCN102811590AImprove capillary suctionImprove cooling efficiencyIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringNarrow channel

Owner:SOUTH CHINA UNIV OF TECH

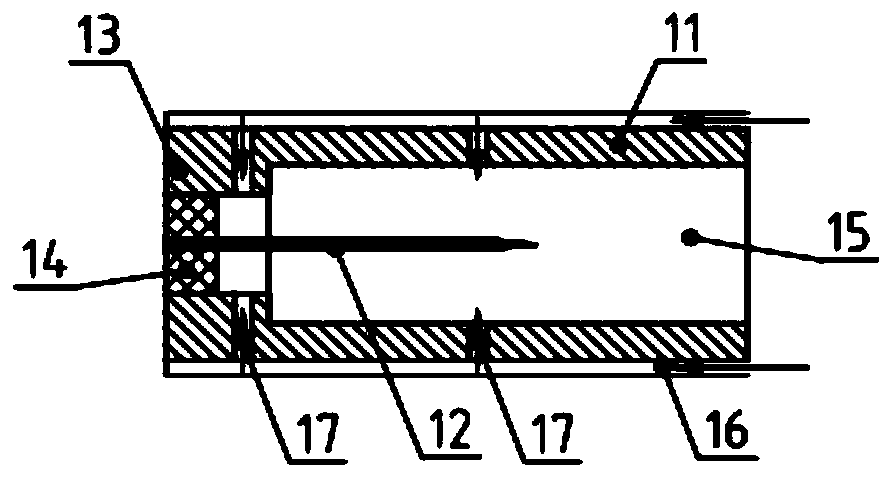

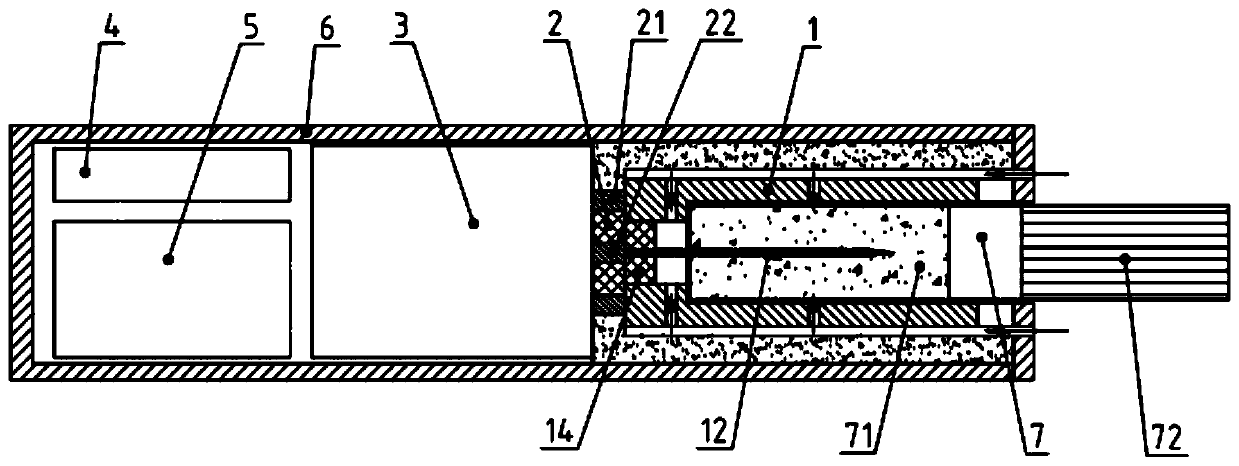

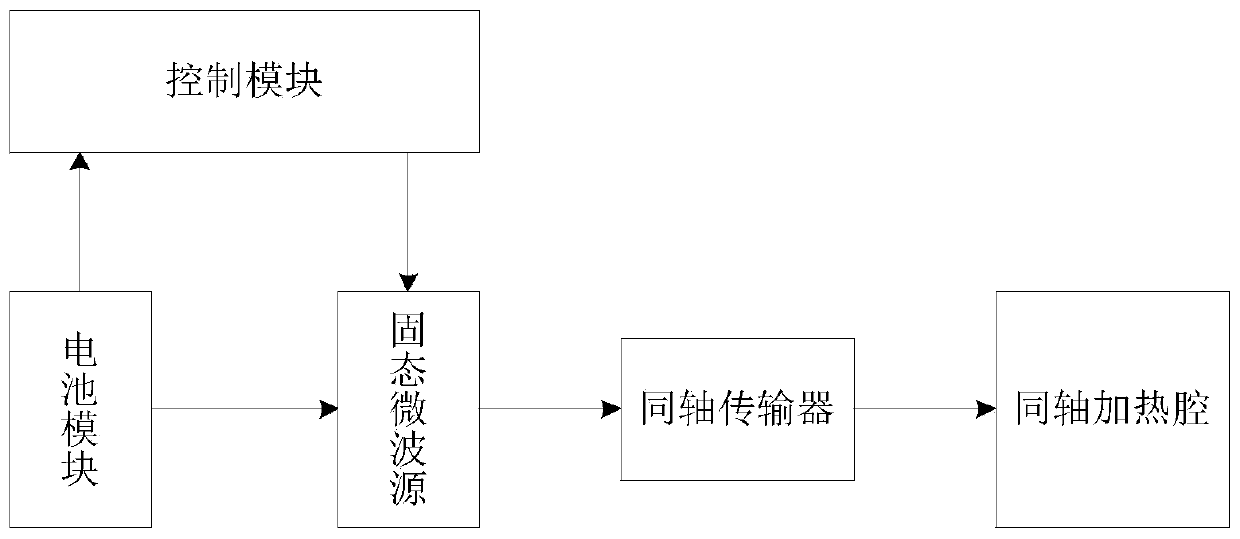

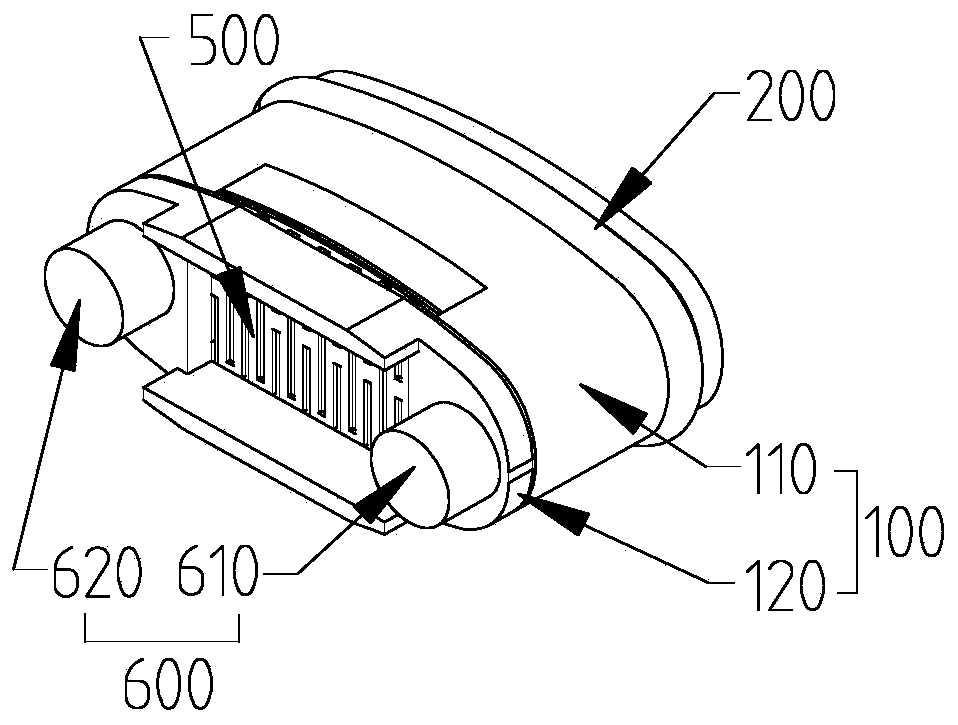

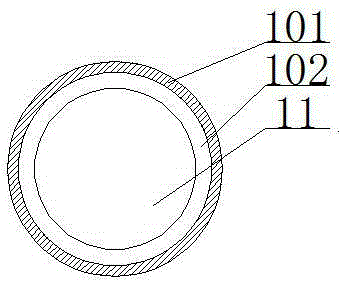

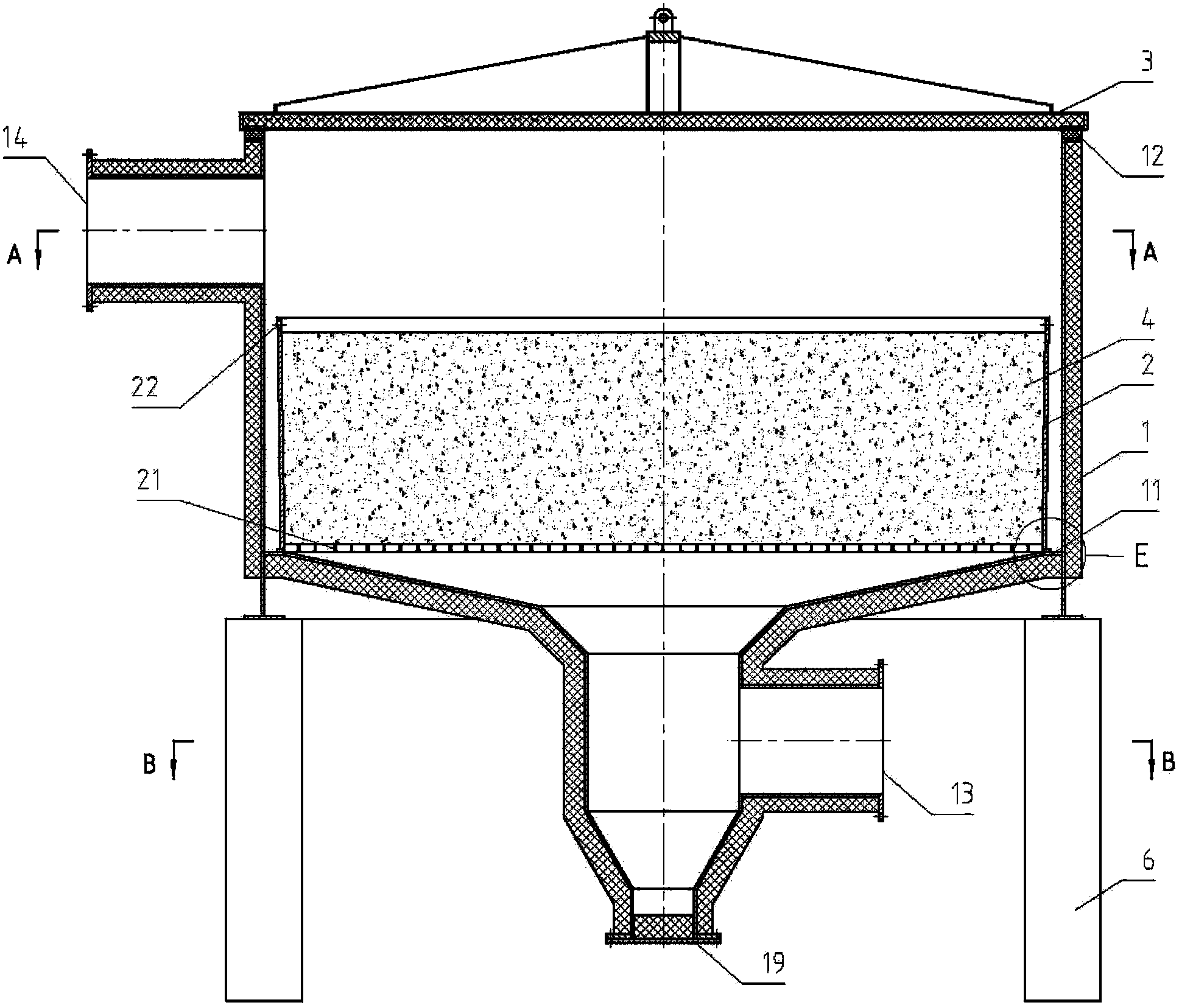

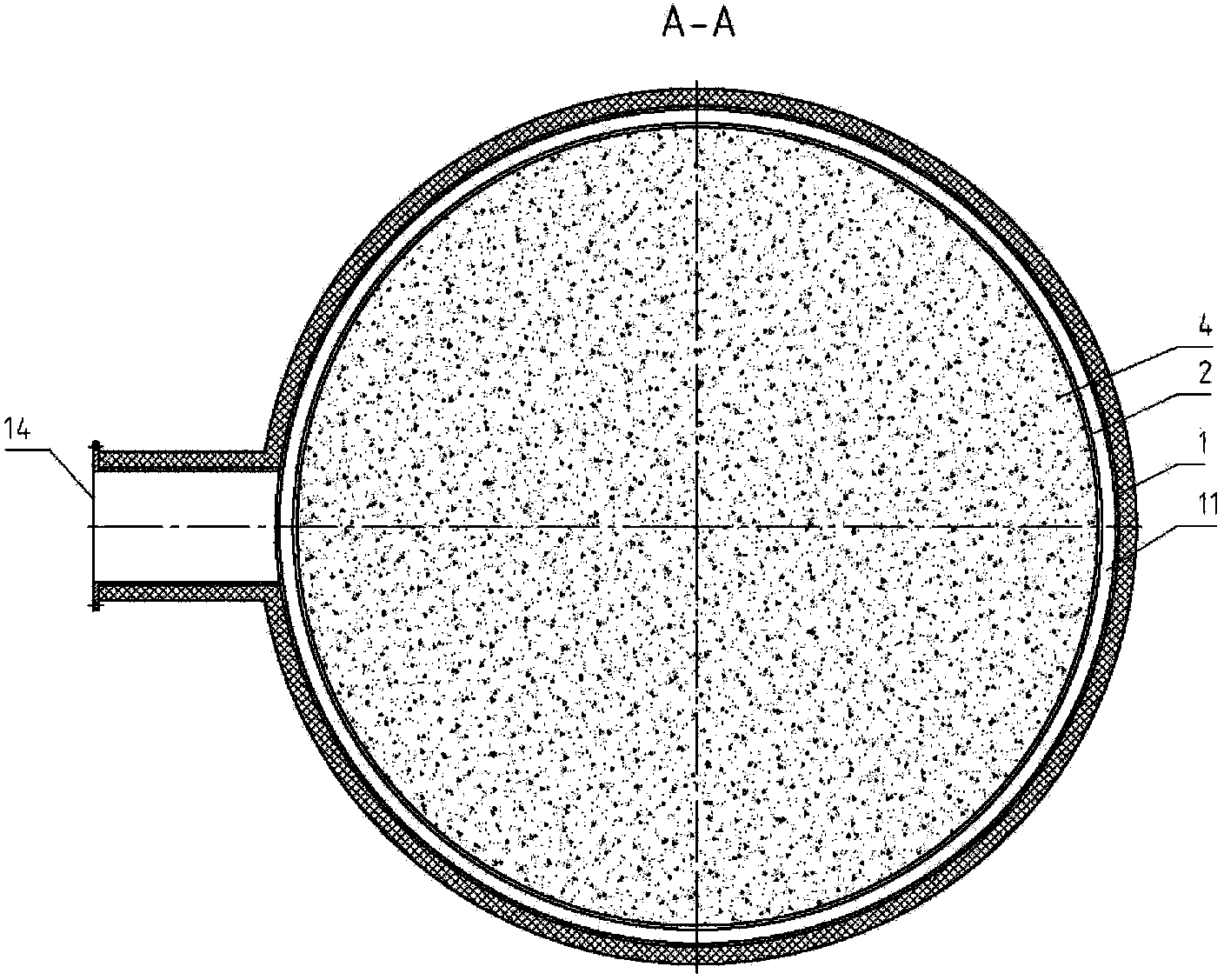

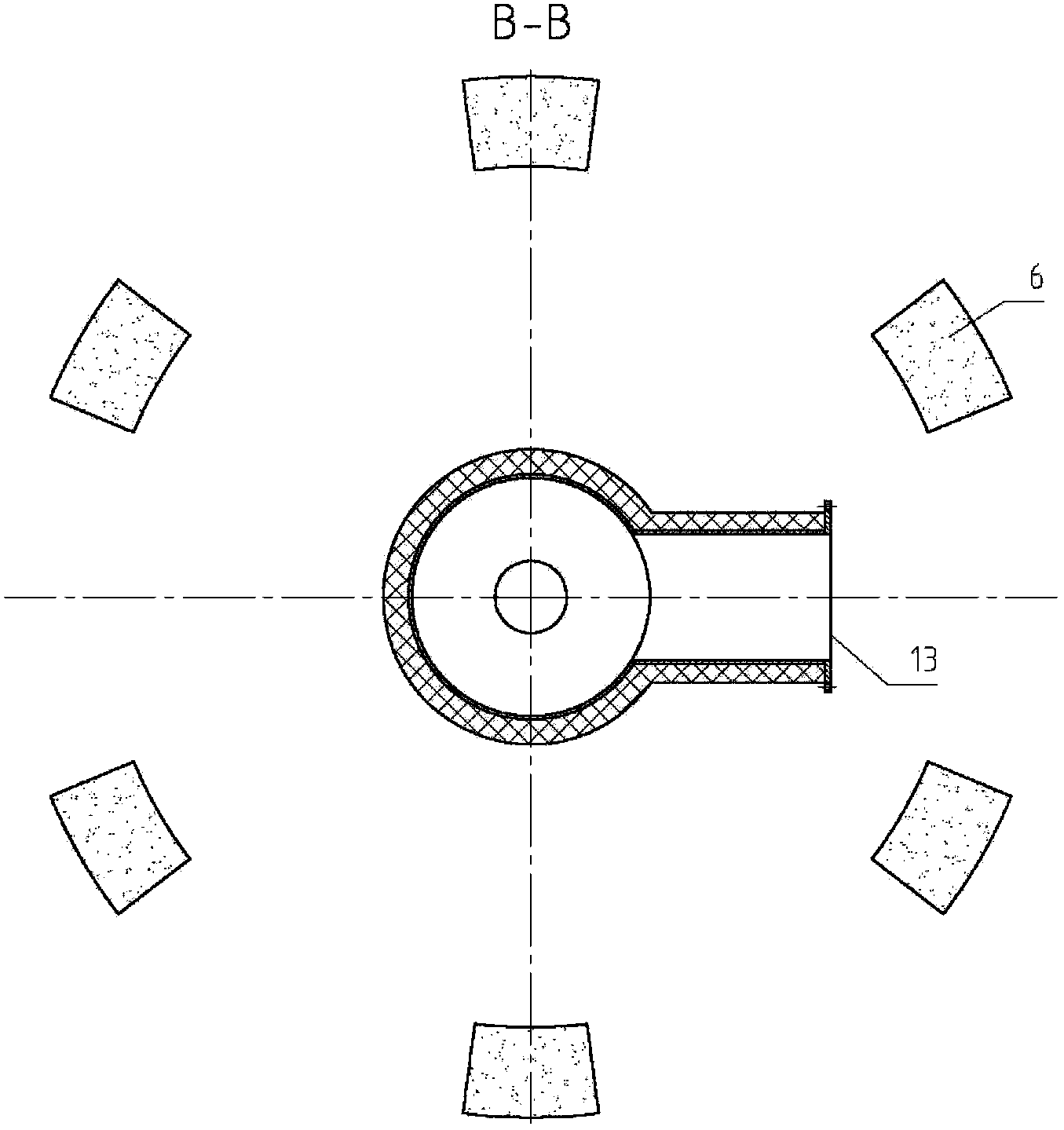

Coaxial heating chamber and electronic cigarette device with coaxial heating chamber

