Patents

Literature

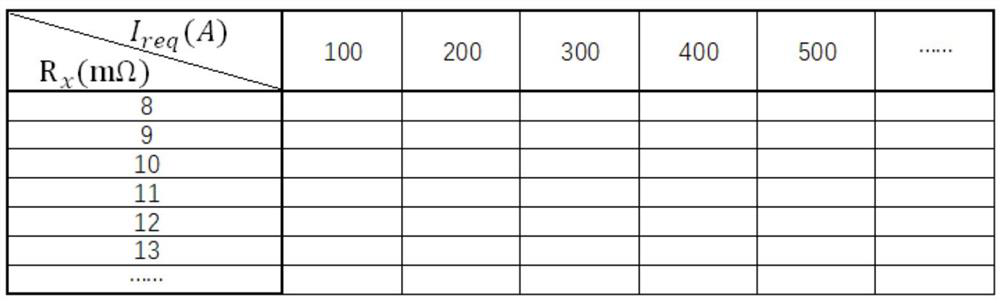

31results about How to "Stable heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

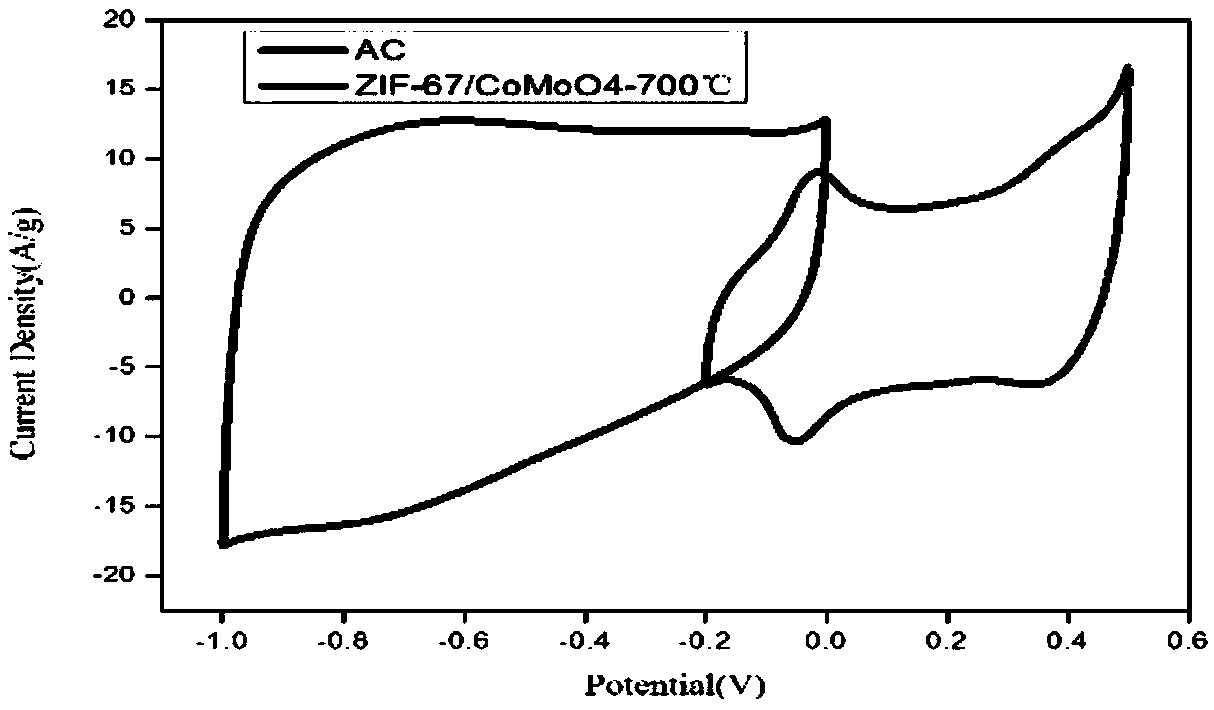

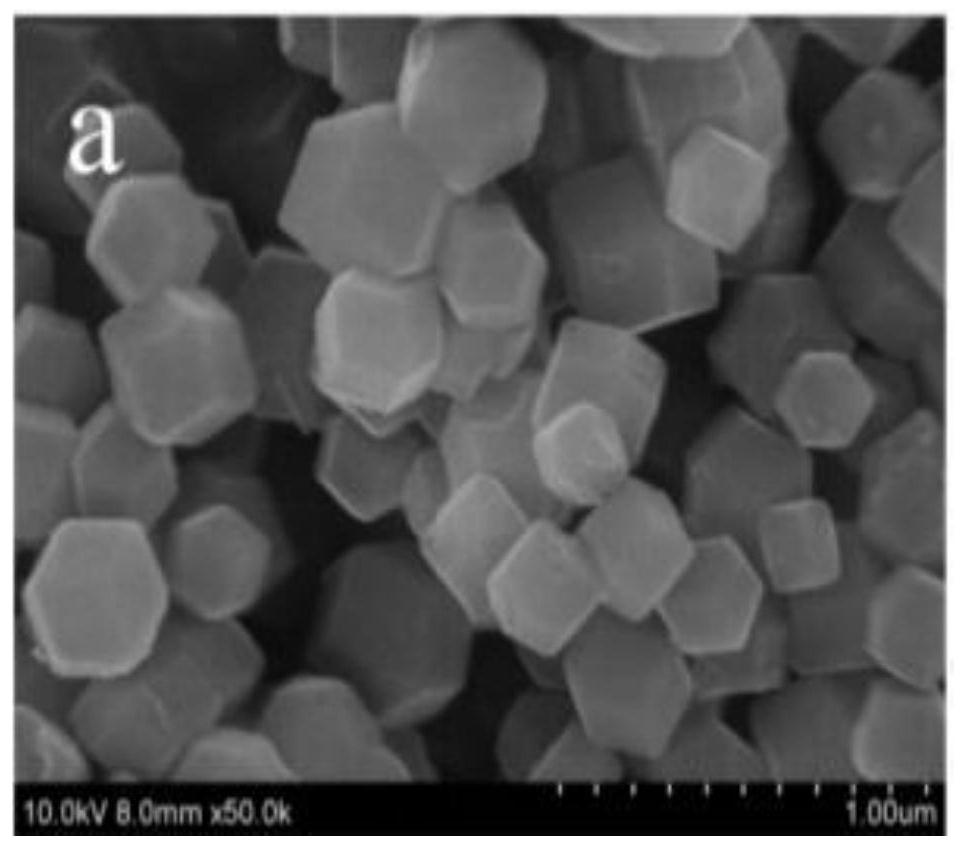

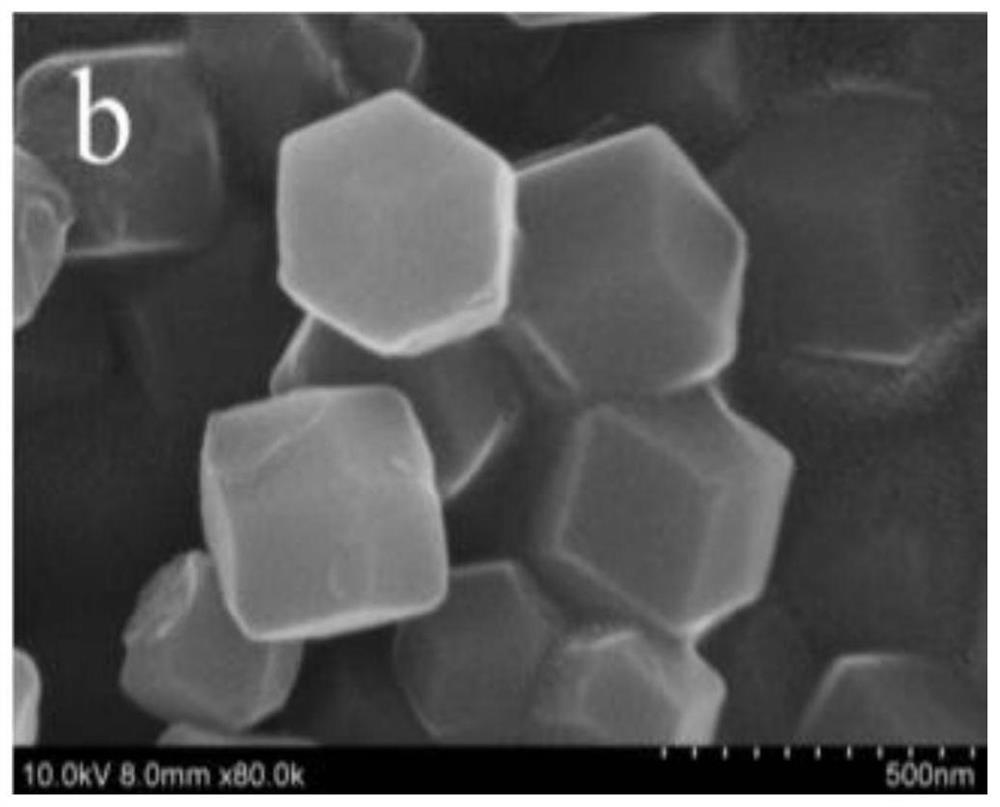

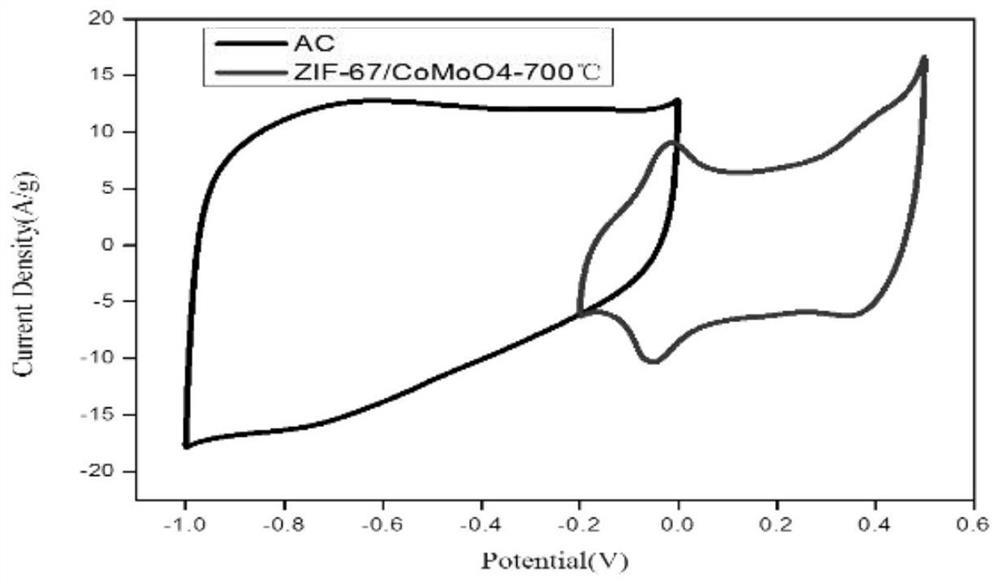

A method for preparing an electrode of ZIF-derived CoMoO4

ActiveCN109243863AChemically stableStable heating rateHybrid capacitor electrodesHybrid/EDL manufactureIonSolvent

The invention provides a method for preparing an electrode of ZIF-derived CoMoO4. the method is characterized in that the method uses a high temperature calcined ZIF-67 as a precursor to prepare CoMoO4 by hydrothermal method., that steps are as follow: (1) molybdate and a compound containing a Co salt are taken and stirred in deionized water until the molybdate and the compound contain the Co saltare dissolved; (2) a small amount of ZIF-67 power are added, stirred to a homogeneou solution; 3, that mixture is transferred to a reaction kettle, and the mixture is cooled to room temperature afterreaction for 2h; (4) alternately cleaning and drying are performed for 24h; (5) Ultrasonic cleaning is performed for 30 min, deionized water cleaning and ultrasonic are performed, drying is performedfor 12 h; 6) that graphite paper is dried at constant temperature, the required material is ground in a mortar, a small amount of solvent is added, uniformly dropping on the dried sheet layer, and then drying is performed, and 7) a regular-shaped electrode of ZIF-derived CoMoO4 is performed. The invention overcomes the problems of poor stability and small specific capacitance of metal oxide electrode in the prior art, and provides a preparation method of CoMoO4 derived from metal oxide electrode material ZIF with high specific capacity and good stability.

Owner:盐城市盐南高新区都市产业发展有限公司

Rapid annealing method for ohmic contact of metal and silicon carbide

ActiveCN102569039AReduce manufacturing costQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactMoisture

