Patents

Literature

79results about How to "Mix tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

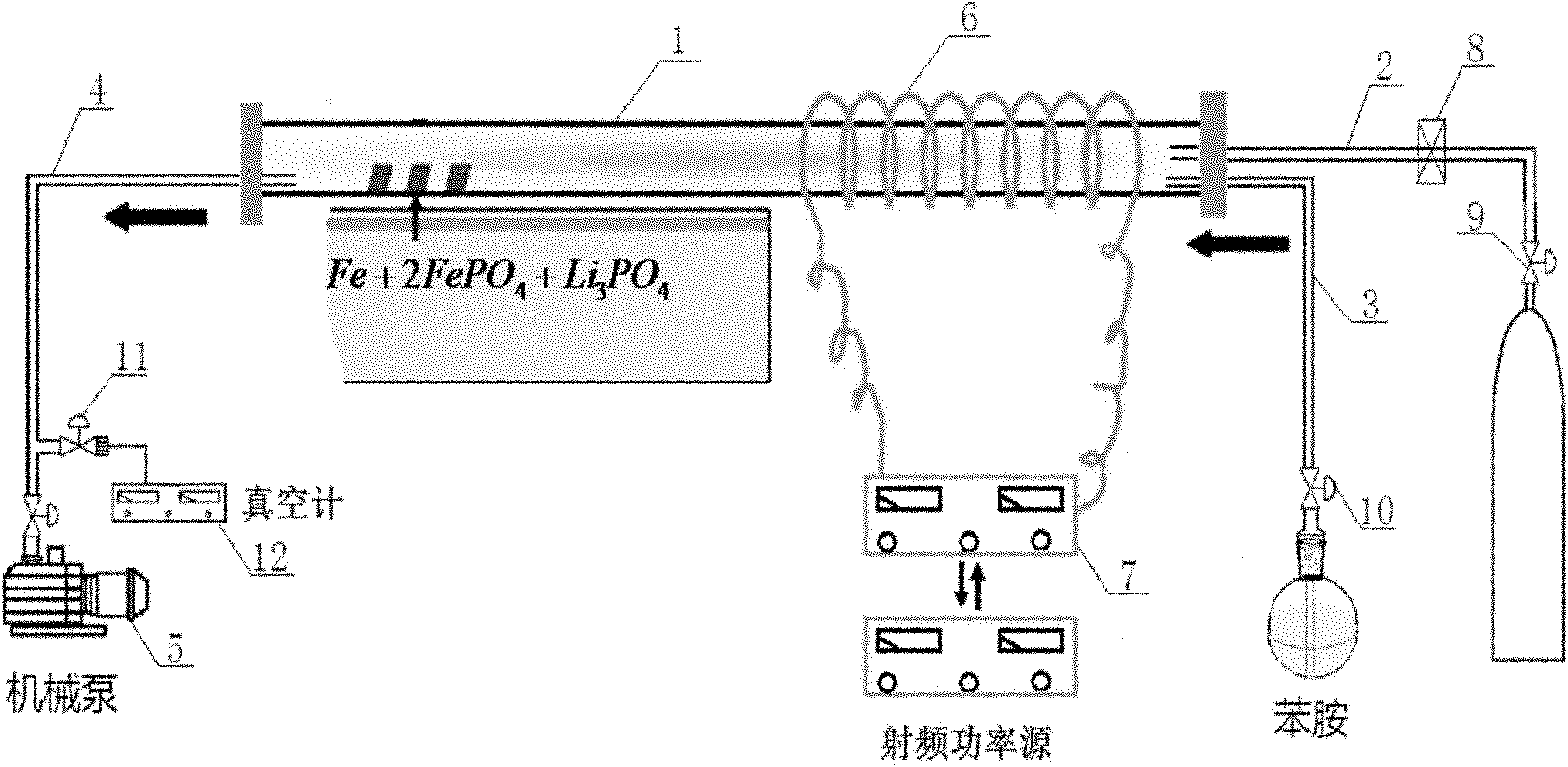

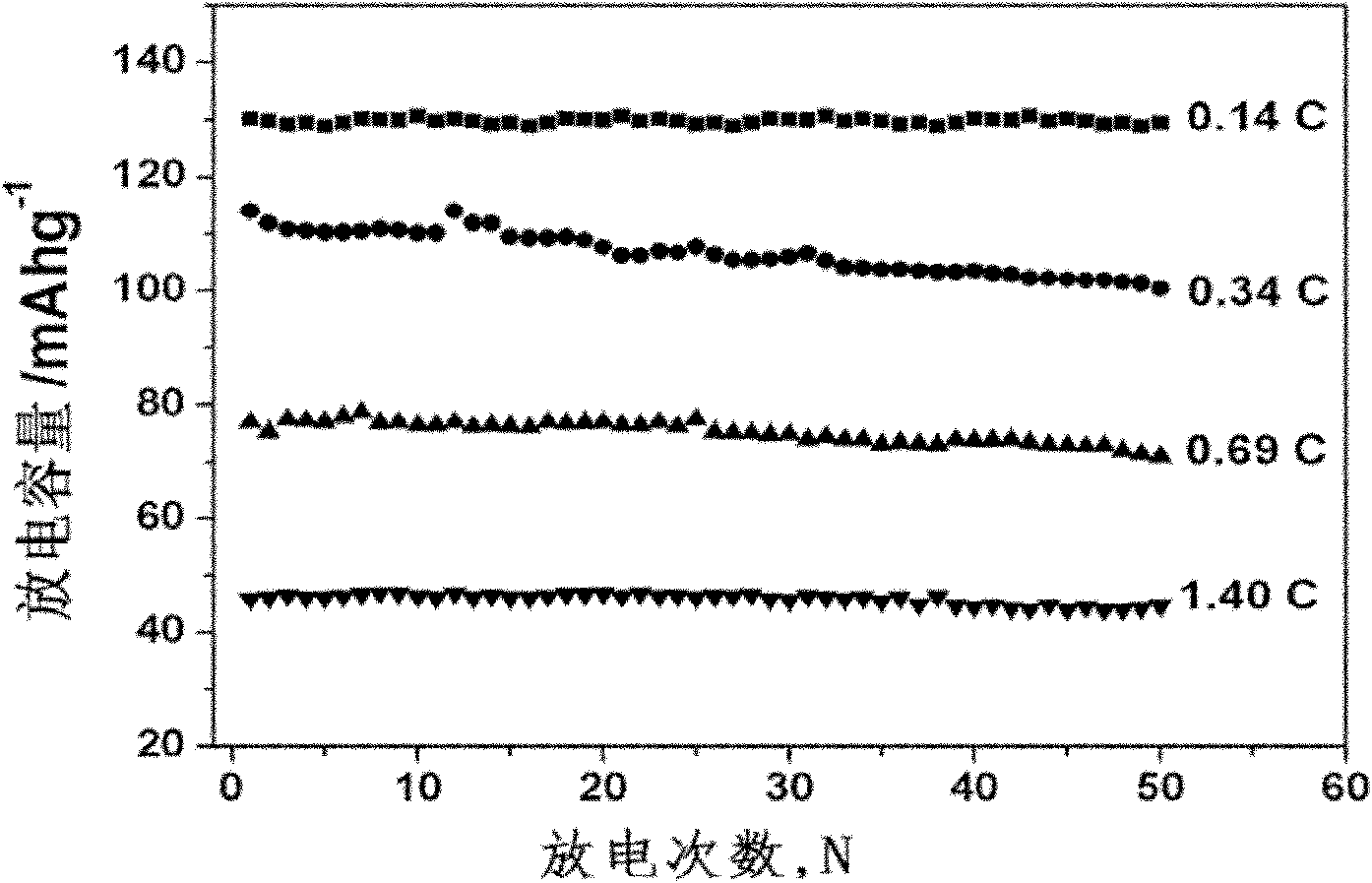

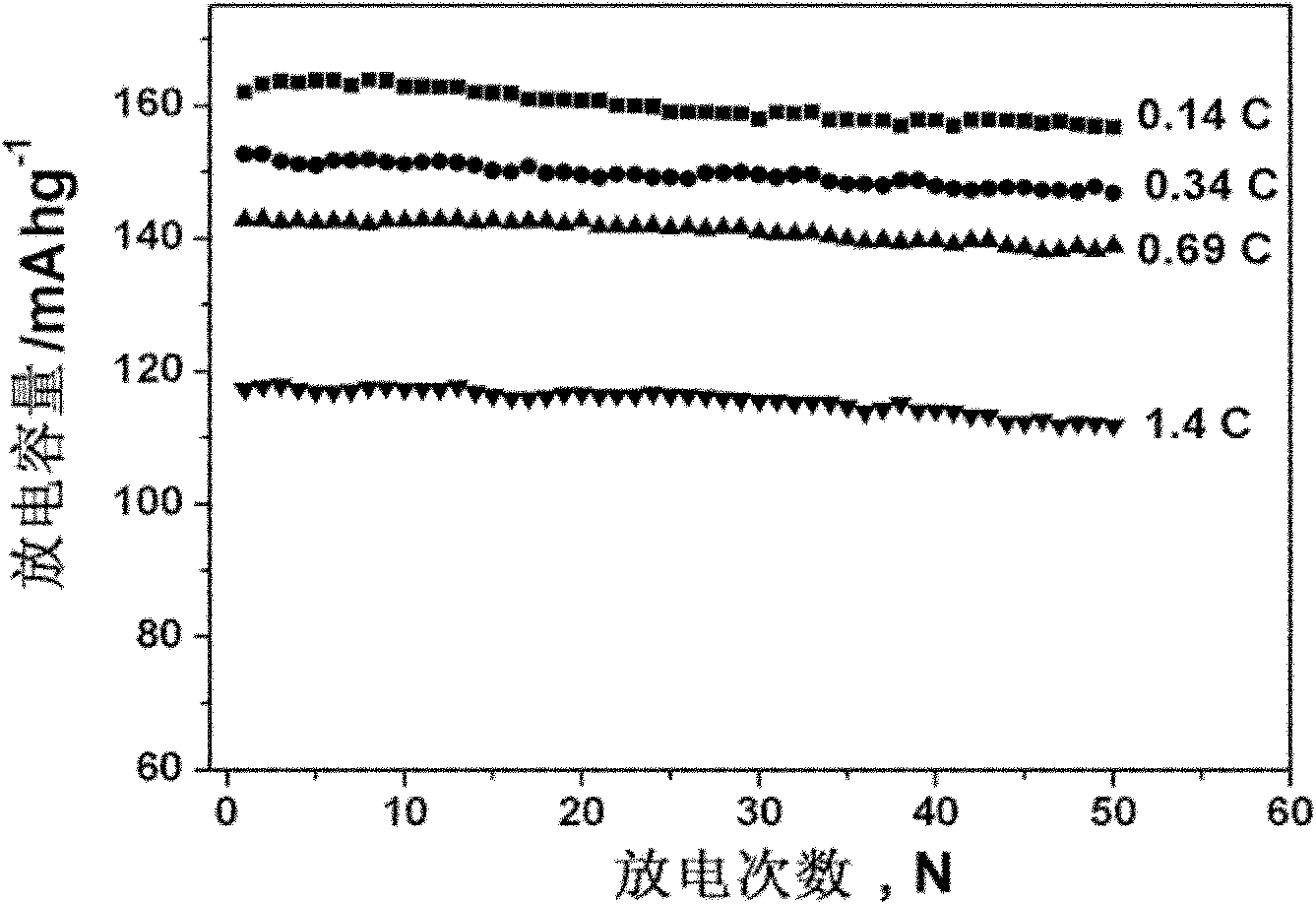

Preparation method of lithium ion battery anode composite material and special device thereof

InactiveCN102148368AEasy to prepareHigh bulk densityCell electrodesRadio frequencyIn situ polymerization

The invention discloses a preparation method of a lithium ion battery anode composite material and a special device thereof. The preparation method is characterized by comprising a first scheme, a second scheme and a third scheme, in the first scheme, a plasma-enhanced chemical vapor deposition method is used for synthesizing sp2-hybridized and carbon nano-material-coated lithium ion battery anode material LiFePO4 growing in-situ; in the second scheme, a direct plasma polymerization method is used for preparing LiFePO4 / conductive macromolecular composite material; and in the third scheme, a plasma in-situ polymerization method is used for preparing LiFePO4 / conductive macromolecular composite material. The special device for preparing the anode composite material comprises a plasma high-temperature quartz tube-type furnace, one end of the plasma high-temperature quartz tube-type furnace is provided with a reducing gas inlet pipe and a reaction gas inlet pipe and the other end of the same is provided with a gas suction pipe, and an inductance coupling plasma coil with two ends connected with radio frequency power sources is wound on the outer surface of the furnace. Tthe preparation method has the advantages of effectively improving the electric conductivity of the lithium ion battery and being simple in technological process, and the special device is simple in structure and convenient in operation.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