PendingCN110141002AHeating evenlyThere will be no local high temperatureTobacco devicesElectrical conductorElectronic cigarette

The invention discloses a coaxial heating chamber and an electronic cigarette device with the coaxial heating chamber. The electronic cigarette device with the coaxial heating chamber includes a coaxial heating chamber which is formed by the fact that an outer conductor chamber is regarded as a chamber, and an inner conductor column which is regarded as a column and inserts from one end of the outer conductor chamber into the outer conductor chamber; and a microwave source from one end of the inner conductor column inserted into the outer conductor chamber into the coaxial heating chamber to conduct microwave transmission to achieve the heating of microwave to a tobacco. A coaxial transmitter and the coaxial heating chamber are used, microwaves with the frequency of 915MHz and 2.45GHz canbe transmitted in the coaxial transmitter and the coaxial heating chamber, and therefore, a relatively mature solid-state microwave device can be used, especially 915MHz electrical conversion efficiency is higher; the size of the device can be effectively controlled; and due to the fact that the microwave has no temperature, through high frequency alternating electric field, polar molecules in thetobacco is made directly to move and heat, tobacco overall temperature is controlled in 200~300 DEG C, local high temperature does not exist, higher temperature does not exist in the overall coaxialheating chamber and the tobacco, cracking does not occur, and aldehyde or other harmful substances cannot be produced.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

A preparation method of ultra-clean cross-linkable polyethylene insulating material for high-voltage cables

The invention discloses a method for preparing an ultraclean crosslinkable polyethylene insulation material of a high-voltage cable, relates to a method for preparing a crosslinkable polyethylene insulation material and solves the problems of low purity, easiness for generating gel and the phenomenon of pre-crosslinking, poor stability of product quality, low production efficiency and high cost of the current method for preparing the crosslinkable polyethylene insulation material. The method comprises the following steps of: taking raw materials; uniformly mixing polyvinyl resin and an antioxidant to obtain a material; filtering, pelletizing, dehydrating and drying the material and mixing the obtained material and a cross linking agent to obtain aggregates mixed with the cross linking agent; and feeding the aggregates into an adsorption material bin to homogenize the aggregates and cooling the obtain product to complete preparation of the crosslinkable polyethylene insulation material. In the method, the gel and the phenomenon of pre-crosslinking are not generated in the production process and equipment does not need to be shut down to be cleaned in the production, so that the production efficiency is increased and the cost is reduced. The number and the sizes of impurities in the crosslinkable polyethylene insulation material reach the level of an imported like product. Each kilogram of cable material contains less than 10 impurities of 70-100 mum and does not contain impurities of more than 100 mum. The ultraclean requirement is met. The product quality has long-term stability.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method of ultra-smooth semiconductive shielding material for high-voltage crosslinked polyethylene insulated cable

The invention discloses a preparation method of an ultra-smooth semiconductive shielding material for a high-voltage crosslinked polyethylene insulated cable, which relates to a preparation method of a semiconductive shielding material and is used for solving the problems that an extruding surface cannot meet the requirement of ultra-smoothness, gelation and pre-crosslinking are caused easily, and the quantity and sizes of impurities in the material cannot meet the standard requirements existing in the preparation of a semiconductive shielding material. The method comprises the following steps of: weighing raw materials; uniformly mixing polyethylene rein, an ethylene-vinyl acetate polymer, an antioxidant and conductive carbon black to obtain a material; filtering the material, pelletizing, dehydrating and drying the filtered material, and mixing with a crosslinking agent to obtain particles mixed with the crosslinking agent; and feeding into an absorption cabin for uniformizing, and cooling. In the invention, gelation and pre-crosslinking are not caused in the production process; the quantity and sizes of impurities in the semiconductive shielding material reach the levels of imported products of the same type; every kilogram of cable materials contain less than ten impurities of 70-100 mum; the requirement of ultra-cleanliness is met; and the extruding surface meets the requirement of ultra-smoothness.

Owner:HARBIN UNIV OF SCI & TECH

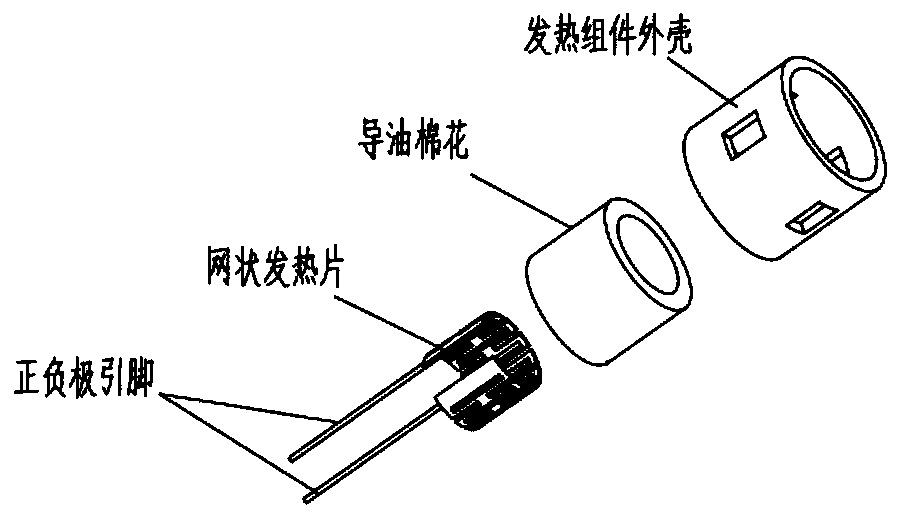

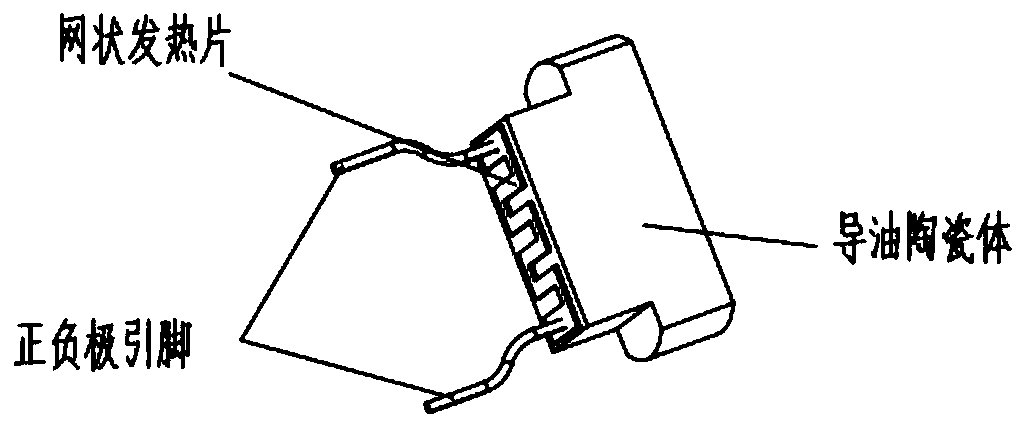

Electronic cigarette heating assembly and portable small-smoke electronic cigarette atomizer thereof

PendingCN111374352ASmall sizeLow structural strength requirementTobaccoElectronic cigaretteSmoke Emission

The invention discloses an electronic cigarette heating assembly and a portable small-smoke electronic cigarette atomizer thereof, and the electronic cigarette heating assembly comprises a support anda sealing part. The support comprises an upper support body and a lower support body, and an oil guide cotton piece, oil guide cotton cloth and a net-shaped heating piece are sequentially clamped between the upper support and the lower support; the upper support is provided with an oil guide channel for introducing oil to the oil guide cotton piece, and the lower support is provided with a smokeoutlet; the net-shaped heating sheet is connected with the conductive electrode to supply power to the net-shaped heating sheet; the internal gap of the oil guide cotton piece is larger than that of the oil guide cotton cloth. The atomizer comprises a shell, an oil cup is arranged in the shell and fixed in the shell through a base, a heating assembly is arranged at the bottom of the oil cup, and asmoke channel is formed between the oil cup and the shell. The electronic cigarette is uniform in heating, free of local high temperature, environmentally friendly and suitable for being used as a portable small-smoke electronic cigarette.