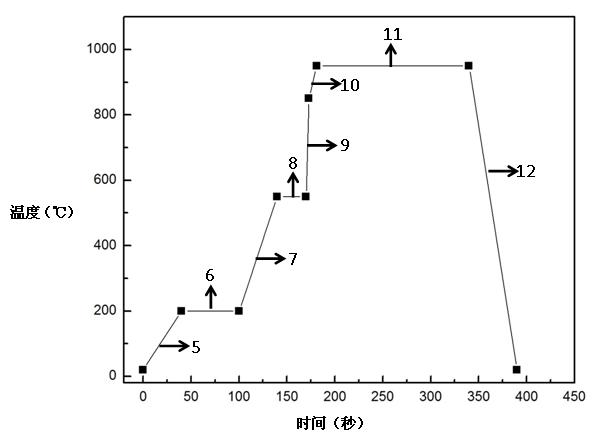

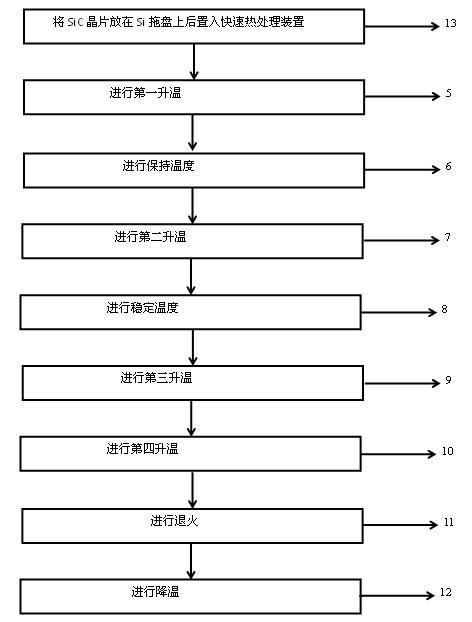

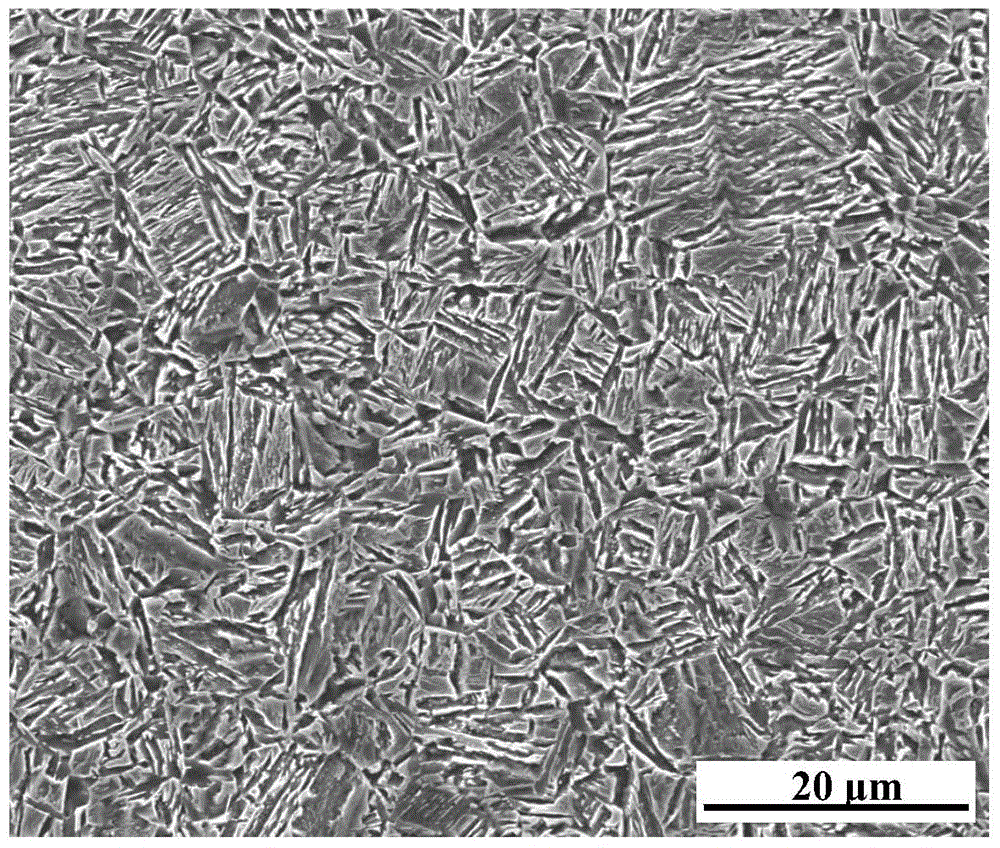

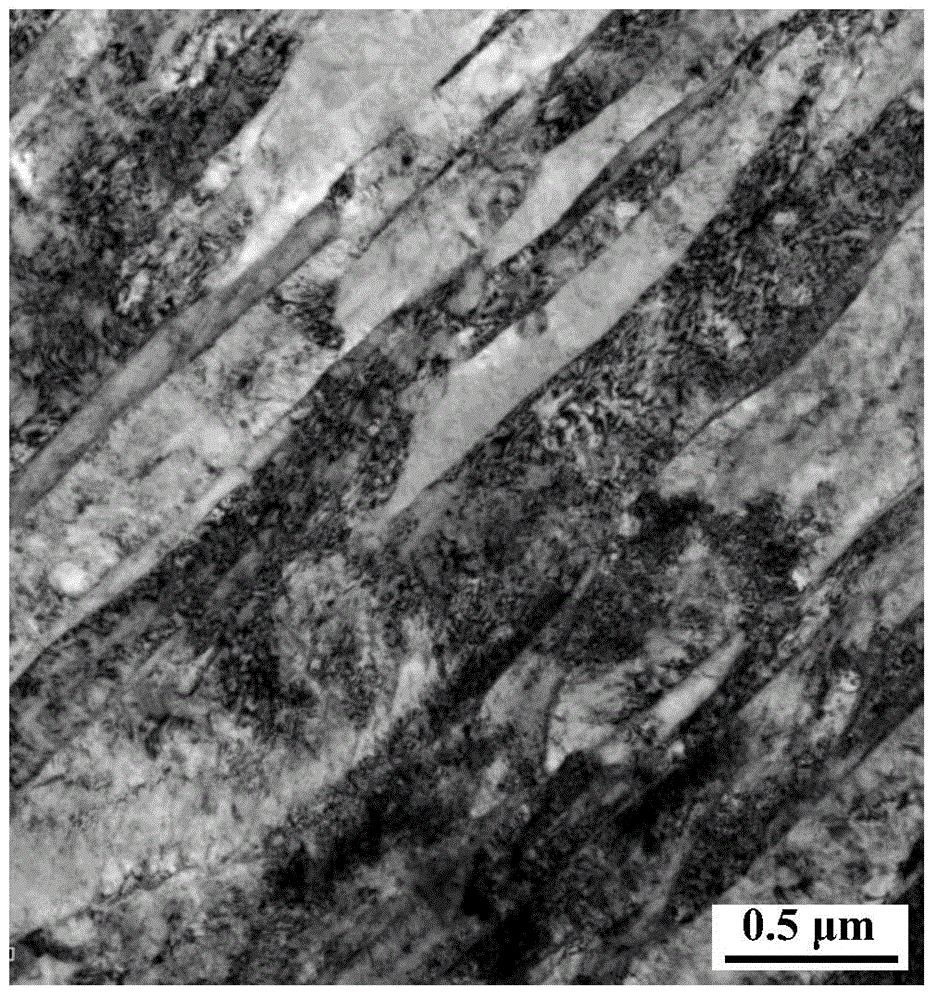

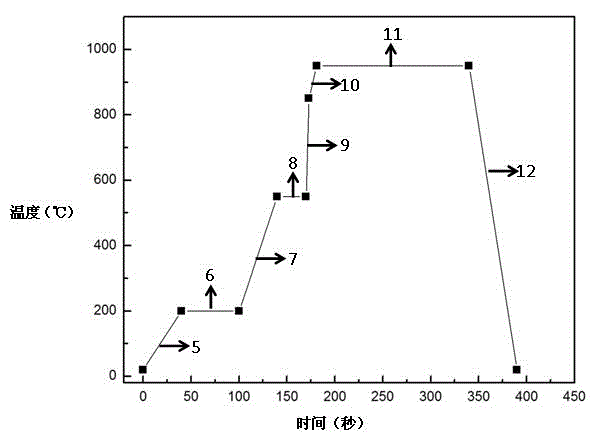

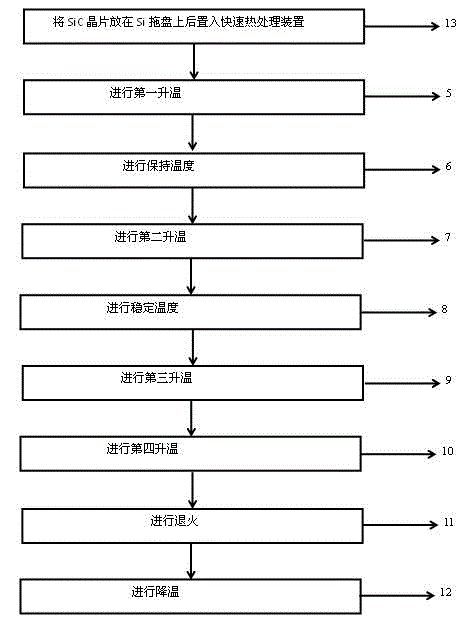

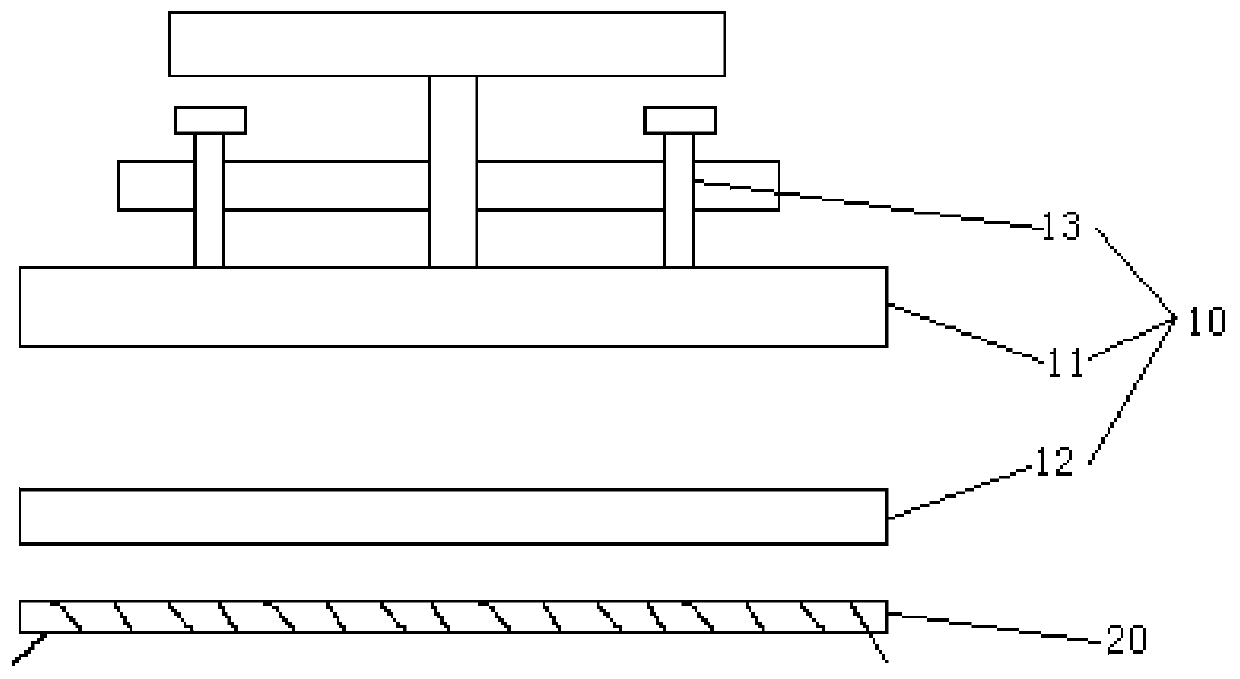

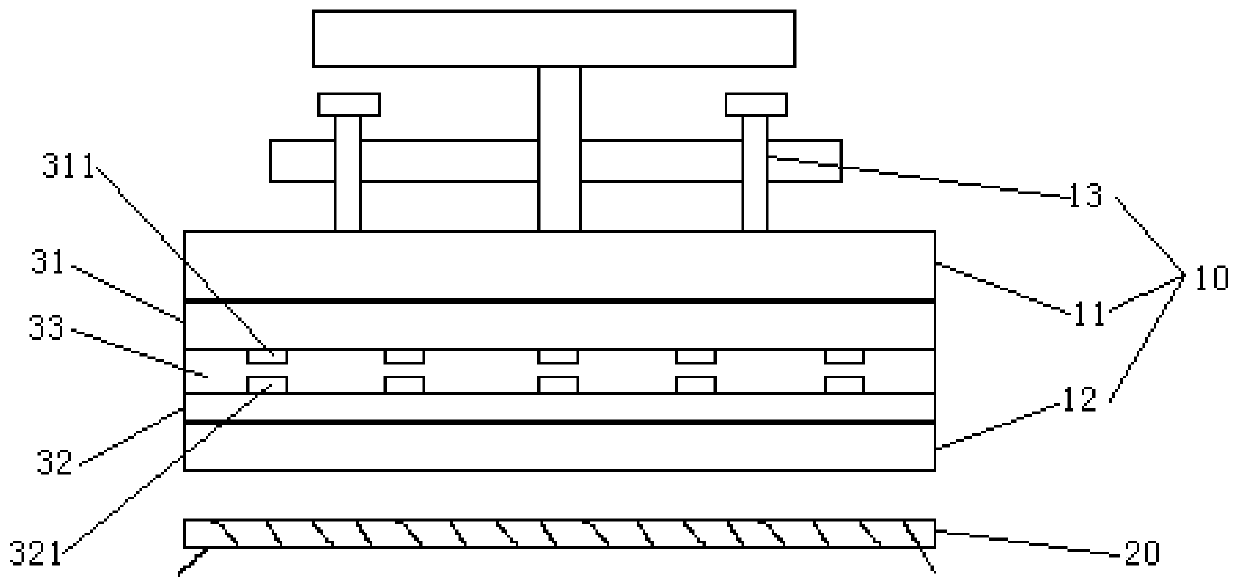

The invention provides a rapid annealing method for ohmic contact of metal and silicon carbide, which comprises the steps of (1) placing SiC wafers on a Si sheet tray, then arranging the Si sheet tray on a rapid thermal treatment device, and simultaneously filling the device with protection gas Ar; (2) performing a first temperature-rise period, and keeping the temperature; (3) performing a second temperature-rise period, and steadying the temperature; (4) performing a third temperature-rise period; (5) performing a fourth temperature-rise period, namely, annealing period; and (6) performing a temperature reducing period. The method has benefits as follows: the method is carried out in the commercial rapid thermal treatment device taking any light radiation as a heat source; and the silicon sheet used as the tray can adopt various standards of commercial polishing monocrystalline silicon sheets and has low cost. The annealing method can remove the moisture on the surface of the silicon carbide wafer and stabilize the temperature. On the premise of ensuring the control precision of the peak thermal treatment temperature, the heating rate is improved through changing the setting value. Finally, the annealed ohmic contact resistance is reduced; and the quality of the ohmic contact, the device reliability and the yield are improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