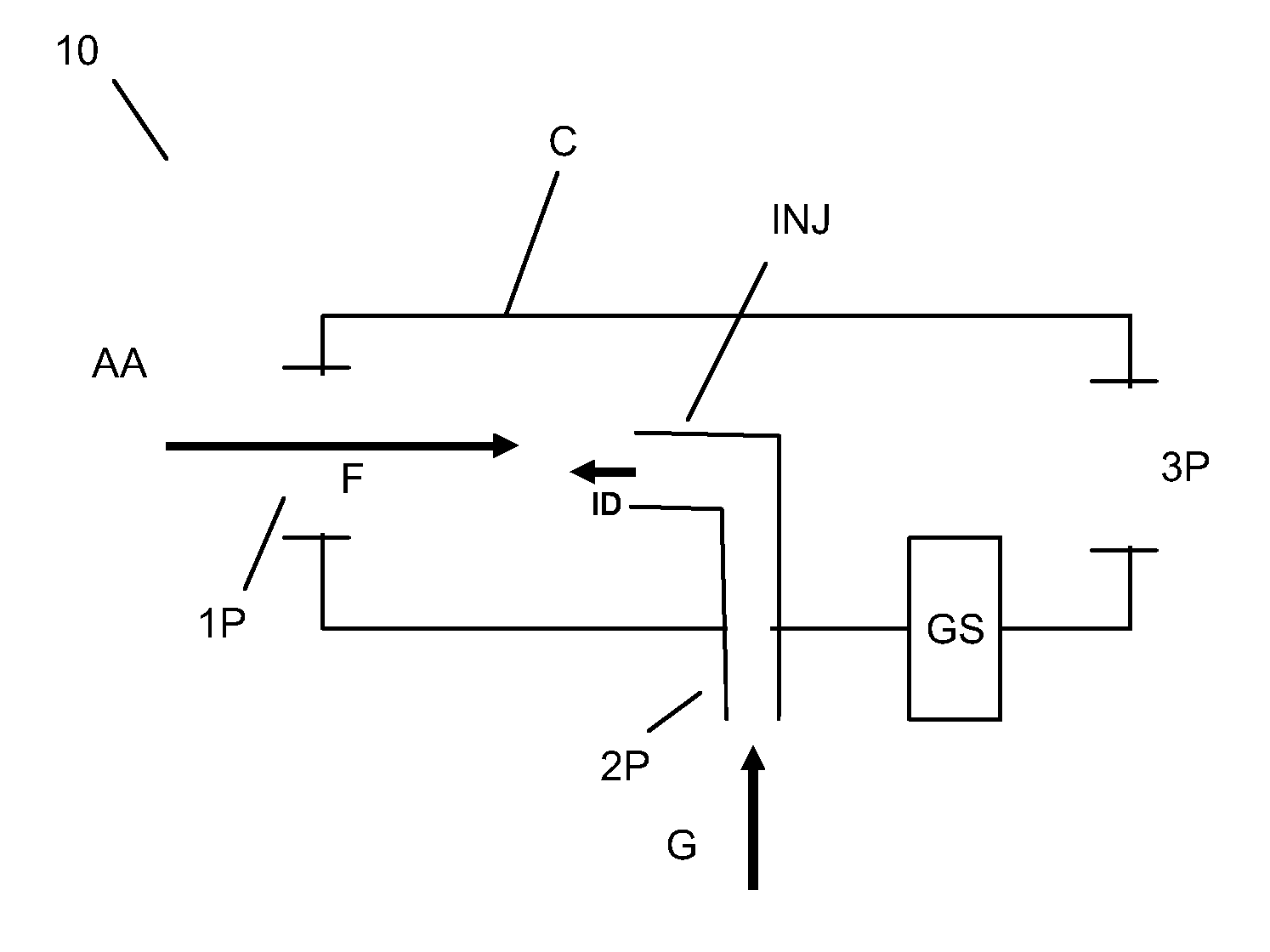

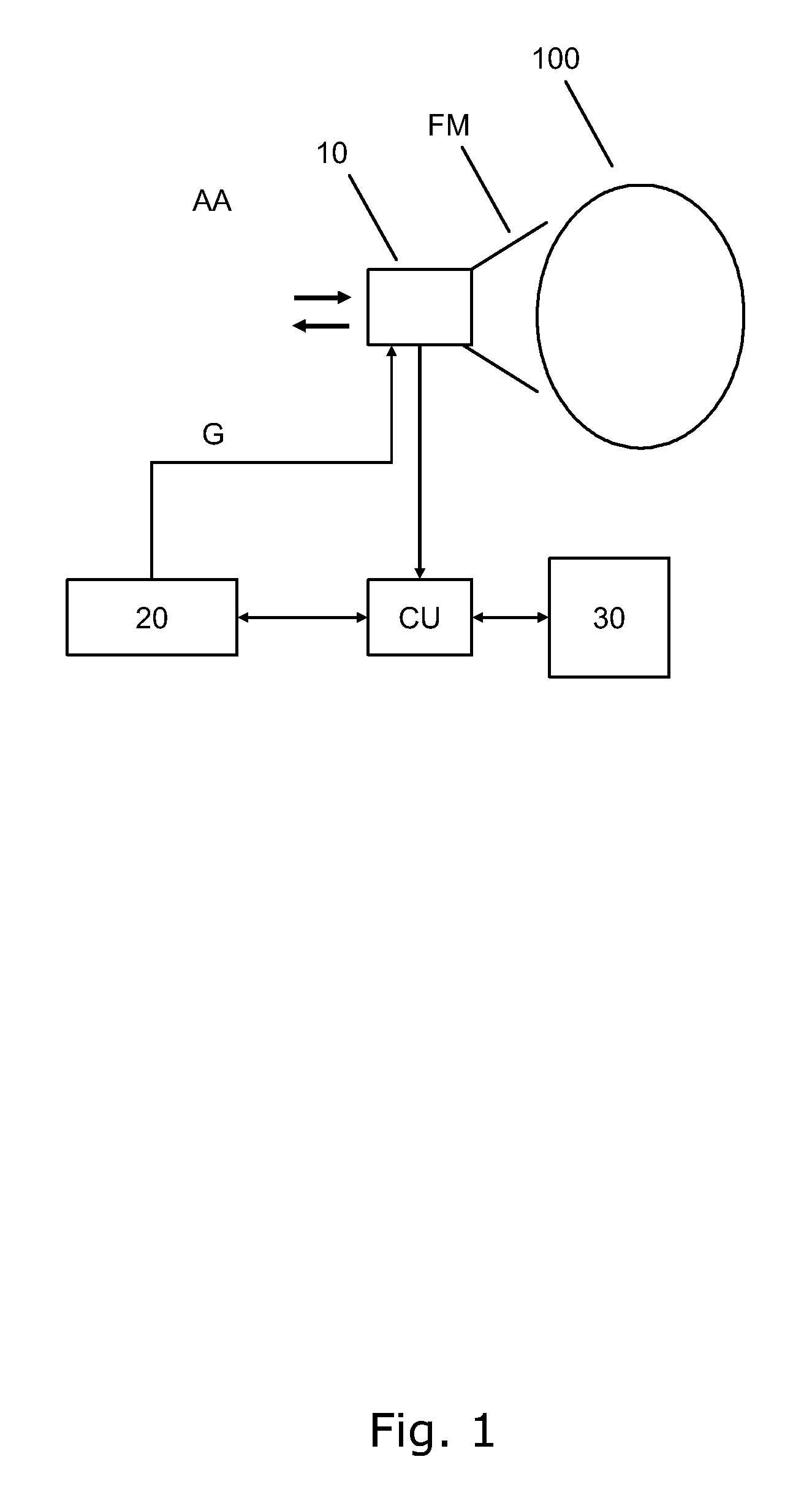

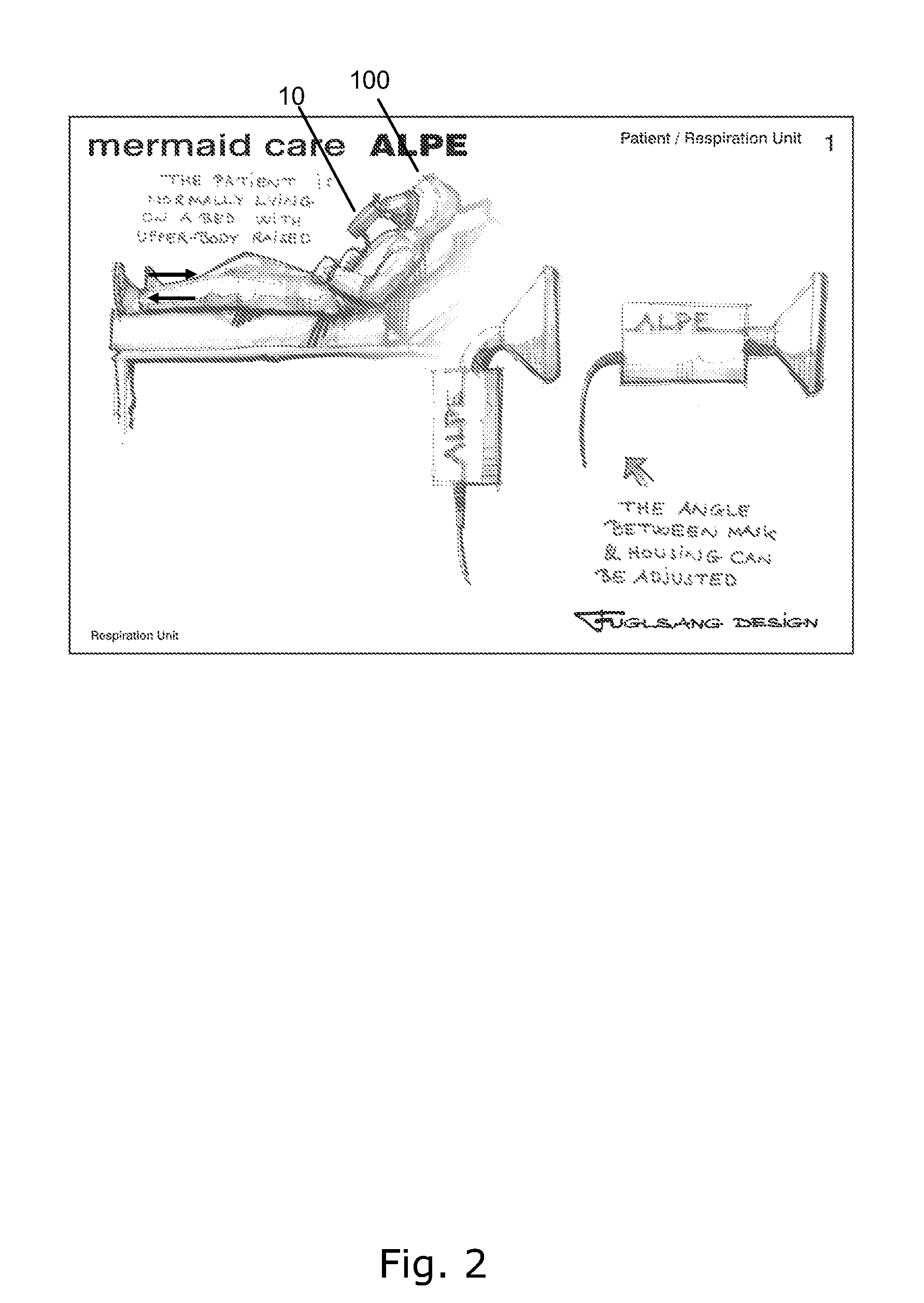

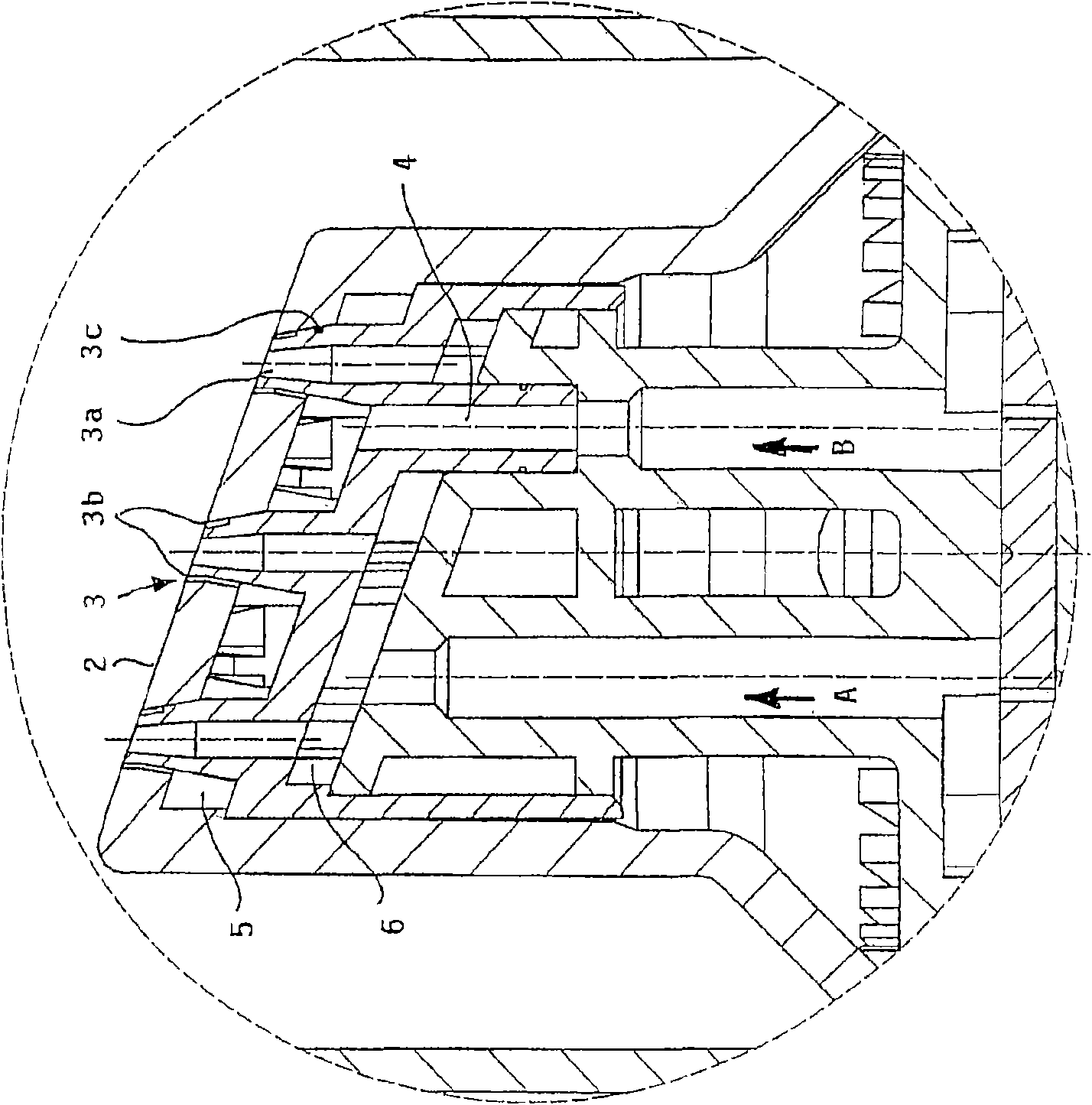

Gas mixing device for an air-way management system

InactiveUS20110319783A1Low breathing resistanceEasy to useRespiratorsMedical devicesAtmospheric airEngineering

The invention relates to a gas mixing device (10) for an air-way management system. The device has an elongated chamber (C) with a first gas inlet port (1P) being arranged for intake of atmospheric air (AA) into the chamber, the first inlet port being positioned at an end section of the internal chamber. Further, a second gas inlet port (2P) is arranged for intake of a gas (G) into the chamber (C), the second gas inlet port having an injector (INJ) from which the gas can exit into the chamber with an injection direction (ID), the injection direction having a projection (ID_proj) being oppositely directed relative to an in-flow direction (F) of the first gas inlet port (1P) so as to provide mixing of the atmospheric air and the gas. Opposite the first gas inlet port (1P) there is a breathing port (3P) for allowing an individual to breathe through the gas mixing device. The device is beneficial in that the breathing resistance is relatively low while the device simultaneously provides a sufficient gas mixing of the gasses to be mixed. Additionally, the invention provides a relatively compact gas mixing device which facilitates easy integration into e.g. a respiration mask for measurements of respiratory parameter of an individual e.g. a patient.

Owner:MERMAID CARE

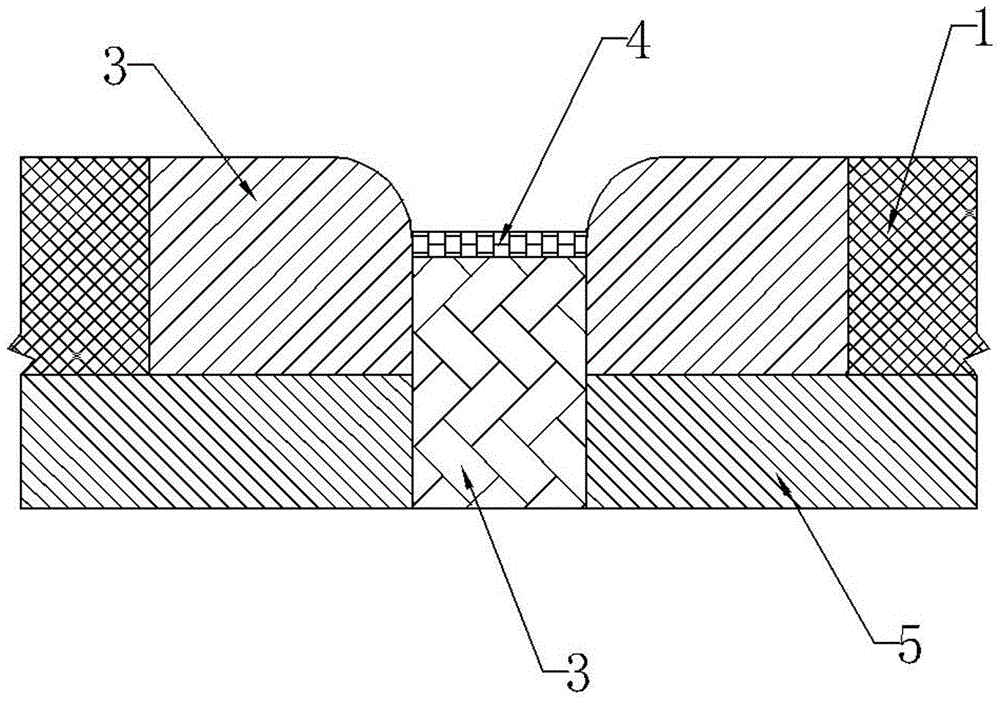

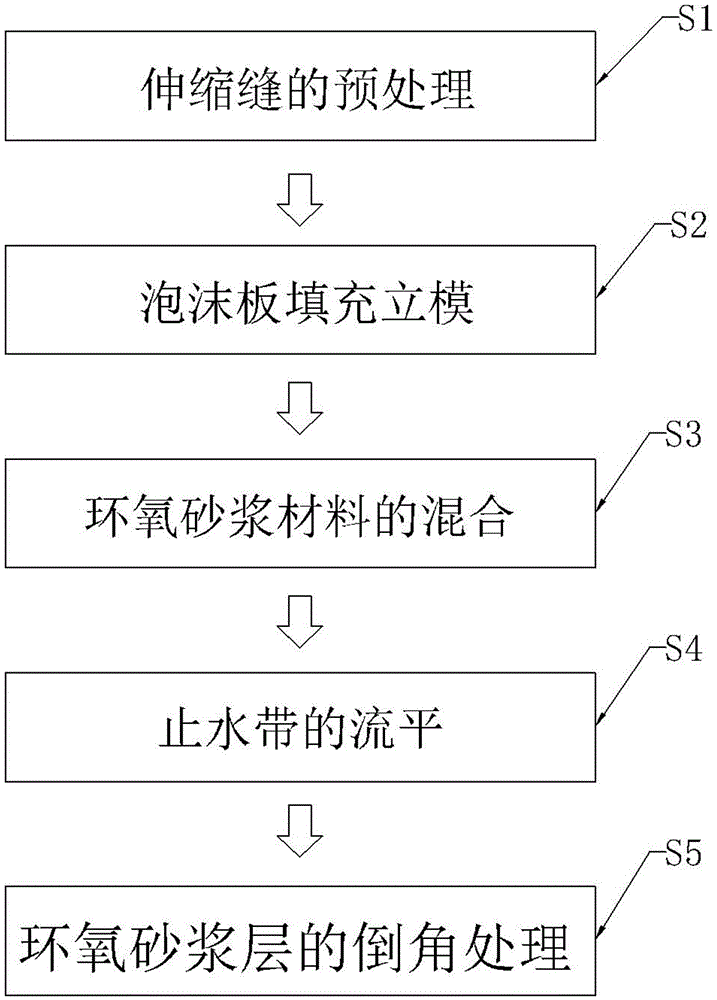

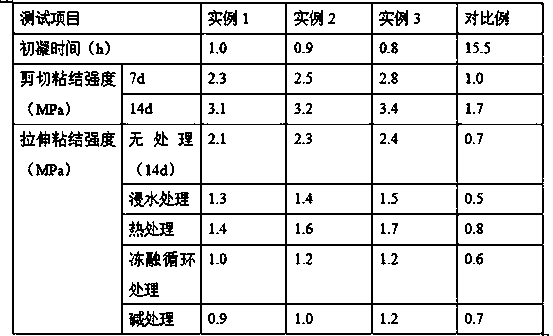

Epoxy mortar for bridge expansion joints and construction method thereof

InactiveCN105541180ALow viscosityHigh viscositySolid waste managementBridge structural detailsFirming agentArchitectural engineering