Owner:SHENZHEN SIYUAN BELL TECH CO LTD

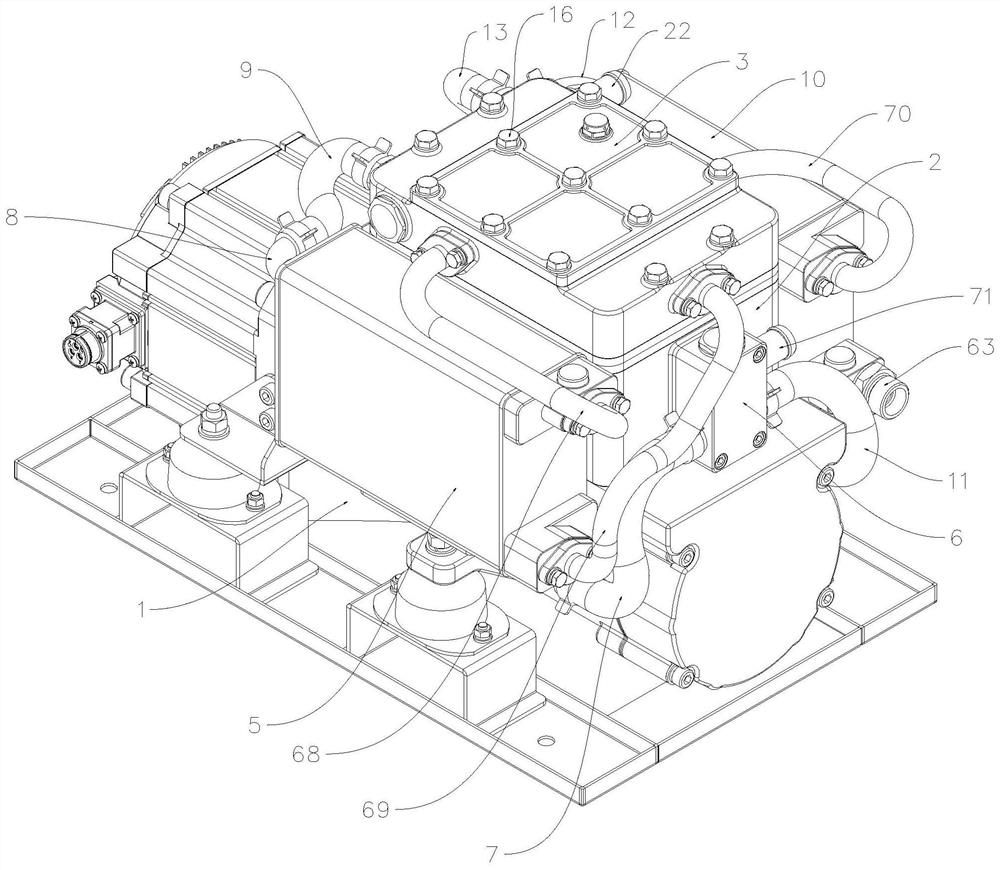

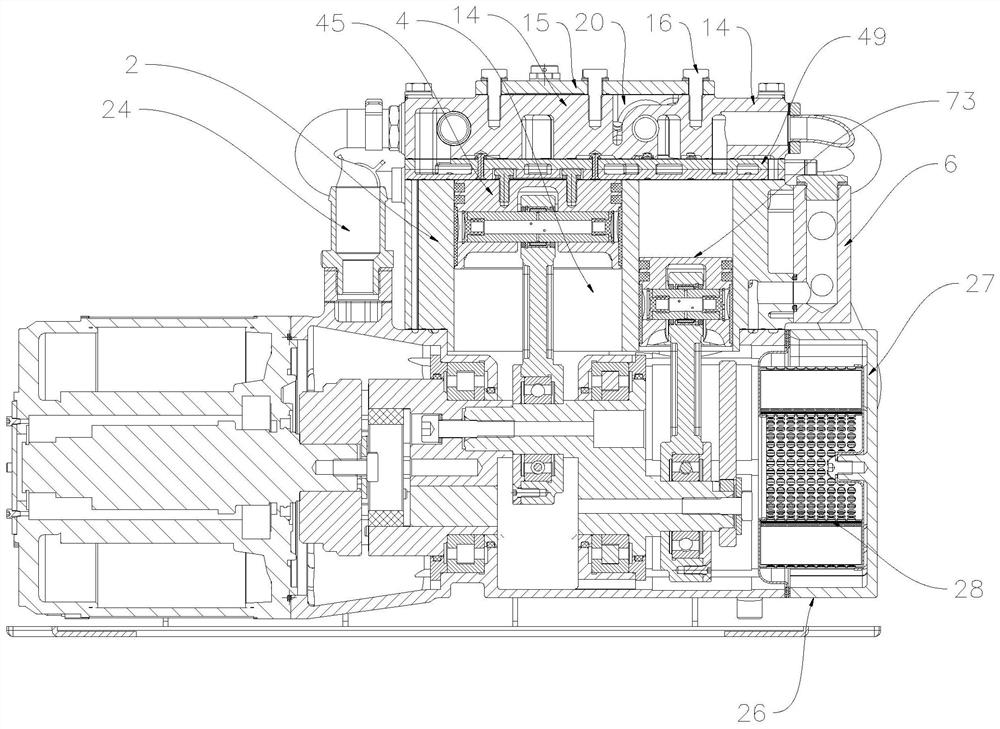

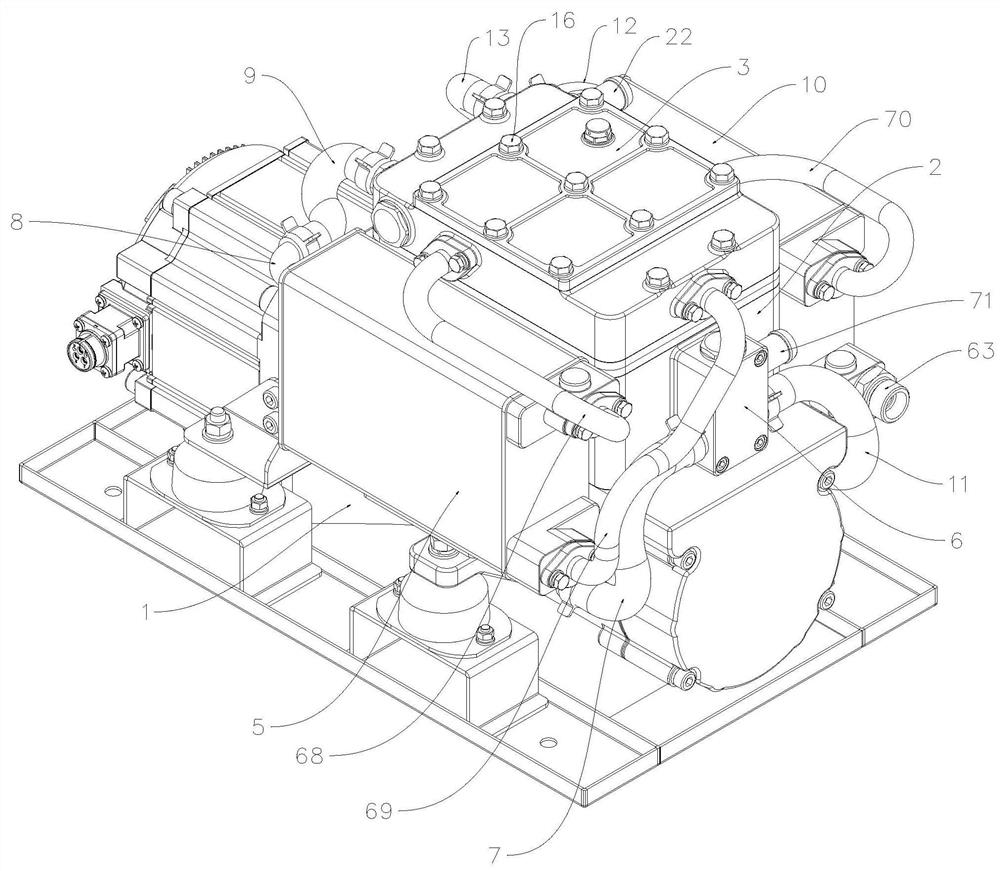

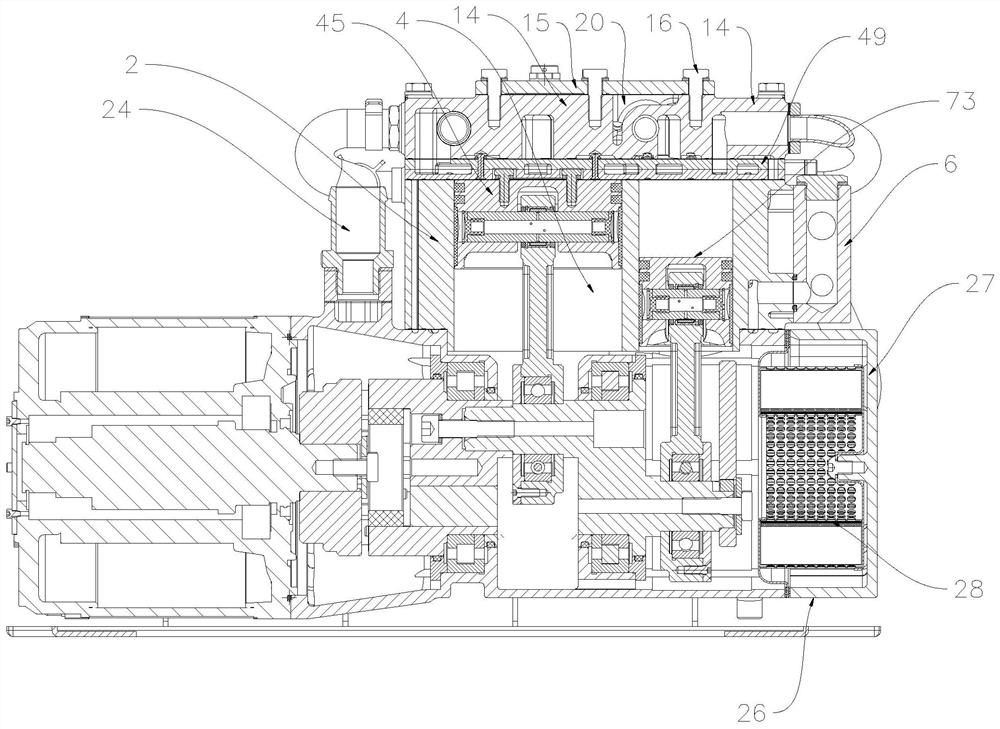

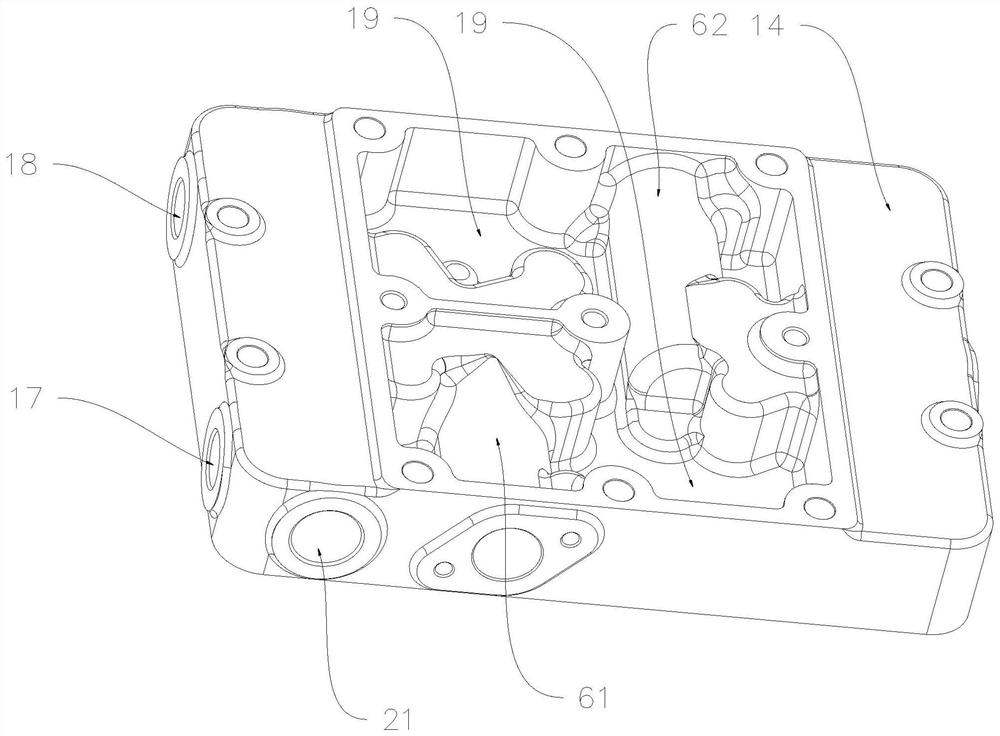

Oil-free piston type air compressor for new energy vehicle

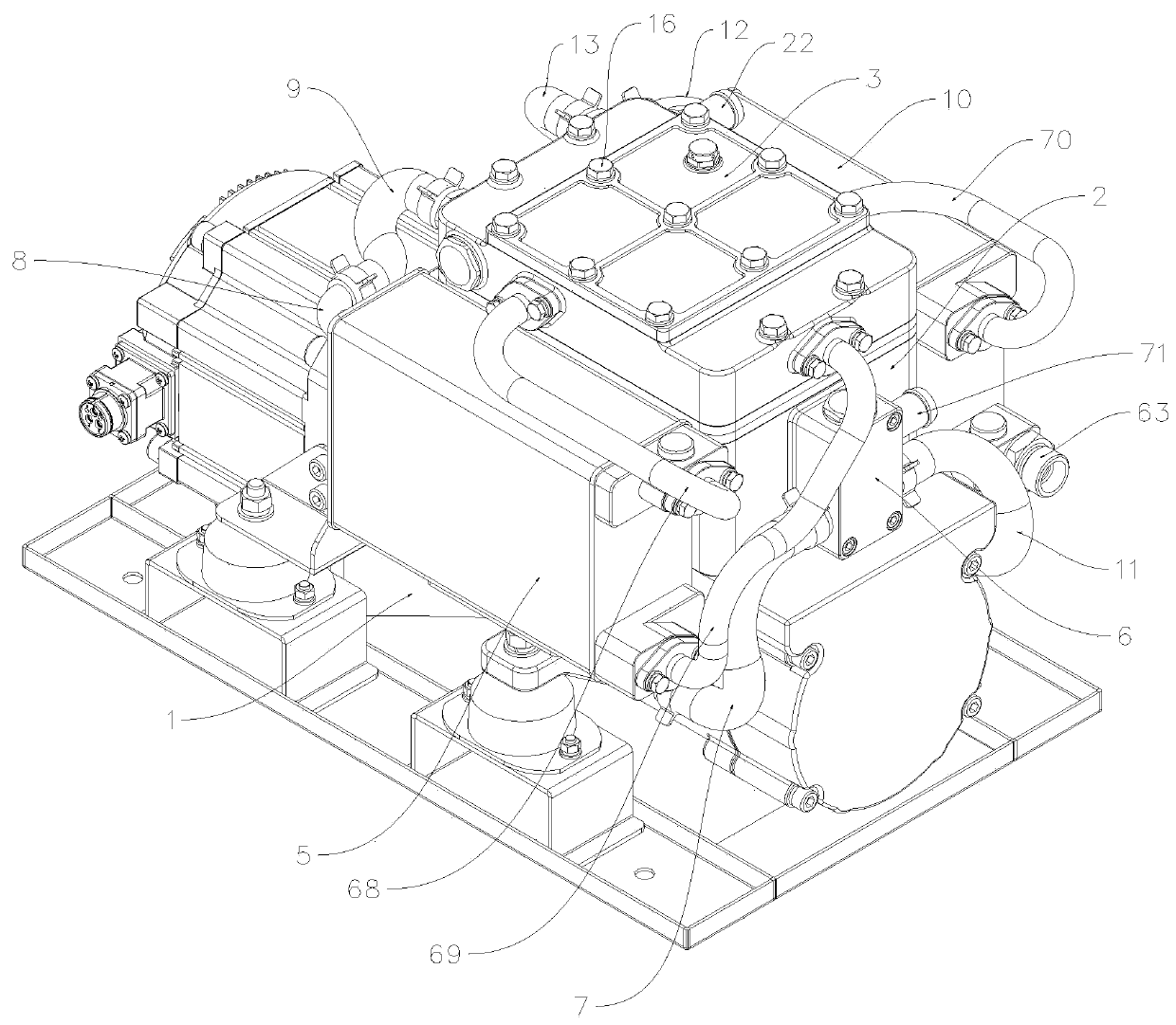

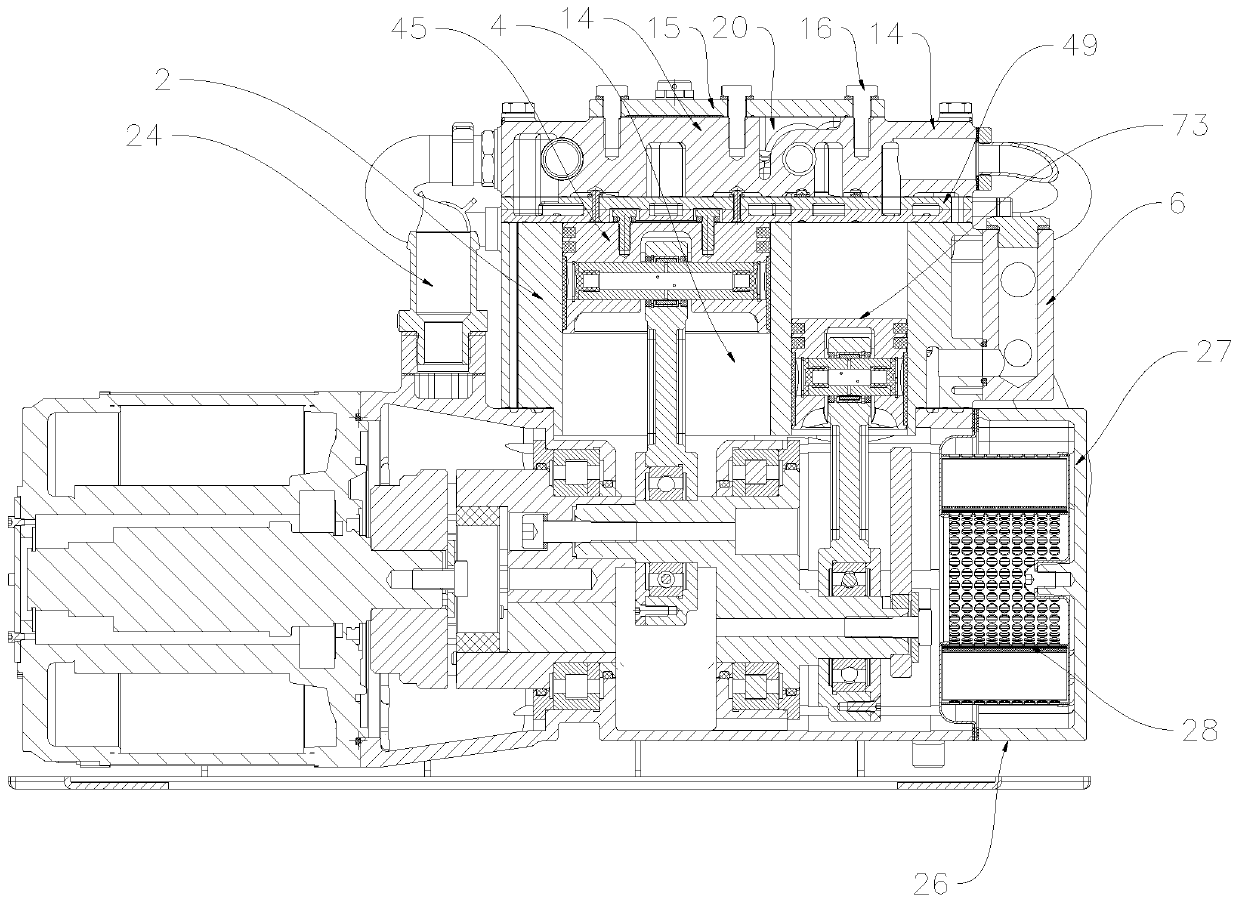

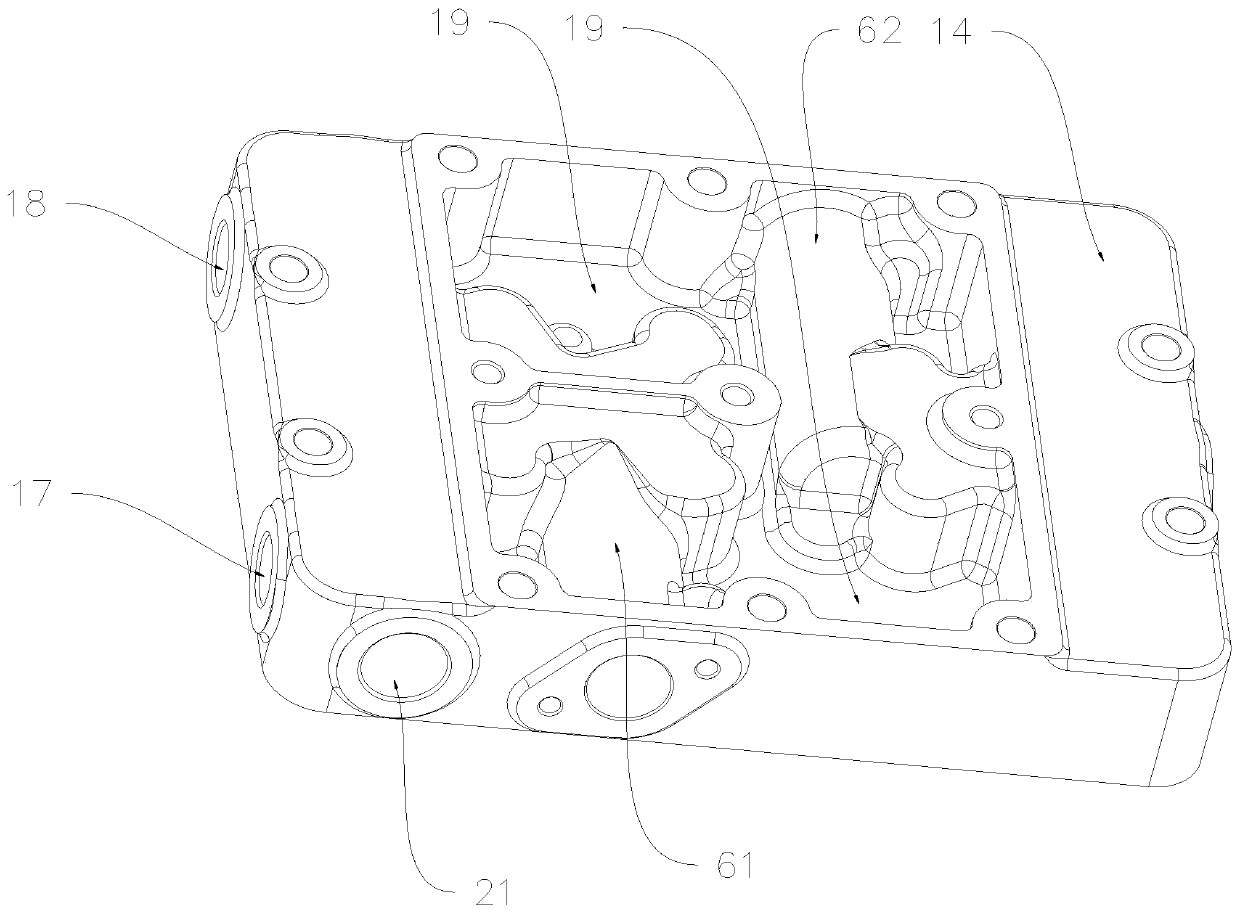

ActiveCN110107473AExtended service lifeImprove lubrication statusPositive displacement pump componentsMulti-stage pumpsCylinder headEngineering

The invention relates to the technical field of air compressors, and discloses an oil-free piston type air compressor for a new energy vehicle. The oil-free piston type air compressor for the new energy vehicle comprises a crank case, a cylinder body and a cylinder head assembly, wherein a piston cylinder is arranged in the cylinder body; the cylinder body is arranged above the crank case and is connected with the crank case; the cylinder head assembly is arranged above the cylinder body and is connected with the cylinder body; a low-pressure heat exchanger connected with the crank case is arranged on the front side of the cylinder body; a manifold block connected with the cylinder body is arranged at the right end of the cylinder body and is connected with the low-pressure heat exchangerthrough a first water inlet pipe; a first water outlet is formed in the left end of the low-pressure heat exchanger and is connected with the cylinder head assembly through a first drainage pipe; a high-pressure heat exchanger connected with the crank case is arranged on the back side of the cylinder body; the manifold block and the high-pressure heat exchanger are connected through a second waterinlet pipe; and a second water outlet is formed in the left end of the high-pressure heat exchanger and is connected with the cylinder head assembly through a second drainage pipe. The oil-free piston type air compressor for the new energy vehicle provided by the invention adopts water-cooling and air-cooling double-acting cooling manners so as to be sufficient in cooling and better in effect.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

Tea producing method

InactiveCN101138367AUniform heating temperatureNo local high temperaturePre-extraction tea treatmentCelsius DegreeChlorophyll

The present invention relates to a production method of tea leaf; the tip leaf of weeping forsythia capsule which is a green forsythia plant is taken as the raw material; the method comprises the following steps that the tip leaf of weeping forsythia capsule is picked and cleaned; the leaf is spread for 5 to 12 hours; the leaf is fried and steamed and the water is removed with a temperature of 120 to 180 Celsius degrees; the leaf is kneaded primarily for 8 to 12 minute with a temperature of 40 to 50 Celsius degrees; the leaf is arranged or formed with a temperature of 65 Celsius degrees; the leaf is baked with a temperature of 70 to 80 Celsius degrees; the leaf is kneaded again for 5 to 6 minutes with a temperature of 40 to 50 Celsius degrees; the leaf is baked again with a temperature of 60 to 80 Celsius degrees and the temperature is changing from a higher one to a lower one; the leaf is baked until the peduncle is broken when the peduncle is removed and the leaf becomes powder when the leaf is kneaded with hand. The beneficial effect of the present invention is that the fresh lead is heated evenly without local high temperature which can be filtrated through the flesh leaf of leaf pile in a short time; the oxydase is purified fast and the chlorophyll is preserved to the most; therefore, the tea is greener and fresher; the taste is diluted and the color is strong; the tea can be stewing for a long time.