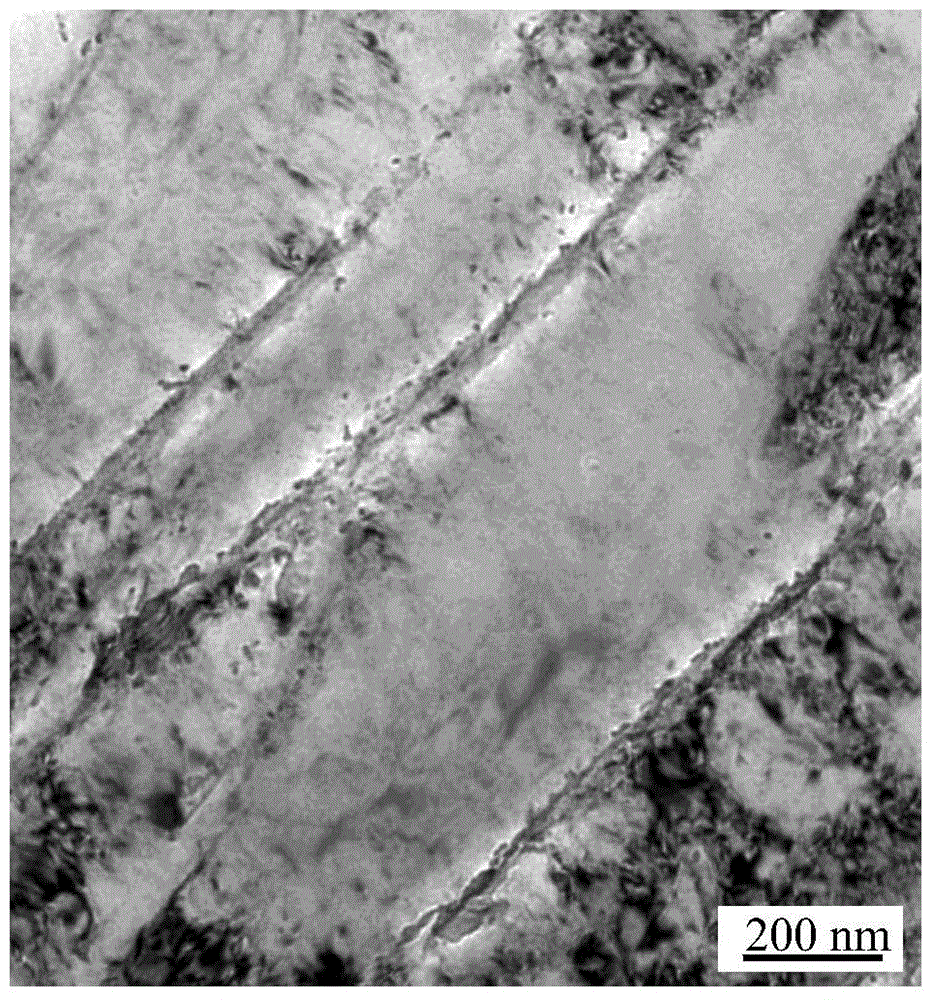

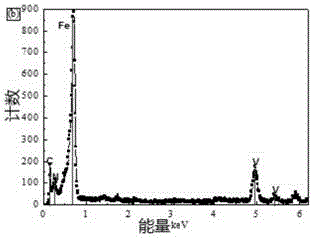

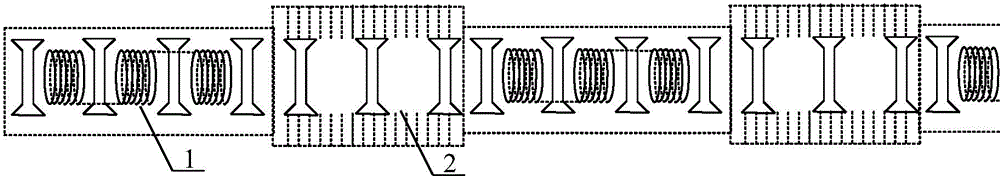

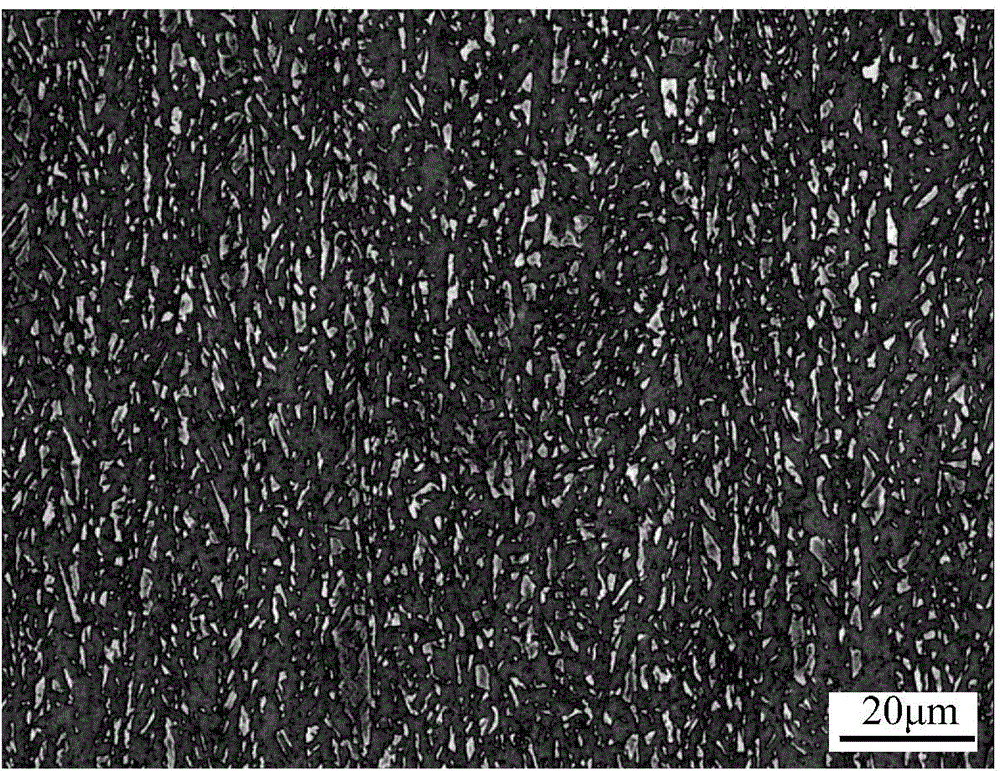

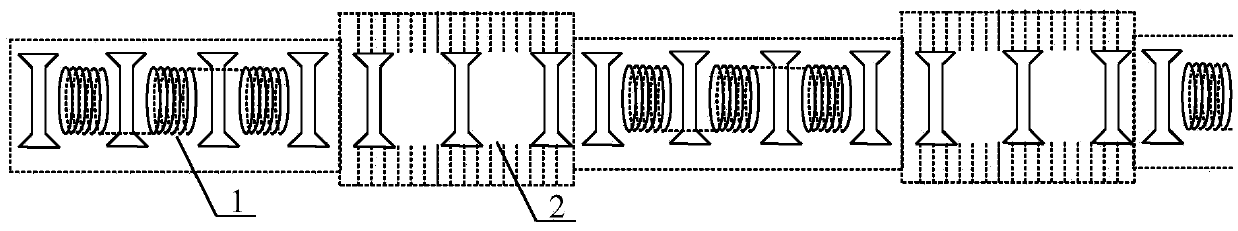

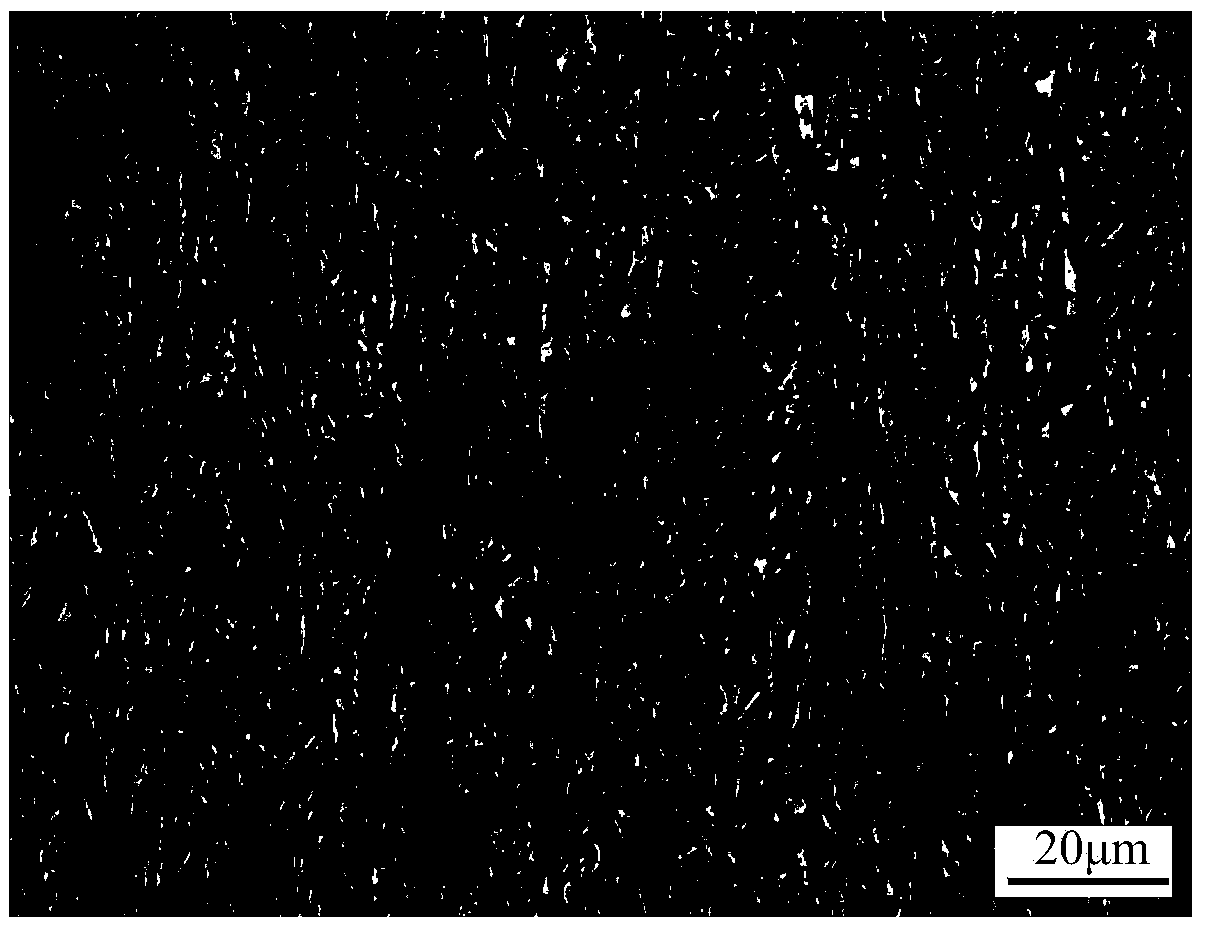

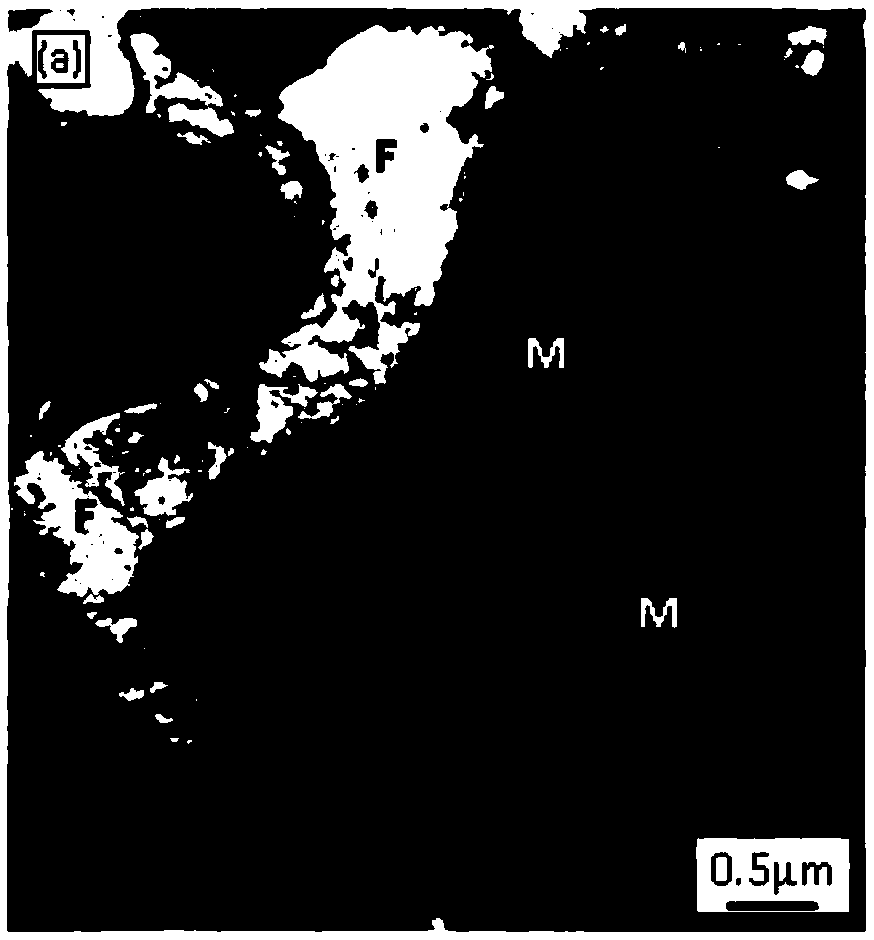

Vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe and preparation method thereof

ActiveCN104372239AStable heating rateHigh degree of automationProcess efficiency improvementSteel tubeHigh intensity

The invention belongs to the steel technical field, and specifically, relates to a vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe and a preparation method thereof. The vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe comprises the chemical ingredients by the weight percentage: 0.18%-0.24% of C, 1.0%-1.6% of Si, 1.2%-1.6% of Mn, 0.17%-0.22% of V, 0.01%-0.03% of N, not more than 0.06% of P, not more than 0.005% of S, and the balance iron and unavoidable impurities. With utilization of an intermediate-frequency induction heat treatment device of a thin-wall steel pipe and with supplementary of a vanadium-nitrogen microalloyed component design, the advantage of cooperation of good strength and elongation of phase-transformation induced plastic steel is successfully applied to the steel pipe production field, a fact of replacing solid components with hollow components is effectively realized so as to achieve automobile light weighting, besides, further development of an internal high pressure forming technology is promoted, not only are the internal high pressure formed components with high strength, large deformation and complex shape produced, but also the production cost is greatly reduced, and the preparation method has wide application prospects are provided.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength plastic vanadium microalloyed dual-phase steel seamless pipe and preparation method thereof

ActiveCN104018067AImprove mechanical propertiesHigh strengthFurnace typesIncreasing energy efficiencySolid componentHigh rate

The invention discloses a high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and an on-line preparation method thereof. The seamless pipe is composed of the following chemical components in percentage by mass: 0.10-0.18% of C, 0.1-0.6% of Si, 1.1-1.6% of Mn, 0.16-0.20% of V, 0.01-0.03% of N, at most 0.006% of P, at most 0.005% of S, and the balance of Fe and other inevitable impurities. The intermediate-frequency induction heat treatment device of the thin-wall steel pipe is utilized and assisted by the vanadium microalloyed component design to produce the dual-phase steel seamless pipe with favorable comprehensive mechanical properties; the advantages of low yield-tensile ratio, high rate of work hardening, favorable strength and favorable elongation percentage of the dual-phase steel are matched and successfully applied to the field of production of steel pipes to efficiently substitute solid components with hollow components, thereby implementing light weight of the automobile; and meanwhile, the seamless pipe promotes further development of the internal high-pressure forming technique, and has wide application prospects.

Owner:LAIWU IRON & STEEL GRP

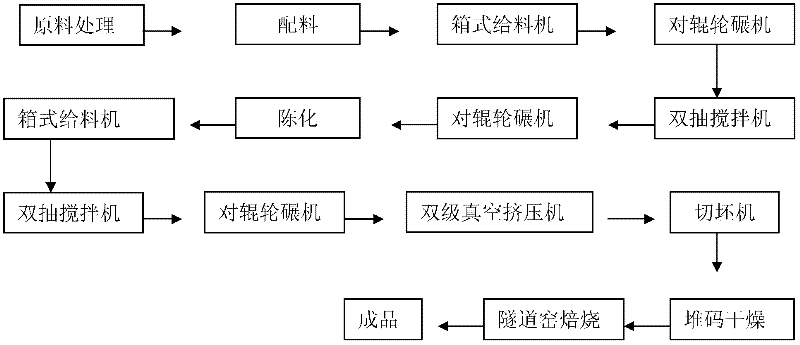

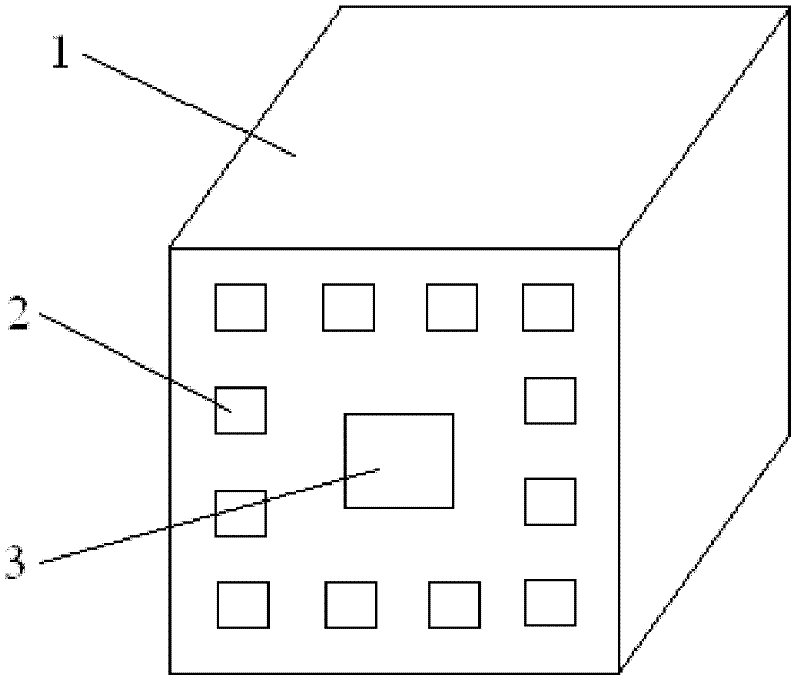

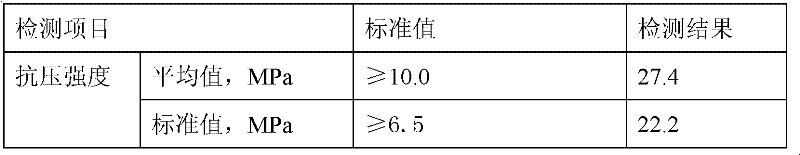

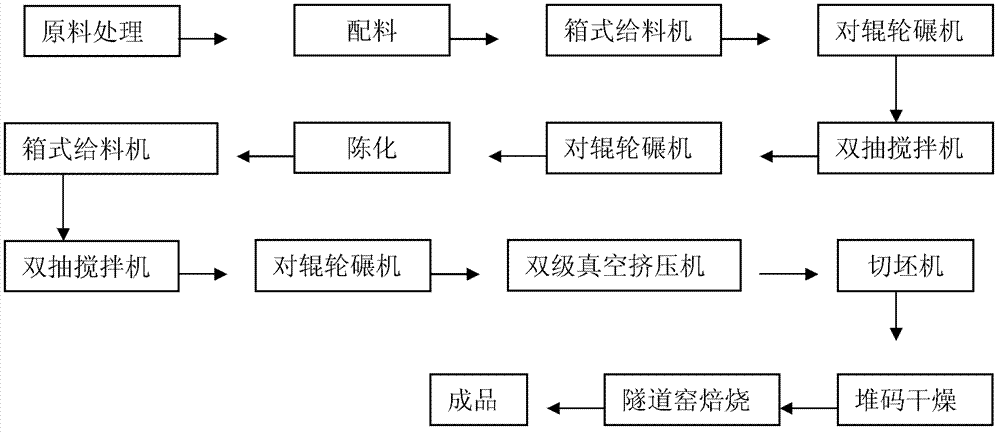

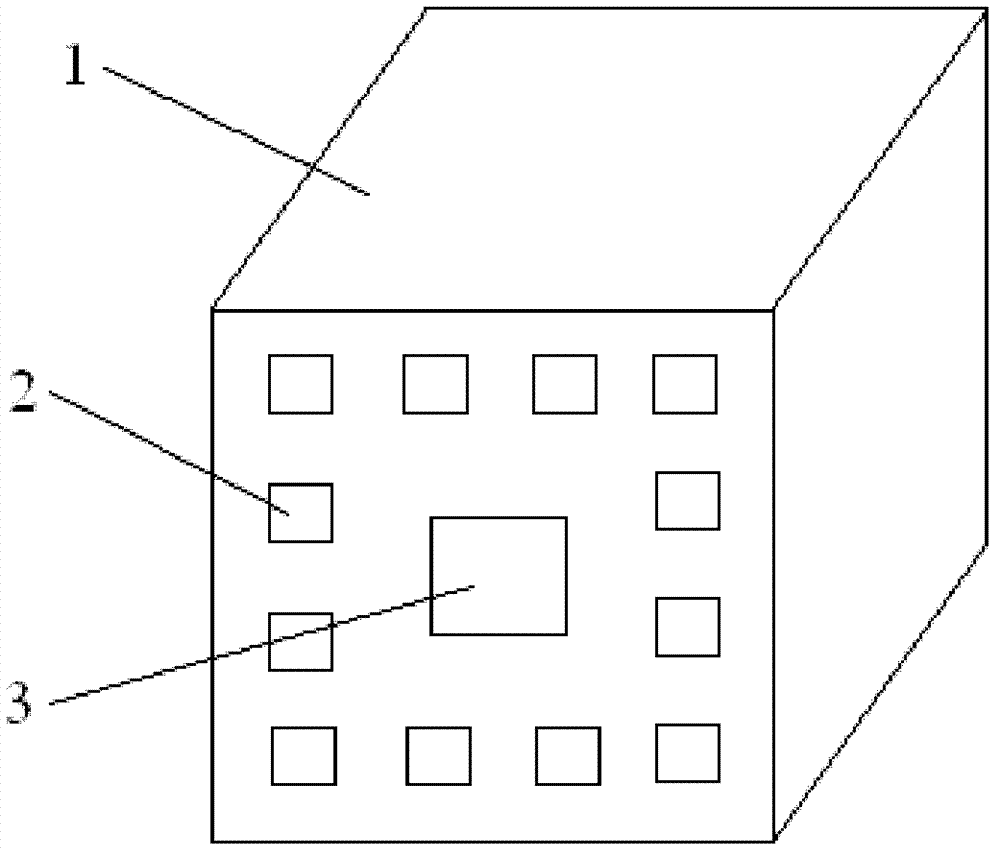

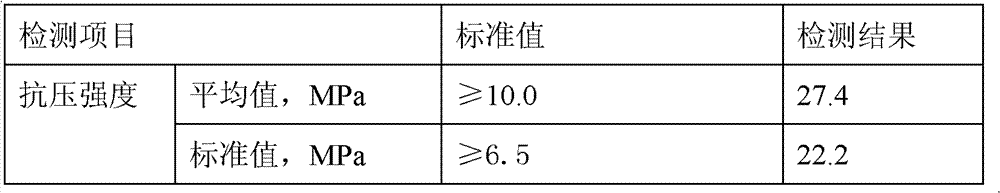

Iron ore slag sintered brick and a preparation technology of same

ActiveCN102491724AImprove performanceSolve the phenomenon of burstingSolid waste managementBrickSlag

The invention relates to a sintered brick, in particular to a sintered brick made of iron ore slag and a preparation technology of the sintered brick. The sintering raw material of the iron ore slag sintered brick comprises the components by bone dry weight as follows: 28 to 36 portions of iron ore slag, 27.6 to 41.4 portions of coal gangue or 25.5 to 38.25 portions of coal slag, 20 to 30 portions of silt and 5 to 15 portions of clinker. The iron ore slag sintered brick provided by the invention has the advantages that the source of raw materials is ample, waste iron ore slag is recycled, soil resources are saved, cultivated lands are protected, waste iron ore slag that can be obtained on a large scale and is of great quantity is fully utilized, the waste is changed into valuable, and theenvironment is purified. The obtained iron ore slag sintered brick has the effects of heat preservation, thermal insulation shock resistance and pressure resistance; and peeling and distortion are avoided, breakage or explosion does not occur easily, the yield can reach over 99%, and the sintered brick is suitable for industrial production and can be widely used as wall bricks of buildings.

