A method for preparing an electrode of ZIF-derived CoMoO4

A ZIF-67 electrode technology, which is applied in the field of ZIF electrode preparation, can solve the problems of poor electrode stability and small specific capacitance, and achieve the effects of increasing specific heat capacity, ensuring heating rate, and increasing migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

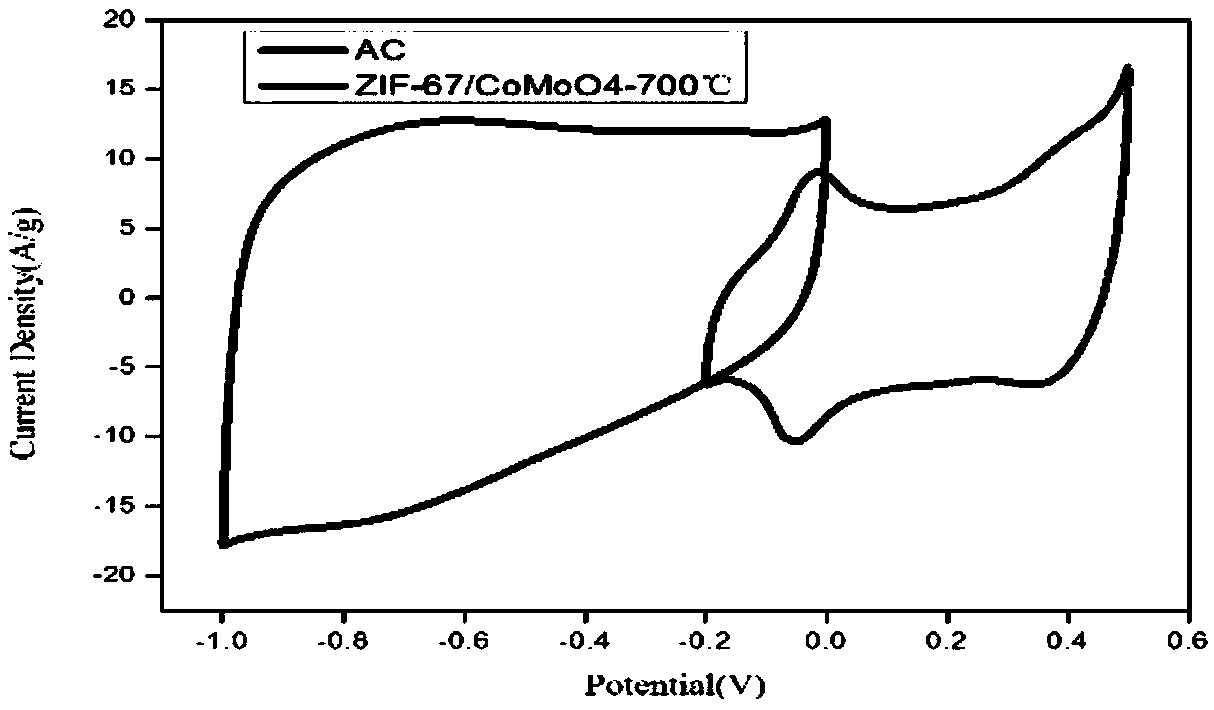

Image

Examples

Embodiment 1

[0029] 1. Sample preparation

[0030] A ZIF-derived CoMoO 4 The preparation method of the electrode is to use high-temperature calcined ZIF-67 as a precursor, and prepare CoMoO by hydrothermal method 4 , the steps are: (1) Take Na respectively 2 MoO4·2H 2 O and CoCl 2 ·6H 2 O was dissolved in deionized water and stirred in a magnetic stirrer until dissolved; (2) adding a small amount of ZIF-67 powder with a calcination temperature of 700 °C and ultrasonically stirring until a homogeneous solution; (3) transferring the obtained solution to a reaction kettle, Reacted at 160°C for 2h, then cooled to room temperature; (4) The obtained product was washed alternately with deionized water and absolute ethanol, then placed in a constant temperature drying oven at 60°C for 24h, taken out and ground to obtain the ZIF-67 derived CoO 4 (5) Soak in acetone for 10 minutes, then add ethanol to wash for 10 minutes, and finally add 2mol / L hydrochloric acid for ultrasonic cleaning for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com