Owner:程韶文

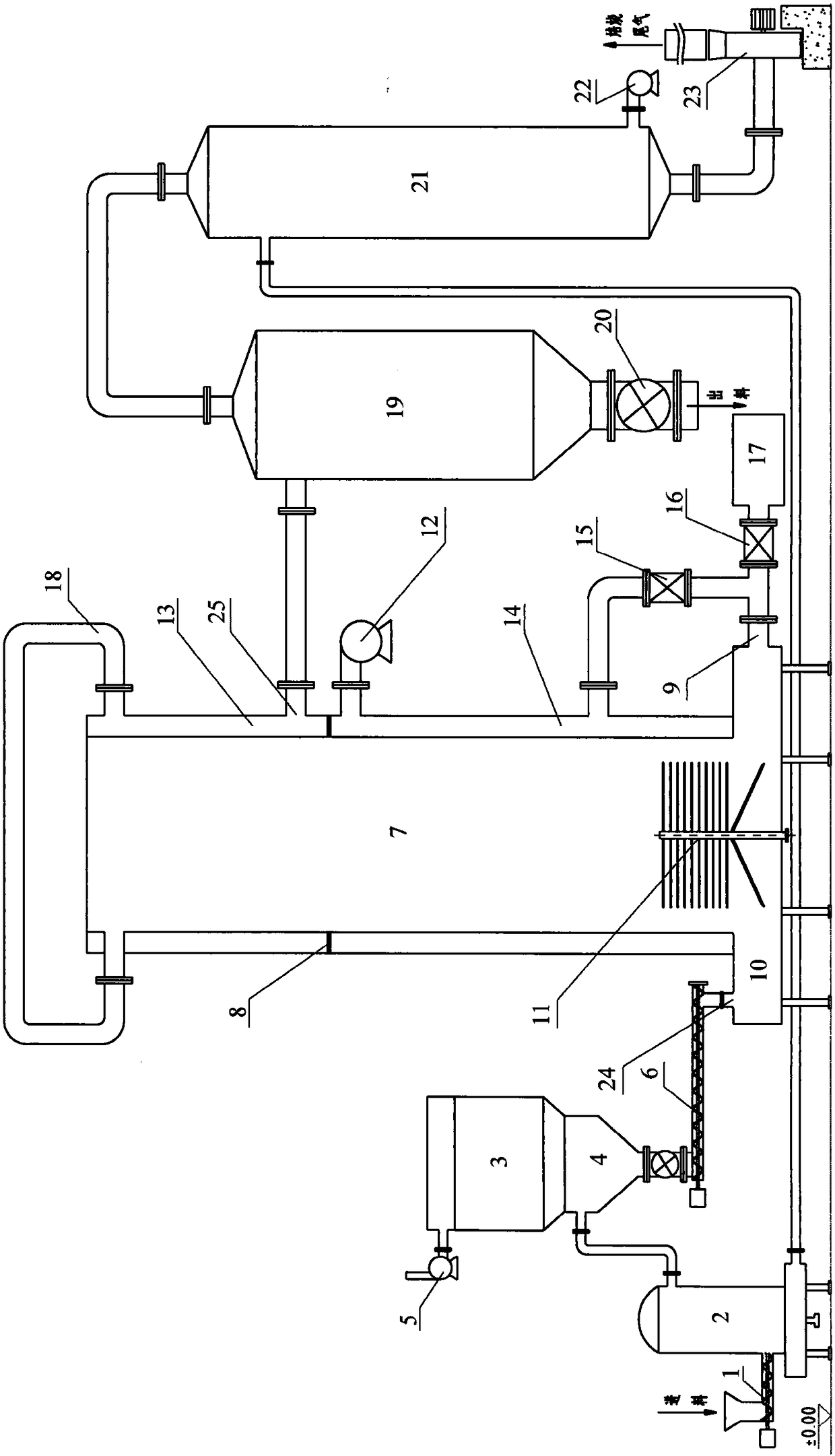

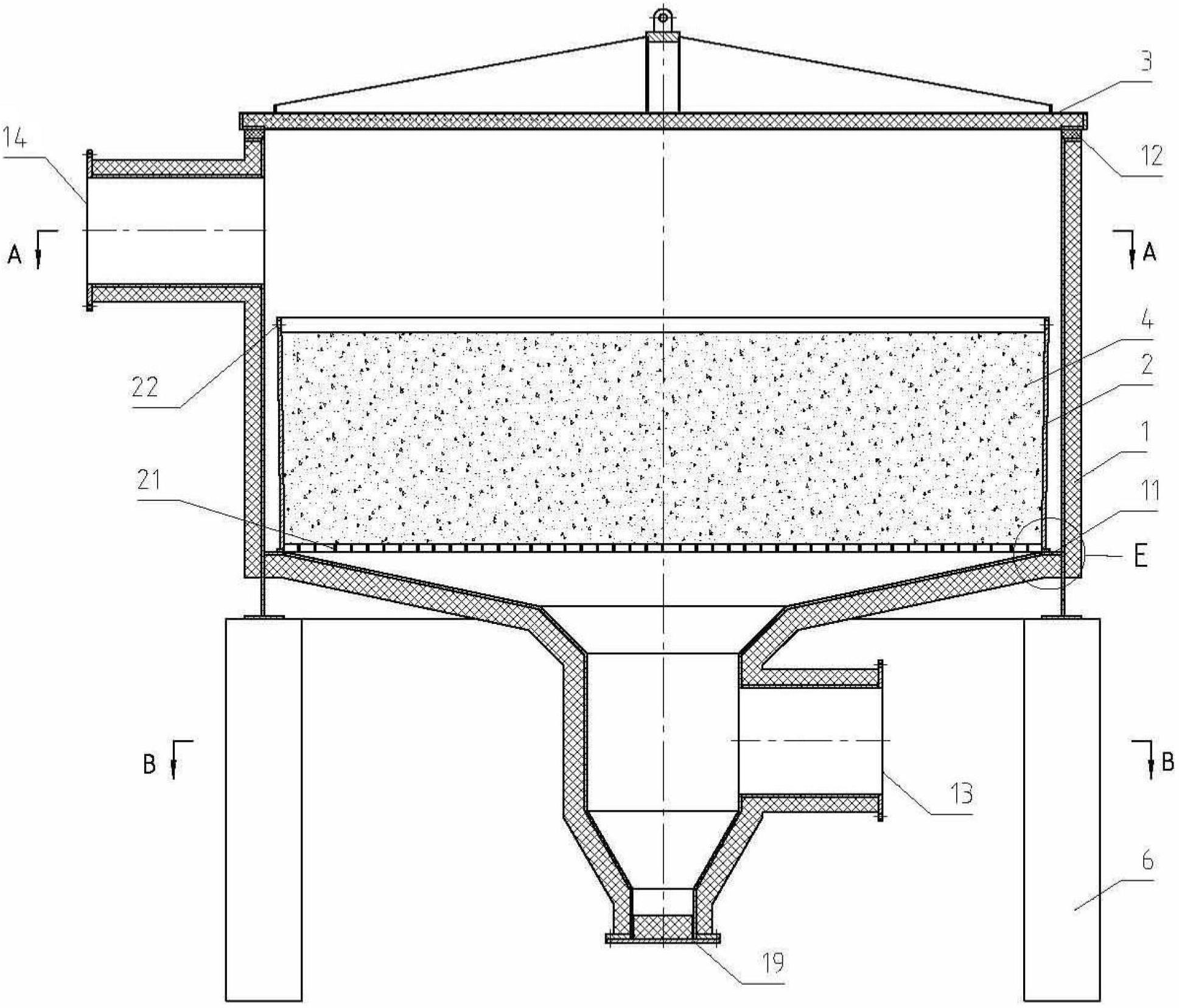

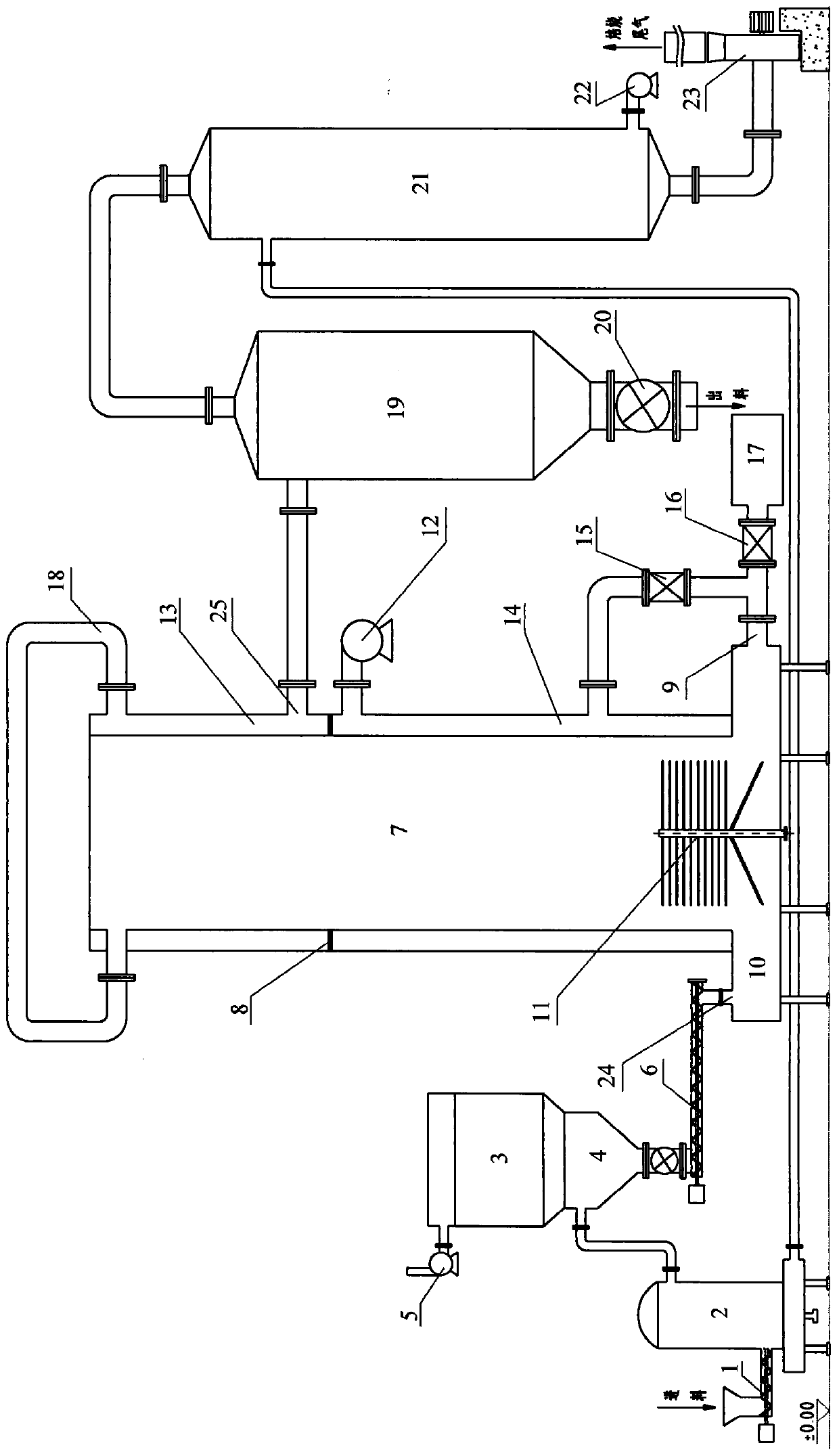

Bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment

ActiveCN108149006AFully roasted oxidation reactionComplete desulfurizationMolybdenum oxides/hydroxidesWaste heat treatmentComing outGas solid

The invention relates to a bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment. A rotational flow roasting furnace provided with a furnace body heat exchanging device is utilized to roast bright molybdenum concentrate so as to produce industrial molybdenum oxide. The heat emitted by a roasting reaction of the bright molybdenum concentrate is utilized to preheat air entering from an interlayer heat exchanging device of a lower furnace body in the roasting process, the preheated air is supplied into the rotational flow roasting furnace from the furnace bottom, a rotational flow wind distributing device makes the bright molybdenum concentrate be subjected to a roasting reaction under a rotational eddy state, a material coming out from the rotational flow roasting furnace enters an upper interlayer heat exchanging device of the rotational flow roasting furnace along with roasting eddy under the effect of negative pressure, a desulfurization reaction is completed in the interlayer heat exchanging device in the rotational advancing process, and a reacted gas-solid mixture enters a gas-solid separation discharging device to be subjected to gas-solid separation so that a solid roasted product and roasted smoke can be separated. The roasted smoke is sent to a SO2 recycling processing system under a draft effect of an induced draft fan afterentering a heat exchanger to exchange heat with the air, and the air after being subjected to heat exchanging is sent to a flash evaporation drying machine to dry the bright molybdenum concentrate.

Owner:NORTHEASTERN UNIV

Tea processing method

InactiveCN104322721AEvenly heatedNo local high temperaturePre-extraction tea treatmentChemistryChlorophyll

The invention belongs to the technical field of tea processing technology and particularly relates to a tea processing method including following steps: picking, cleaning, tedding, de-enzyme, cooling, rolling, drying, selecting and packaging. By means of the tea processing method, fresh tea is heated uniformly without local high temperature. Foliages or stacks of fresh leaves can be penetrated in a short time. Oxidase can be quickly passivated so that chlorophyll can be retained maximumly. The tea is more green and fresh, is delicate in taste, is thick in color and is soaking-durable.

Owner:LEIYANG JIANGTOU ECOLOGICAL AGRI DEV

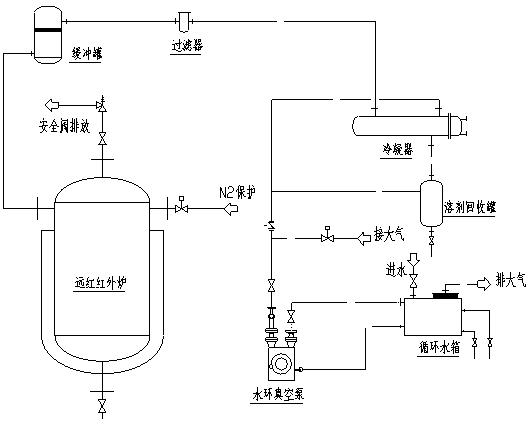

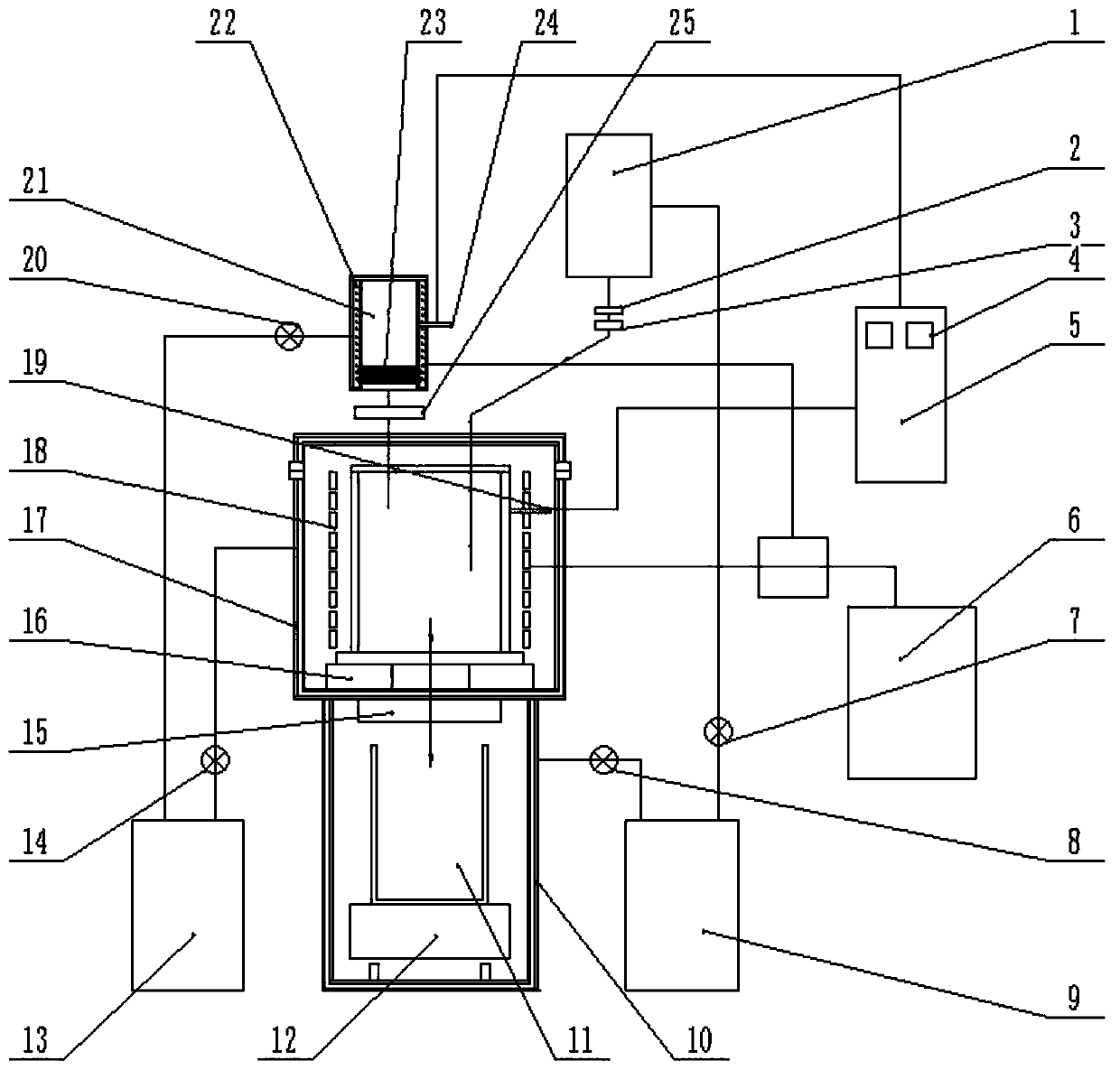

Device and method for recovering organic solvents in flammable explosive high-viscosity polymer waste

ActiveCN108452548AHeating evenlyReduce raw material consumptionCombination devicesSolid waste disposalSolventScrap

The invention discloses a device and a method for recovering organic solvents in flammable explosive high-viscosity polymer waste. A far-infrared furnace, a buffer tank, a filter and a condenser are connected in sequence; the condenser is connected with a solvent recovery tank while connected with a water tank via a vacuum pump; the side surface of the water tank has an overflow port; the heatingelement of the far-infrared furnace is a silicon carbide plate arranged out of the furnace and coated with a far-infrared paint; a far-infrared heating wire is arranged in the silicon carbide plate; and one surface, coated with the far-infrared paint, of the silicon carbide plate clings to the outer wall of the far-infrared furnace. According to the invention, waste slurry blocks and solvents in flammable and explosive materials adhered onto metal surfaces are recovered in a vacuum state by heating and condensing; the far-infrared furnace is employed for heating, so uniform heating in the furnace is realized, local high temperature and open flames do not occur, and the phenomenon of flash explosion is eliminated; the waste slurry blocks and the flammable and explosive melt materials adhered onto metal surfaces are separated under high vacuum and high temperature, and the separated and evaporated flammable and explosive organic solvents are condensed into liquid which is collected for recycling; so spinning solvents can be recycled, raw material consumption is reduced, and production cost is lowered.