Owner:上海鑫晶山建材开发有限公司 +1

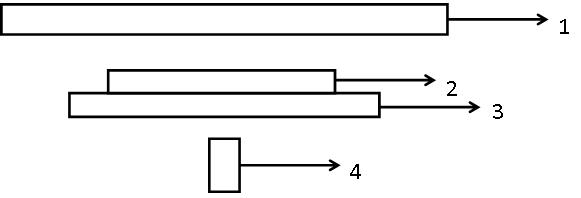

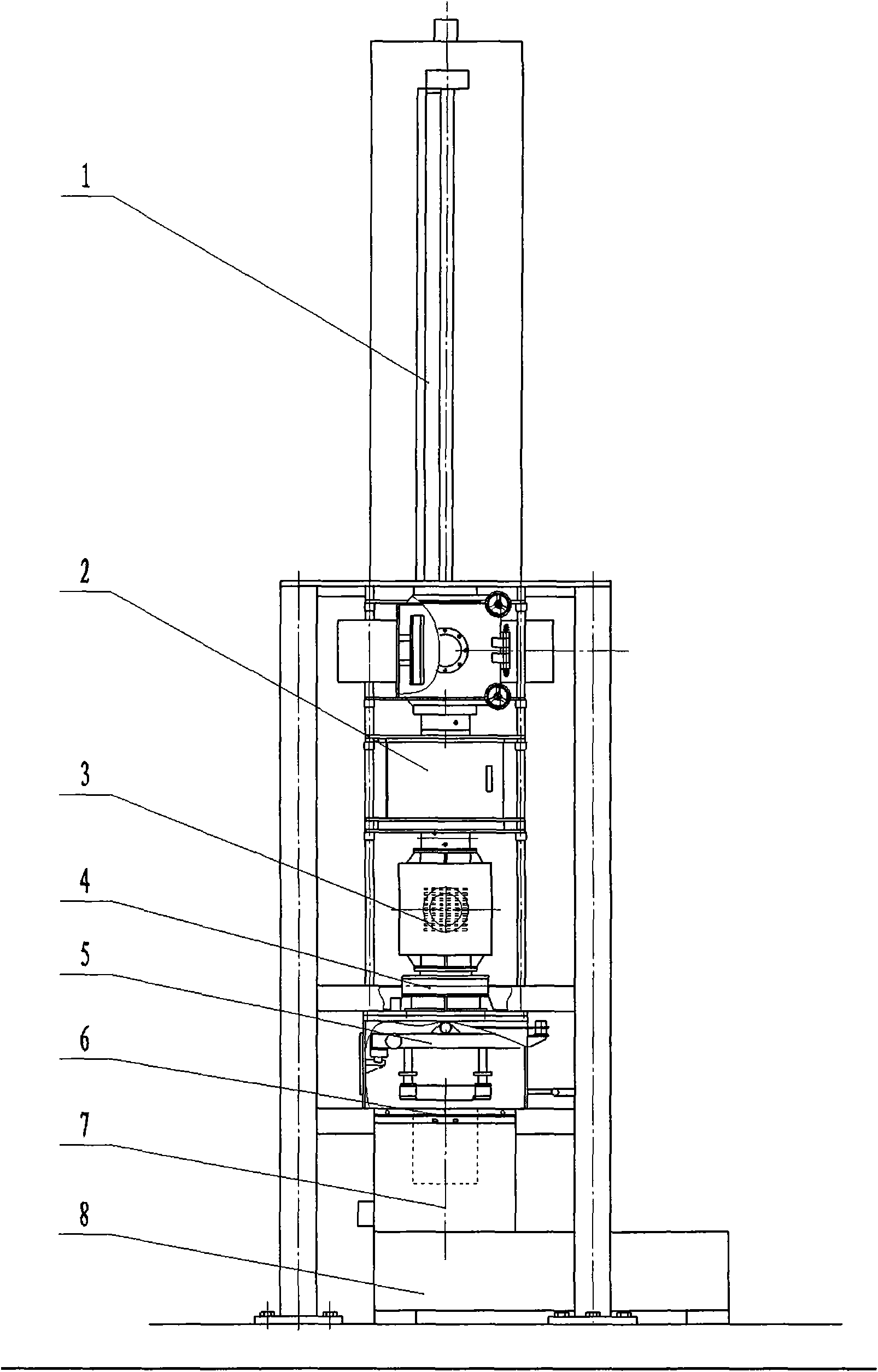

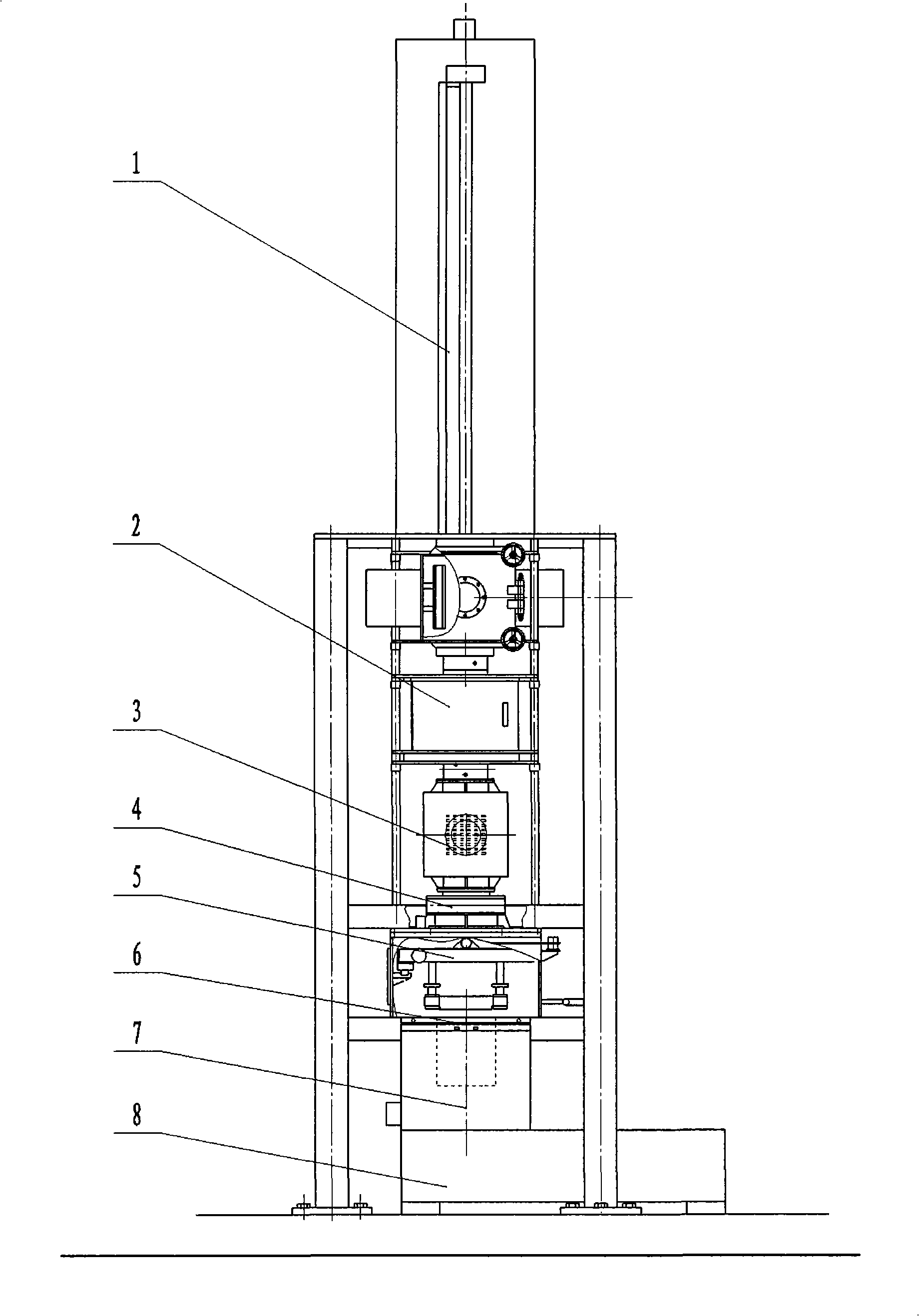

Multifunctional device used for plating layer research

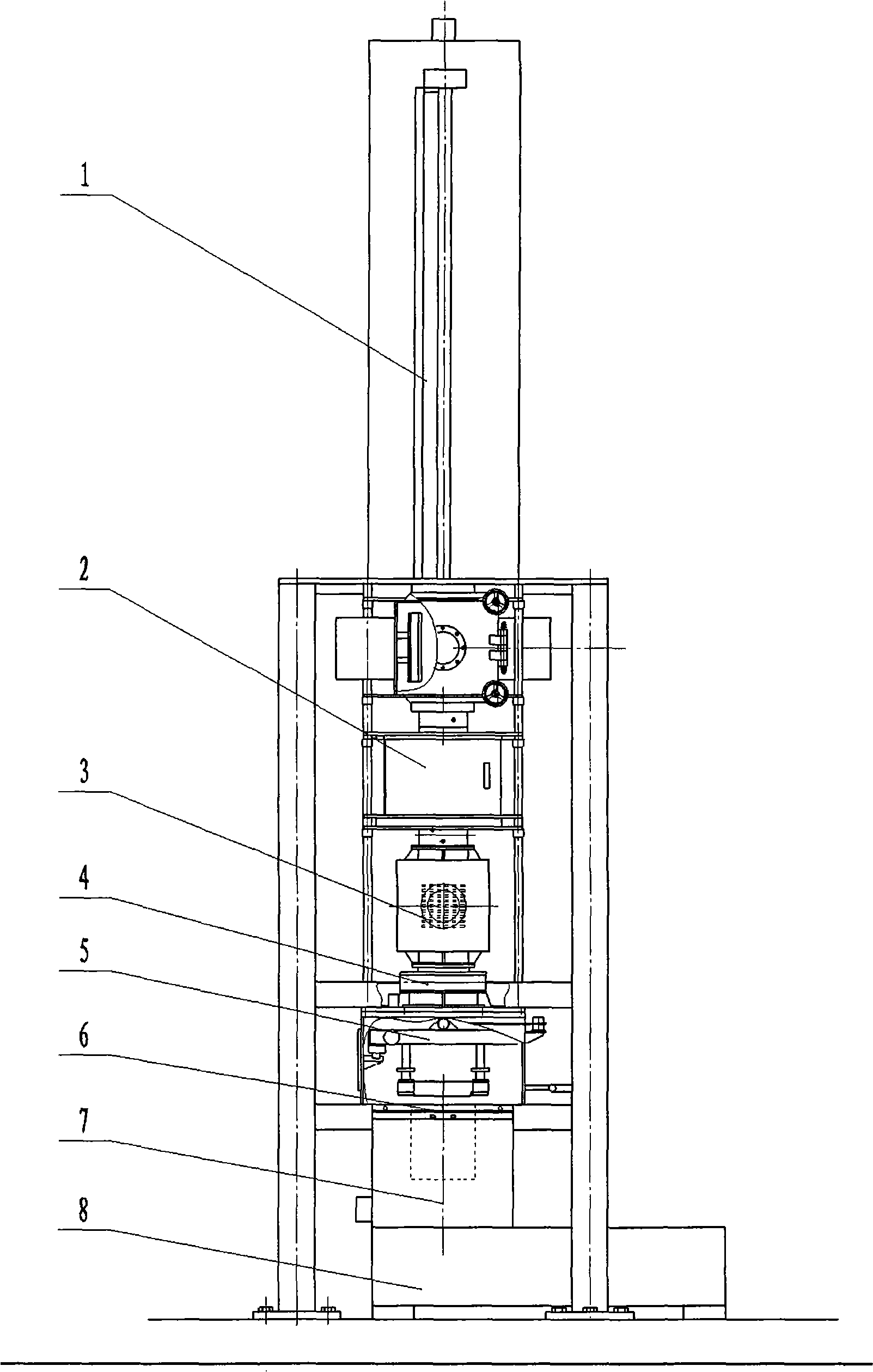

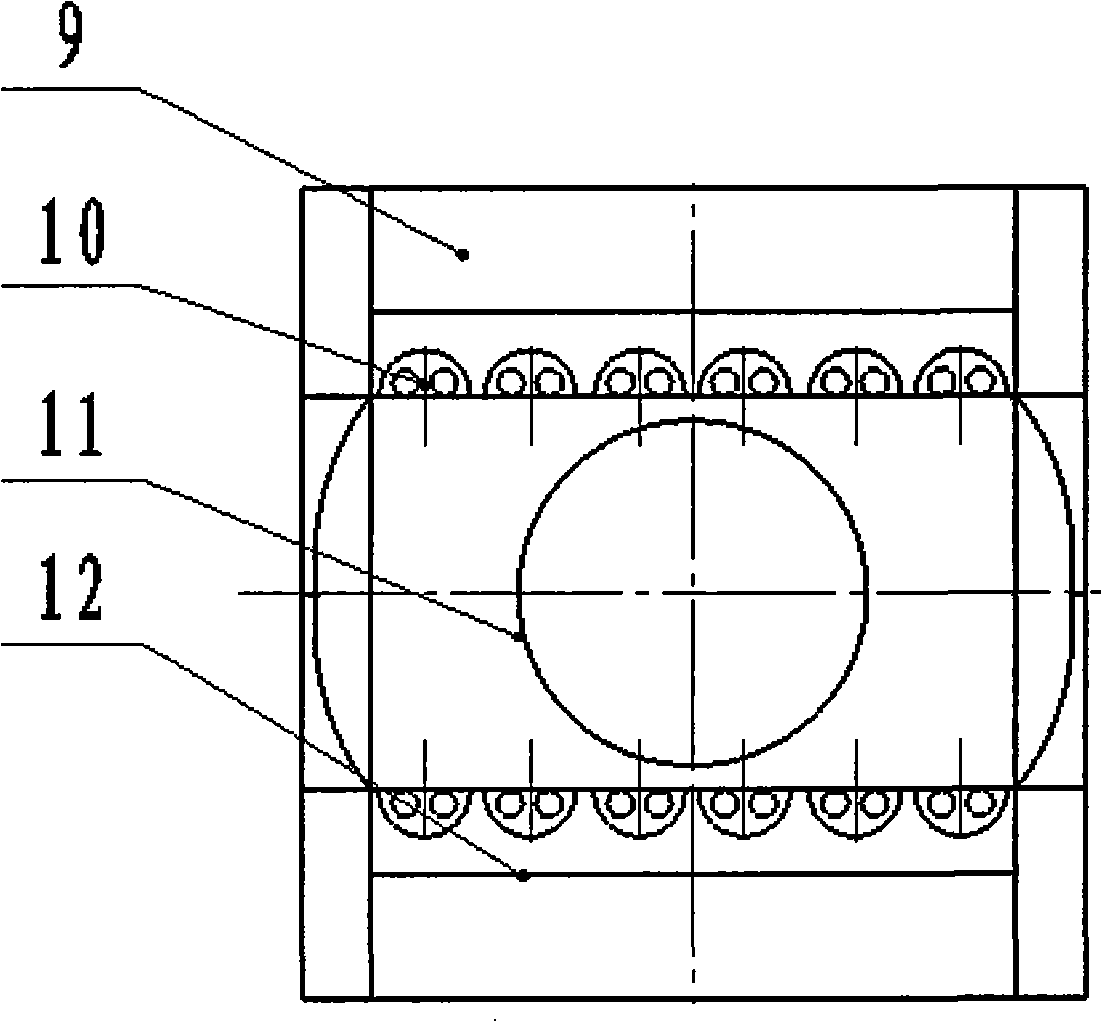

ActiveCN101538695ACompact structureThe overall layout is simpleHot-dipping/immersion processesIncreasing energy efficiencyThermal inertiaElectromagnetic induction

The invention relates to a multifunctional device used for plating layer research, belonging to the technical field of material annealing. An infrared radiation furnace (2) which can be used in normal pressure and vacuum is arranged below a driving system (1); an electromagnetic induction heating furnace (3) is arranged below the infrared radiation furnace (2); a set of high temperature resistant high vacuum isolation room (4) is arranged below the electromagnetic induction heating furnace (3); an air knife (5) is arranged below the high temperature resistant high vacuum isolation room (4); a sample clamping mechanism (6) is arranged below the air knife; and a hot-dipping metallic plating melting furnace (7) and a corresponding hydraulic transmission and sealing system (8) are arranged below the sample clamping mechanism (6). A continuous annealing furnace heated by low-inertia infrared radiation can realize a continuous annealing curve simulating industrial production, reduce the thermal inertia of the sample, control the temperature precision of the sample within 1 DEG C, and control a soaking zone of the sample within 100*150mm; meanwhile the test process is clean and does not have any pollution of noise, light and electricity.

Owner:北京钢研新冶工程技术中心有限公司

Green gold glaze ceramic and preparation method thereof

ActiveCN113387578AImprove liquidityGood film formingCeramic materials productionVitrificationTemperature control

The invention relates to a green gold glaze ceramic which comprises a green body and a green gold glaze material, the green gold glaze material is arranged on the surface of the green body, the green gold glaze material comprises calcite, potassium feldspar, black wool soil, aluminum ore, plant ash, albite, quartz and agate, and the glaze material has good fluidity and film-forming property, is reduced in temperature sensitivity, is not sensitive to small-range temperature fluctuation, and low in vitrification temperature and can complte vitrification at 1230 DEG C, stable temperature rise can be realized during firing molding, temperature rise speed is slow, temperature control by adopting a mixed carbon paste cover scattering method is adopted to guarantee stable temperature rise speed, and the problems of high temperature requirement and difficult firing during firing of the green gold glaze ceramic can be solved.