The invention relates to an epoxy mortar for bridge expansion joints and construction method thereof, and belongs to the technical field of building materials. The epoxy mortar material consists of a liquid A, a liquid B and a filler; and diamines D2000 and D230 are mixed as an epoxy curing agent. The curing agent has low viscosity, good compatibility with the epoxy resin, long working life, high bonding strength, good flexibility and thermal shock resistance, and can be applied to the epoxy mortar material capable of absorbing the stress. The epoxy mortar material mixed from the liquid A, liquid B and filler for construction of bridge expansion joints changes the condition that rigid concrete, which can to be easily damaged under impact stress, needs profile steel for protection in the traditional bridge expansion joint; epoxy mortar material substitutes the rigid concrete in traditional expansion joints, avoids a steel structure, and has good waterproof and seal performance; the expansion joints have color consistent with the color of the adjacent concrete or asphalt, so that the bridge is more beautiful; the expansion joints cannot cause vibration of vehicles when the vehicles pass by the expansion joints; and the noise generated by the vehicles is lower.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

Waterproof and suncare straw wood composite high density fiberboard and preparation method thereof

InactiveCN104999539AImprove fusion effectImprove consistencyDomestic articlesFlat articlesFiberMethacrylate

The invention discloses a waterproof and suncare straw wood composite high density fiberboard. The waterproof and suncare straw wood composite high density fiberboard is characterized by being prepared by the following raw materials in parts by weight: 42-45 of crop straws, a proper amount of sodium hydroxide with a concentration of 2%, 2-2.5 of silane coupling agents kh450, 66-70 of ethanol with a concentration of 95%, 30-32 of wood leftovers, 3-4 of methyl sodium silicate, 3-5 of nanometer titanium dioxide, 7-8 of waterborne polyurethane adhesive, 1.5-2 of microcrystalline wax, 0.03-0.05 of ammonium persulfate, 2-3 of methacrylate, and a proper amount of water. The methyl sodium silicate is added when fibers are treated in the formula, the methacrylate, the microcrystalline wax and the like are added when the fibers are glued, and the raw materials coact to greatly enhance the product water resistance and to prevent the corrosion caused by water seepage; and meanwhile, the suncare nanometer titanium dioxide is added, so that the produced product can replace a plastic board or a wood board, or even can be used outdoors.

Owner:ANHUI BAIYI FURNITURE

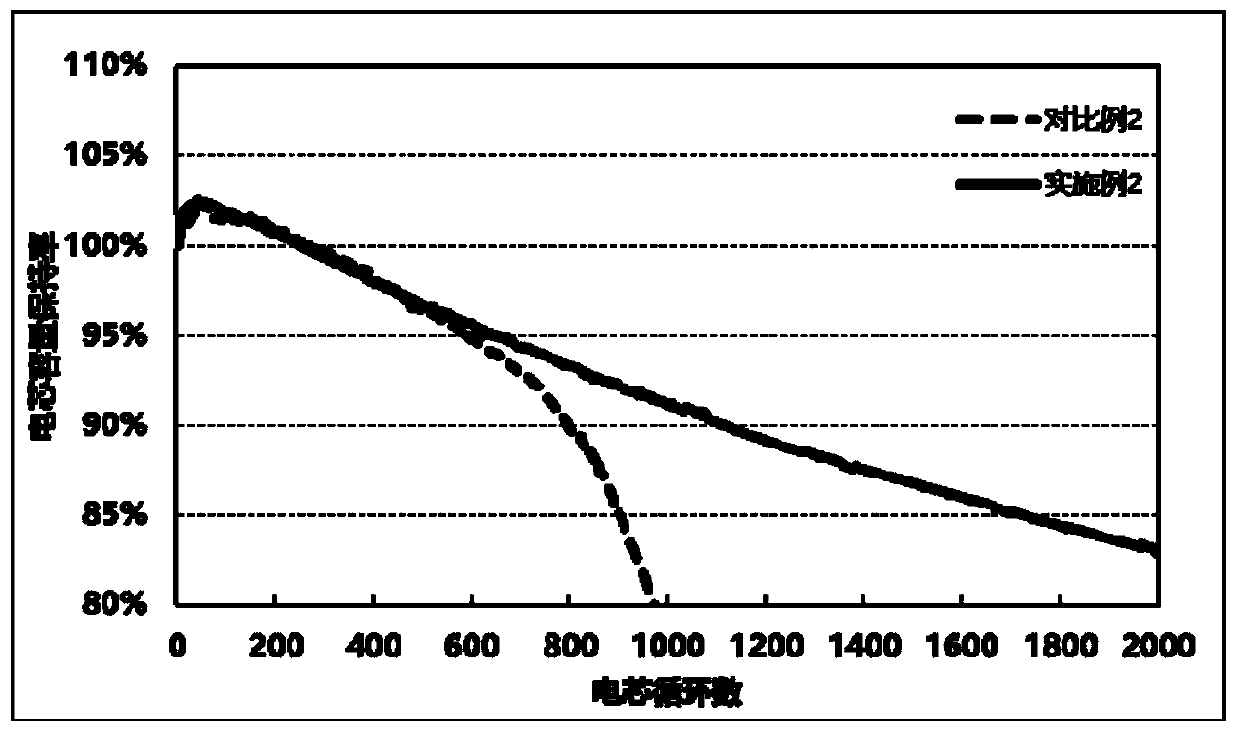

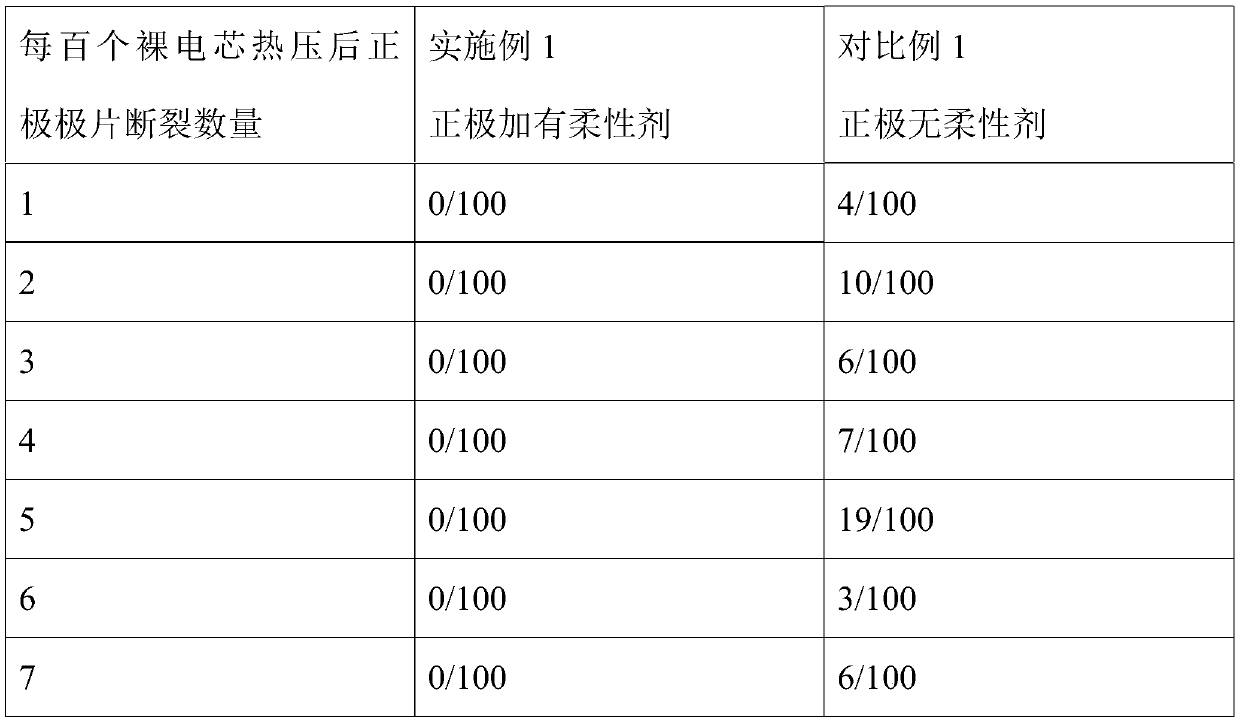

Lithium ion battery pole piece slurry, pole piece and preparation method and application thereof

ActiveCN110459773AImprove processing yieldImprove the safety of useSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon numberSlurry

The invention relates to lithium ion battery pole piece slurry, a pole piece and a preparation method and an application thereof. The pole piece slurry comprises an electrode active material, a conductive agent, a binder, a solvent and a flexibilizer, wherein the flexibilizer is alcohol with the carbon number of 2-5, and the volume percentage of the flexibilizer is 0.1-15% if it is assumed that the sum of the contents of the solvent and the flexibilizer is 100%. When the pole piece is prepared, the pole piece is prepared by mixing the flexibilizer into the pole piece slurry or coating the surface of the prepared pole piece with the flexibilizer so as to obtain a pole piece with low hardness and brittleness. Meanwhile, the invention further provides a method for reducing the fracture of thepole piece, which is realized by adding the flexibilizer into the pole piece. The probability of breakage of the positive pole piece provided by the invention in the processing and using processes isgreatly reduced, the processing yield and the use safety of the lithium ion battery are improved, the problem that powder falls off in the charging and discharging processes of the negative electrodeis overcome, and the service life of the lithium ion battery is prolonged.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

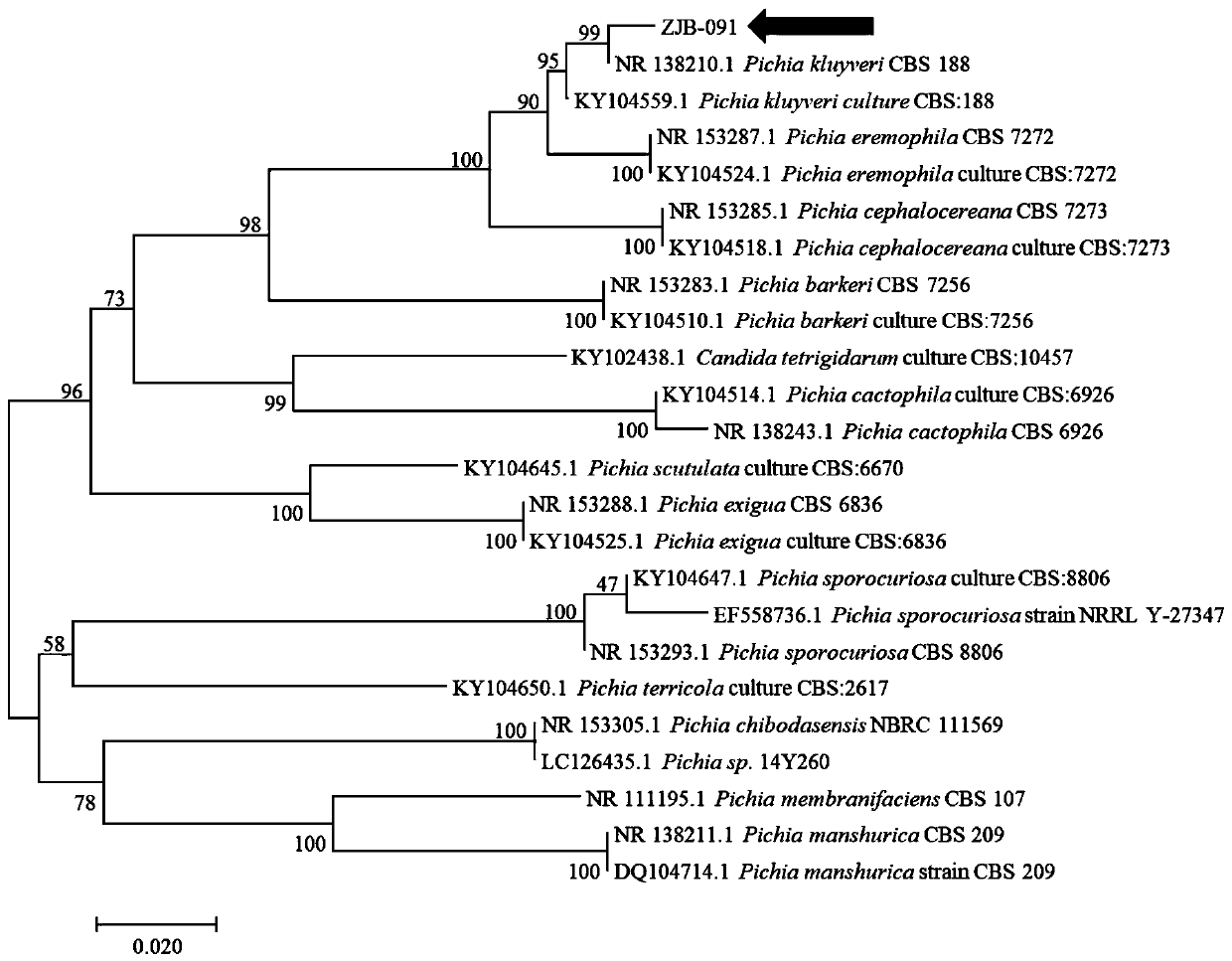

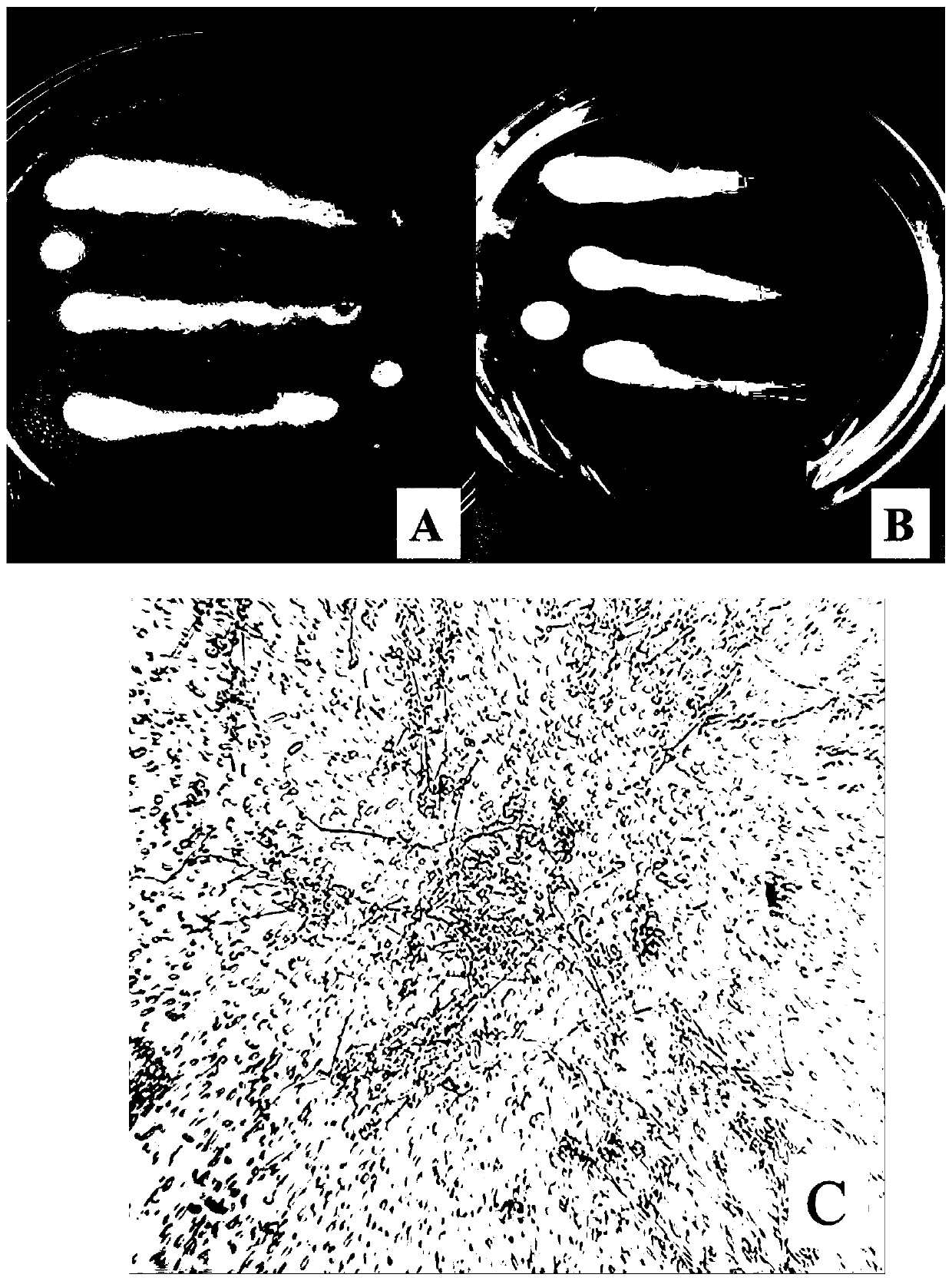

Preparation method of immobilized microbial agent for kitchen waste treatment and application thereof

ActiveCN110257365AHigh viable countAvoid lostTransportation and packagingSolid waste disposalHigh densityGeotrichum silvicola

The invention discloses a preparation method of an immobilized microbial agent for kitchen waste treatment and an application thereof. The method comprises the following steps: respectively performing high-density liquid fermentation on Kluyer pichia yeast and geotrichum silvicola, and mixing the bacterial liquids in proportion; after concentrating a composite bacterial solution, adding the composite bacterial solution to a modified carrier, mixing the materials, adding a crosslinking agent during a mixing process, and then performing constant temperature aeration culture; and after constant temperature aeration, performing low temperature drying to obtain the immobilized microbial agent. The method of the invention not only significantly increases the amount of carrier immobilized thalline, but also makes the binding between the carrier and the thalline tight, prevents the living bacteria from being lost in the preparation process and the preservation, improves the live bacteria of the unit mass of the microbial agent, and reduces the amount of the microbial agent; The prepared microbial agent has strong capability for decomposing the kitchen waste, the odor generated in the process of degrading the kitchen waste can be eliminated, the amount of the thalline immobilized in the carrier is large, the binding between the carrier and the thalline is closer, and the biomass of the living bacteria is large.