Owner:SINOPEC YIZHENG CHEM FIBER +1

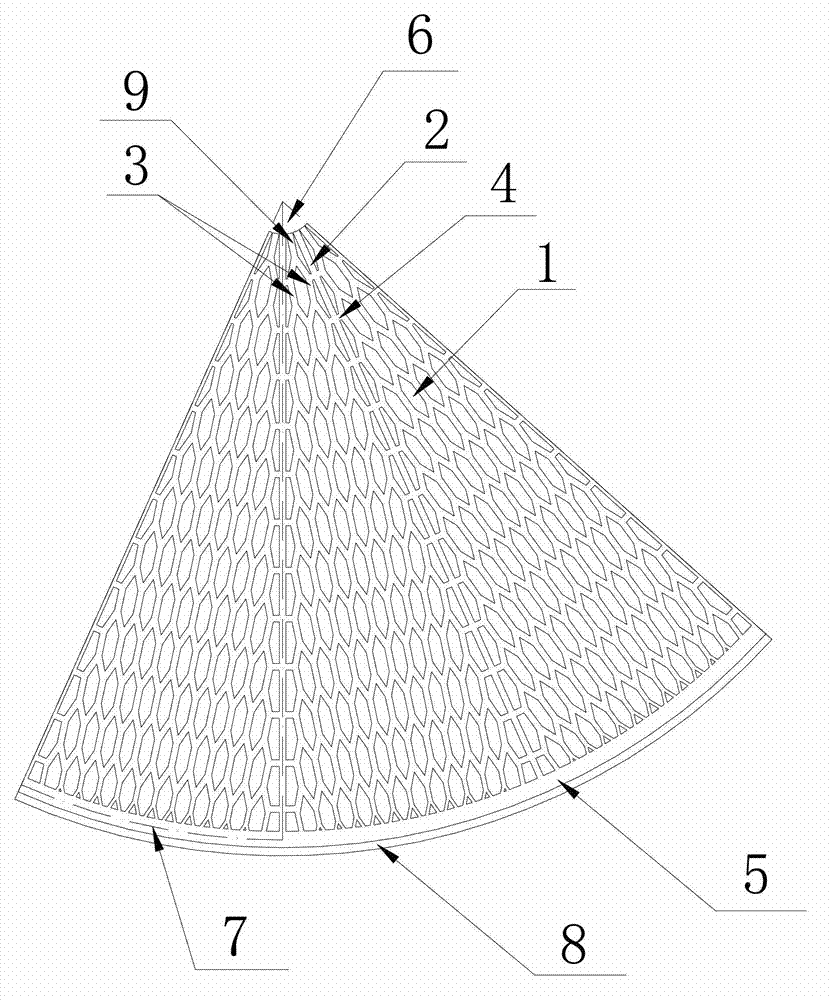

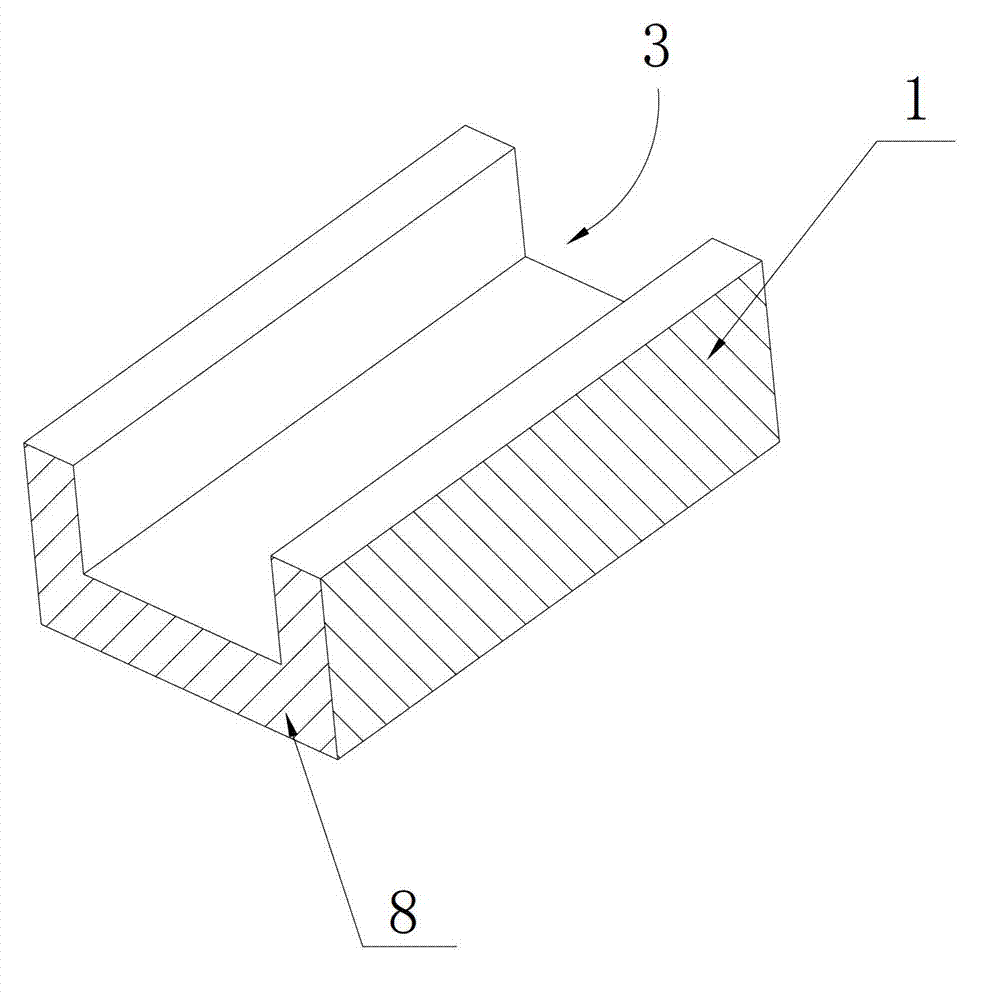

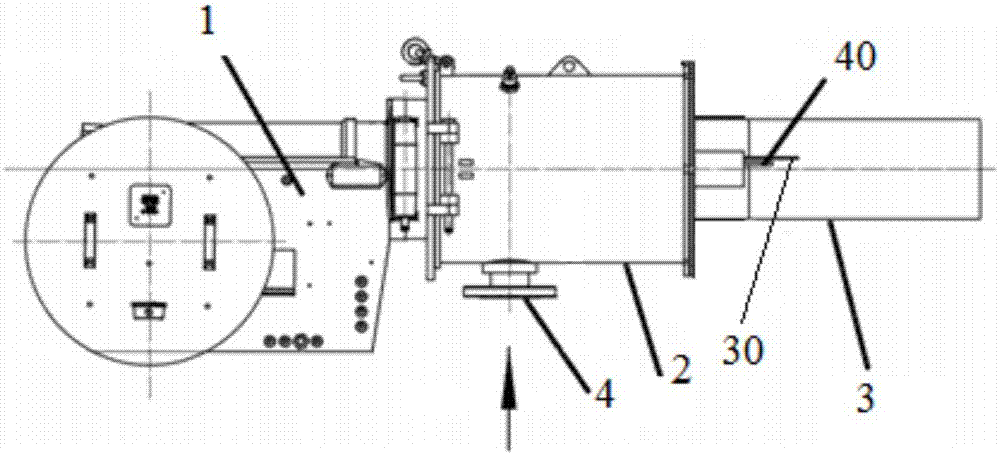

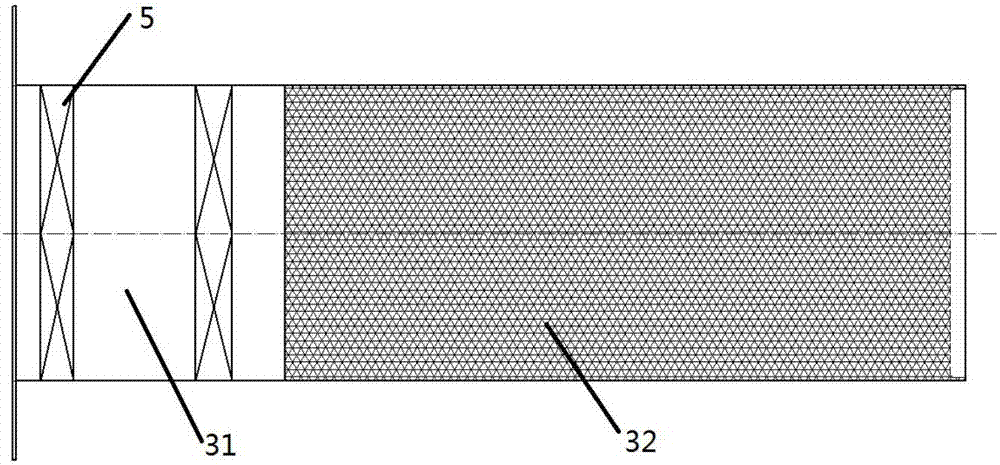

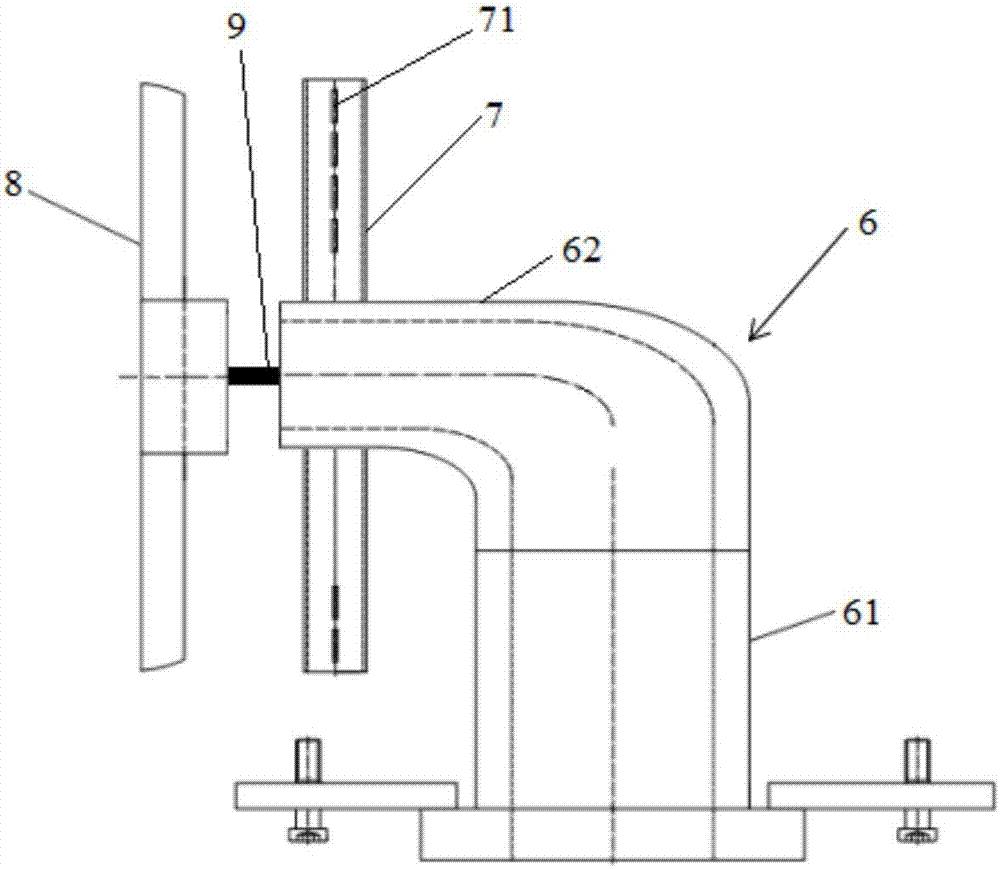

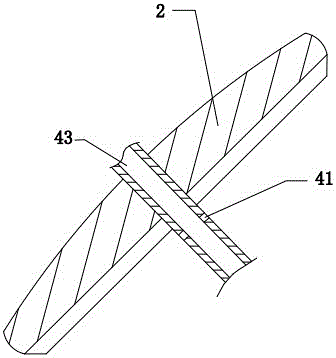

Full pre-mixing metal fiber burner

PendingCN106969356AStable combustionUniform temperature distributionGaseous fuel burnerEngineeringNOx

The invention discloses a full pre-mixing metal fiber burner. The full pre-mixing metal fiber burner comprises a draught fan, a pre-mixing chamber and a burning head. An air outlet of the draught fan is connected with the front end of the pre-mixing chamber; the rear end of the pre-mixing chamber is connected with the burning head, an ignition assembly and an air distributing ring are arranged in the pre-mixing chamber, the ignition assembly is located at the rear end of the pre-mixing chamber, and the air distributing ring is connected with a fuel gas inlet of the side wall of the pre-mixing chamber; and an air mixing wheel is arranged in the burning head. According to the full pre-mixing metal fiber burner, the mode that a metal fiber surface burning head is additionally provided with an air fuel gas mixing structure is adopted, thus air and fuel gas are mixed twice before burning, mixing is more even, air supplying is sufficient, and generation of NOx and CO is inhibited.

Owner:北京节能技术监测中心

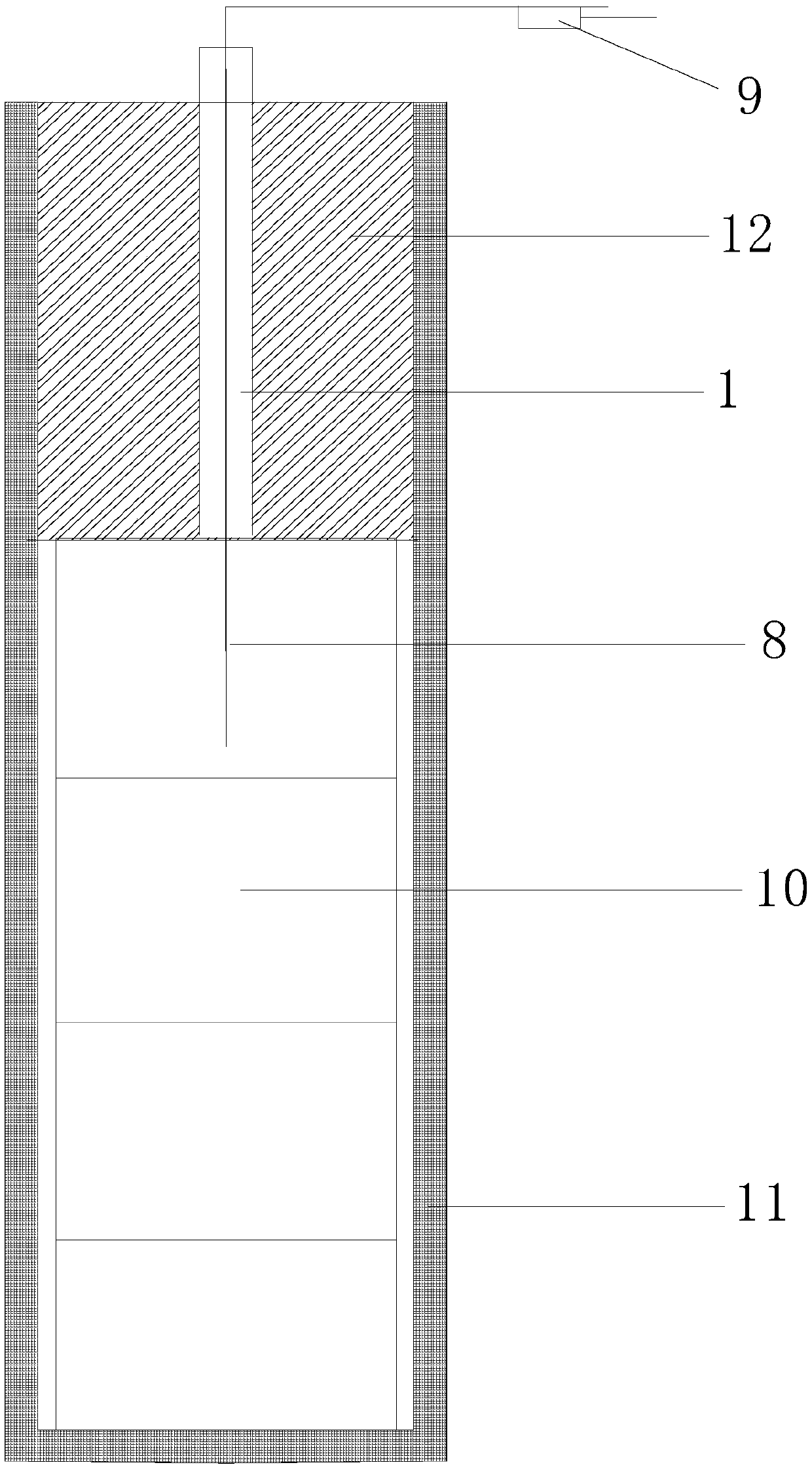

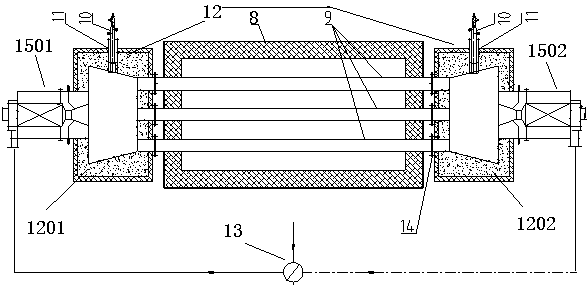

Continuous production equipment and continuous production method for magnesium metal

The invention discloses continuous production equipment and a continuous production method for a magnesium metal. The continuous production equipment comprises a charging device, a reduction room, a crystallizer and a deslagging room. The charging device, the reduction room, the crystallizer and the deslagging room are provided with vacuum detectors and communicate to a vacuum device. The chargingdevice is located above the reduction room and communicates to the reduction room, a material isolating valve is arranged between the charging device and the reduction room, the deslagging room is arranged right below the reduction room, the reduction room communicates to the deslagging room and a deslagging isolating valve is arranged between the reduction room and the deslagging room, and the crystallizer communicates to the upper side of the reduction room; the inner wall of the reduction room is a graphite crucible, titanium boride is plasma sprayed to the surface of the graphite crucible, and an electromagnetic induction heating device is arranged in the reduction room, so that no other heating devices are available in the reduction room, and therefore, the equipment is large in space and quick and uniform to head, the reaction time can be saved obviously and a slag adhesion phenomenon can be also avoided.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

Detonating fuse heat insulating protection device and detonating method

InactiveCN107764138AAbsorbentSolve the problem of unusable high temperatureBlasting cartridgesBlastingEngineeringWater layer

The invention discloses a detonating cord heat insulation protection device and a blasting method. The device includes a heat insulation protection cylinder and a pre-embedded wire, the heat insulation protection cylinder is a hollow cylinder, and the pre-embedded wire is arranged on a heat insulation The inner cavity of the protection cylinder extends along the axis of the heat insulation protection cylinder to the outside of the heat insulation protection cylinder. The side wall of the heat insulation protection cylinder includes a water-permeable layer, a water-absorbing layer and a waterproof layer arranged sequentially from outside to inside. The waterproof layer includes a water-proof layer and a rubberized layer arranged in sequence from the inside to the outside. The invention is used to protect the detonating cord, so that the detonating cord can be safely used at high temperature for a certain period of time, which ensures the safety of blasting and solves the problem that the current detonating cord cannot be used at high temperature; secondly, it has strong water absorption, but the total water consumption Supply is not a problem, and it can be applied to high-temperature blasting in a large area to improve blasting efficiency; in addition, it is easy to operate, and the materials used are common products on the market, and the cost is low.