Owner:河南弘宝汝瓷坊有限公司

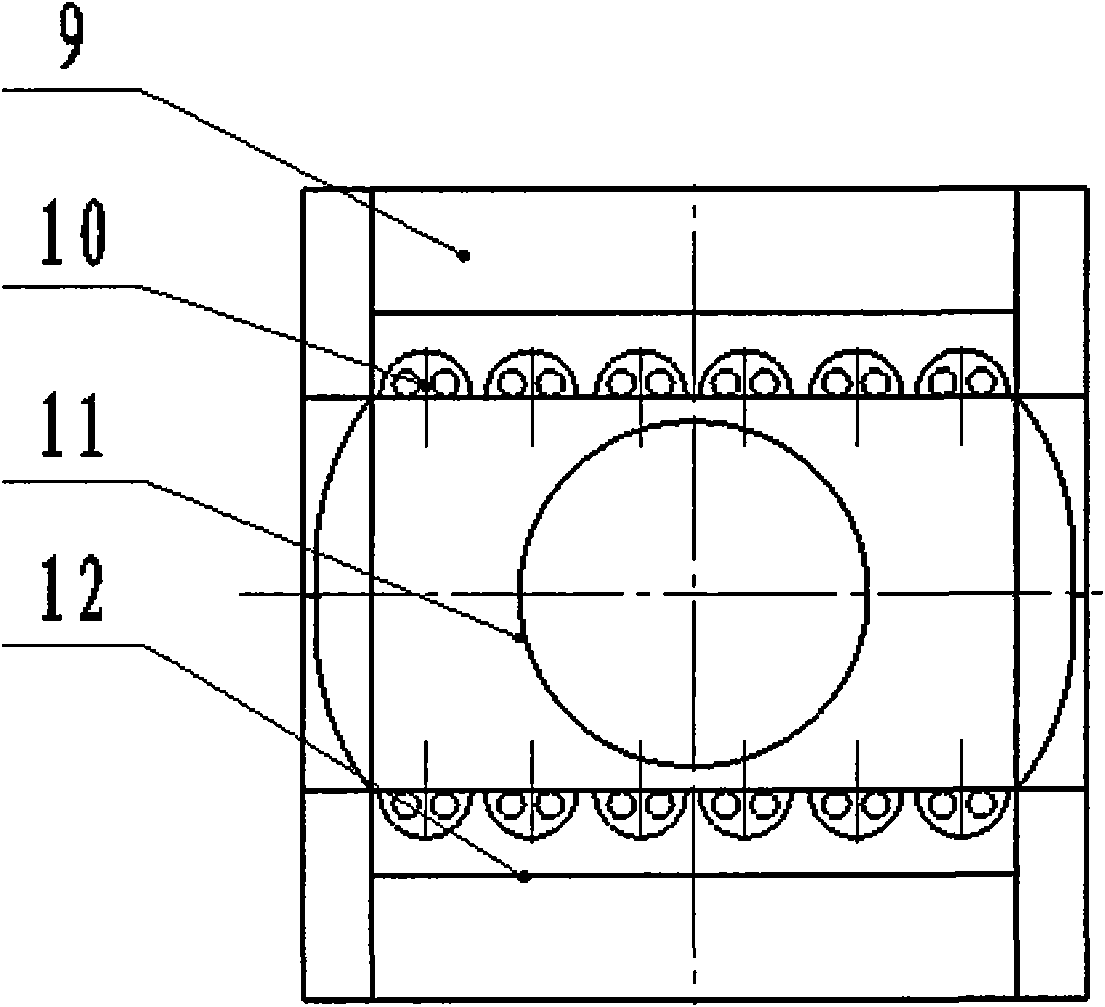

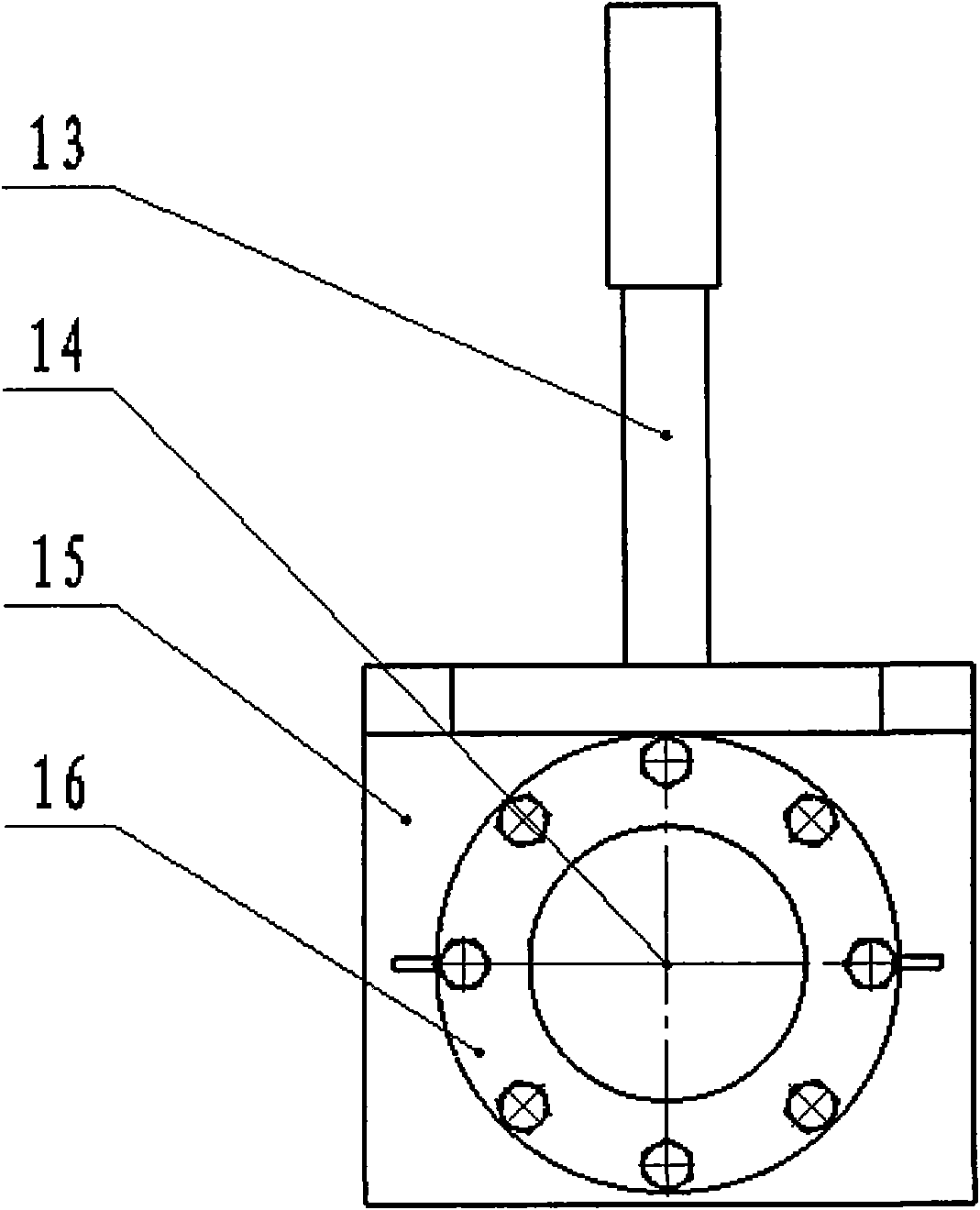

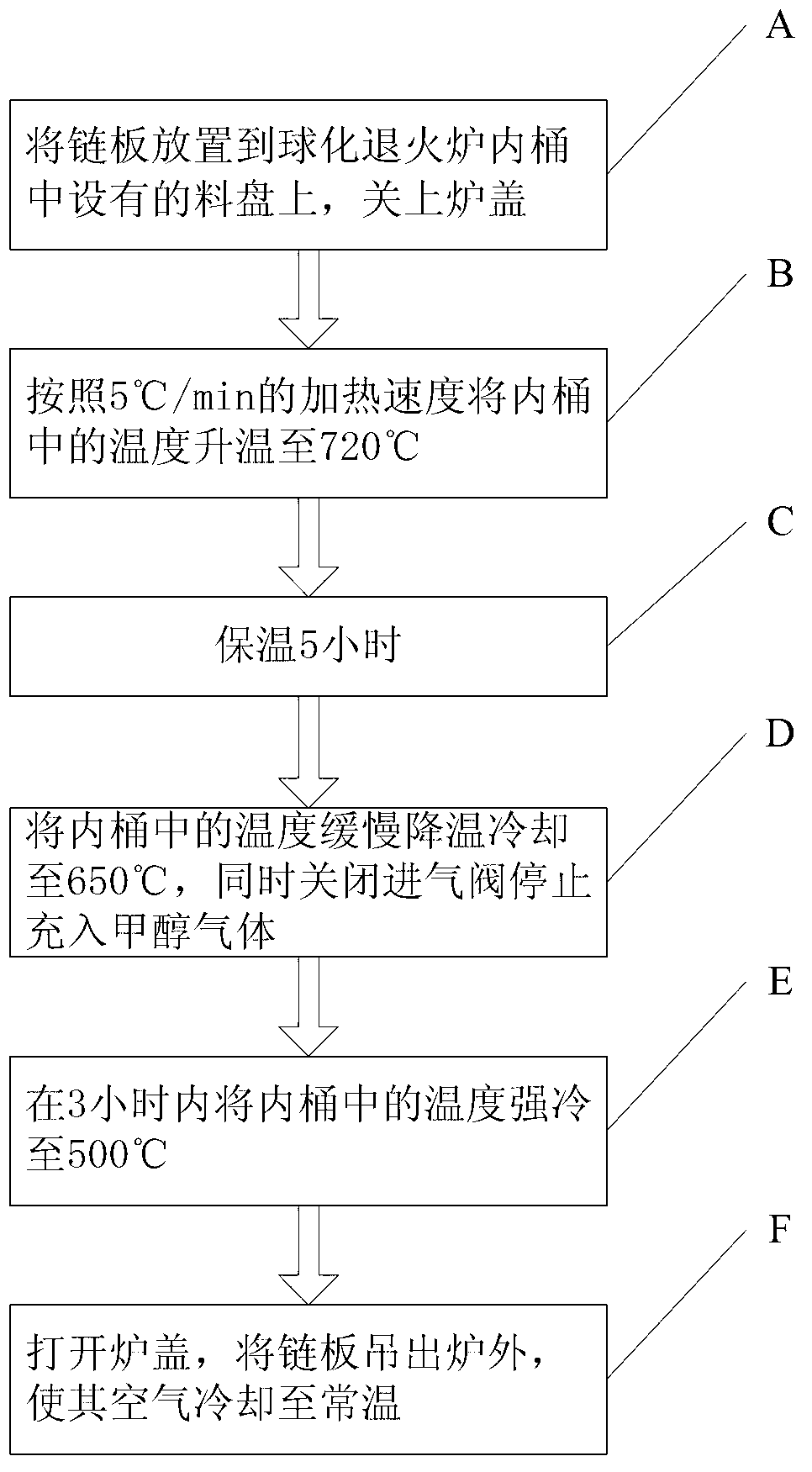

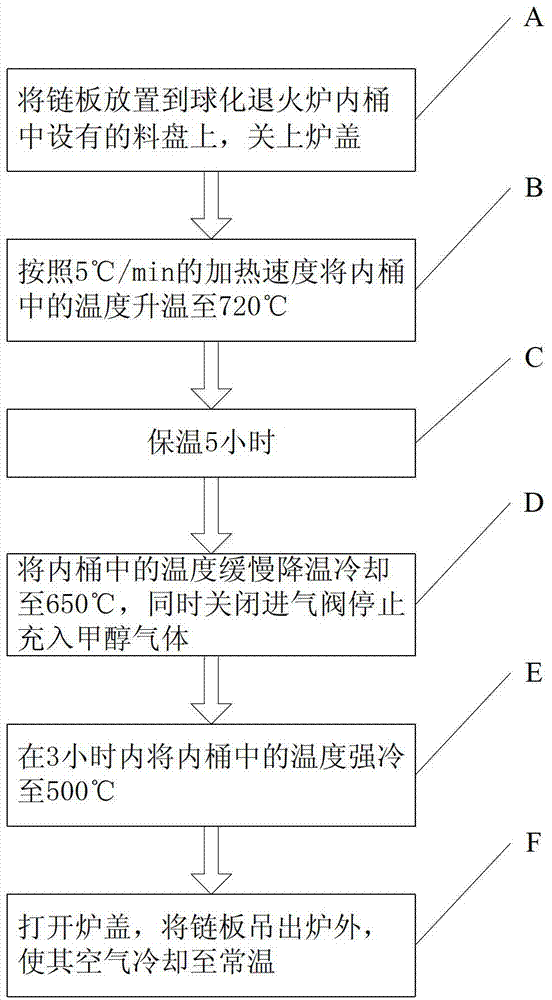

Link plate balling and annealing technology

The invention discloses a link plate balling and annealing technology which comprises the following steps of: putting a link plate on a tray in an inner barrel of a balling and annealing furnace and closing a furnace cover; heating the inner barrel to the temperature of 720 DEG C at the speed of 5 DEG C per minute; preserving the heat for 5 hours; slowly cooling the inner barrel to the temperature of 650 DEG C, and closing an air inlet valve to stop charging methanol gas; forcibly cooling the inner barrel to the temperature of 500 DEG C in 3 hours; and opening the furnace cover, hoisting the link plate out of the furnace, and cooling the link plate to normal temperature with air. The technology can ensure that the treated workpiece has good cutting performance, low hardness and high deformability, so that the quality and the service performance of the product are improved.

Owner:TANGSHAN JINSHI SUPER ABRASIVE

Rapid annealing method for ohmic contact of metal and silicon carbide

ActiveCN102569039BReduce manufacturing costQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactMoisture

The invention provides a rapid annealing method for ohmic contact of metal and silicon carbide, which comprises the steps of (1) placing SiC wafers on a Si sheet tray, then arranging the Si sheet tray on a rapid thermal treatment device, and simultaneously filling the device with protection gas Ar; (2) performing a first temperature-rise period, and keeping the temperature; (3) performing a second temperature-rise period, and steadying the temperature; (4) performing a third temperature-rise period; (5) performing a fourth temperature-rise period, namely, annealing period; and (6) performing a temperature reducing period. The method has benefits as follows: the method is carried out in the commercial rapid thermal treatment device taking any light radiation as a heat source; and the silicon sheet used as the tray can adopt various standards of commercial polishing monocrystalline silicon sheets and has low cost. The annealing method can remove the moisture on the surface of the silicon carbide wafer and stabilize the temperature. On the premise of ensuring the control precision of the peak thermal treatment temperature, the heating rate is improved through changing the setting value. Finally, the annealed ohmic contact resistance is reduced; and the quality of the ohmic contact, the device reliability and the yield are improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Pressure welding device and pressure welding method

ActiveCN111225514AEvenly heatedAvoid damagePrinted circuit assemblingAdhesive materialsElectrically conductive adhesive

The embodiment of the invention provides a pressure welding device and a pressure welding method. The pressure welding device comprises a pressing mechanism and an induction heating mechanism, whereinthe pressing mechanism is used for pressing a display panel, an electrical component and a conductive adhesive film located between the display panel and the electrical component; and the induction heating mechanism is matched with the conductive adhesive film and used for generating an alternating magnetic field, so that the conductive adhesive film is self-heated and cured, and the display panel is fixedly connected with the electrical component. The alternating magnetic field is generated through the induction heating mechanism, so that a ferromagnetic material in the conductive adhesive film is enabled to generate heat to complete curing of an adhesive material in the conductive adhesive film. Compared with the prior art, through self-heating of the conductive adhesive film, the heating rate is more stable, the display panel and electrical components such as an IC and an FPC are heated more uniformly, and damage of a high-temperature pressure head to the display panel and the electrical components such as the IC and the FPC is avoided. Meanwhile, due to the fact that a hardware heat source is omitted, potential safety hazards brought by the high-temperature pressure head in the production process are avoided.

Owner:BOE TECH GRP CO LTD +1

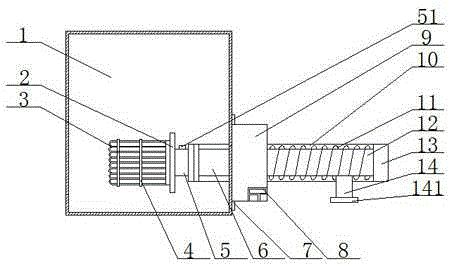

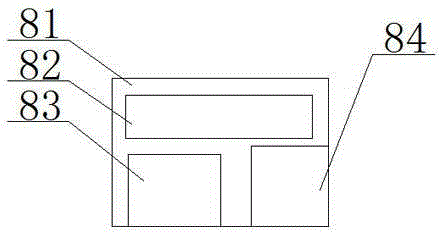

Petroleum heater

InactiveCN105318532AFast heatingStable heating rateWater heatersMicrocomputer controlElectromagnetic heating

The invention provides a petroleum heater. The petroleum heater comprises an electric heater, an interior petroleum conveying device, a microcomputer control cabinet, a petroleum pumping device and an electromagnetic heating device, wherein the electric heater is arranged at the bottom part of the petroleum storage tank; electric heating rods are arranged on the left side of the electric heater; clamping boards are arranged on the electric heating rods; the interior petroleum conveying device is arranged on the right side of an anti-explosion wire connecting cavity; the petroleum pumping device is arranged on the bottom right part of the petroleum storage tank; the microcomputer control cabinet is arranged on the bottom right part of the petroleum pumping device; the right side of the petroleum pumping device is provided with a heating and insulating pipe; a petroleum conveying pipe is arranged in the heating and insulating pipe; the electromagnetic heating device is arranged on the right side of the heating and insulating pipe; and a petroleum conveying opening is formed in the bottom part of the right side of the heating and insulating pipe. Compared with the prior art, the petroleum heater has the following beneficial effects that the petroleum heater is convenient for use; petroleum can be heated more fast and stably through the electric heater at the bottom; and the petroleum in the oil tank is prevented from being heated repeatedly.

Owner:CHONGQING ENERGY COLLEGE

A carbon fiber thermal core floor based on a modified carbon fiber thermal core layer

InactiveCN106273921BHigh activityImprove surface propertiesCarbon fibresLaminationActivated carbonModified carbon

The invention provides a novel carbon fiber hot-core floor based on a modified carbon fiber hot-core layer. A preparation method comprises the specific operation steps that long fibers of carbon fibers are cut off and stirred to be broken, and carbon fiber short fibers to be modified are obtained; the carbon fiber short fibers to be modified are placed in a low-temperature plasma apparatus to be subjected to plasma treatment, and activated carbon fiber short fibers are obtained; the activated carbon fiber short fibers are added into a hydrochloric acid solution containing aniline, slow stirring is conducted, an initiator is added, reacting is conducted at room temperature, and the carbon fiber short fibers are taken out, washed and dried to obtain polyaniline-coated modified carbon fibers; the polyaniline-coated modified carbon fibers are placed in paper making equipment or non-woven fabric manufacturing equipment, and modified carbon fiber paper is obtained or a carbon fiber non-woven fabric is obtained; the modified carbon fiber paper or carbon fiber non-woven fabric is composited with an electrode and an insulating material phase to obtain the based modified carbon fiber hot-core layer, and the modified carbon fiber hot-core layer is composited with a wooden layer phase to obtain the carbon fiber hot-core floor based on the modified carbon fiber hot-core layer.

Owner:建滔地暖技术(清远)有限公司

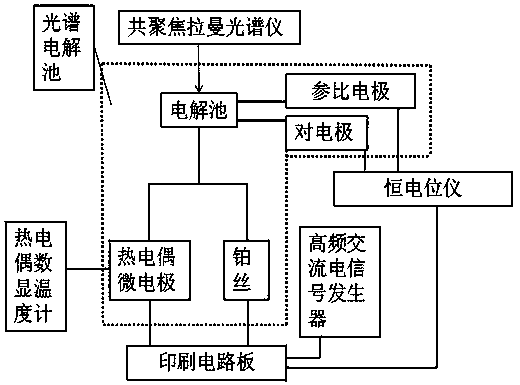

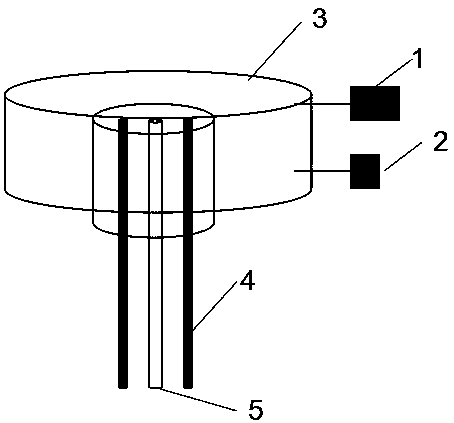

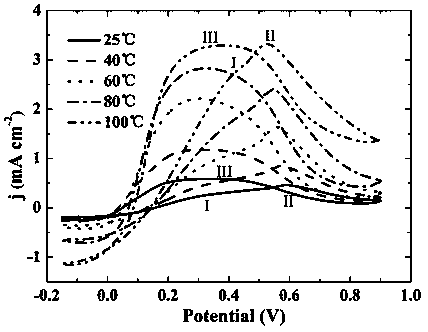

High-frequency warming electrochemical-surface enhanced Raman spectrum detection system

InactiveCN108132238AEasy to operateFast heatingRaman scatteringMaterial electrochemical variablesSurface-enhanced Raman spectroscopyAlternating current

The invention discloses a micro high-frequency warming electrochemical-surface enhanced Raman spectrum detection system which comprises a high frequency alternating current signal generator, a spectrum electrolytic tank, a thermocouple digital readout thermometer, a constant potential rectifier, a printed circuit board and a confocal Raman spectrometer. A microelectrode of a thermocouple is heatedand warmed by means of a high-frequency warming technology, the temperature is monitored in real time through the thermocouple digital readout thermometer, the potential of the electrode is changed by means of an electrochemical technology, and meanwhile, a spectrum sampling research on a research system is carried out by means of the confocal Raman spectrometer. The system process is simple andconvenient to operate, extremely high and stable in heating rate and sensitive to detect, and provides a convenient, systematic, novel and cheap detection technology and method for the research systemof warming electrochemical-surface enhanced Raman spectrum.

Owner:FUZHOU UNIV

Link plate balling and annealing technology

Owner:TANGSHAN JINSHI SUPER ABRASIVE

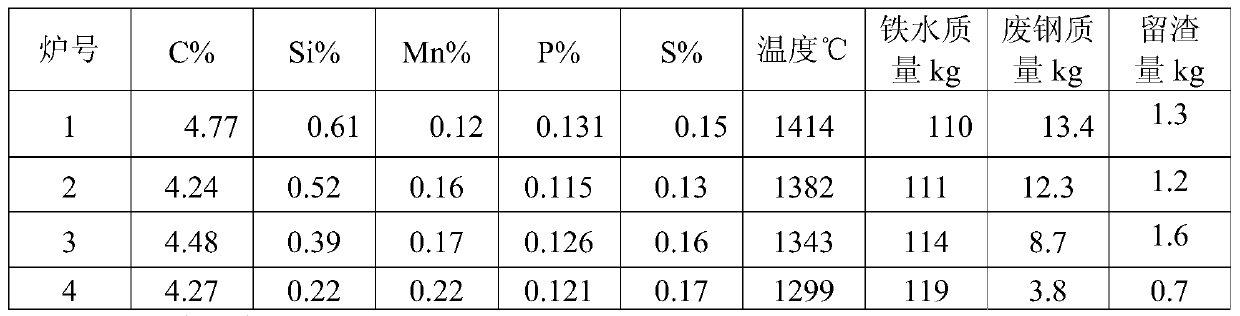

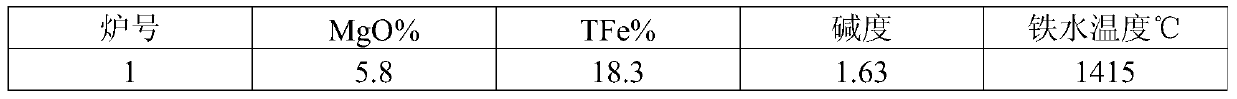

A control method for increasing the blowing end temperature of steelmaking converter

ActiveCN108570528BImprove temperature control effectImprove controlManufacturing convertersSteelmakingTemperature control

Owner:TIANJIN IRON & STEEL GRP

A vanadium-nitrogen microalloy high-strength phase transformation-induced plasticity steel seamless pipe and its preparation method

ActiveCN104372239BReduce intensityGood value for moneyProcess efficiency improvementSolid componentIntermediate frequency

The invention belongs to the steel technical field, and specifically, relates to a vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe and a preparation method thereof. The vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe comprises the chemical ingredients by the weight percentage: 0.18%-0.24% of C, 1.0%-1.6% of Si, 1.2%-1.6% of Mn, 0.17%-0.22% of V, 0.01%-0.03% of N, not more than 0.06% of P, not more than 0.005% of S, and the balance iron and unavoidable impurities. With utilization of an intermediate-frequency induction heat treatment device of a thin-wall steel pipe and with supplementary of a vanadium-nitrogen microalloyed component design, the advantage of cooperation of good strength and elongation of phase-transformation induced plastic steel is successfully applied to the steel pipe production field, a fact of replacing solid components with hollow components is effectively realized so as to achieve automobile light weighting, besides, further development of an internal high pressure forming technology is promoted, not only are the internal high pressure formed components with high strength, large deformation and complex shape produced, but also the production cost is greatly reduced, and the preparation method has wide application prospects are provided.