Owner:ZHEJIANG UNIV OF TECH

Waterproof and moisture-proof enhanced type high-density fiberboard and preparation method thereof

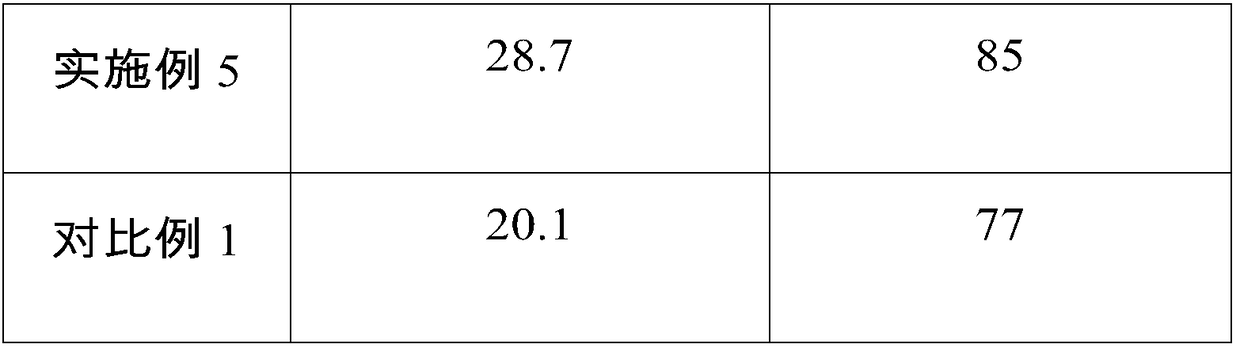

InactiveCN105171885AMix tightlyLower waxy layerFlat articlesDomestic articlesPolyurethane adhesivePeroxydisulfate

The invention discloses a waterproof and moisture-proof enhanced type high-density fiberboard. The waterproof and moisture-proof enhanced type high-density fiberboard is characterized by being prepared from, by weight, 42-45 parts of crop straw, 30-32 parts of wood scraps, a proper amount of sodium hydroxide with the concentration of 2%, 2-2.5 parts of silane coupling agents kh450, 66-70 parts of ethyl alcohol with the concentration of 95%, 7-8 parts of waterborne polyurethane adhesives, 1.5-2 parts of emulsified paraffin, a proper amount of water, 0.5-0.6 part of OP-10, 0.015-0.02 part of potassium peroxydisulfate and 3-4 parts of polypropylene fibers. A large number of crop straw and wood scraps replace wood, so that a large number of forest resources are saved and the production cost is reduced. The fibers are processed through the polypropylene fibers and the like, in the hot pressing process, the polypropylene fibers are molten at high temperature and soaked among the fibers, the waterproofness of products is enhanced by cooperation of the polypropylene fibers, the waterborne polyurethane adhesives and other components, the tenacity is good and particles are fine and smooth.

Owner:ANHUI BAIYI FURNITURE

Sheath material with scrape and friction resistance, low friction, low smoke and zero halogen, and flame retardation as well as preparation method thereof

InactiveCN107082942AWith wear resistanceFlame retardantPlastic/resin/waxes insulatorsSilanesEthylic acid

The invention discloses a sheath material with scrape and friction resistance, low friction, low smoke and zero halogen, and flame retardation. The sheath material comprises the following components in parts by weight: 10-15 parts of EVA, 2-5 parts of a silane coupling agent, 70-90 parts of a flame retardant, 5-8 parts of a lubricant, 5-8 parts of a compatilizer, 2-5 parts of a smoke suppressant, 2-5 parts of a viscosifier, 8-10 parts of a flow promoter, 1-5 parts of an anti-oxidant, and 5-8 parts of a flexibilizer. EVA is used as a carrier, the silicone coupling agent is used as a main component, aluminium powder is used as a fire retardant, blending and granulation are carried out in order to produce a high-molecular material silicone master batch, high density polyethylene is used as a compatilizer, so that an ethylene and acetic acid copolymer and the inorganic fire retardant aluminium powder are fully mixed and tightly combined; silicon system and molybdenum system compounds are added into the material formula system as lubricants in order to reduce the friction coefficient of the material surface; halogen is not contained in the material, so that halogen free performance of cables is guaranteed, and environmental protection benefits are provided. The sheath material has the advantages of flame retardation, low friction, scrap and friction resistance, and the like; and the sheath material can be applied to outdoor wiring systems, in order to improve wiring quantity and wiring length.

Owner:HEFEI XINGLIAN COMM

Rough-wrought charing bagasse fertilizer and preparation method thereof

InactiveCN104829303AMix tightlyGood sustained release effectFertilizer mixturesSodium bicarbonateCellulose

The invention discloses a rough-wrought charing bagasse fertilizer and a preparation method thereof. The rough-wrought charing bagasse fertilizer comprises the following raw materials by weight part: 30-50 parts of bagasse, 8-15 parts of wheat straw, 5-10 parts of dolomite powder, 1-2 parts of sodium bicarbonate, 20-30 parts of peat soil, 10-15 parts of decay leaf, 10-15 parts of 1mol / L hydrochloric acid solution, 15-20 parts of potassium nitrate, 14-18 parts of ammonium bicarbonate, 15-18 parts of calcium-magnesia phosphate fertilizer, 7-9 parts of calcium ammonium nitrate, 10-14 parts of urea, 4-5 parts of cross-linking agent and a proper amount of water. The rough-wrought charing bagasse fertilizer has the advantages of treatment of charing particle and selection of a coating agent, the charing particles select bagasse with high cellulose amount as a material, high temperature sealing and charing are carried out, dilute hydrochloric acid is used for immersing and washing to obtain a porous active carbon structure, dilute hydrochloric acid and a pulvis chemical fertilizer are tightly mixed, slow release effect is good, the coating agent is prepared by stone flour can provide a structural framework, the added sodium bicarbonate can be decomposed after being heated to leave the micropores, and water absorption and cracking are convenient.

Owner:TONGLING JIAYAN ECOLOGICAL AGRI DEV

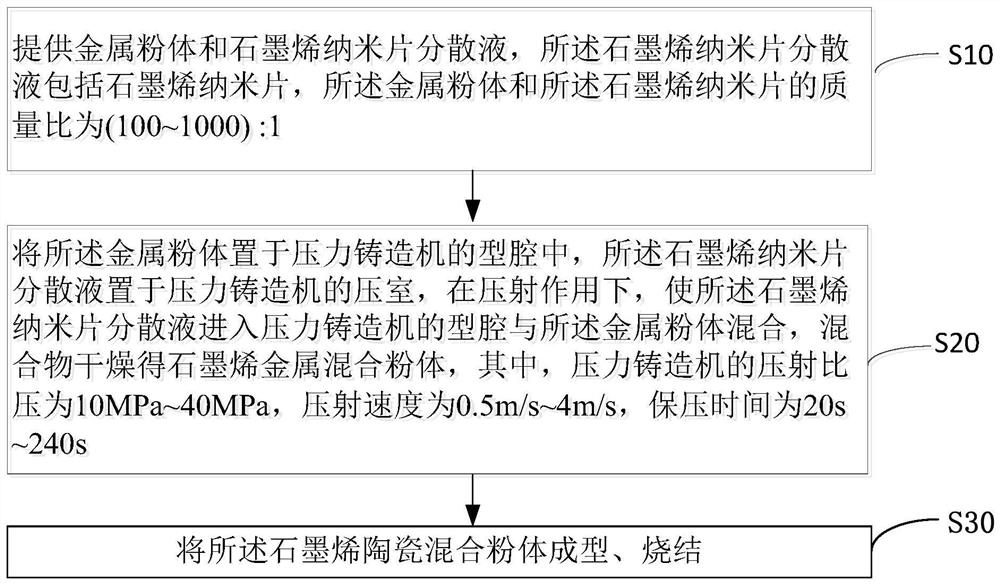

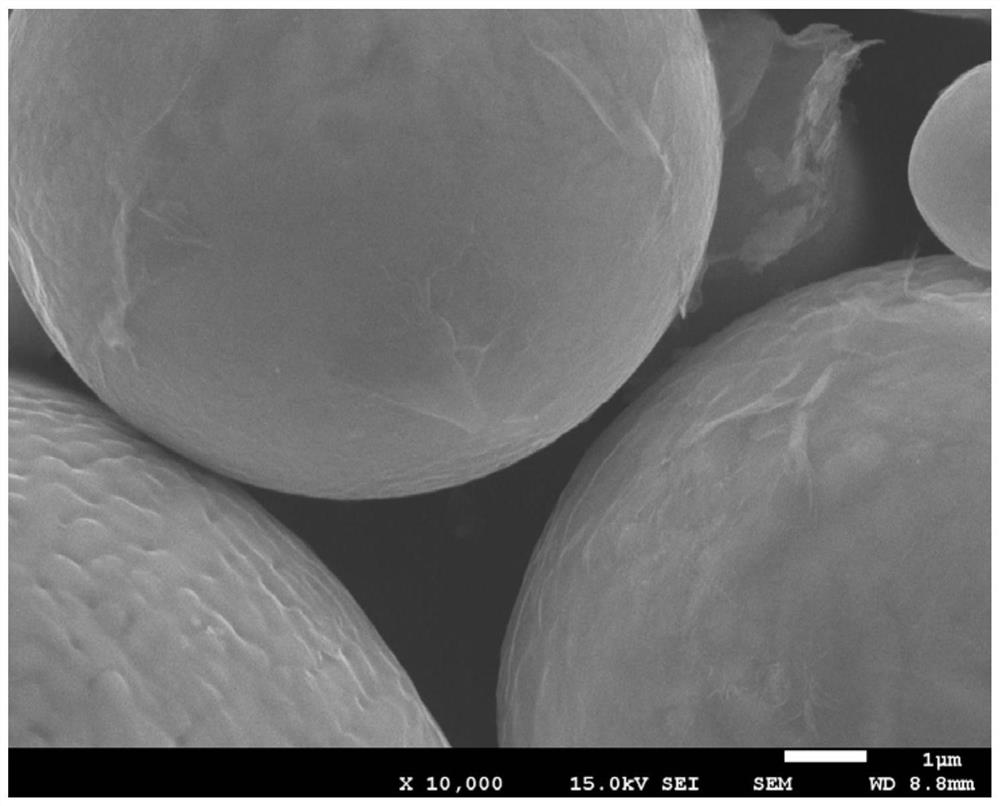

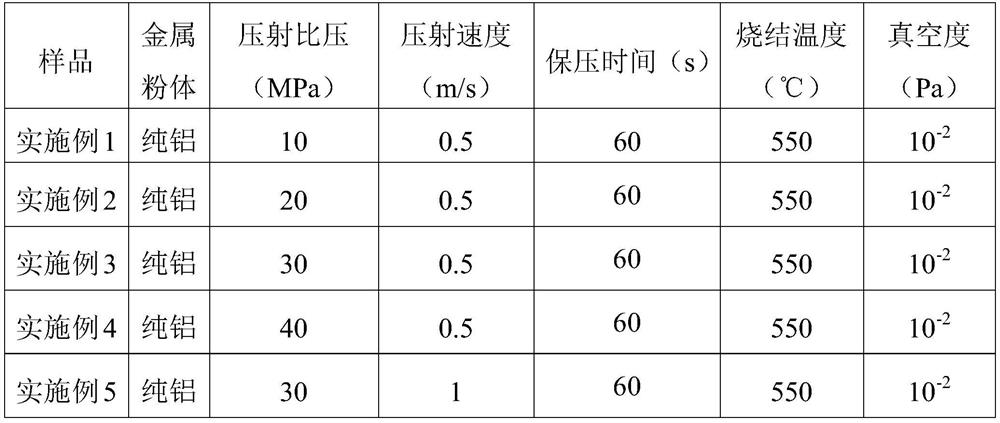

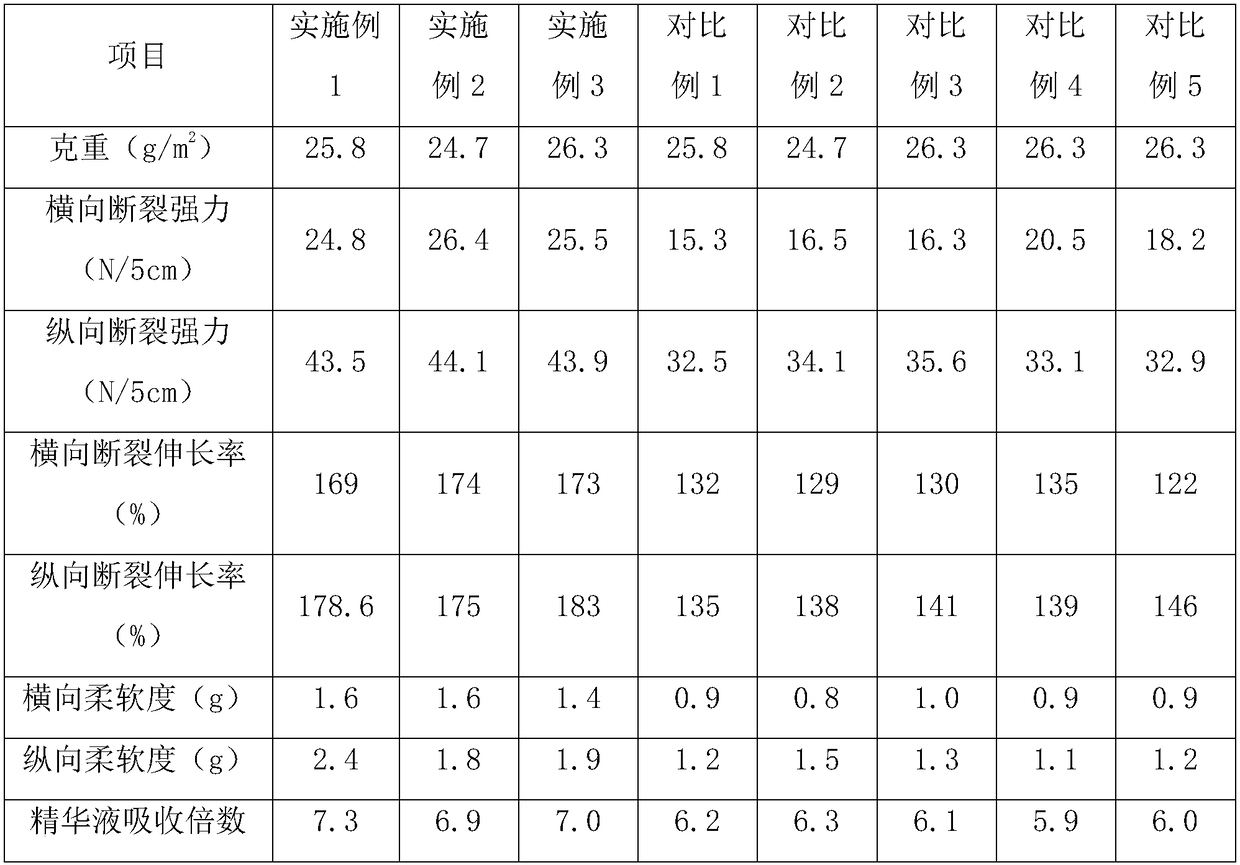

Graphene modified metal composite material, preparation method and workpiece

ActiveCN112853142AImprove fracture toughnessImprove thermal conductivityTransportation and packagingMetal-working apparatusPressure castingGraphite

The invention relates to a preparation method of a graphene modified metal composite material. The preparation method comprises the following steps that metal powder and a graphene nanosheet dispersion liquid are provided, the graphene nanosheet dispersion liquid comprises graphene nanosheets, and the mass ratio of the metal powder to the graphene nanosheets is (100-1000): 1; the metal powder is placed in a cavity of a pressure casting machine, the graphene nanosheet dispersion liquid is placed in a pressure chamber of the pressure casting machine, the graphene nanosheet dispersion liquid enters the cavity of the pressure casting machine to be mixed with the metal powder under the action of injection, the mixture is dried, and graphene metal mixed powder is obtained, the injection specific pressure of the pressure casting machine ranges from 10 MPa to 40 MPa, the injection speed ranges from 0.5 m / s to 4 m / s, and the pressure maintaining time ranges from 20 s to 240 s; and the graphene metal mixed powder is formed and sintered. The invention further relates to the graphene modified metal composite material and a workpiece.