Owner:HONGDA MINING IND

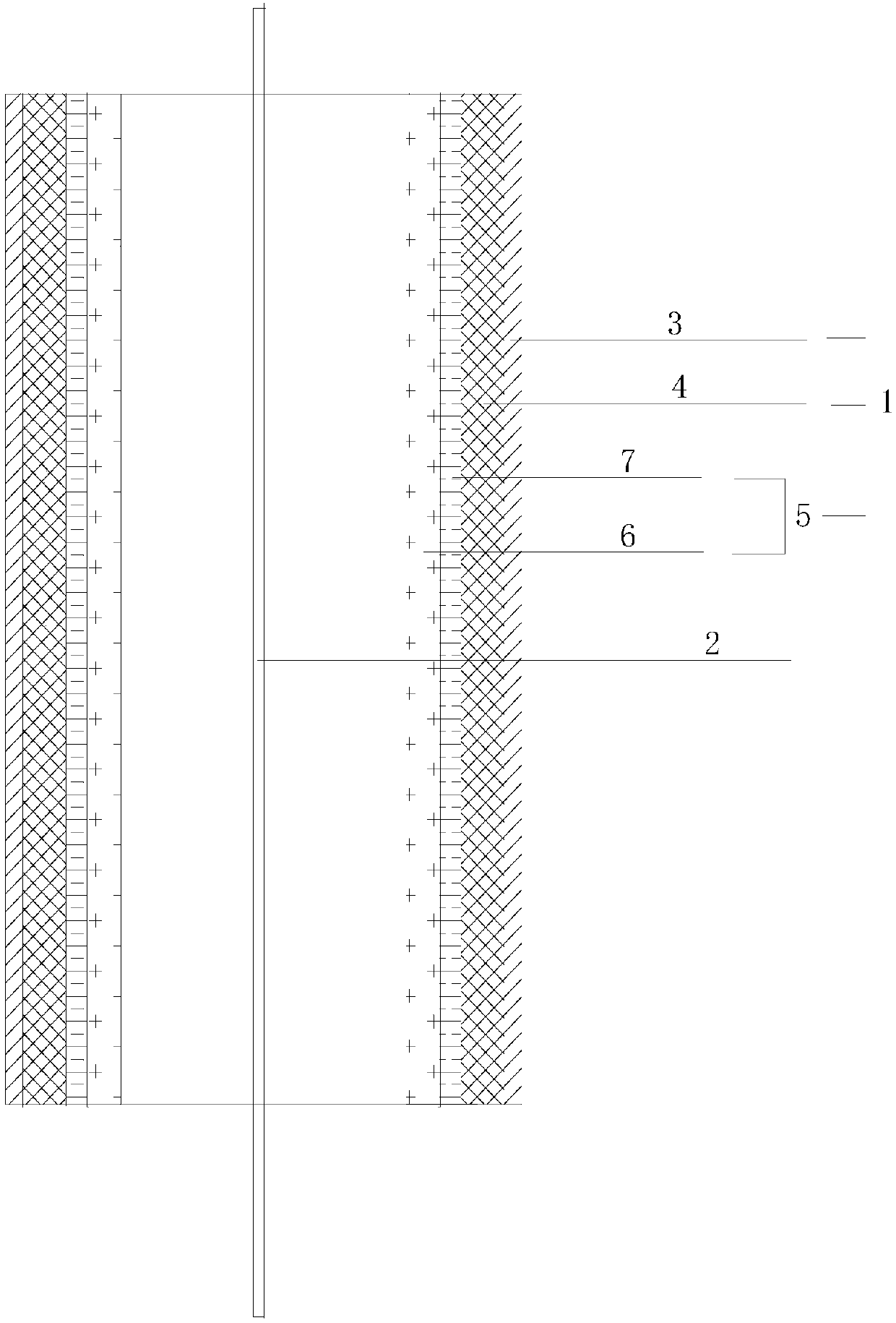

Heating furnace with double furnace bodies

The invention is suitable for heating and roasting blocky materials such as an iron alloy for steelmaking and the like and relates to a heating furnace with double furnace bodies. The heating furnace comprises an outer furnace body, an inner furnace body and a furnace cover, wherein the outer furnace body is a steel container and is provided with a heat-insulating layer; a bearing platform is arranged inside the outer furnace body; a sealing ring is arranged at the upper part of the outer furnace body; ventilation holes are respectively formed in the upper side and the lower side of the bearing platform of the outer furnace body; a grate made of heat-resistant steel is arranged at the bottom of the inner furnace body; a hoisting hole or a hoisting lug shaft is arranged at the upper part of the inner furnace body; an iron alloy material is accommodated inside the inner furnace body; the inner furnace body is laid on the bearing platform in the outer furnace body; a contacted surface between the inner furnace body and the bearing platform in the outer furnace body is a sealing surface; the furnace cover is laid on the sealing ring of the outer furnace body; and when the furnace cover is moved away, the inner furnace body can be hoisted into or out of the outer furnace body. The heating furnace disclosed by the invention has the advantages of uniformity in heating of the iron alloy material, simple structure, high reliability, no burning nozzle in the furnace, no local high temperature, no possibility of burning out a furnace wall, high thermal efficiency, reliable performance and long service life, and a general flue gas furnace is used in a matching manner.

Owner:杨东进

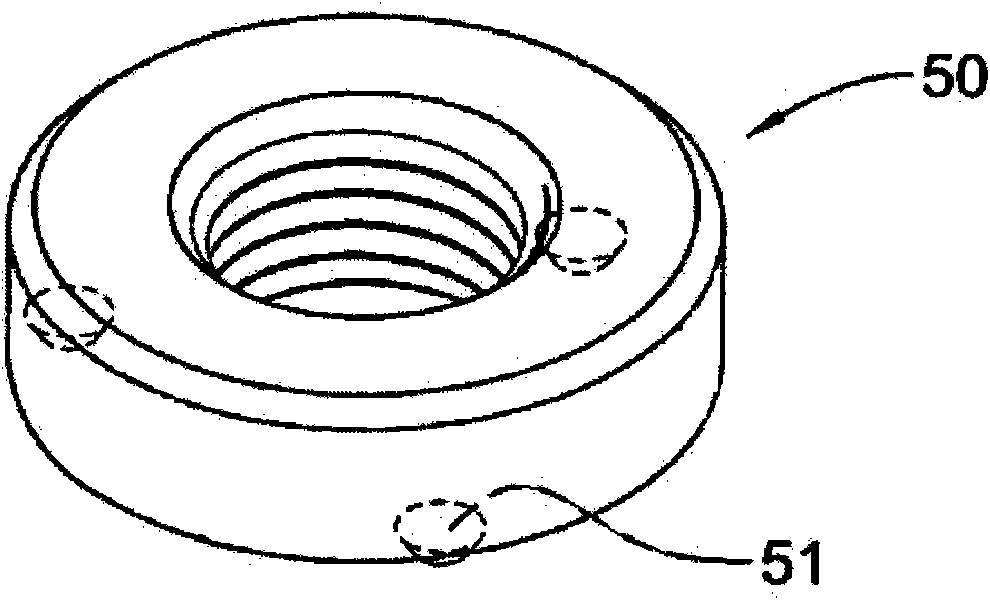

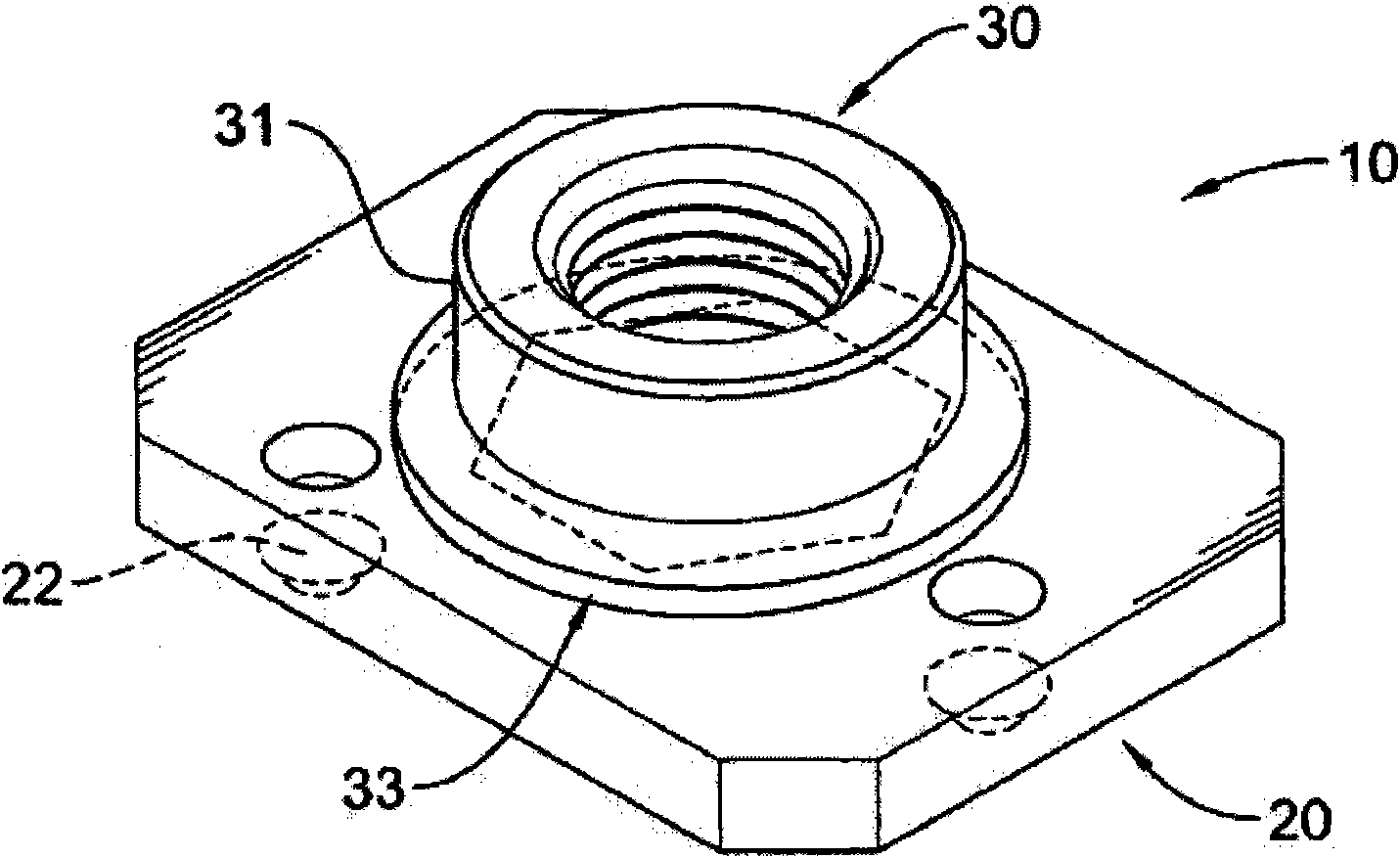

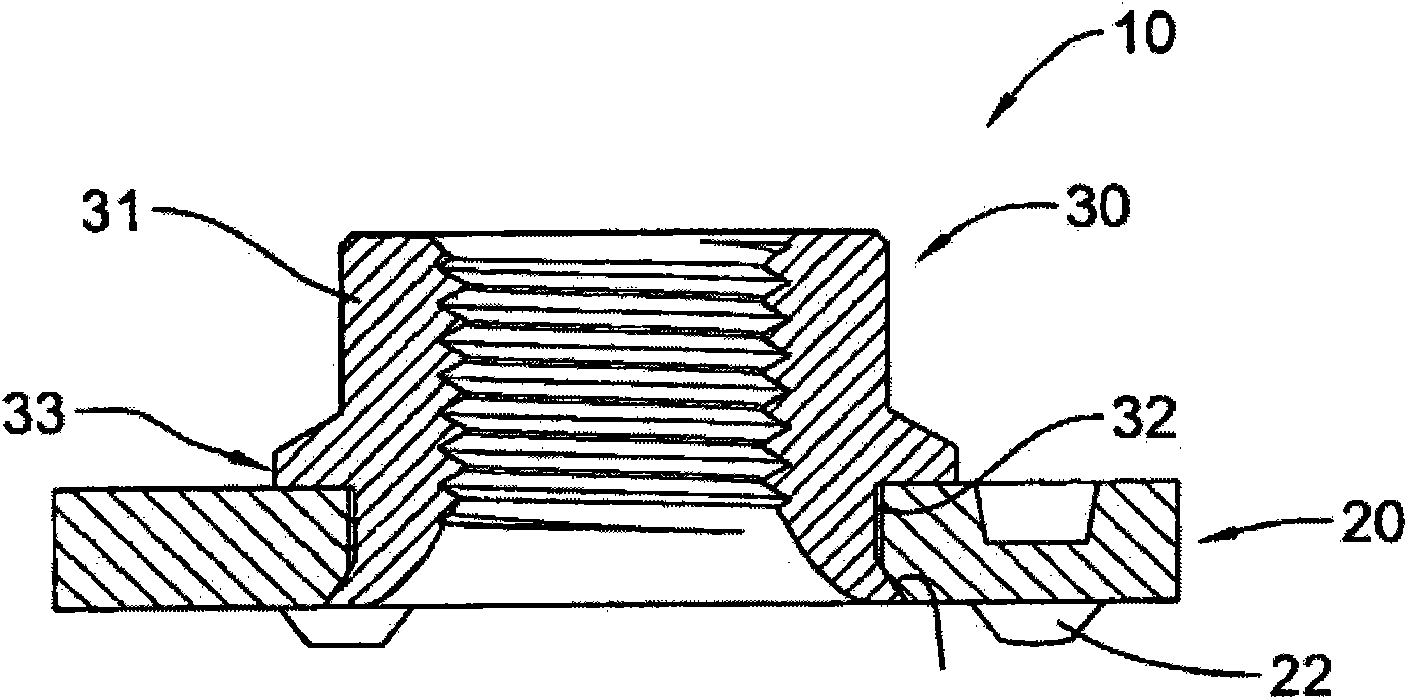

Welding nut

InactiveCN102465948ANot easy to damageNo local high temperatureNutsCircular discArchitectural engineering

The invention discloses a welding nut, which comprises a flat piece and a nut piece, wherein a perforation is formed on the flat piece, and the bottom of the flat piece is provided with a welding boss; the upper end of the nut piece is provided with a cap part, and the lower end of the nut piece is provided with a combining part; a disc is arranged on a connecting part of the cap part and the combining part; the combining part is fixed in the perforation of the flat piece; and the bottom of the disc is pressed against the top of the flat piece. The invention has the advantages that: the welding nut is firmly and reliably welded, a workpiece is difficultly damaged, and the like.