Owner:SHANDONG IRON & STEEL CO LTD

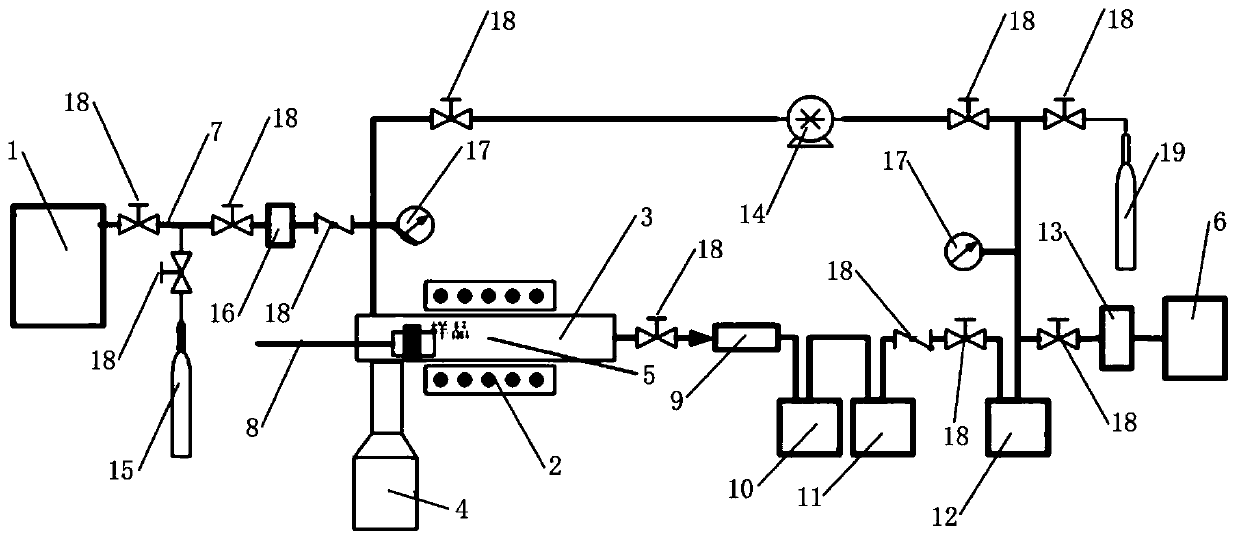

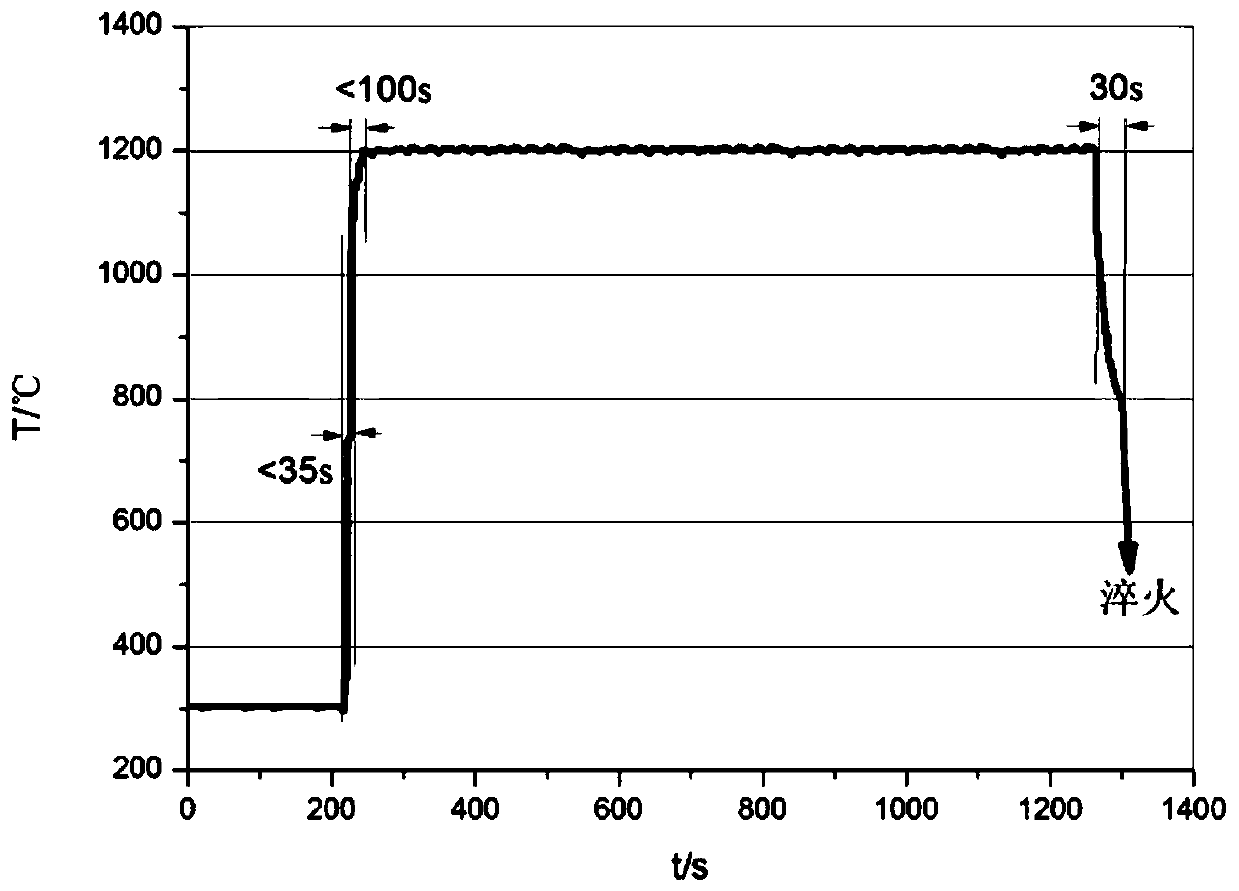

Reactor cladding material high temperature steam oxidation quenching test device and test method

ActiveCN107167488BImprove efficiencyEasy to controlMaterial thermal analysisSafety controlEngineering

The invention belongs to the technical field of nuclear safety control and relates to a high-temperature steam oxidation quenching test device and method for a reactor cladding material. The test device comprises a steam generator, an ordinary resistance furnace, a reaction chamber, a quenching tank, a thermocouple, a hydrogen analyzer and connecting pipes, wherein high-temperature steam provided by the steam generator enters the reaction chamber through the connecting pipe; the reaction chamber is used for accommodating a sample for a high-temperature steam oxidation quenching test; the reaction chamber is heated by a common resistance furnace outside the reaction chamber; the thermocouple is installed in the reaction chamber for measuring and controlling the temperature; the quenching tank is connected to the lower part of the reaction chamber for quenching the sample falling into the water in the quenching tank; the hydrogen analyzer is connected to the reaction chamber through the connecting pipe for analyzing content of hydrogen gas generated in the reaction chamber. With adoption of the test device and method, whether the reactor cladding material meets safety criteria can be evaluated easily and efficiently with the temperature accurately controlled and at a low cost.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Heat pipe superconducting liquid and preparation method thereof

InactiveCN111334259ANo irritating smellNot corrosiveHeat-exchange elementsSodium metasilicateCleansing Agents

The invention provides a heat pipe superconducting liquid and a preparation method thereof. The heat pipe superconducting liquid is prepared from the following components in parts by mass: 40 to 50 parts of n-pentane, 20 to 40 parts of ethanol, 15 to 20 parts of isopropanol, 5 to 10 parts of 3-methyl-1-butene, 8 to 10 parts of organic acid, 10 to 15 parts of triethanolamine, 3 to 5 parts of sodiumbenzoate, 8 to 10 parts of anhydrous sodium metasilicate and 30 to 40 parts of deionized water. According to the invention, the characteristics of low boiling point and no pungent smell of the n-pentane serving as a component can improve the heat conduction speed of the heat pipe superconducting liquid; in addition, the components of the cleaning agent do not contain a strong oxidant; the heat pipe superconductive liquid prepared by the method disclosed by the invention is stable in performance, the performance of the heat pipe superconducting liquid can be activated through the reaction of triethanolamine and organic acid, the heat pipe superconducting liquid can be rapidly heated, the heating speed is stable and uniform, and the heat pipe superconducting liquid prepared by the method disclosed by the invention is non-toxic, non-corrosive, free of pungent smell and high in safety.

Owner:SAIMOXI ENERGY SAVING & ENVIRONMENT PROTECTION ENG HANGZHOU CO LTD

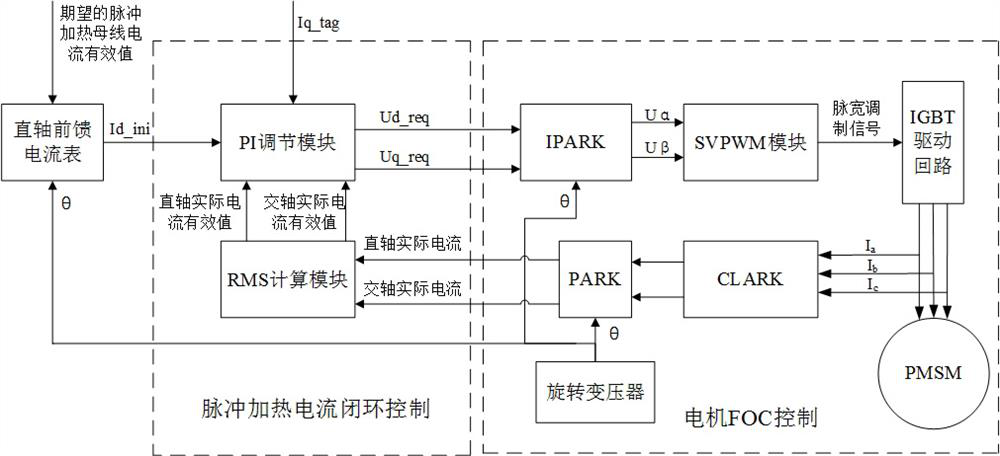

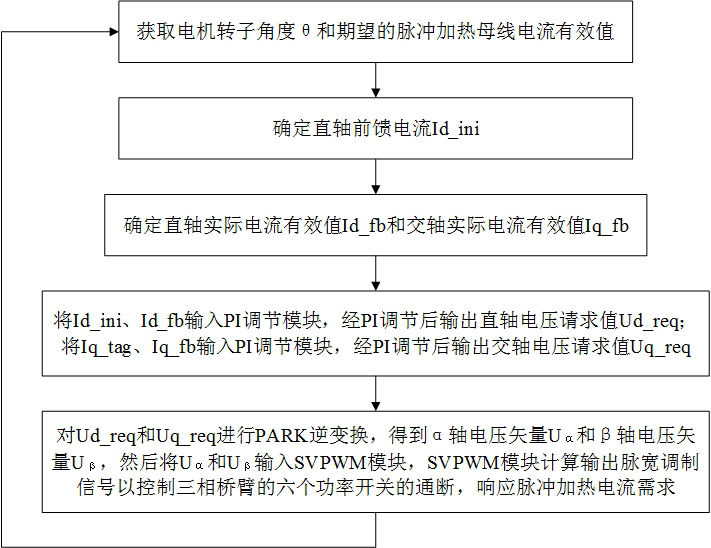

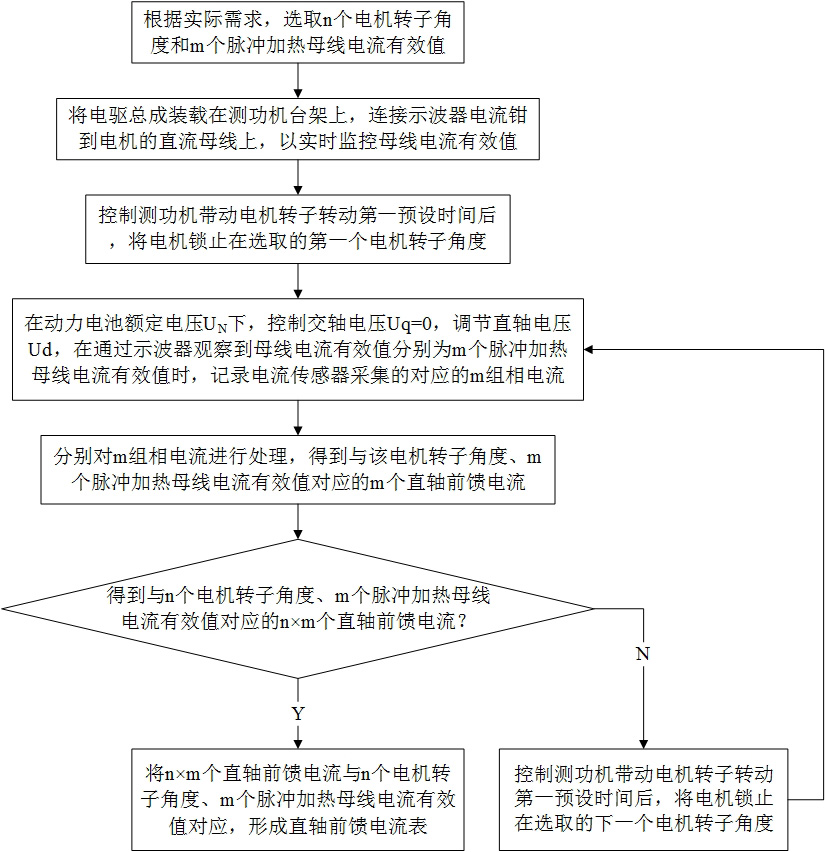

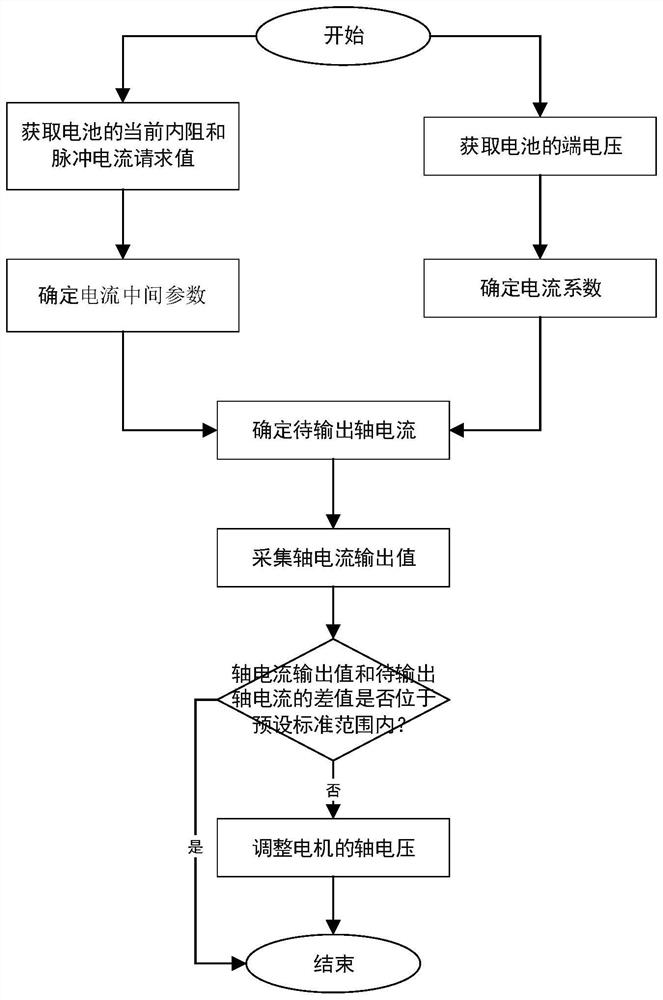

Pulse heating current control method and system of power battery and electric automobile

ActiveCN114789679ARealize closed-loop precise controlImprove stabilityVehicular energy storageBattery/fuel cell control arrangementPower batteryElectric machine

The invention discloses a pulse heating current control method and system for a power battery and an electric automobile, and the method comprises the steps: taking a motor rotor angle into consideration when determining a pulse heating current demand, and taking a direct-axis feed-forward current determined according to the motor rotor angle and an expected pulse heating bus current effective value as the pulse heating current demand; the current control deviation caused by the motor rotor angle can be reduced; a direct-axis feed-forward current Idini and a direct-axis actual current effective value Idfb are adjusted through PI to output a direct-axis voltage request value Udreq, a preset quadrature-axis target current Iqtag and a quadrature-axis actual current effective value Iqfb are adjusted through PI to output a quadrature-axis voltage request value Uqreq, closed-loop accurate control over the pulse heating current can be achieved, and the stability of the pulse heating current is improved.