Owner:北京石墨烯技术研究院有限公司

Graphene non-woven fabric and manufacturing method thereof

InactiveCN108691099AEvenly heatedEasy to addMelt spinning methodsConjugated synthetic polymer artificial filamentsCvd grapheneWoven fabric

The invention provides graphene non-woven fabric and a manufacturing method thereof. The method comprises the steps of uniformly mixing non-woven fabric raw materials with graphene master batches, afterwards, putting the mixture under a vacuum condition for extrusion fusion, and then preparing the graphene non-woven fabric through the sequential steps of yarn jetting, drafting, lapping, hot rolling and the like. In the preparing process of the graphene master batches, graphene is endowed with negative charges through an electrostatic sprayer, so that graphene is more closely combined with thenon-woven fabric raw materials. Water and clove oil are also added in the preparing process of the graphene master batches, so that the internal mixing effect is good, and the performance of the graphene master batches is improved. In the graphene non-woven fabric, the graphene master batches are uniformly distributed in the non-woven fabric raw materials, so that the prepared graphene non-woven fabric is uniform in performance and high in strength and has performance of good adsorbability, infrared ray absorption, bacteria resistance and inhibition and the like.

Owner:山东恒鹏卫生用品有限公司

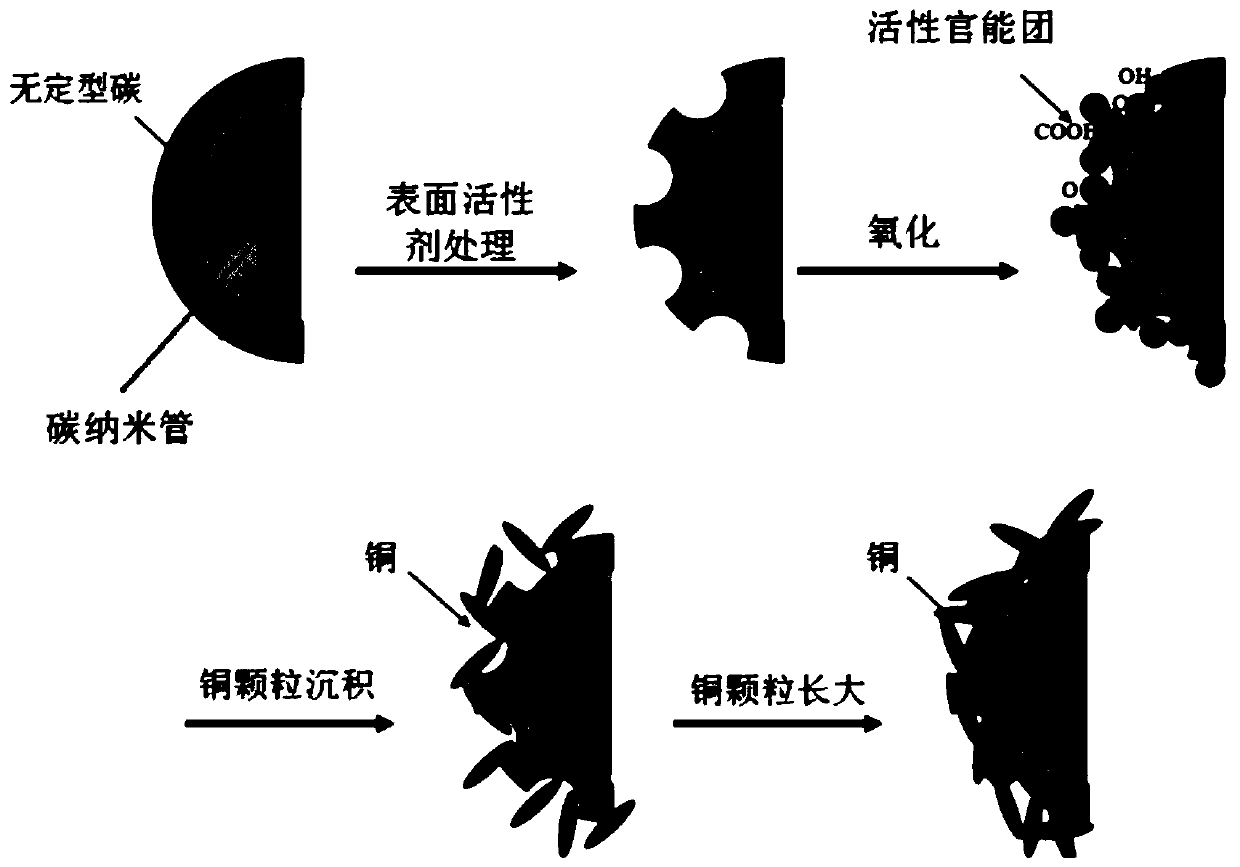

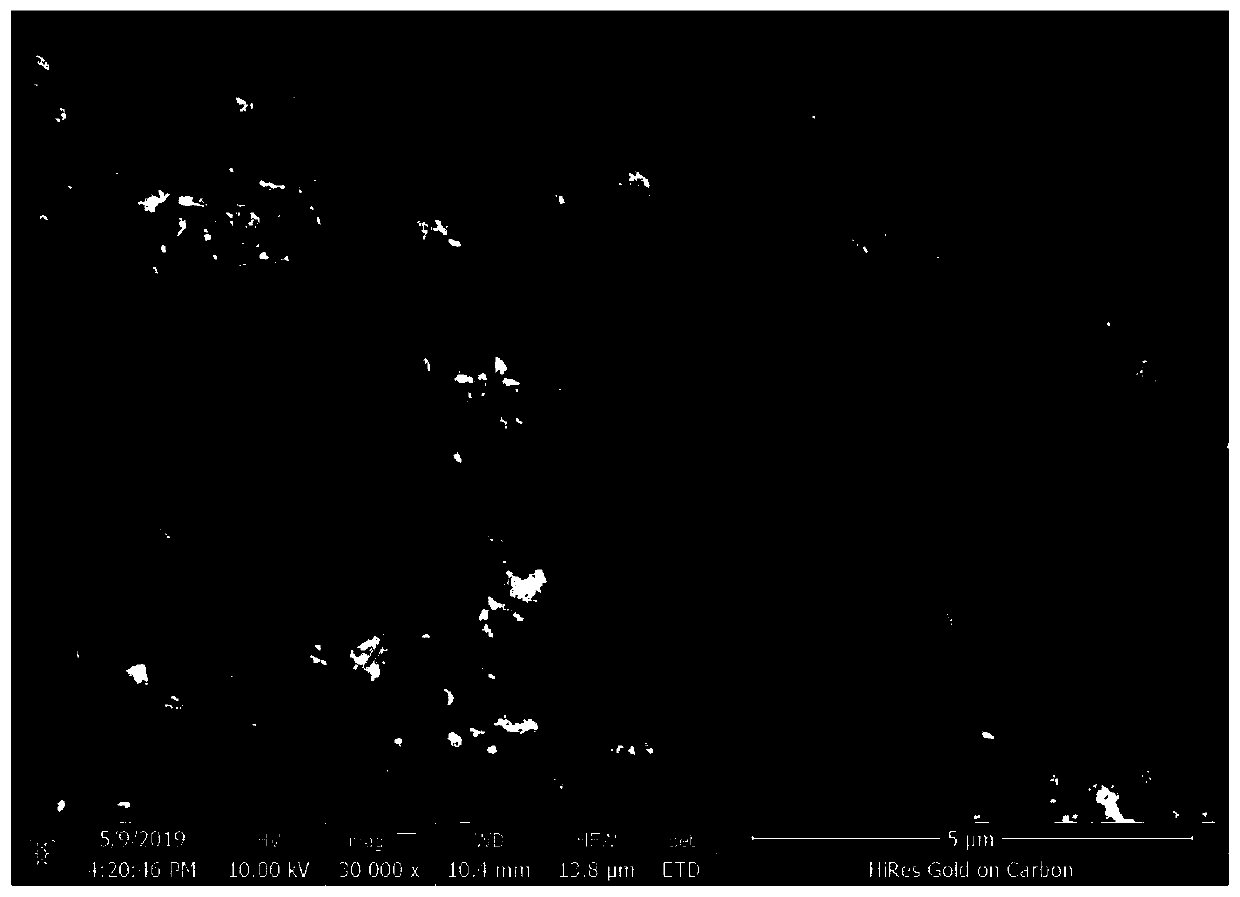

Low-melting-point metal-water-based conductive composite slurry and preparation method thereof

ActiveCN110189849AImprove performanceMix tightlyNon-conductive material with dispersed conductive materialCable/conductor manufactureChemical platingCarbon nanotube

The invention discloses low-melting-point metal-CNTS / Cu water-based conductive composite slurry. The low-melting-point metal-CNTS / Cu water-based conductive composite slurry comprises the following components in percentage by mass: 50-80% of a mixed conductive phase, 5-15% of tin powder or bismuth powder, 15-30% of a water-based carrier, 0.1-0.5% of an additive P and 0.1-4.5% of an additive Ga, wherein the total amount is 100%. The present invention further discloses a preparation method of low-melting-point metal-CNTS / Cu water-based conductive composite slurry. In the product and the preparation method thereof, the mixed conductive phase is prepared by employing a chemical plating method, so that the combination of the copper and a carbon nano tube is more compact and uniform; the low-melting-point metal tin or bismuth is used as a new bonding phase, so that the sintering temperature can be reduced, and the comprehensive performance of the slurry is improved; and the water-based carrier is environment-friendly, so that the cost is obviously reduced.

Owner:扬州虹运电子材料有限公司

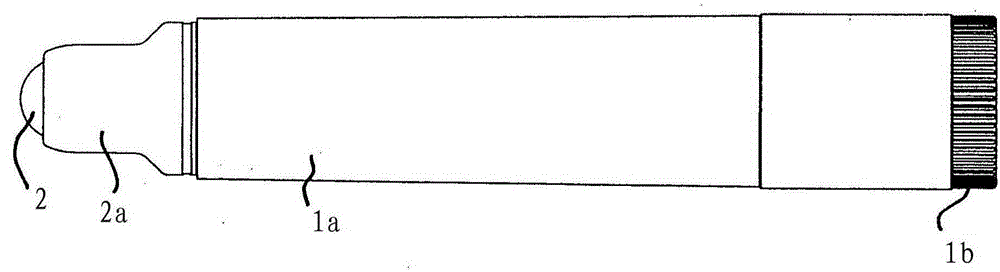

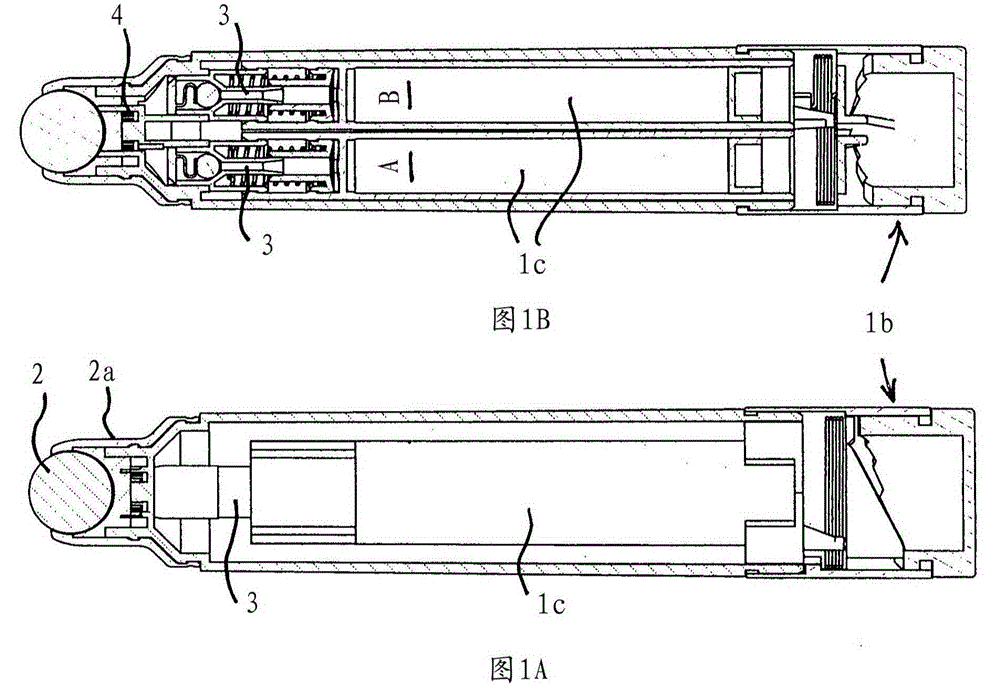

Application dispenser for at least one component

ActiveCN105188464AReliable wettingReliable fillingFlow mixersMixer accessoriesBiomedical engineering

Owner:格哈德·布鲁格

Lightweight crack-resistant adhesive mortar

InactiveCN110357658AHigh bonding strengthImprove thermal insulation performanceCeramicwareCrack resistanceThermal insulation

The invention discloses a lightweight crack-resistant adhesive mortar. The raw materials of the lightweight crack-resistant adhesive mortar include, by weight, 25-35 parts of dried sands, 15-25 partsof biochar, 8-15 parts of a modified mica powder, 20-30 parts of 525 cement, 2-8 parts of redispersible latex powder, 0.1-0.7 part of hydroxypropyl methylcellulose, 0.5-1.5 parts of starch ether and 0.5-2 parts of a silane coupling agent. The lightweight crack-resistant adhesive mortar provided by the invention has the characteristics of small self-weight, high bonding strength, good thermal insulation property and good crack resistance, and is suitable for the building exterior wall thermal insulation system.

Owner:蚌埠市阿尔贝斯建材有限公司

Antibacterial and environment-protection building joint mixture

InactiveCN108641635AMaintain aestheticsMaintain durabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAcrylic resin

The invention mainly relates to the technical field of joint mixture processing,and discloses an antibacterial and environment-protection building joint mixture. The joint mixture is prepared from,a water-based acrylic resin,natural latex,a starch glue,waste porcelain powder,nano eggshell powder,nail sodium silicate,a polycarboxylate water reducer,zinc sulfate,nano titanium dioxide and tourmalineanion powder; the antibacterial and environment-protection building joint mixture is green and environment-protection,does not contain toxic reagents,does not emit irritating odor,and can effectivelyinhibit bacteria and mildew,the inhibition rate reaches 93.7%,and the aesthetics and durability of a building are maintained; the water-based acrylic resin and the natural latex are mixed and slowly stirred to avoid bubble generation,the flow state of the joint mixture is maintained,convenience is provided for extrusion and seam filling during use,the mixture is tightly combined with a seam,the addition of the zinc sulfate can increase the viscosity of the joint mixture,the joint mixture is made in close contact with tiles,marbles and wood products,the antibacterial activity of the joint mixture is improved,and mildew and discoloration of the joint mixture are avoided.