Owner:倪国栋

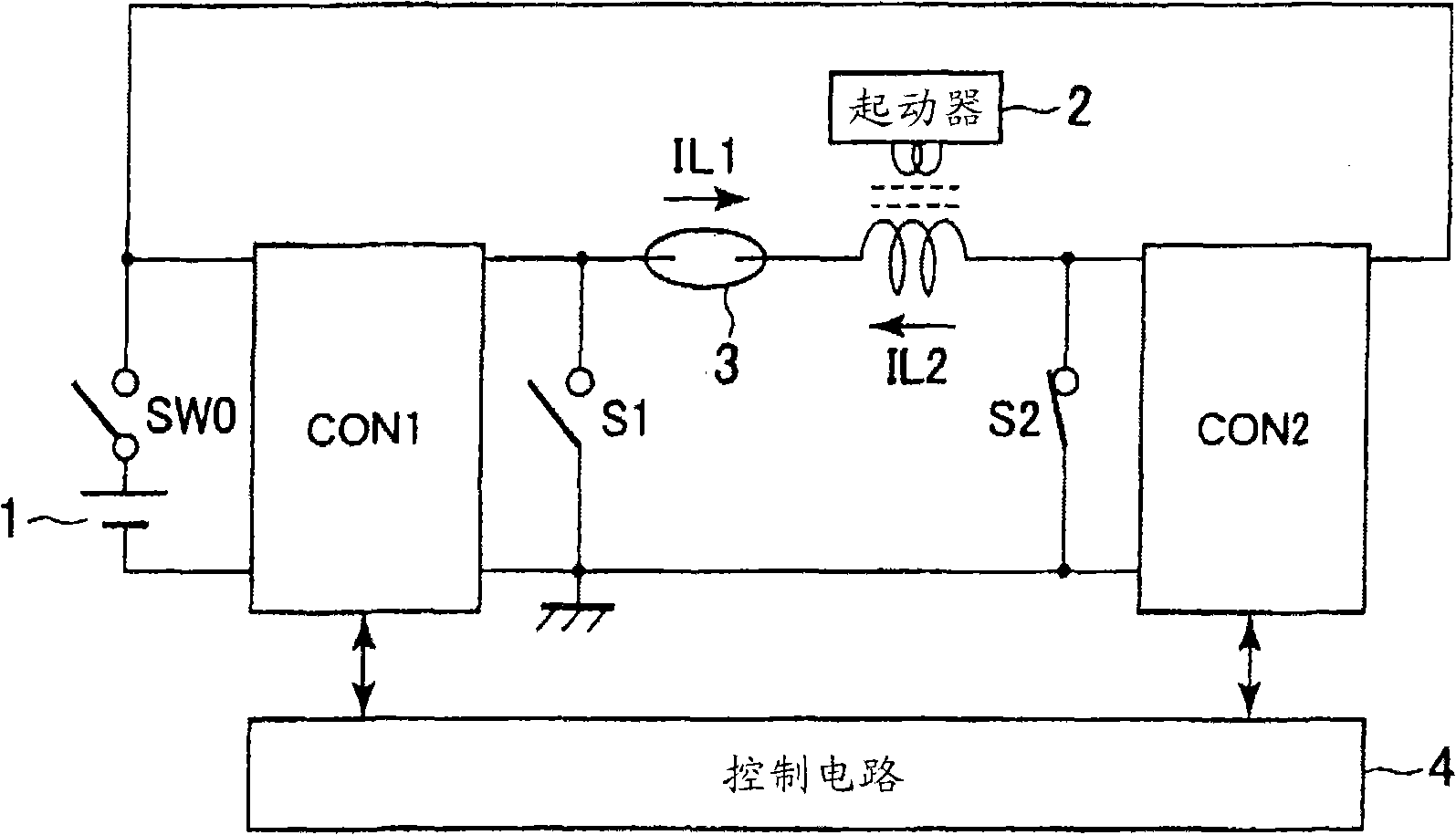

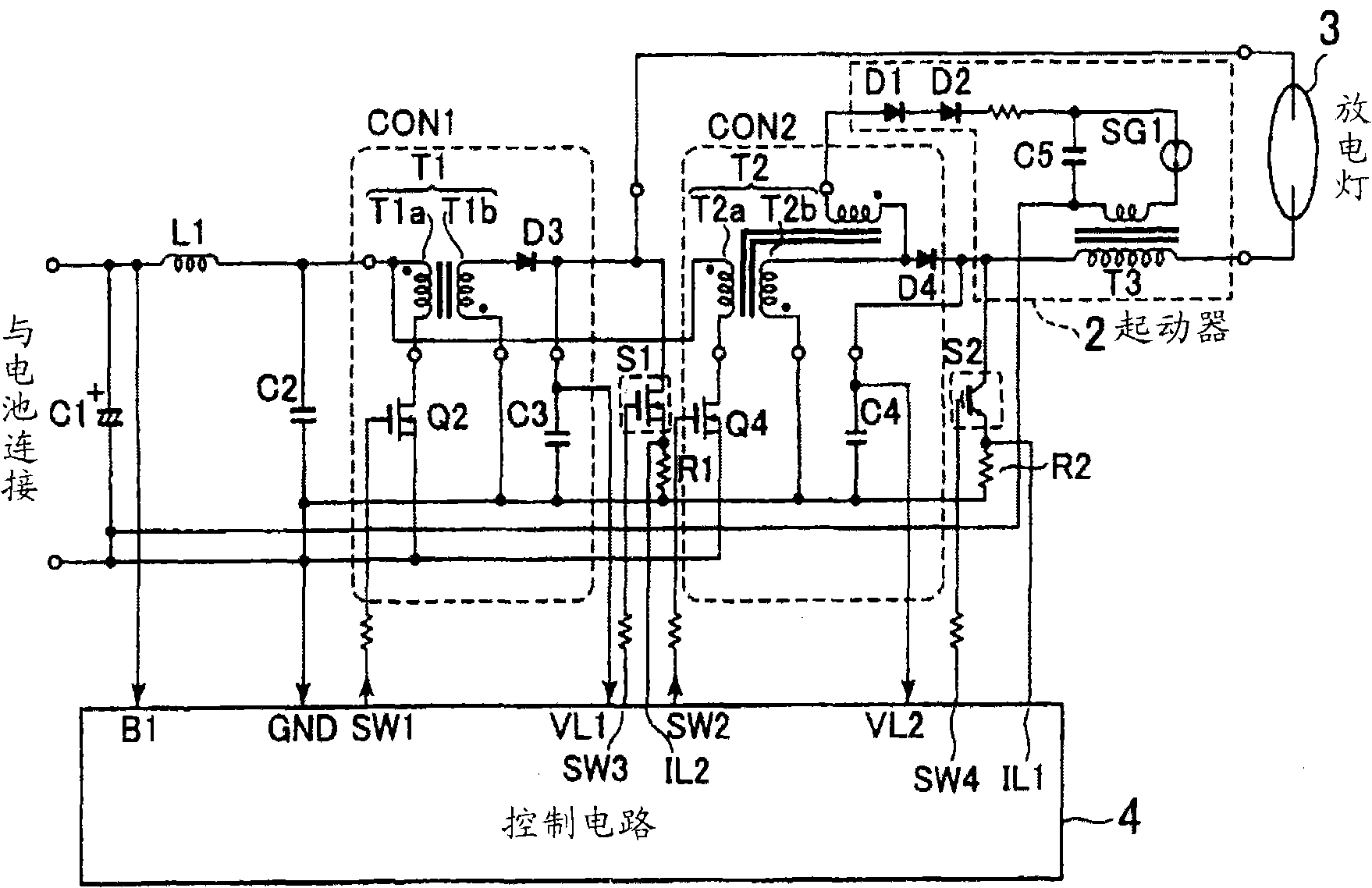

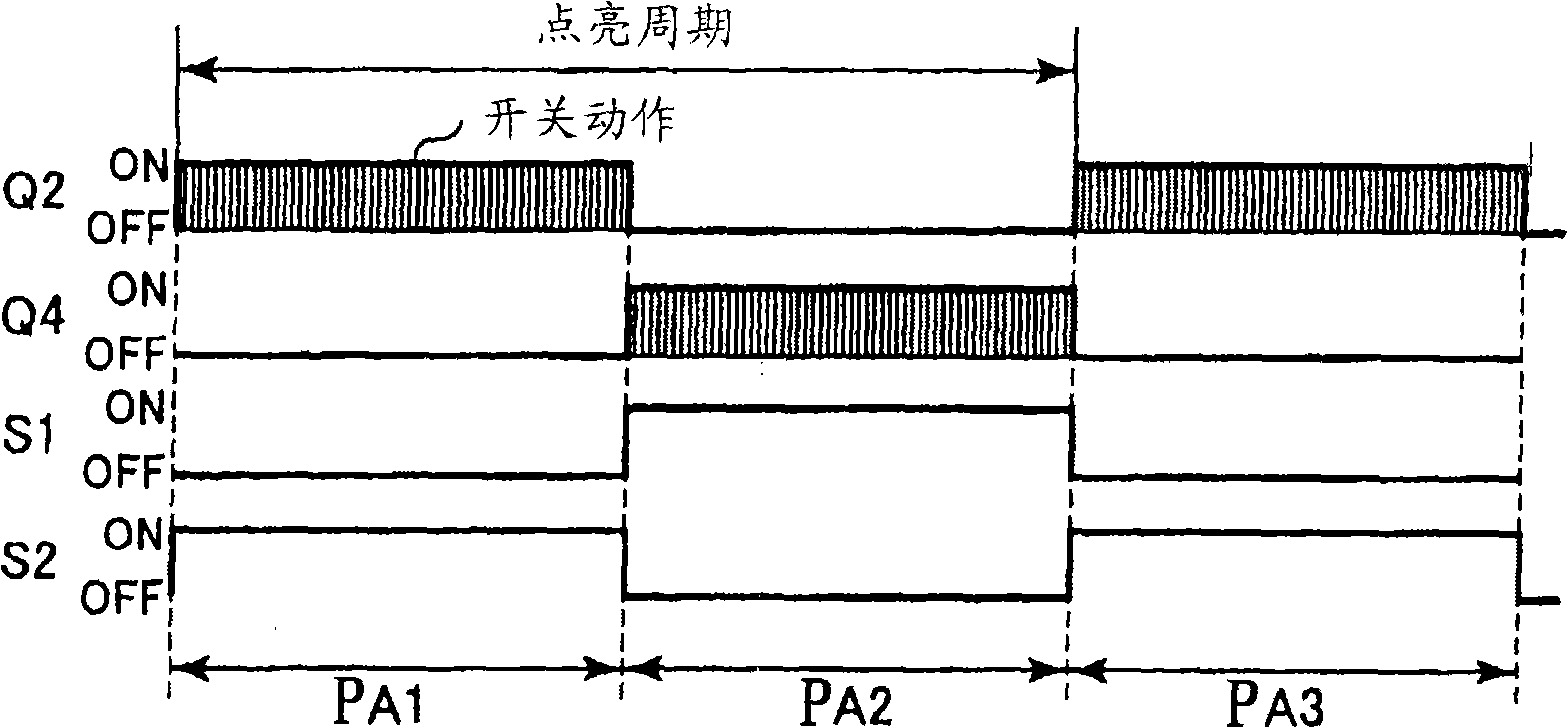

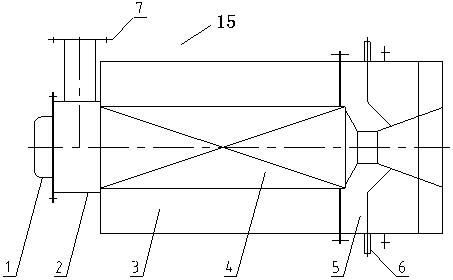

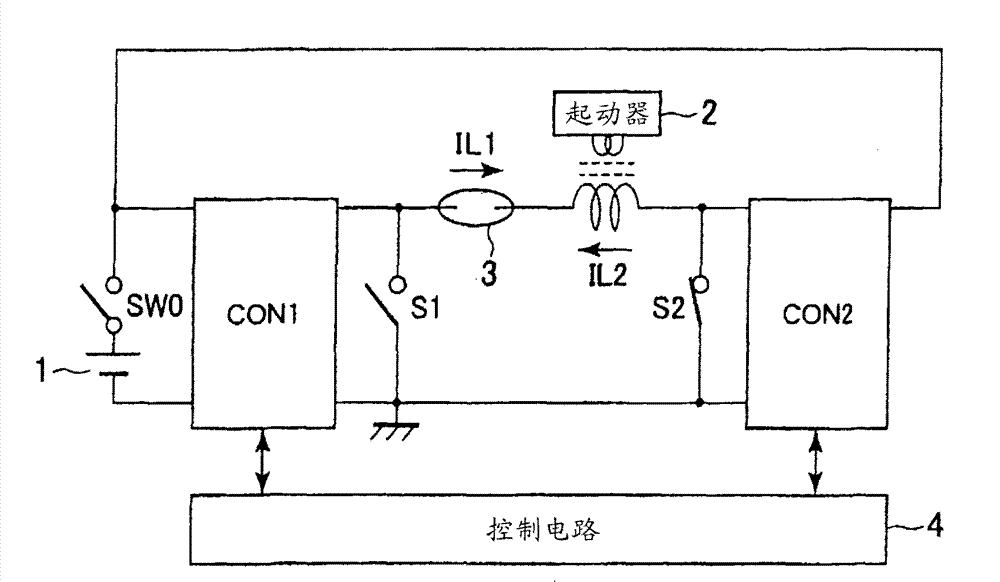

Discharge lamp lighting circuit

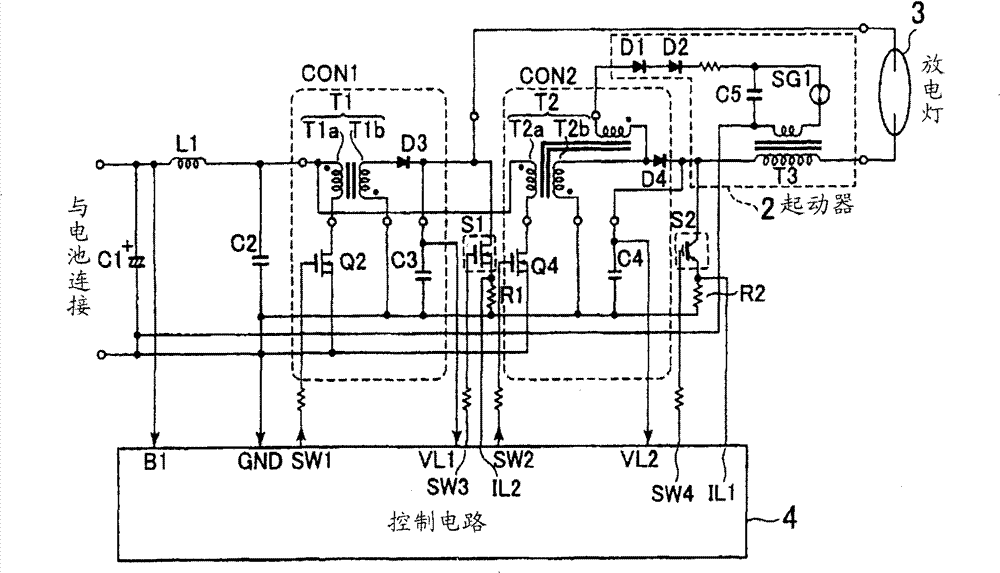

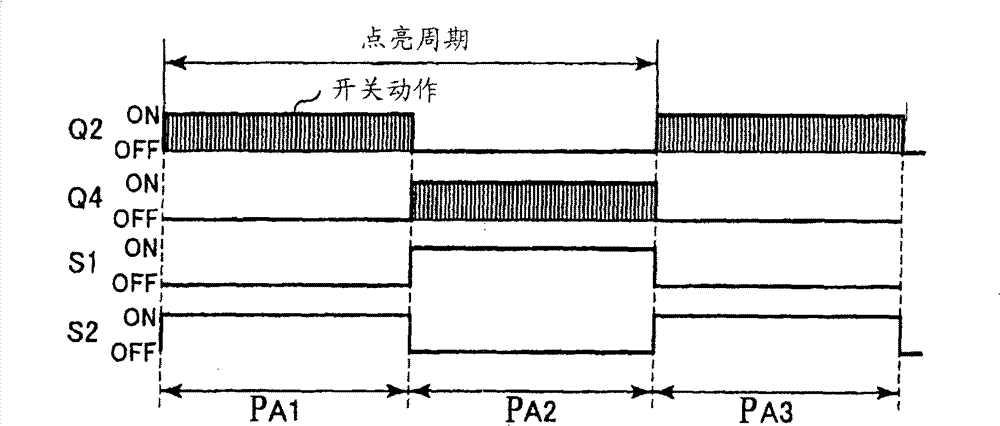

InactiveCN101527996ALow costLow calorific valueElectric lighting sourcesDc-ac conversion without reversalGas-discharge lampEffect light

The invention relates to a discharge lamp lighting circuit which realizes the miniaturization and cost reduction of a light circuit. The discharge lamp lighting circuit for supplying an AC power to a discharge lamp 3 includes first and second converters for receiving a DC voltage and stepping up the voltage. A controlling circuit drives the first and second converters CON1, CON2 alternately at a first frequency and stops an operation of a side that is not driven such that the AC power is supplied to the discharge lamp to execute a lighting operation.

Owner:KOITO MFG CO LTD

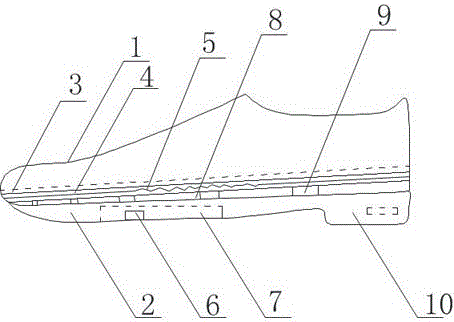

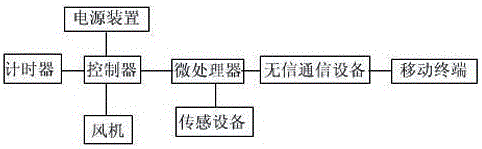

Internet data analysis based automatic-drying smart shoe

The invention discloses an internet data analysis based automatic-drying smart shoe comprising an upper and a sole connected with the upper. A cavity is arranged inside the sole, an insole is arranged between the upper and the sole and comprises a heat conduction layer, a heating unit is embedded into the periphery of the heat conduction layer and connected with a circuit system, and the circuit system is installed in the cavity inside the sole. The insole further comprises a venting layer arranged under the heat conduction layer, and at least two through holes are formed in the venting layer. The circuit system comprises a power supply unit, a controller, a microprocessor, a fan and a sensing unit, the power supply unit is connected with the controller which is connected to the microprocessor, the microprocessor is connected with the sensing unit and connected to a mobile terminal through a wireless communication device, and the controller is communicated with the fan and further connected with a timer; the sensing unit comprises a humidity sensor and a temperature sensor. The internet data analysis based automatic-drying smart shoe realizes automatic dehumidification and is good in dehumidification effect and short in time.

Owner:成都欧魅时尚科技有限责任公司

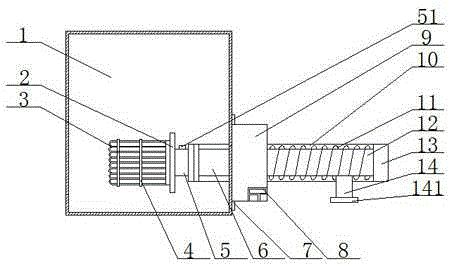

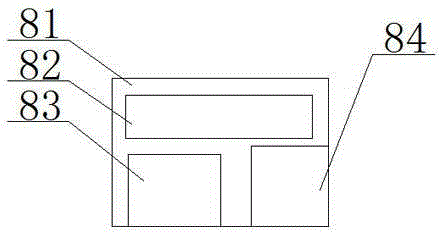

Petroleum heater

InactiveCN105318532AFast heatingStable heating rateWater heatersMicrocomputer controlElectromagnetic heating

The invention provides a petroleum heater. The petroleum heater comprises an electric heater, an interior petroleum conveying device, a microcomputer control cabinet, a petroleum pumping device and an electromagnetic heating device, wherein the electric heater is arranged at the bottom part of the petroleum storage tank; electric heating rods are arranged on the left side of the electric heater; clamping boards are arranged on the electric heating rods; the interior petroleum conveying device is arranged on the right side of an anti-explosion wire connecting cavity; the petroleum pumping device is arranged on the bottom right part of the petroleum storage tank; the microcomputer control cabinet is arranged on the bottom right part of the petroleum pumping device; the right side of the petroleum pumping device is provided with a heating and insulating pipe; a petroleum conveying pipe is arranged in the heating and insulating pipe; the electromagnetic heating device is arranged on the right side of the heating and insulating pipe; and a petroleum conveying opening is formed in the bottom part of the right side of the heating and insulating pipe. Compared with the prior art, the petroleum heater has the following beneficial effects that the petroleum heater is convenient for use; petroleum can be heated more fast and stably through the electric heater at the bottom; and the petroleum in the oil tank is prevented from being heated repeatedly.

Owner:CHONGQING ENERGY COLLEGE

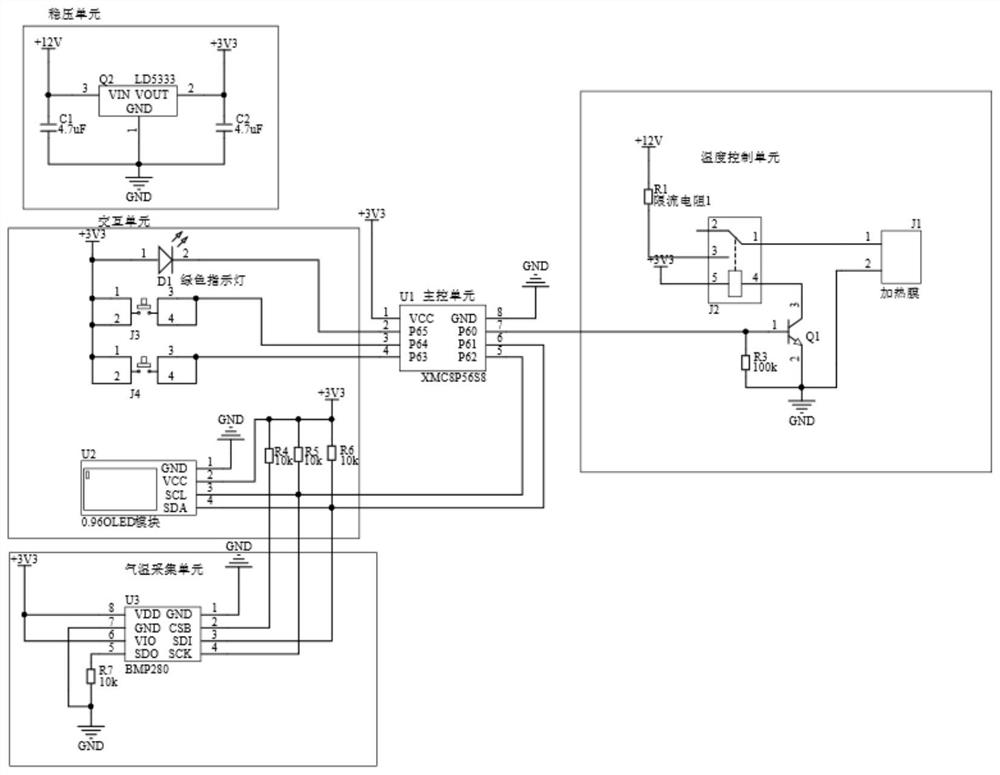

Silent constant-temperature heating method and system and container using system

PendingCN114052488AHeating evenlyNo local high temperatureWater-boiling vesselsRoasters/grillsTemperature controlEngineering

The invention discloses a silent constant-temperature heating method, which comprises the following steps: a main control unit acquires the temperature of liquid to be heated and the air pressure of the current environment at set intervals through an air temperature acquisition unit, and acquires the boiling point of the liquid under the current air pressure, then the main control unit takes corresponding actions according to the boiling point under the air pressure, when the temperature is not close to the boiling point, a temperature control unit is set to be in a working state, a heating film is controlled to heat the liquid, when the temperature is close to the boiling point and does not reach the boiling point, the temperature control unit is set to be stopped, the water temperature is controlled not to reach the boiling point, and then a constant-temperature mode is started. The heating film is adopted to replace a traditional heating wire, and due to the fact that the heating film is even in heating, local high temperature and too high temperature difference between the upper portion and the lower portion are avoided, and noise is avoided. The temperature of the liquid is controlled below the boiling point to prevent the temperature from reaching the boiling point, so that the liquid cannot boil, and the mute function is achieved.