Owner:深蓝汽车南京研究院有限公司 +1

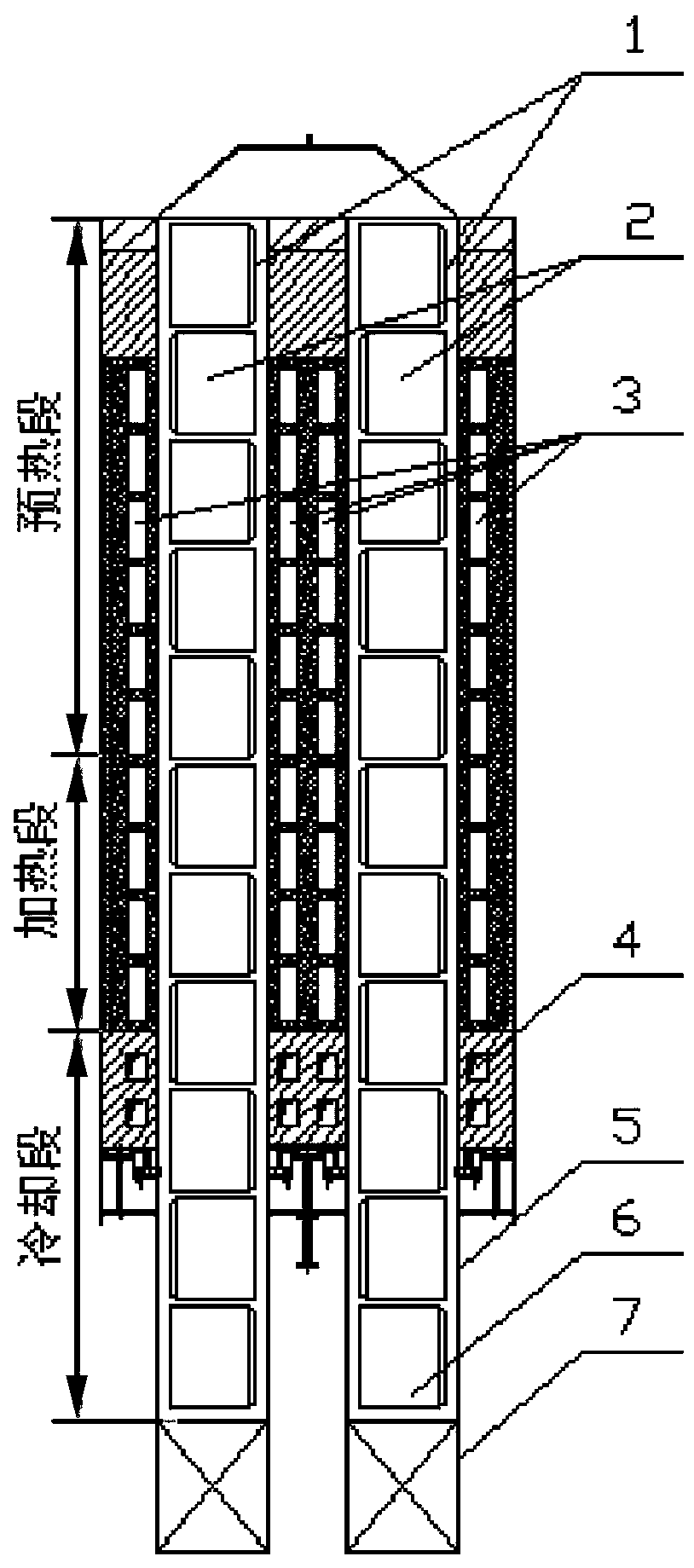

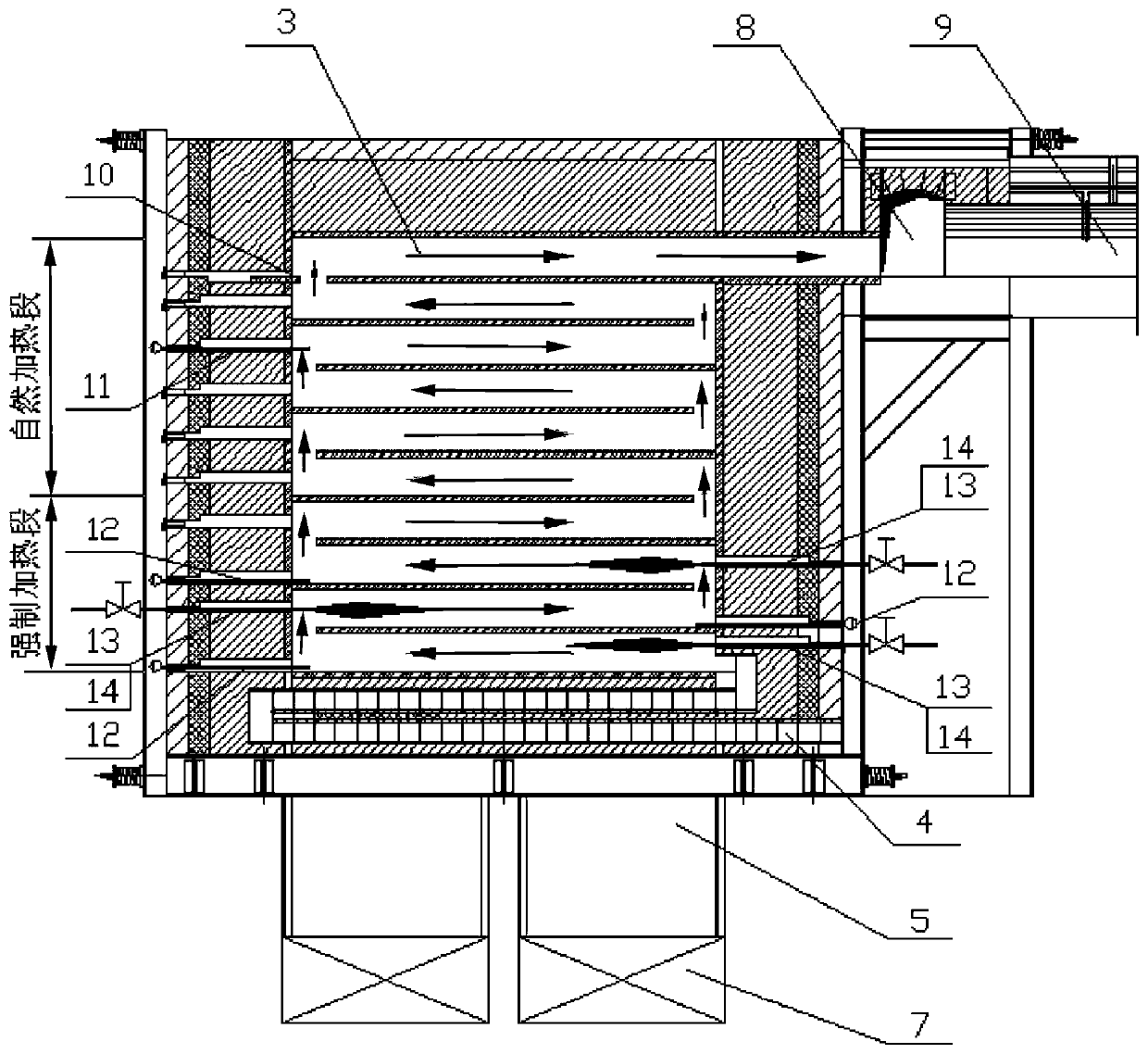

A roasting furnace roasting control method

ActiveCN107238289BControl heating rateTemperature controlFurnace typesControl devices for furnacesTemperature controlCombustion

The invention relates to a roasting furnace roasting control method. The method comprises the steps that roasting product green bodies and filler are fed through inlets in the tops of workbins and operate from top to bottom under the effect of self weight, high-temperature flue gas in flues on the two sides flows from bottom to top, and an indirect countercurrent heating mode is formed; the flues are partitioned into a forced heating section and a natural heating section according to temperature levels of all layers inside the flues, flue temperatures of the forced heating section are controlled to be within target temperature ranges mainly through fuel added from nozzles, and the temperature levels of the all layers of the flues of the natural heating section are mainly maintained through combustion of volatile matter precipitated from roasting products; and the workbins are also partitioned into a preheating section, a heating section and a cooling section according to temperature levels of materials in the workbins during falling, the heating rates, the final roasting temperatures and the tapping temperature levels of the materials in a roasting furnace are controlled through the flue temperatures, and the high-temperature roasting and cooling process of the products is completed. Manual operation is greatly reduced, and the novel roasting furnace is made to have a higher automation level and higher system stability.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

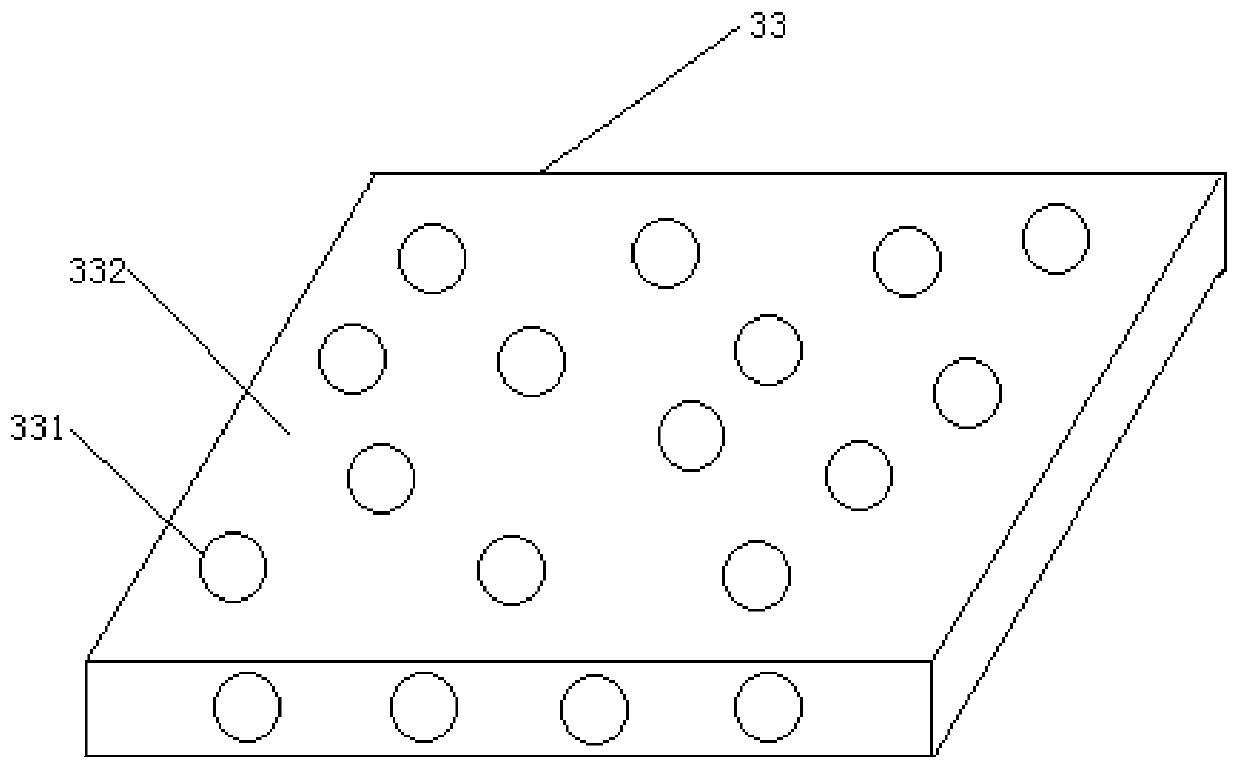

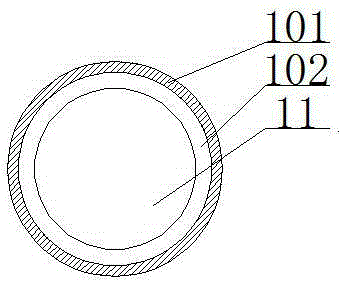

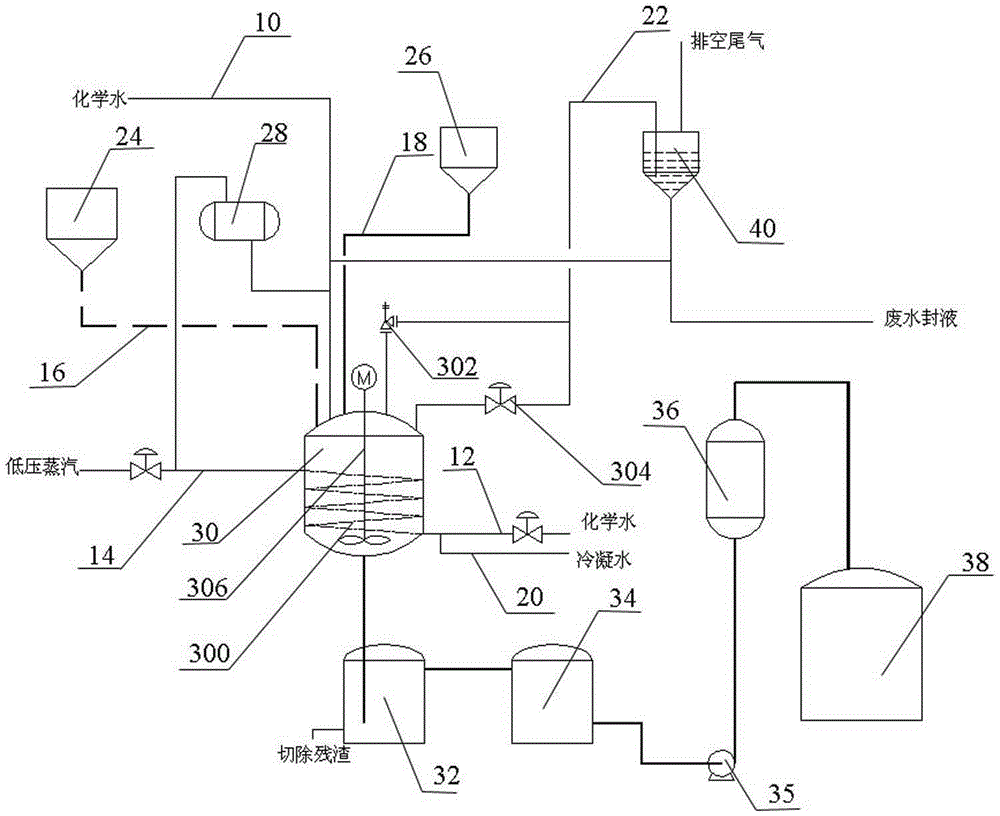

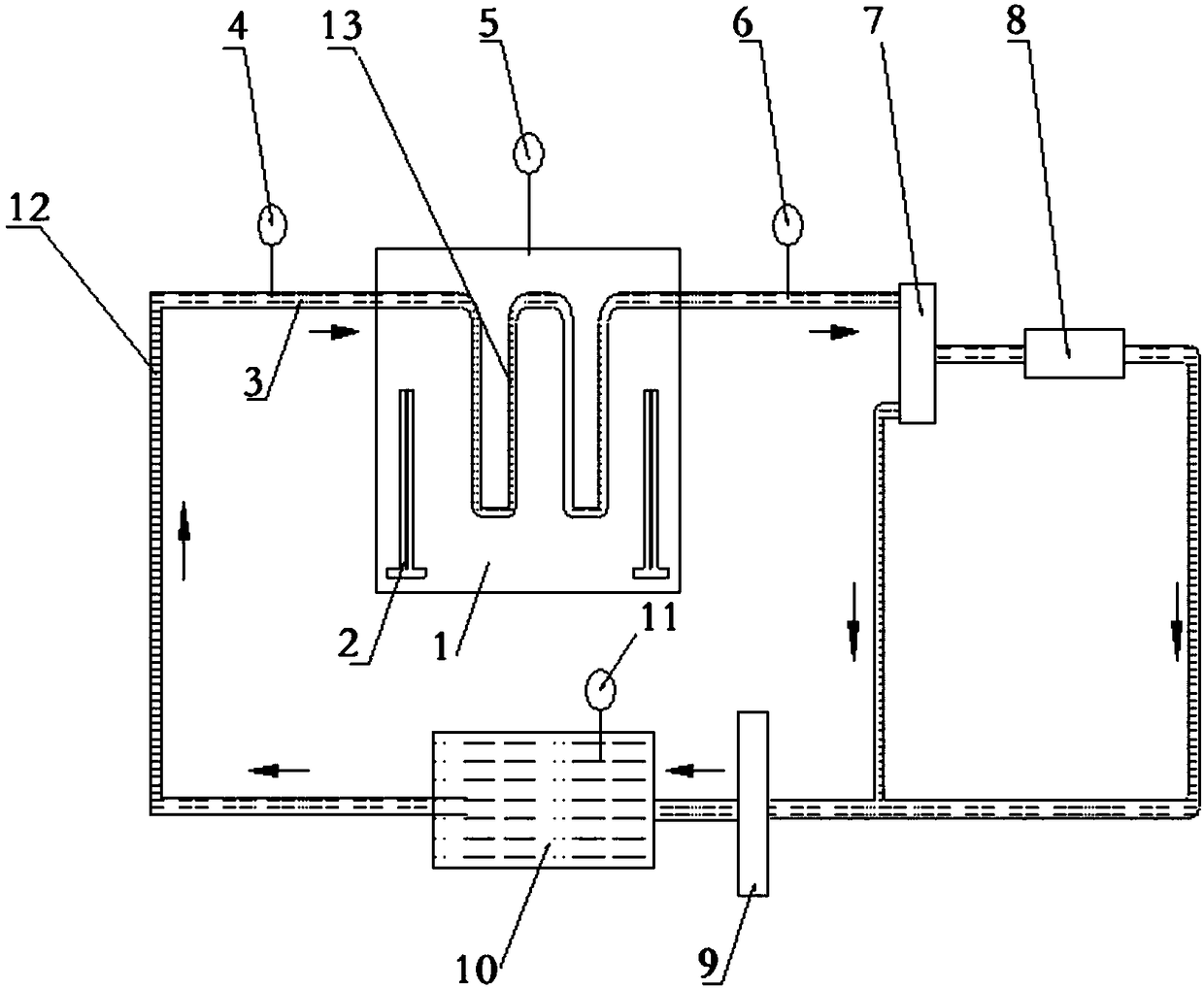

Synthetic device for aluminum sulfate and method for synthesizing aluminum sulfate using it

The invention provides a device for synthesizing aluminum sulfate. The device comprises a first water inlet pipe, a second water inlet pipe, a low-pressure steam pipe, an aluminum powder feeding pipe, a concentrated sulfuric acid feeding pipe, a condensed water pipe, a hot water storage tank, a reactor, a slag cutting pot, an intermediate storage tank, a precision filter and an aluminum sulfate storage tank, wherein the hot water storage tank, the reactor, the slag cutting pot, the intermediate storage tank, the precision filter and the aluminum sulfate storage tank are connected in sequence; a coiled pipe is arranged on the inner wall of the reactor; an inlet and an outlet of the coiled pipe are formed in the outer wall of the reactor; one end of the low-pressure steam pipe is connected with the inlet of the coiled pipe; one end of the condensed water pipe is connected with the outlet of the coiled pipe; one end of the hot water storage tank is connected with the inlet of the coiled pipe, and the other end of the hot water storage tank is connected with the first water inlet pipe; and one end of the second water inlet pipe is connected with the outlet of the coiled pipe. The invention further provides a method for synthesizing aluminum sulfate by using the device. The device and the method provided by the invention have the advantages of operation stability and security and high conversion rate of raw materials. By adopting the device and the method, the loss of sulfuric acid and steam can be reduced greatly, and the pollution to air can be alleviated significantly, and the energy consumption of the device is reduced.

Owner:CHANGLING PETRO CHEM ENG DESIGN

A zif derived comoo 4 The preparation method of the electrode

ActiveCN109243863BGuaranteed purityIncrease specific volumeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMolybdate

Owner:盐城市盐南高新区都市产业发展有限公司

Iron ore slag sintered brick and a preparation technology of same

ActiveCN102491724BImprove performanceSolve the phenomenon of burstingSolid waste managementBrickSlag

The invention relates to a sintered brick, in particular to a sintered brick made of iron ore slag and a preparation technology of the sintered brick. The sintering raw material of the iron ore slag sintered brick comprises the components by bone dry weight as follows: 28 to 36 portions of iron ore slag, 27.6 to 41.4 portions of coal gangue or 25.5 to 38.25 portions of coal slag, 20 to 30 portions of silt and 5 to 15 portions of clinker. The iron ore slag sintered brick provided by the invention has the advantages that the source of raw materials is ample, waste iron ore slag is recycled, soil resources are saved, cultivated lands are protected, waste iron ore slag that can be obtained on a large scale and is of great quantity is fully utilized, the waste is changed into valuable, and theenvironment is purified. The obtained iron ore slag sintered brick has the effects of heat preservation, thermal insulation shock resistance and pressure resistance; and peeling and distortion are avoided, breakage or explosion does not occur easily, the yield can reach over 99%, and the sintered brick is suitable for industrial production and can be widely used as wall bricks of buildings.