Owner:含山县金中环装饰材料有限公司

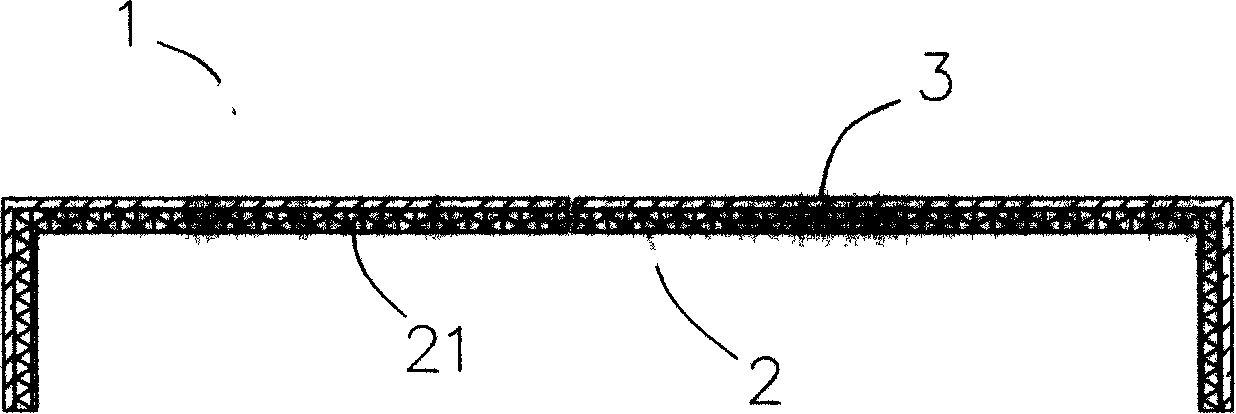

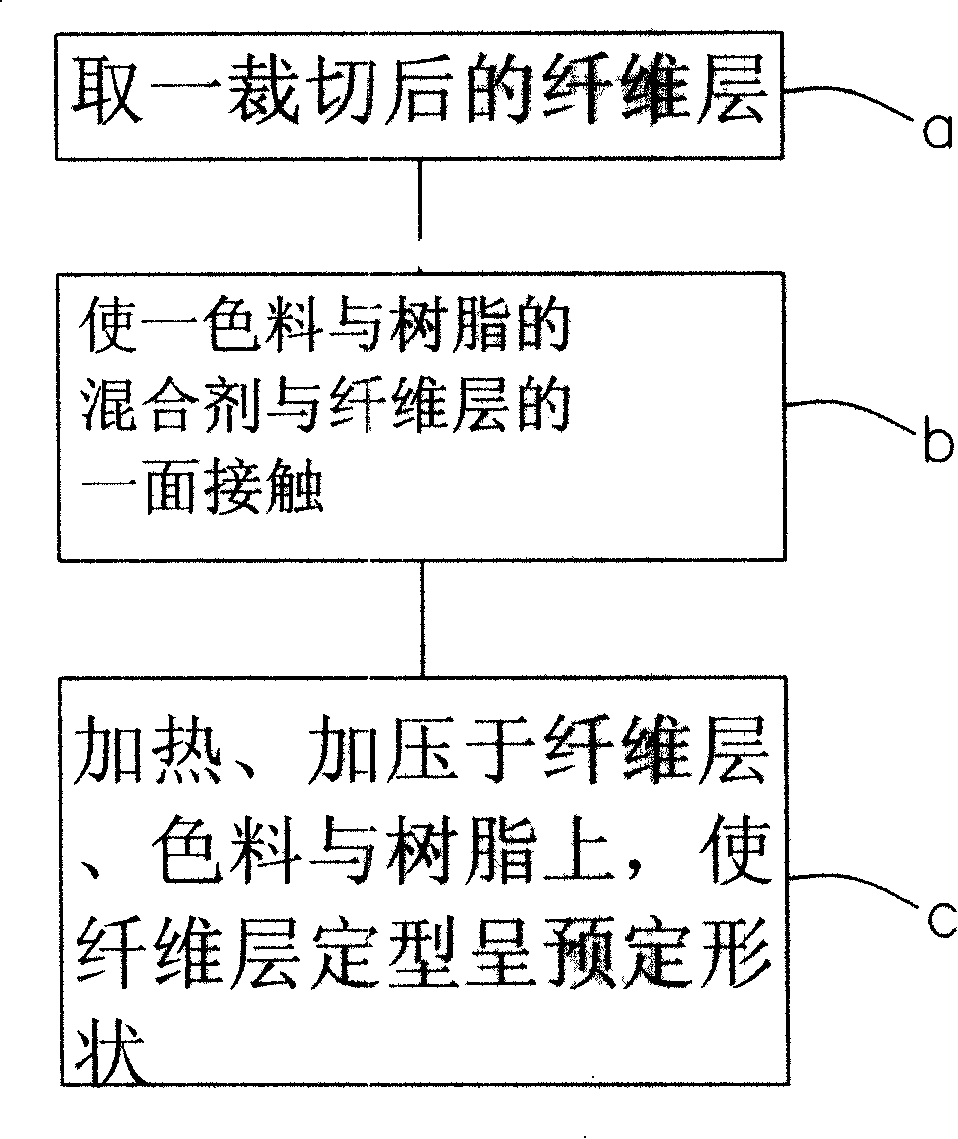

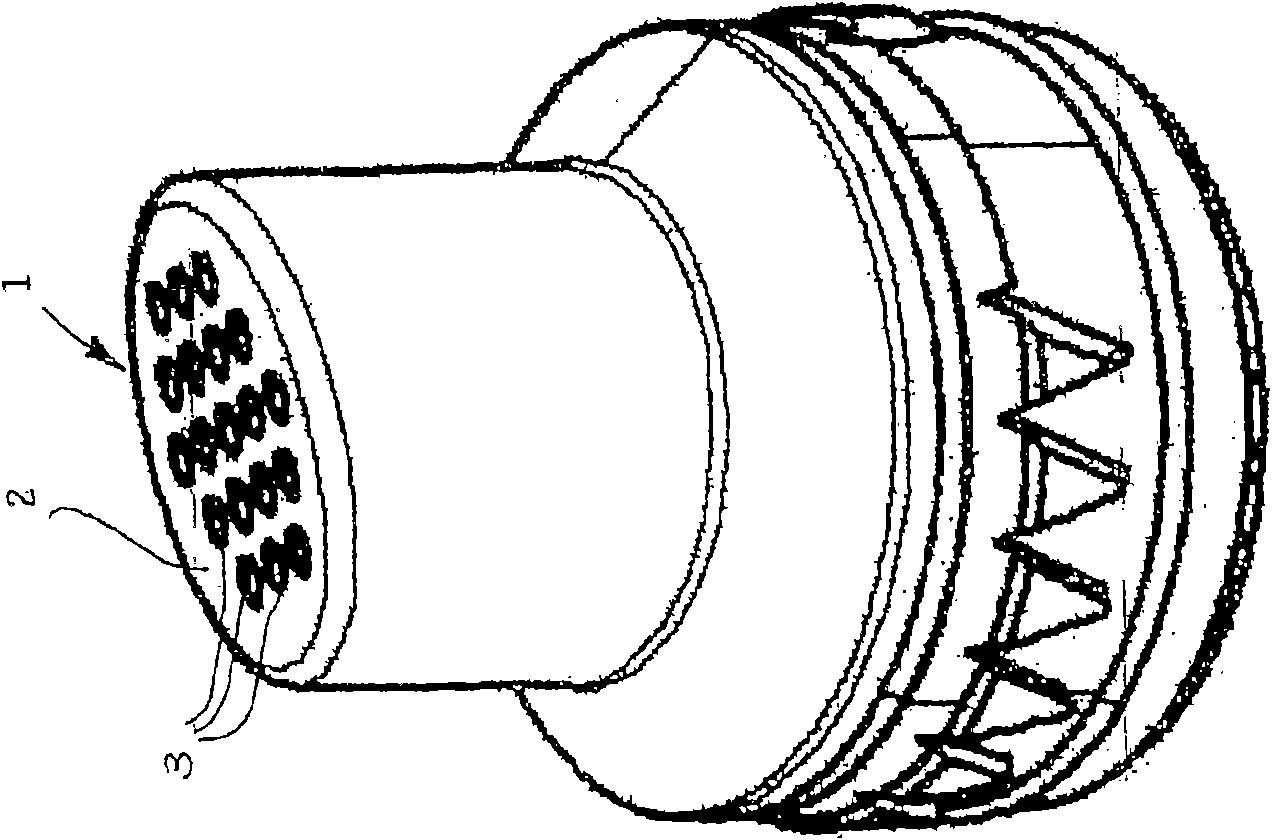

Manufacturing method of colored panel and products produced thereby

InactiveCN101239519AIncrease attractivenessAvoid wastingLamination ancillary operationsDigital data processing detailsPolyresinFiber layer

The invention discloses a kind of colored panel and the manufacturing method. The cutting fiber surface is sprayed with a mixture of coloring matter and resin, and then heated and pressed with them to make the fiber layer mould with the prescheduled shape. The mixture is first sprayed onto the mould cave of the mould, then fiber is put on the mixture layer; or the mixture of colored matter and resin is sprayed one surface of the fiber layer, then it is put into the mould cave, after heating and pressure, the fiber layer can be molded to a panel and the panel can display color and the fiber stereo texture.

Owner:HOCHENG CORPORATION

Stone plastic board and processing method thereof

PendingCN109897302AReduce mutual disengagementImprove surface strengthSynthetic resin layered productsLaminationColor filmLubricant

The invention relates to the technical field of building materials, and specifically relates to a stone plastic board, which comprises a substrate layer, a color film layer, and a UV layer from bottomto top. The substrate layer is prepared from following raw materials in percentage by weight: 52.5 to 72.5% of calcium powder, 20 to 30% of PVC powder, 2.5 to 8.5% of a lubricant, and 5 to 9% of a reinforcing agent. The color film layer is prepared from PVC. The stone plastic board is nontoxic and environmentally friendly, and is harmless to the environment and humans. The substrate layer mainlymade of PVC powder and the color film layer made of PVC can be better combined.

Owner:上海普濡建材科技有限公司

Applicator for two or more components

InactiveCN101636332AMix tightlyImprove the mixing effectLiquid surface applicatorsPackaging toiletriesEngineering

Owner:格哈德·布鲁格

Brucite-fiber-reinforced high-density fiberboard and preparation method thereof

InactiveCN105108874AImprove fusion effectImprove consistencyDomestic articlesFlat articlesWater basedFiber

The invention discloses a brucite-fiber-reinforced high-density fiberboard. The brucite-fiber-reinforced high-density fiberboard is characterized by being prepared from the following raw materials in parts by weight: 42-45 parts of crop straws, 30-32 parts of wood scraps, a proper amount of sodium hydroxide with a concentration of 2%, 2-2.5 parts of a silane coupling agent kh450, 66-70 parts of ethanol with a concentration of 95%, 1-2 parts of ethylene glycol monostearate, 7-8 parts of a water-based polyurethane adhesive, 1.5-2 parts of emulsion paraffin, a proper amount of water, 2-3 parts of chromium sesquioxide, 5-7 parts of brucite fibers and 1-2 parts of a pure acrylic emulsion. According to the brucite-fiber-reinforced high-density fiberboard, lots of crop straws and wood scraps are adopted to replace wood, so that lots of wood resources can be saved; as chromium sesquioxide, the brucite fibers and other ingredients are added and compounded, the product strength and acid and alkali resistance can be improved; and the prepared brucite-fiber-reinforced high-density fiberboard is excellent in water resistance, high in breaking strength and smooth in surface, and can serve as base materials of composite wood floors, door panels, partitions, packing materials and the like.

Owner:ANHUI BAIYI FURNITURE

System and method for reducing the amount of sulfur oxides in exhaust gas

InactiveCN109152979AUniform compositionShorten speedGas treatmentInternal combustion piston enginesSulfurSpray tower