Owner:SHENZHEN HASWARE TECH DEV CO LTD

Molybdenite concentrate self-heating swirl roasting process and equipment

ActiveCN108149006BFully roasted oxidation reactionComplete desulfurizationMolybdenum oxides/hydroxidesWaste heat treatmentComing outRotational flow

The invention relates to a self-heating cyclone roasting process and equipment for molybdenum concentrate. A cyclone roasting furnace with a furnace body heat exchange device is used to roast the molybdenum concentrate to produce industrial molybdenum oxide. The molybdenum concentrate is used in the roasting process. The heat released by the roasting reaction preheats the air entering through the interlayer heat exchange device in the lower furnace body. The preheated air is supplied from the bottom of the furnace into the cyclone roasting furnace. The cyclone air distribution device causes the molybdenite concentrate to circulate in the rotating air flow state. The roasting reaction occurs. The material coming out of the cyclone roasting furnace enters the interlayer heat exchange device on the upper part of the rotary roaster with the roasting airflow under the action of negative pressure. The desulfurization reaction is completed while rotating forward in the interlayer heat exchange device. The reacted gas The solid mixture enters the gas-solid separation and discharging device for gas-solid separation to separate solid roasting sand and roasting flue gas. After the roasting flue gas enters the heat exchanger and exchanges heat with the air, it is sent to SO under the action of the induced draft fan. 2 In the recovery and treatment system, the heat-exchanged air is sent to the flash dryer to dry the molybdenum concentrate entering the furnace.

Owner:NORTHEASTERN UNIV LIAONING

Oil-free piston air compressor for new energy vehicles with cooling system

ActiveCN110145459BExtended service lifeImprove lubrication statusPositive displacement pump componentsPositive-displacement liquid enginesNew energyCylinder head

The invention relates to the technical field of air compressor cooling, and discloses an oil-free piston type air compressor with a cooling system for a new energy vehicle. The oil-free piston type air compressor comprises a crankcase, a cylinder body, a cylinder head assembly, a piston cylinder is arranged in the cylinder body, the cylinder body is arranged above the crankcase and is connected with the crankcase, the cylinder head assembly is arranged above the cylinder body and is connected with the cylinder body; the oil-free piston type air compressor is characterized in that a low-pressure heat exchanger connected with the crankcase is arranged on the front side of the cylinder body, a manifold block connected with the cylinder body is arranged at the right end of the cylinder body, the manifold block and the low-pressure heat exchanger are connected through a first water inlet pipe, a first water outlet is formed in the left end of the low-pressure heat exchanger, the first wateroutlet is connected with the cylinder head assembly through a first water discharge pipe; a high-pressure heat exchanger connected with the crankcase is arranged on the rear side of the cylinder body, the manifold block is connected with the high-pressure heat exchanger through a second water inlet pipe, a second water outlet is formed in the left end of the high-pressure heat exchanger, the second water outlet is connected with the cylinder head assembly through a second water discharge pipe. According to the oil-free piston type air compressor, a water-cooling and air-cooling double-actioncooling mode is adopted, so that full cooling is realized, and the effect is better.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

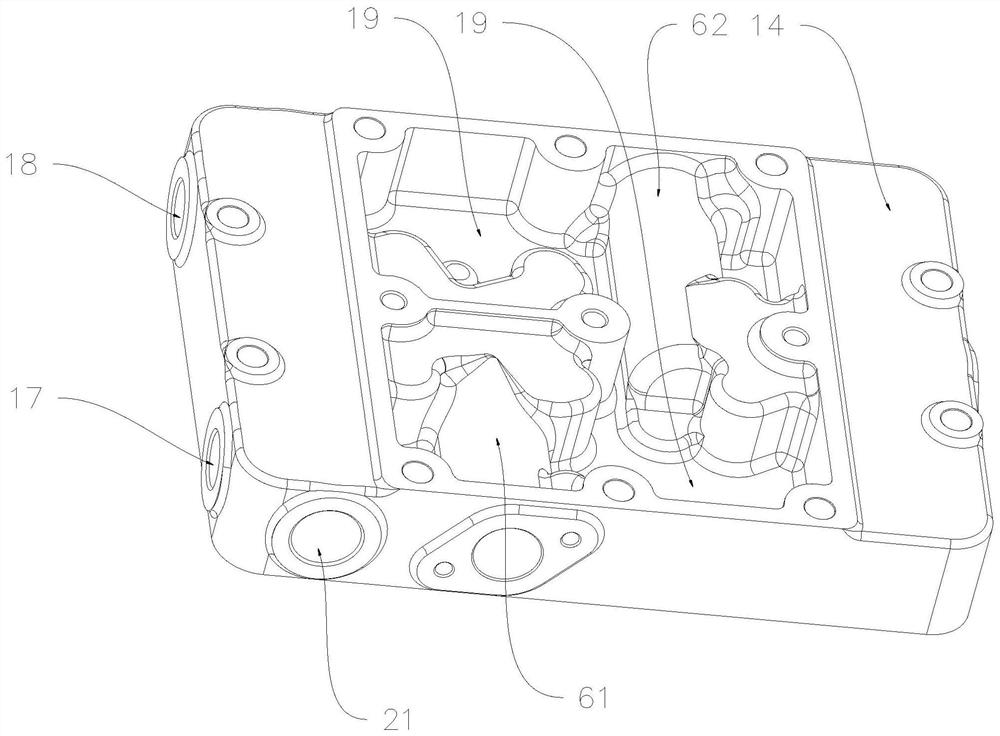

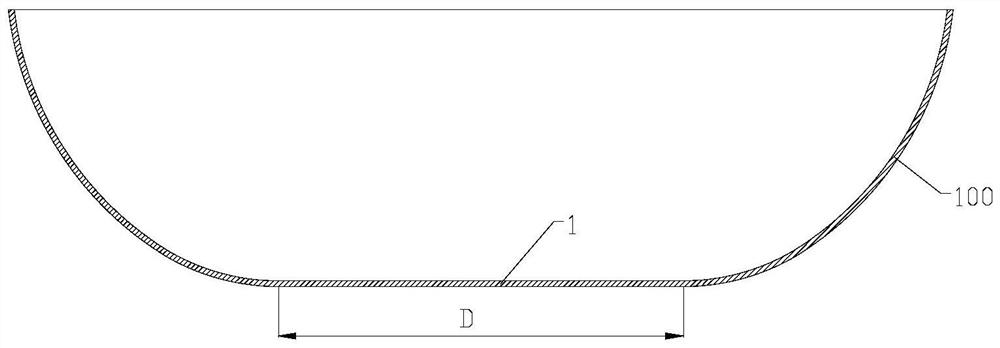

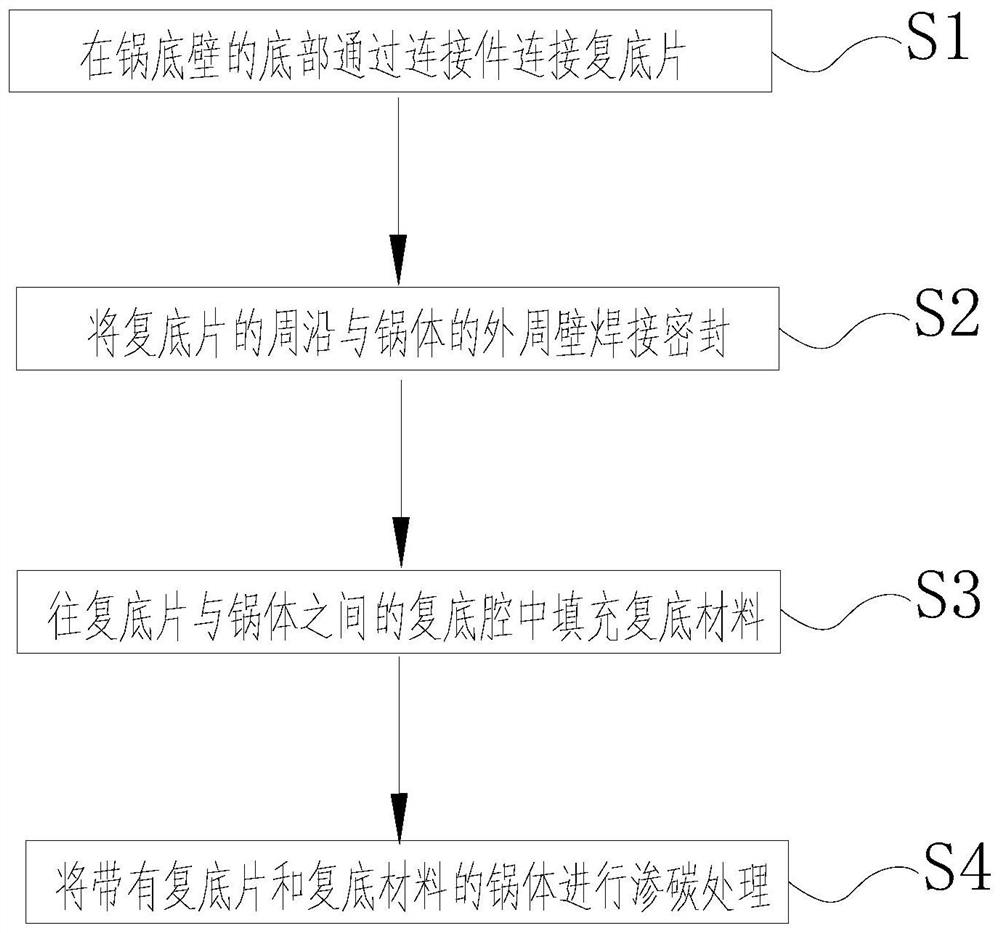

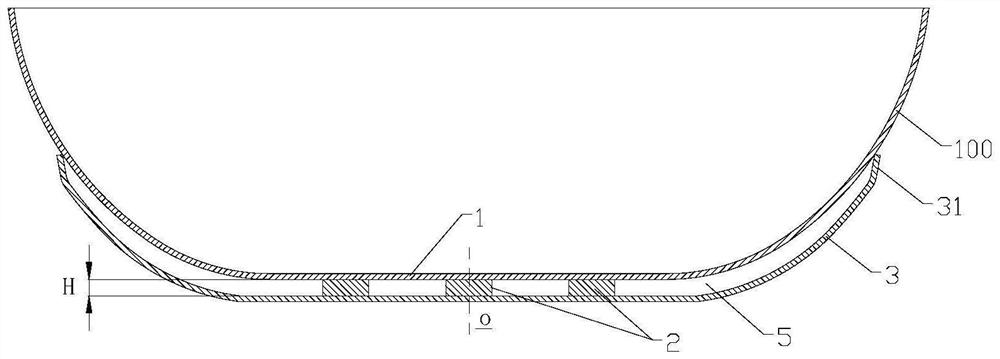

Composite bottom pot body and manufacturing method thereof

ActiveCN111772461BImprove heat storage effectIncrease heat storageCooking-vessel materialsSoldering apparatusThermal treatmentMechanical engineering

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Oil-free piston air compressor for new energy vehicles

ActiveCN110107473BExtended service lifeImprove lubrication statusPositive displacement pump componentsMulti-stage pumpsNew energyCylinder head

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

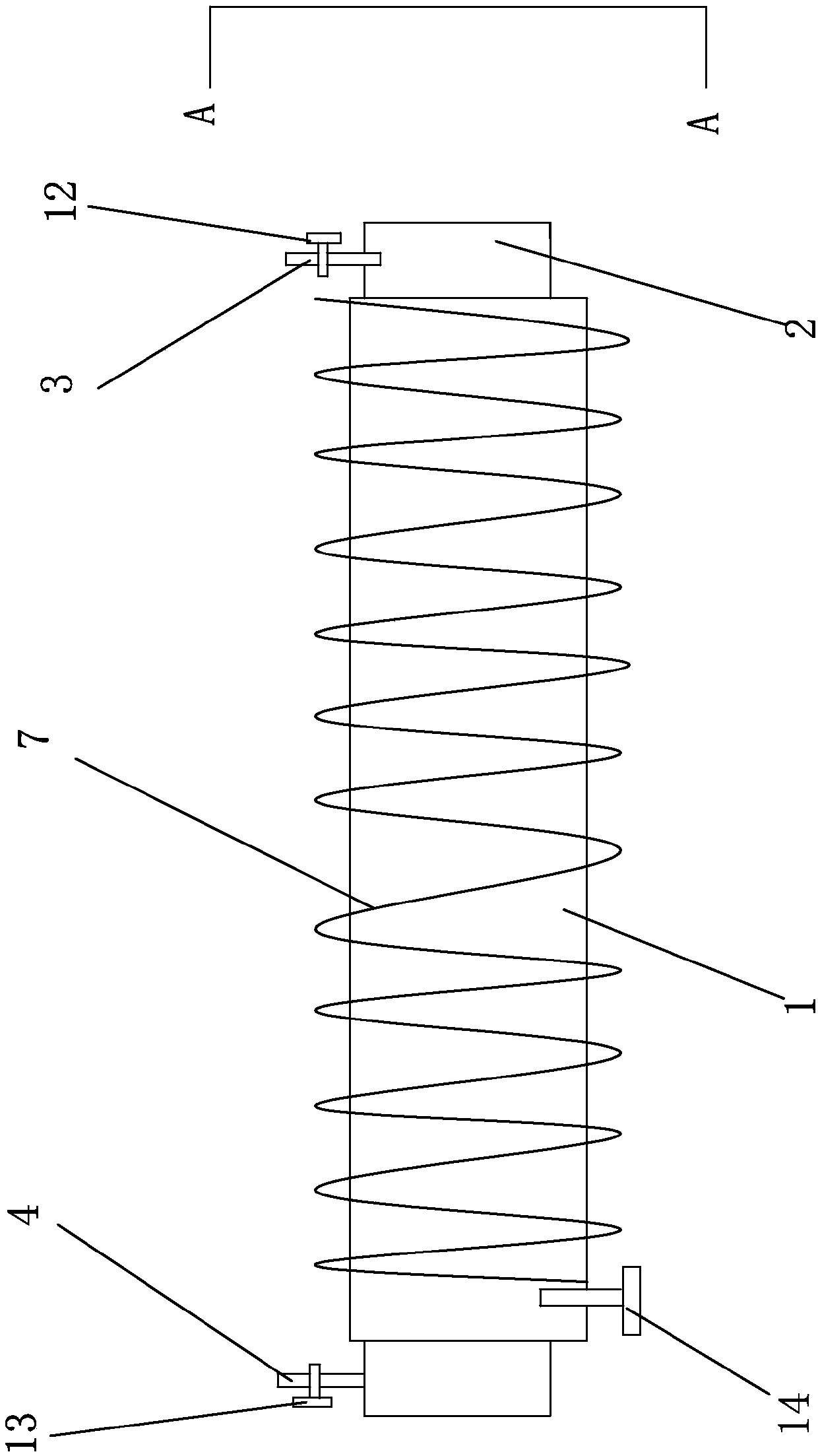

Magnetic energy heating body

PendingCN107860123AEvenly heatedReduce security risksCoil arrangementsWater heatersMagnetic heatingImpeller

The invention discloses a magnetic energy heating body. The magnetic energy heating body comprises a heating pipe body, and two glands mounted at two ends of the heating pipe body; the heating pipe body is connected with a water inlet pipe and a water outlet pipe; an insulation layer is arranged at the external of the heating pipe body; a protection layer is arranged at the external of the insulation layer; a coil is wound at the external of the protection layer; a rotating shaft is arranged in the heating pipe body; a blade is arranged at the external of the rotating shaft; one end of the rotating shaft is fixedly connected with an impeller; blades of the impeller are correspondingly arranged at the position of the water inlet pipe; bearings are arranged in the two glands; and the rotating shaft is correspondingly mounted between the two bearings. The magnetic energy heating body can achieve the purposes of uniform heating and reduction of potential safety hazards.

Owner:ZHONGSHAN GONGZHI NEW ENERGY TECH CO LTD

Wick structure for vapor chamber

ActiveCN102811590BImprove capillary suctionImprove cooling efficiencySemiconductor/solid-state device detailsIndirect heat exchangersEngineeringNarrow channel

Owner:SOUTH CHINA UNIV OF TECH

A New Regenerative Radiant Tube Combustion Device

ActiveCN106482100BEvenly distributedIncrease powerIndirect carbon-dioxide mitigationGaseous fuel burnerBrickFour-way valve

Owner:SHENWU TECH GRP CO LTD

Discharge lamp lighting circuit

InactiveCN101527996BLow costLow calorific valueElectrical apparatusElectric lighting sourcesGas-discharge lampMiniaturization

The invention relates to a discharge lamp lighting circuit which realizes the miniaturization and cost reduction of a light circuit. The discharge lamp lighting circuit for supplying an AC power to a discharge lamp 3 includes first and second converters for receiving a DC voltage and stepping up the voltage. A controlling circuit drives the first and second converters CON1, CON2 alternately at a first frequency and stops an operation of a side that is not driven such that the AC power is supplied to the discharge lamp to execute a lighting operation.

Owner:KOITO MFG CO LTD

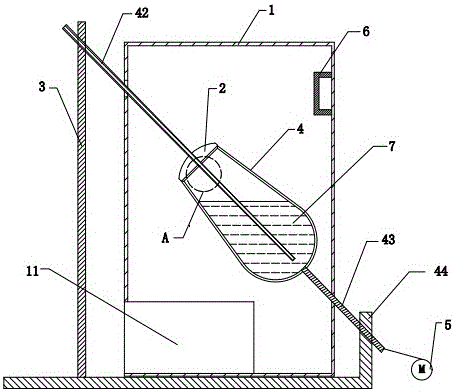

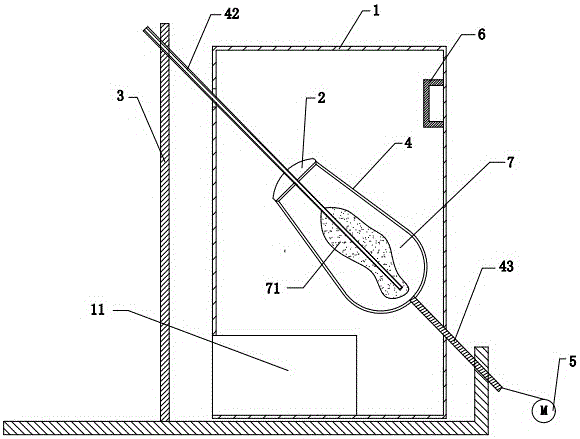

Device for decocting maltose

The invention relates to the field of sugar decocting devices, and in particular relates to a device for decocting maltose, which comprises a heating cabinet, a supporting mechanism, a decocting jar and a motor, wherein a heating wire is arranged on the inner wall of the heating cabinet, the supporting mechanism comprises an L-shaped fixed supporting base and a movable supporting base in slip connection on the L-shaped fixed supporting base, the decocting jar is fixed on the L-shaped fixed supporting base and the movable supporting base in an inclined manner, a sealing cover is arranged at the top end of the decocting jar, a hollow rotating shaft penetrates the sealing cover and is in plug bush connection with the seal cover, a gas outlet is arranged on the hollow rotating shaft, the hollowing rotating shaft is connected with the movable supporting base and extends into the interior of the decocting jar, a solid rotating shaft is fixedly connected to the bottom end of the decocting jar and is hinged on the L-shaped fixed supporting base, and the output end of the motor is connected with the solid rotating shaft. The jar body is uniformly heated to prevent burning of the jar and deactivation of amylase; and the formed maltose is bonded on the hollow rotating shaft and can be taken out by drawing the movable rotating shaft, so as to facilitate scooping out of maltose.

Owner:CHONGQING YU NIU FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com