Owner:上海鑫晶山建材开发有限公司 +1

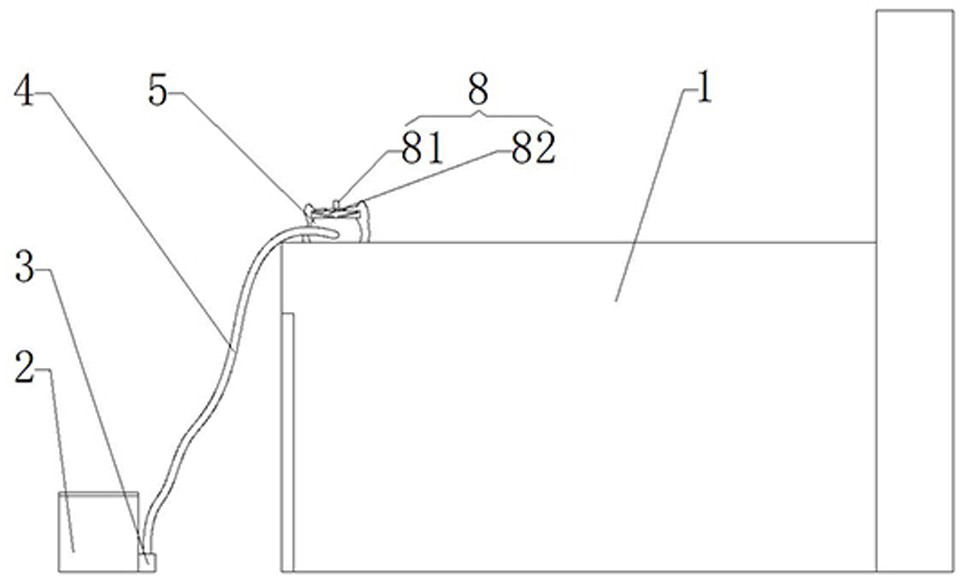

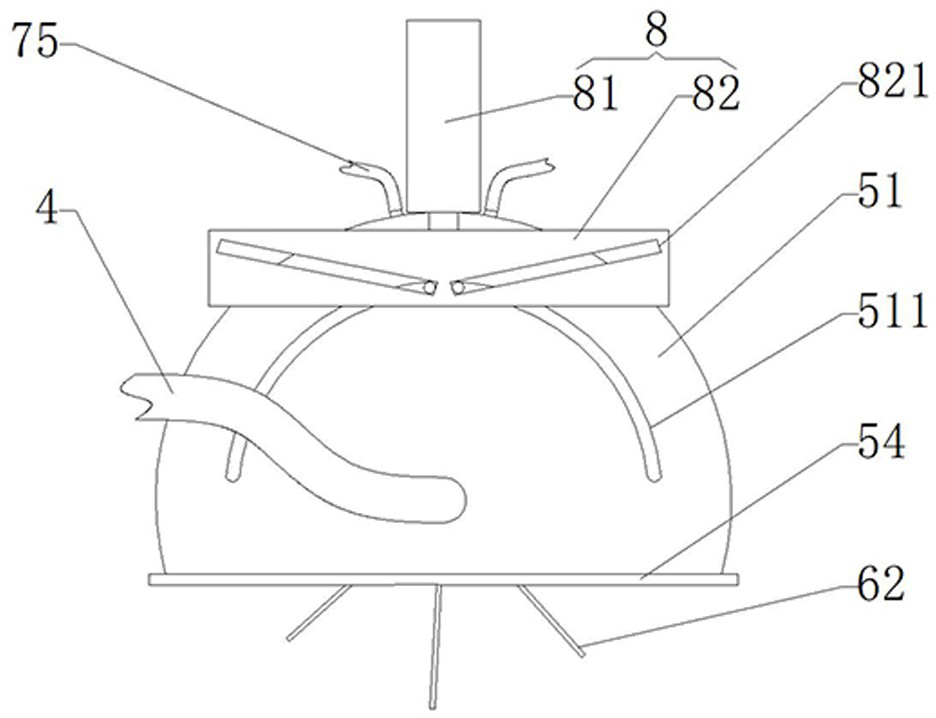

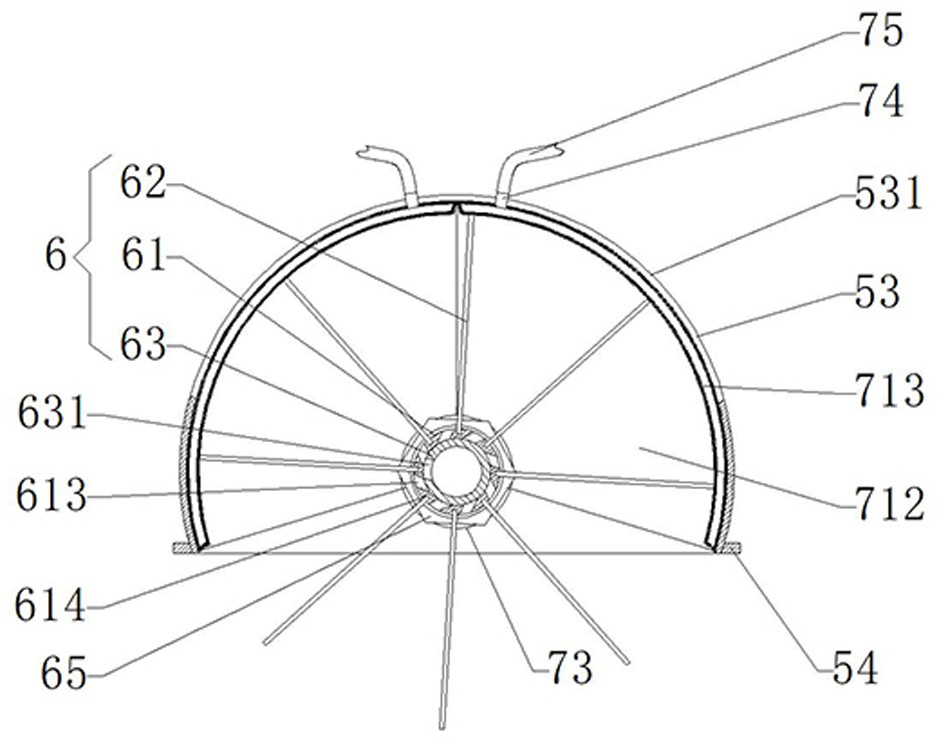

Firewood and carbon co-firing kiln

PendingCN113432430AControl heating rateReduce burning rateFurnace typesControl devices for furnacesFirewoodProcess engineering

The invention relates to a firewood and carbon co-firing kiln. The firewood and carbon co-firing kiln comprises a firewood kiln body, a dispersion machine and a slurry pump, an inlet of the firewood kiln body is located at the left end of the firewood kiln body, the dispersion machine is connected with the slurry pump, a hose of the slurry pump is connected with the firewood kiln body through a dispersion device, the dispersion device comprises a shell, a dispersion assembly, a protection assembly and an adjusting assembly, the dispersion assembly is arranged inside the shell and comprises a rotating sleeve, dispersion blades and a material injection pipe, two protection assemblies are arranged between the shell and the dispersion assembly, each protection assembly comprises a movable cover, a control column and a connecting ring, the adjusting assembly comprises an air cylinder and a control panel, a rectangular feeding hole penetrating through a roof of the firewood kiln body to communicate with the interior of the firewood kiln body is formed in the left portion of the upper surface of the firewood kiln body, and the dispersion blades, located below the rotating sleeve, of the above multiple dispersion blades stretch into the feeding hole.

Owner:河南弘宝汝瓷坊有限公司

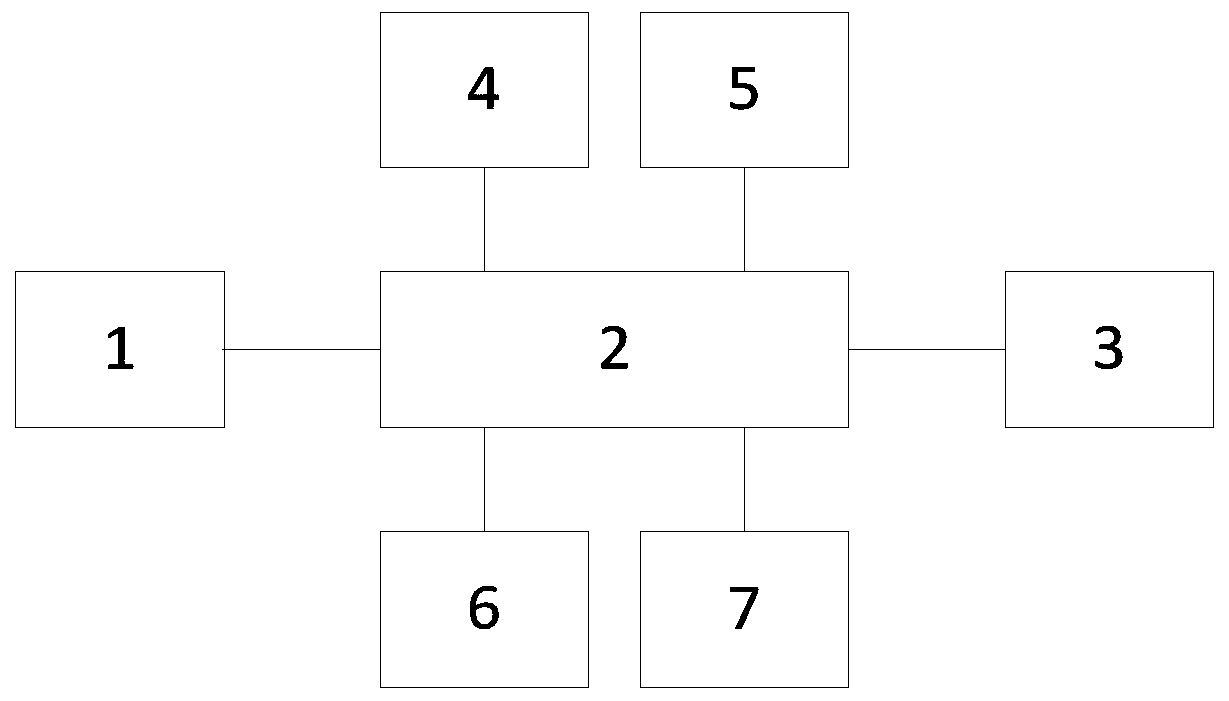

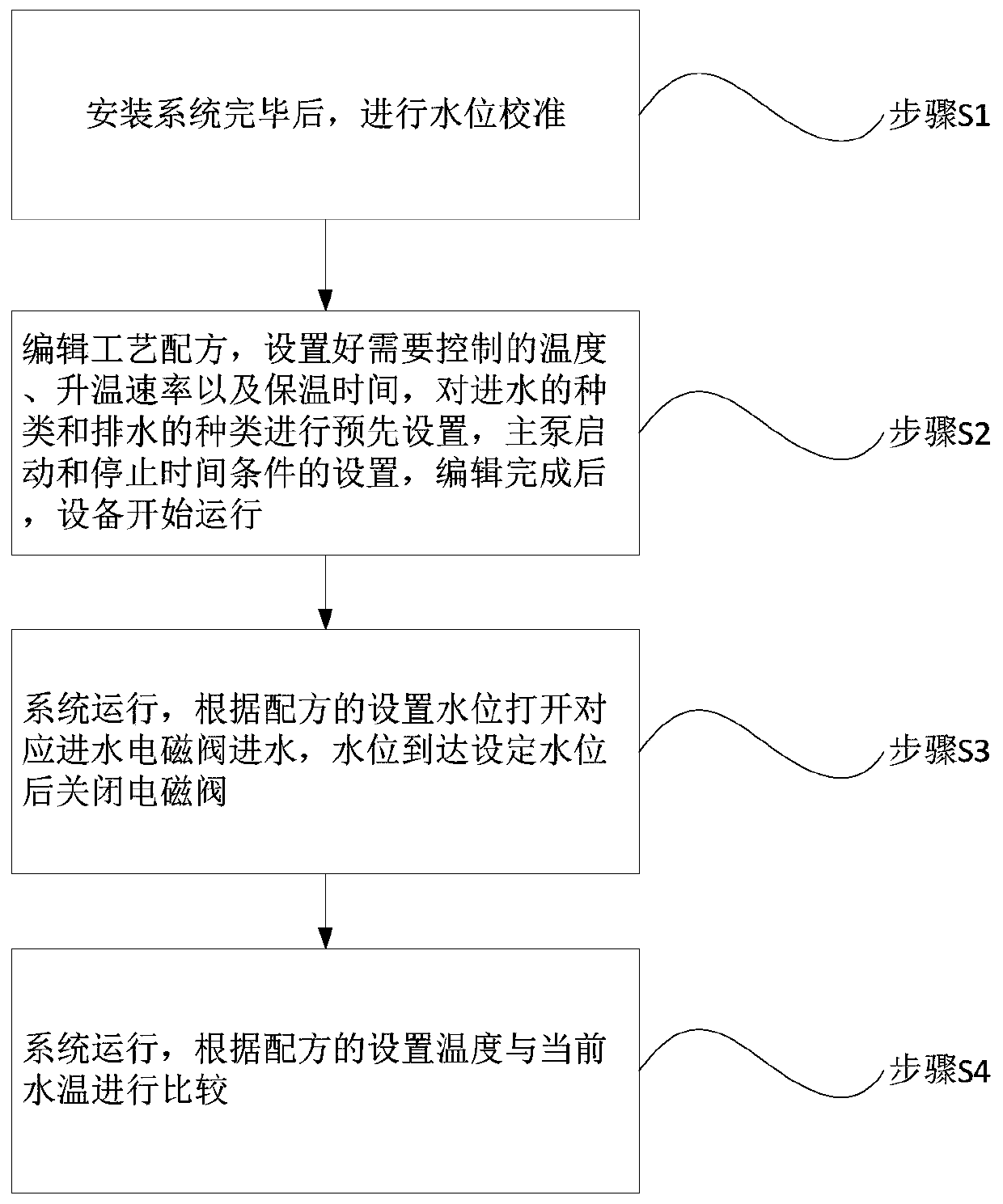

Computer dyeing centralized control system and method

ActiveCN110989520AIncrease profitEmission reductionTotal factory controlProgramme total factory controlTemperature controlControl system

The invention discloses a computer dyeing centralized control system and method. The system comprises a main control module, a PLC module, a touch control module, a water inlet and outlet control module, a temperature control module, a main pump control module and a water level control module, the main control module is connected with the PLC module, and the PLC module is connected with the touchcontrol module, the water inlet and outlet control module, the temperature control module, the main pump control module and the water level control module. By the adoption of the technical scheme, industrial personal computer configuration software serves as a control core, and the requirements for equipment operation, data acquisition and analysis, wastewater recycling and reasonable dischargingare met through cooperation of a TPC / IP protocol, configuration of a touch screen and programming of a PLC.

Owner:桐乡市新拓自动化设备有限公司

Multifunctional device used for plating layer research

ActiveCN101538695BCompact structureOptimize layoutHot-dipping/immersion processesIncreasing energy efficiencyElectricityEngineering

The invention relates to a multifunctional device used for plating layer research, belonging to the technical field of material annealing. An infrared radiation furnace (2) which can be used in normal pressure and vacuum is arranged below a driving system (1); an electromagnetic induction heating furnace (3) is arranged below the infrared radiation furnace (2); a set of high temperature resistanthigh vacuum isolation room (4) is arranged below the electromagnetic induction heating furnace (3); an air knife (5) is arranged below the high temperature resistant high vacuum isolation room (4); asample clamping mechanism (6) is arranged below the air knife; and a hot-dipping metallic plating melting furnace (7) and a corresponding hydraulic transmission and sealing system (8) are arranged below the sample clamping mechanism (6). A continuous annealing furnace heated by low-inertia infrared radiation can realize a continuous annealing curve simulating industrial production, reduce the thermal inertia of the sample, control the temperature precision of the sample within 1 DEG C, and control a soaking zone of the sample within 100*150mm; meanwhile the test process is clean and does not have any pollution of noise, light and electricity.

Owner:北京钢研新冶工程技术中心有限公司

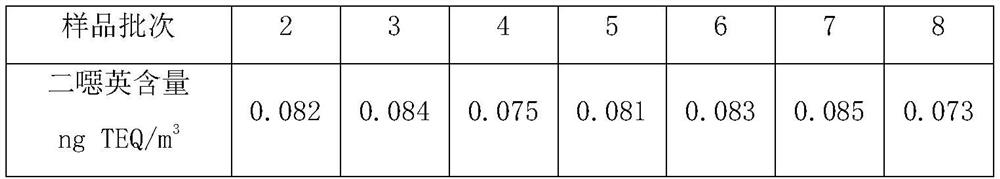

Synthesis Process of Catalyst Activated Carbon Composites for Dioxin Decomposition

ActiveCN110302800BLarge specific surface areaHigh and stable removal rateGas treatmentDispersed particle separationActivated carbonActivated charcoal powder

The invention discloses a synthesis process of a catalytic activated carbon composite material for decomposing dioxins, comprising the following steps: A, pulverizing the activated carbon and sieving to obtain product A; B, putting product A into a container filled with concentrated sulfuric acid In the process, nitrogen gas is introduced into the bottom of the container, soaked, washed, and dried to obtain product B; C, take product B and metal salt, add alcohol and deionized water, and stir to obtain product C; D, add complexing agent to product C , ultrasonic infiltration, stirring, adjusting pH, and stirring until it is in a sol state, to obtain product D; E, drying product D into a gel to obtain product E; F, under the protection of hydrogen, sintering product E to obtain product F; G. Remove impurities from product F, wash and dry to obtain a finished product. In the present invention, the specific surface area of the modified activated carbon increases, the catalyst is evenly distributed in the activated carbon, the finished product is not easy to form pores and cracks, the structure of the catalyst and the activated carbon is dense, the removal rate of the finished product to dioxin is high and stable, and the finished product Increased service life.

Owner:HANGZHOU XINGYU CARBON TECH GREEN CO LTD

Method for providing heated hydraulic fluid for hydraulic component test

InactiveCN108916159AHigh accuracy of oil temperatureStable heating rateFluid-pressure actuator testingFluid-pressure actuator componentsElectric heatingMaterials science

The invention relates to a method for providing a heated hydraulic fluid for a hydraulic component test. A hydraulic pipeline connected with a hydraulic component and a hydraulic oil tank are involved, a liquid heating device is involved, the body of the liquid heating device is an aluminum ingot, electric heating pipes are arranged in the aluminum ingot, a curved liquid passage is also formed inthe aluminum ingot, and a first temperature sensor is arranged on the surface of the aluminum ingot body of the liquid heating device; the liquid heating device is circularly communicated with the hydraulic component and the hydraulic oil tank through the hydraulic pipeline, the hydraulic pipeline between the liquid heating device and the hydraulic component is divided into a first branch and a second branch through a reversing valve, the first branch passes through the hydraulic component and then enters the hydraulic oil tank, and the second branch is directly communicated with the hydraulicoil tank. A second temperature sensor is disposed between the liquid heating device and the reversing valve.

Owner:XIAN AIRCRAFT IND GROUP

A high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and its preparation method

ActiveCN104018067BHigh work hardening rateGood low yield ratioFurnace typesIncreasing energy efficiencySolid componentHigh rate

Owner:LAIWU IRON & STEEL GRP

Motor pulse current control method and device and electric vehicle

ActiveCN114194073AEasy to controlGuaranteed reliabilitySpeed controllerVehicular energy storagePower batteryTerminal voltage

The invention relates to a motor pulse current control method and device and an electric automobile, and the method comprises the steps: determining a current intermediate parameter based on a received pulse heating current request value of a power battery and an obtained current internal resistance of the power battery when it is determined that the power battery has a pulse heating demand, determining a current coefficient based on the obtained current terminal voltage of the power battery; determining a to-be-output shaft current of the motor based on the current intermediate parameter and the current coefficient; and controlling a motor to output according to the to-be-output shaft current.

Owner:深蓝汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com