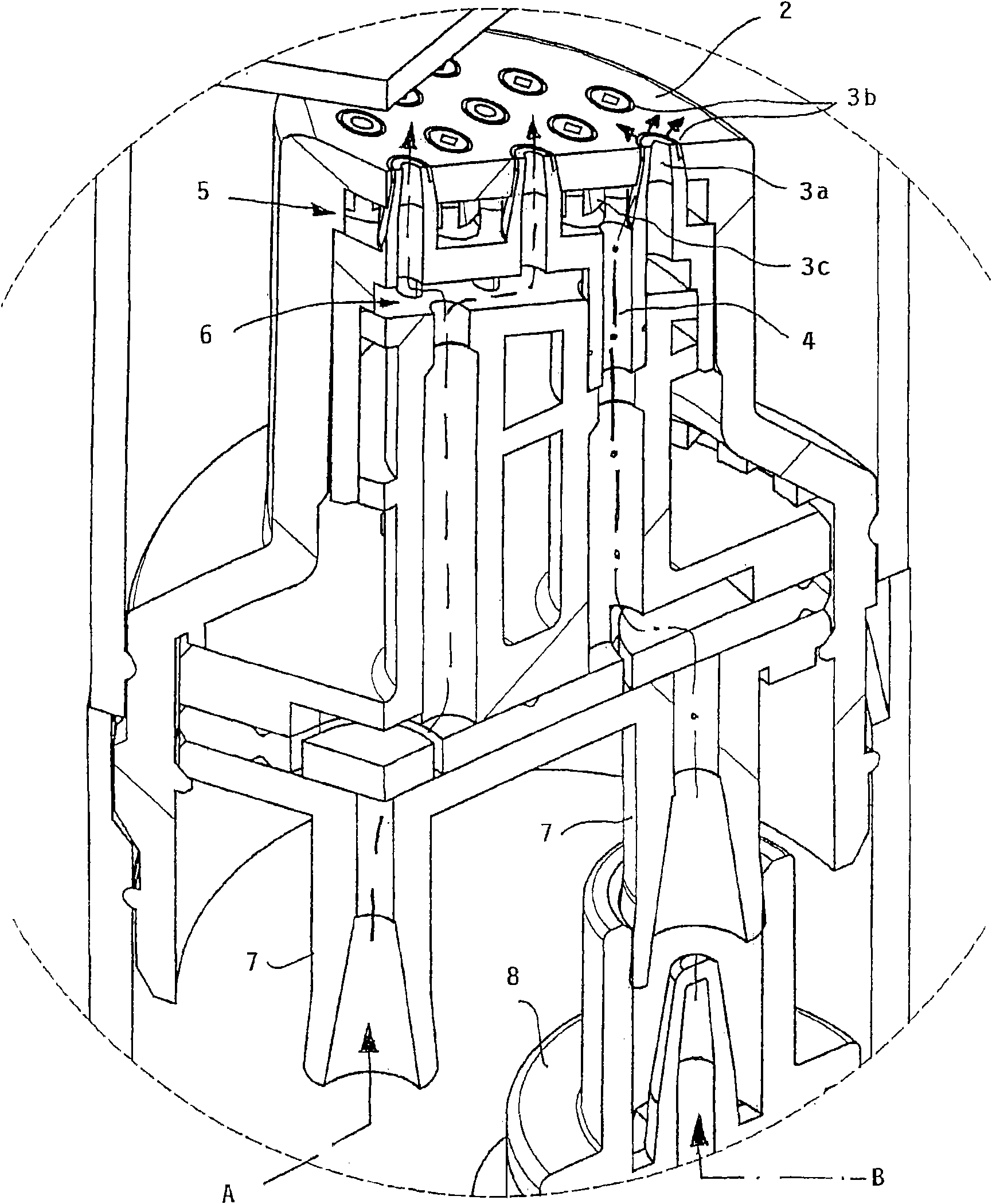

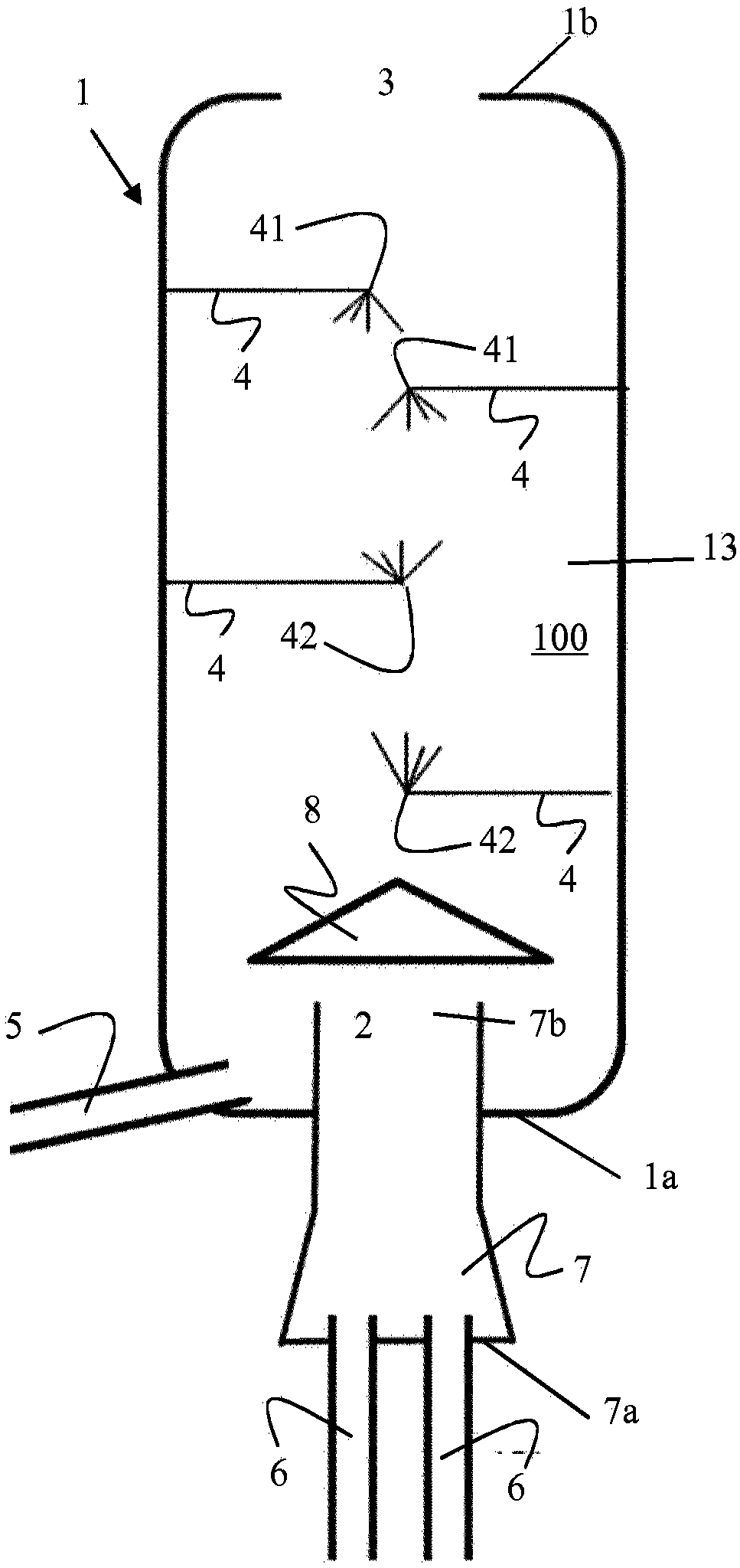

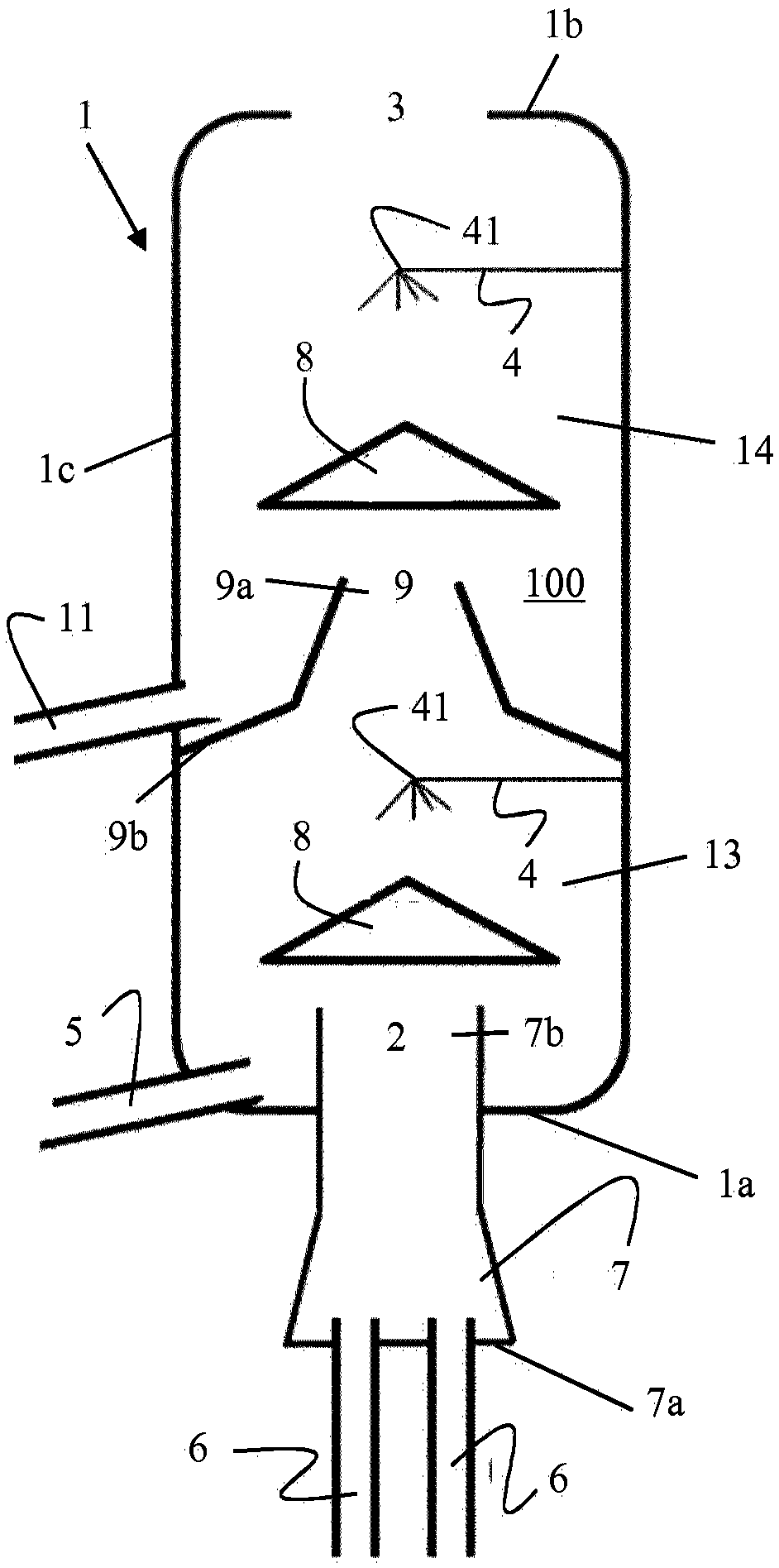

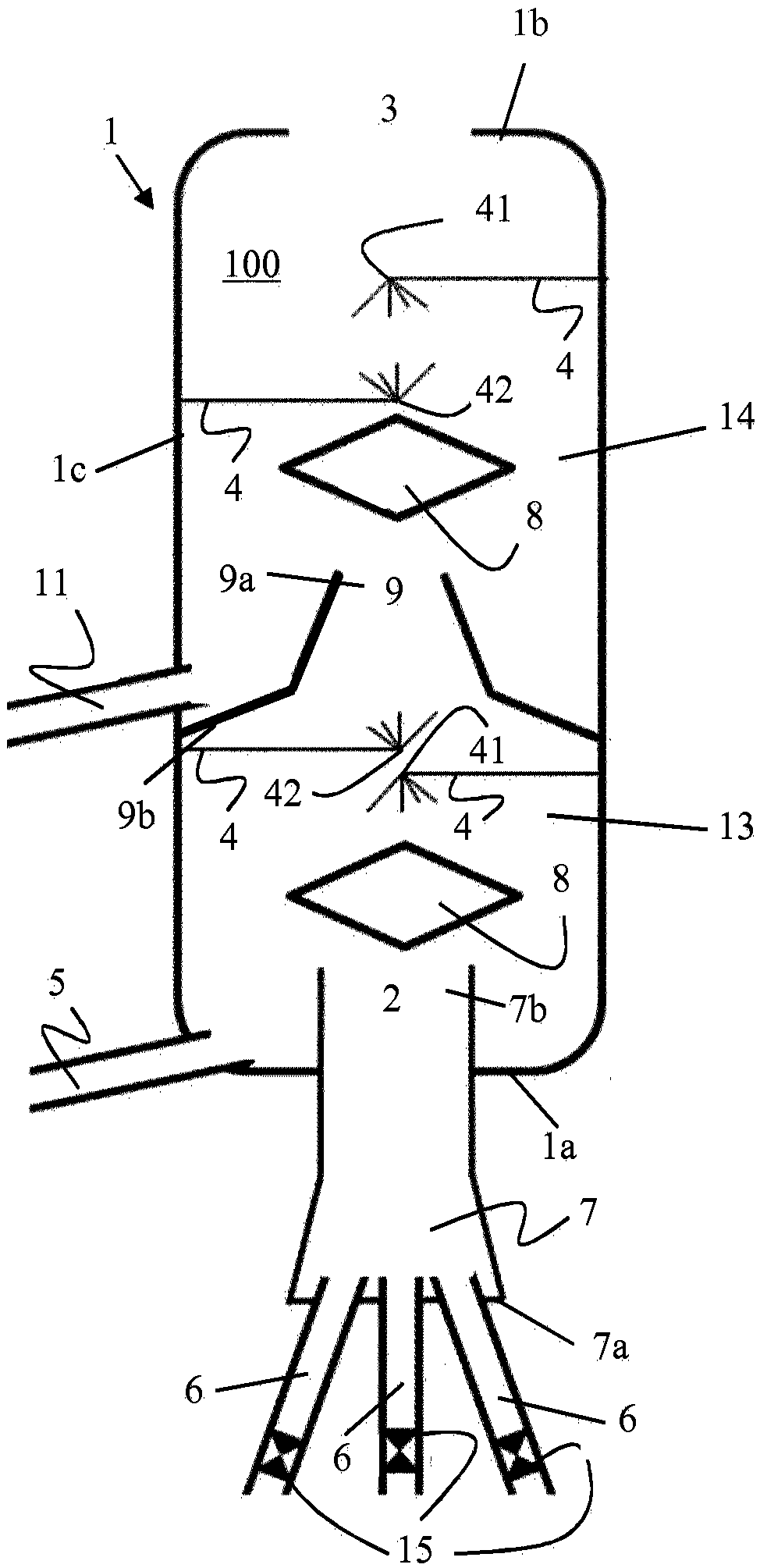

The present application relates to a spray tower (1) arranged to be vertically positioned and having an inner space (100), wherein the spray tower comprises, a central exhaust gas pipe (7) arranged for introducing exhaust gas into the inner space of the spray tower through an exhaust gas inlet (2) positioned at a proximal end (7a) of the central exhaust gas pipe, the central exhaust gas pipe beingpositioned at a bottom end (1a) of the spray tower in installed position, the central exhaust gas pipe being in fluid connection with the inner space of the spray tower through an exhaust gas inlet (2) at a top end of the central exhaust gas pipe, and at least one exhaust gas outlet (3 arranged for withdrawing purified exhaust gas from the inner space of the spray tower, the exhaust gas outlet being positioned at a top end (1b) of the spray tower in installed position, the exhaust gas outlet being in fluid connection with the inner space of the spray tower, wherein from the exhaust gas inletto the exhaust gas outlet, a general exhaust gas flow is passing through the inner space of the spray tower, one or more spray devices (41, 42) configured to provide a stream of scrubber liquid withinthe inner space of the spray tower counter current to the general exhaust gas flow, and at least two engine exhaust gas pipes (6) being in fluid connection with the distal end (7b) of the central exhaust gas pipe. Furthermore, a method for reducing the amount of SOx in exhaust gas is described.

Owner:YARA MARINE TECH AS

Novel aqueous damping coating material for automotive interiors, preparation method and equipment thereof

InactiveCN110951286AImprove composite loss factorMix tightlyFireproof paintsRotary stirring mixersFirming agentGraphite

The invention discloses a novel aqueous damping coating material for automotive interiors, a preparation method and equipment thereof, wherein the novel aqueous damping coating material is prepared from the following components in parts by weight: 10-20 parts of a graphene slurry, 1-3 parts of a defoaming agent, 0.5-1.5 parts of a thickening agent, 50-60 parts of modified glass powder, 3-5 parts of a curing agent, 30-40 parts of an environment-friendly flame retardant, 60-80 parts of a filler and 2-6 parts of a film forming aid. According to the invention, by improving the matching of the components, the preparation method and the equipment of the material, the problems of low comprehensive performance, complex preparation process, many devices and high comprehensive manufacturing cost ofthe material are solved, the comprehensive performance of the material is improved, the preparation process is simplified, the number of the equipment is reduced, and the comprehensive manufacturing cost is reduced; after the graphene and the modified glass powder in the material are mixed, a stable damping structure is formed in the coating; and the bubbles generated in the mixing process of thegraphene and the modified glass powder are removed through the defoaming agent, so that the damping layer is mixed tightly, the gaps are filled, the strength of the damping layer is improved, the preparation process is simplified, and the number of equipment is reduced.

Owner:清远明宇材料科技有限公司

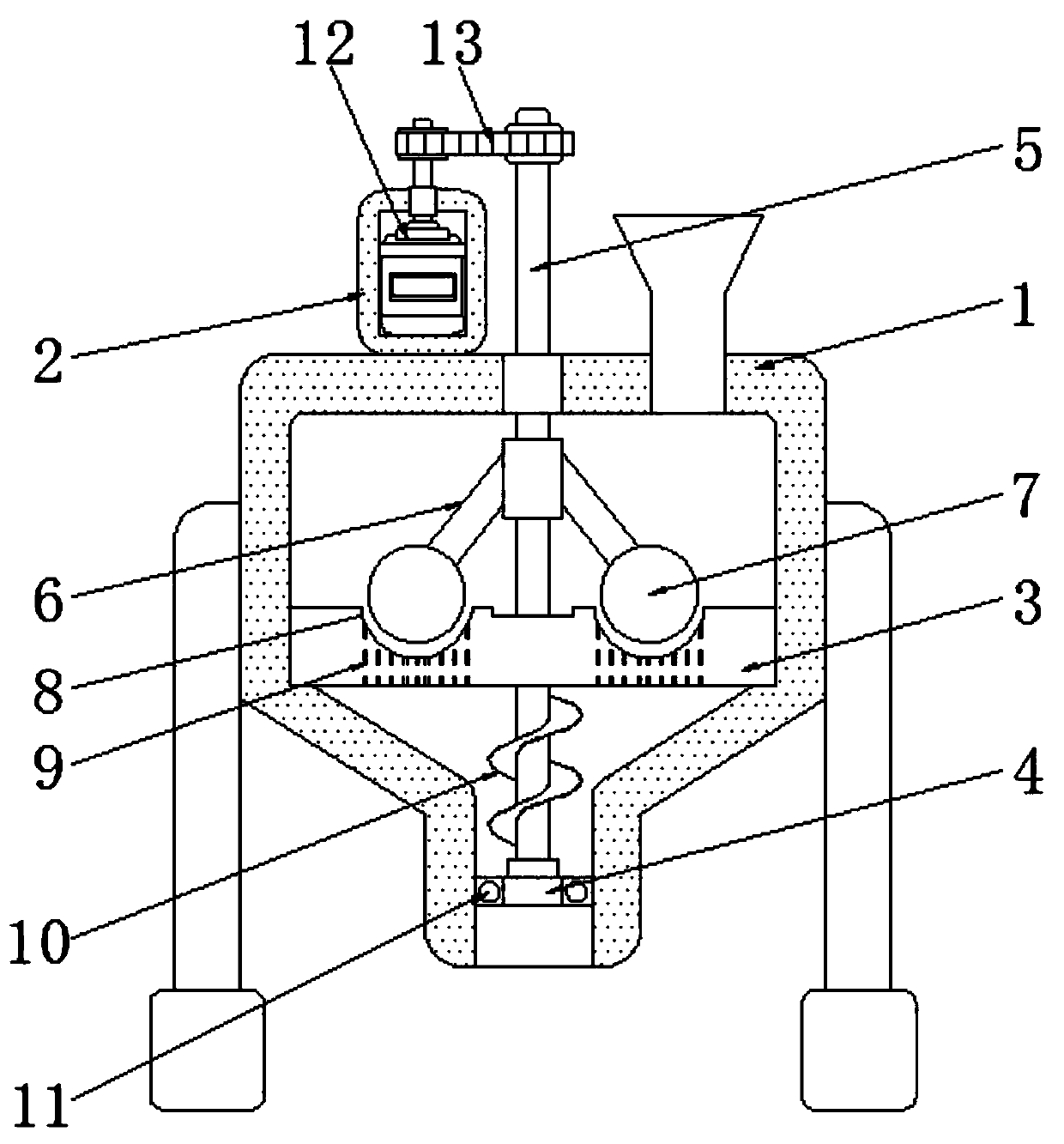

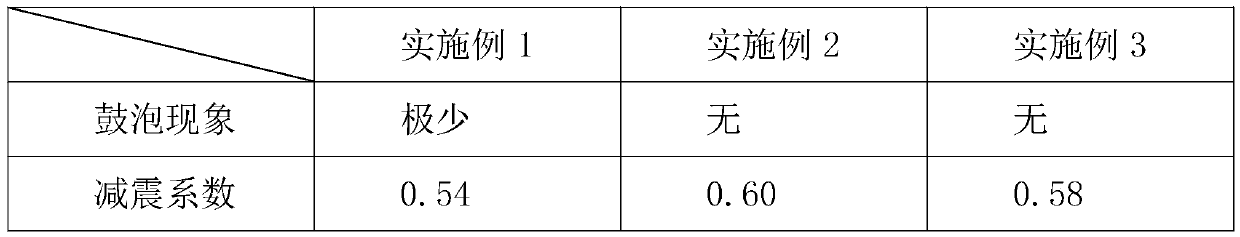

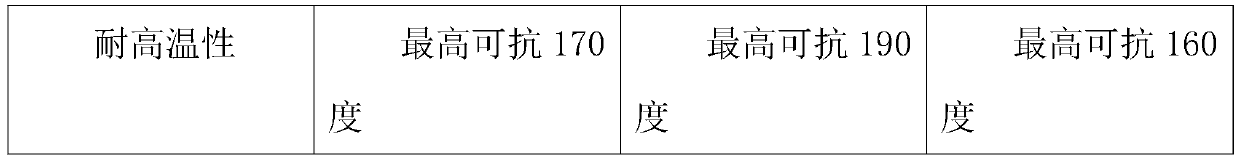

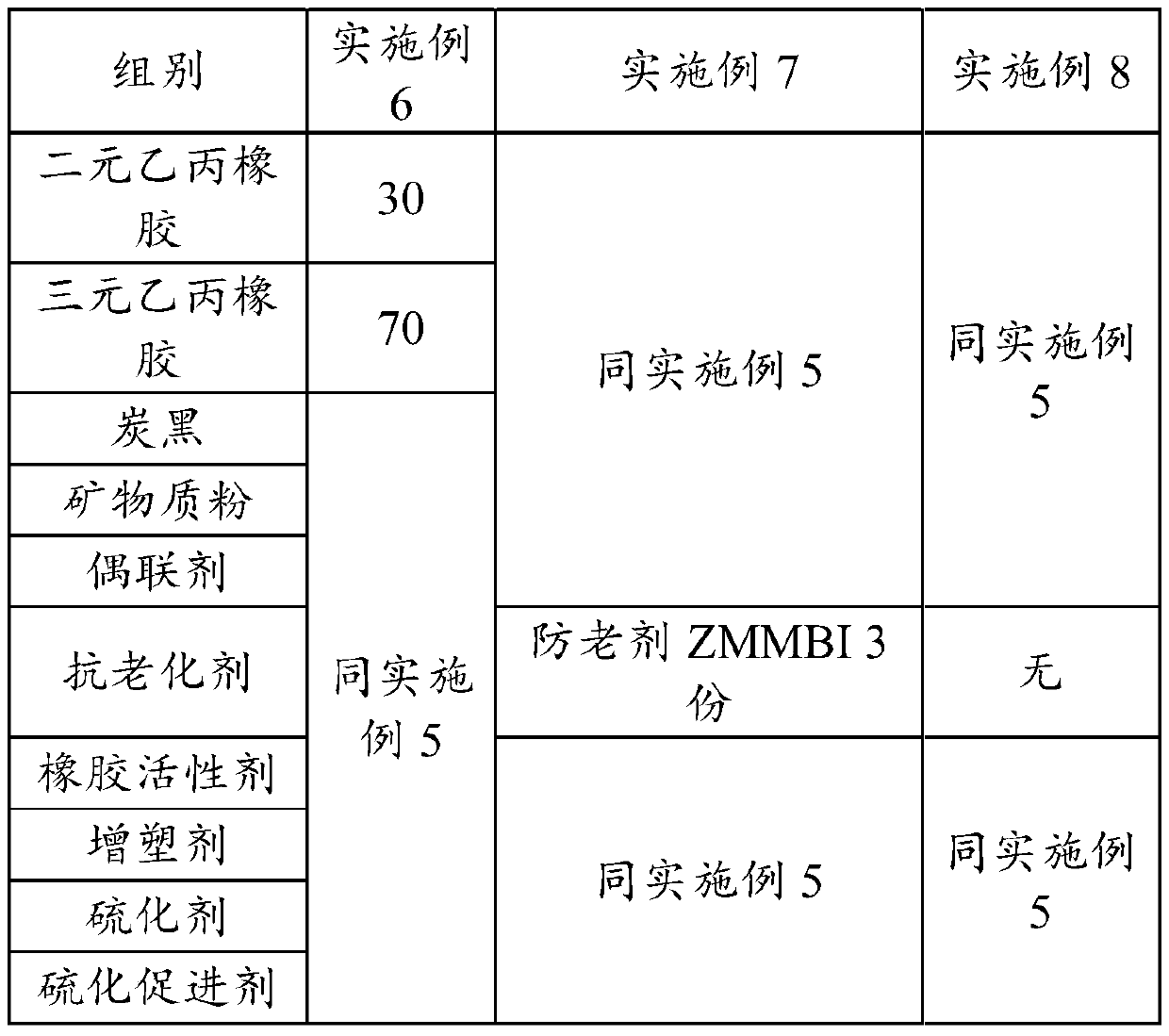

Rubber material, cooling rubber pipe prepared from rubber material and automobile engine comprising cooling rubber pipe

InactiveCN111019244AImprove high temperature resistanceHigh mechanical strengthRubber materialPolymer science

The invention provides a rubber material, a cooling rubber pipe prepared from the rubber material and an automobile engine comprising the cooling rubber pipe, which relate to the technical field of automobile fuel systems. The rubber material is mainly prepared from ethylene propylene diene monomer, ethylene propylene diene monomer, mineral powder and a coupling agent according to specific component contents. The ethylene propylene diene monomer and the ethylene propylene diene monomer which have good heat resistance and aging resistance are creatively matched and used according to a specificratio, so that the prepared rubber material has good high-temperature resistance and chapping resistance; meanwhile, the mineral substance powder is added, so that the mechanical strength and the extrusion fluidity of the rubber material are improved; in addition, the invention also comprises a coupling agent, and the coupling agent can connect the ethylene propylene diene monomer with the mineralsubstance powder in a chemical manner, so that the resistance effect is better achieved. Therefore, the performance of the existing rubber material is optimized by selecting the raw materials of thecomponents and compounding the contents of the components.

Owner:TIANJIN PENGYI GRP CO LTD

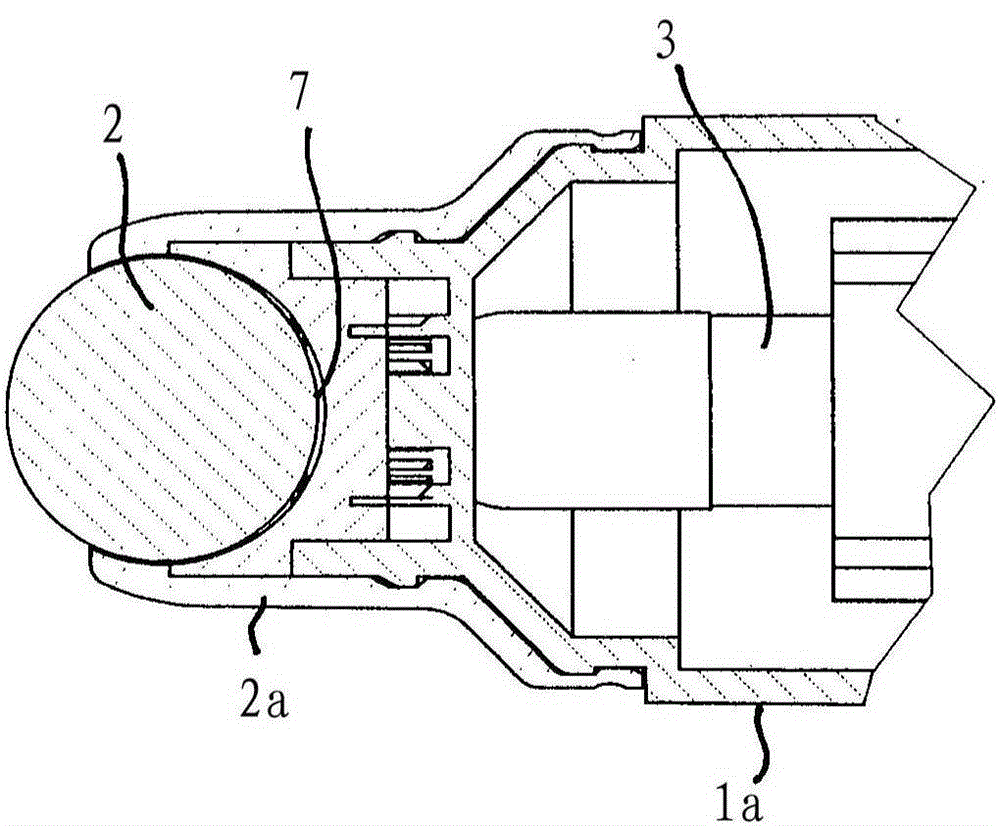

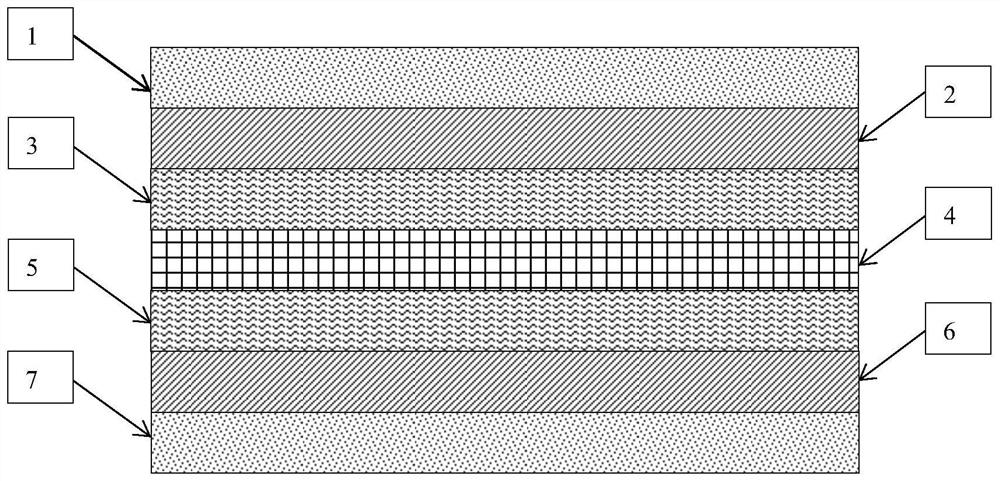

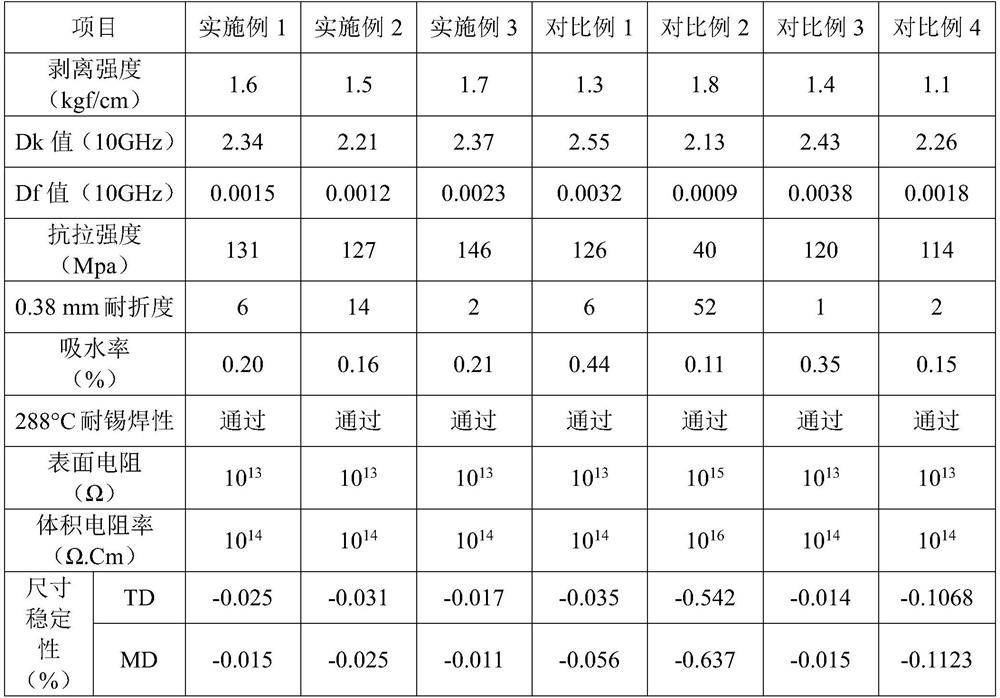

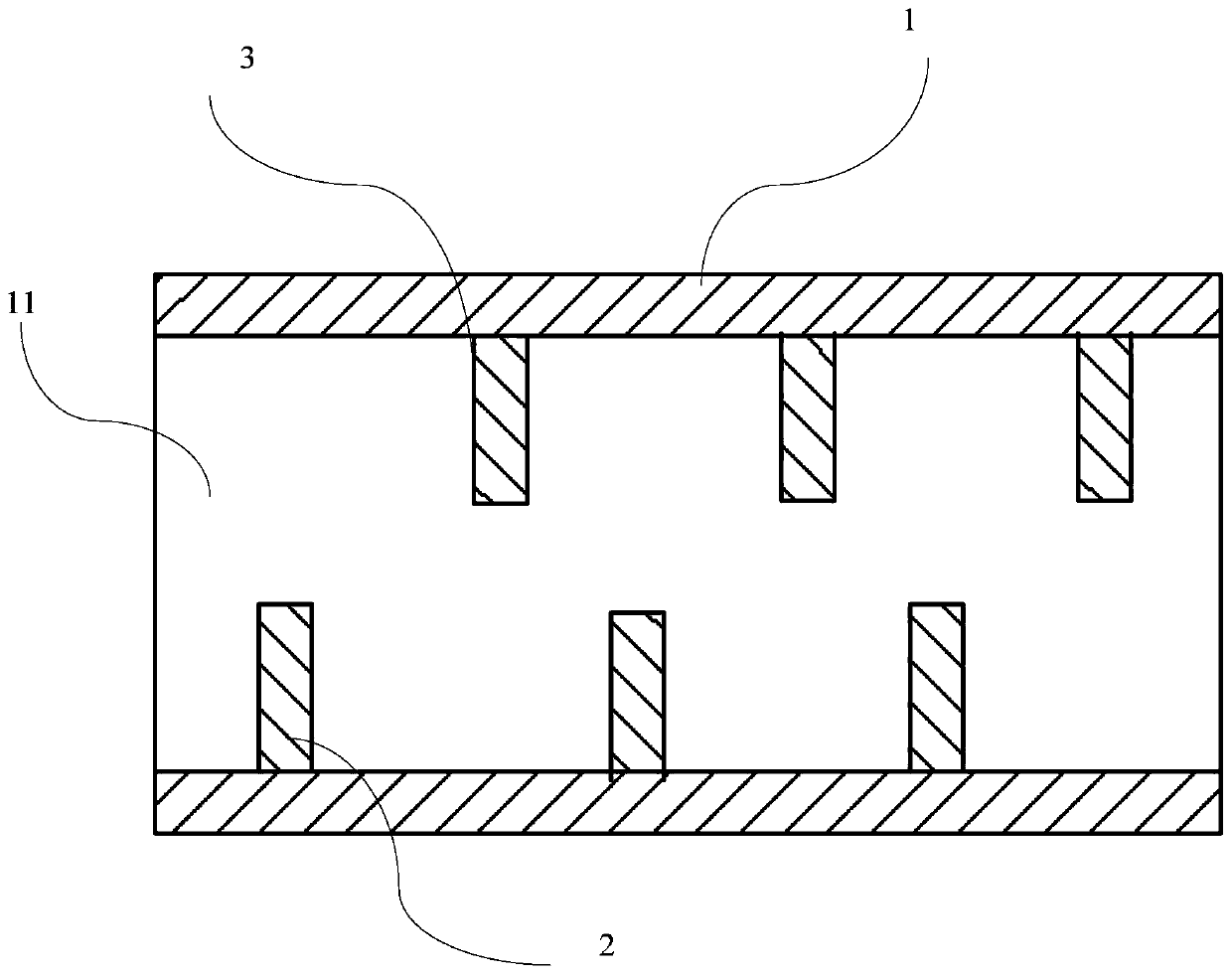

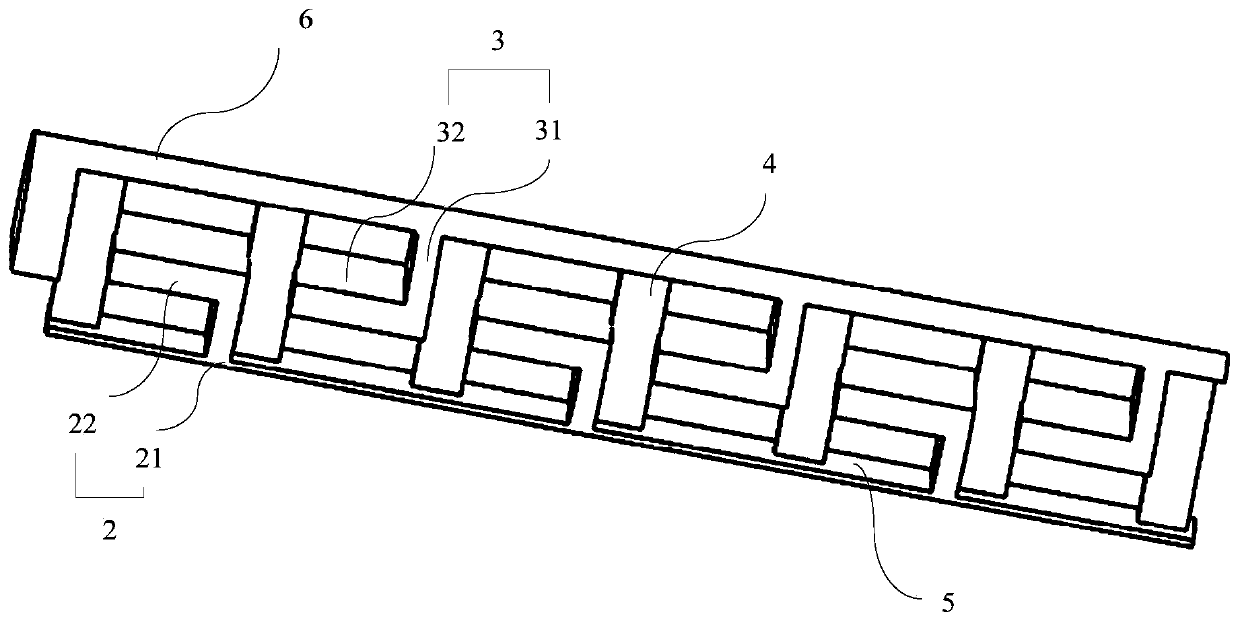

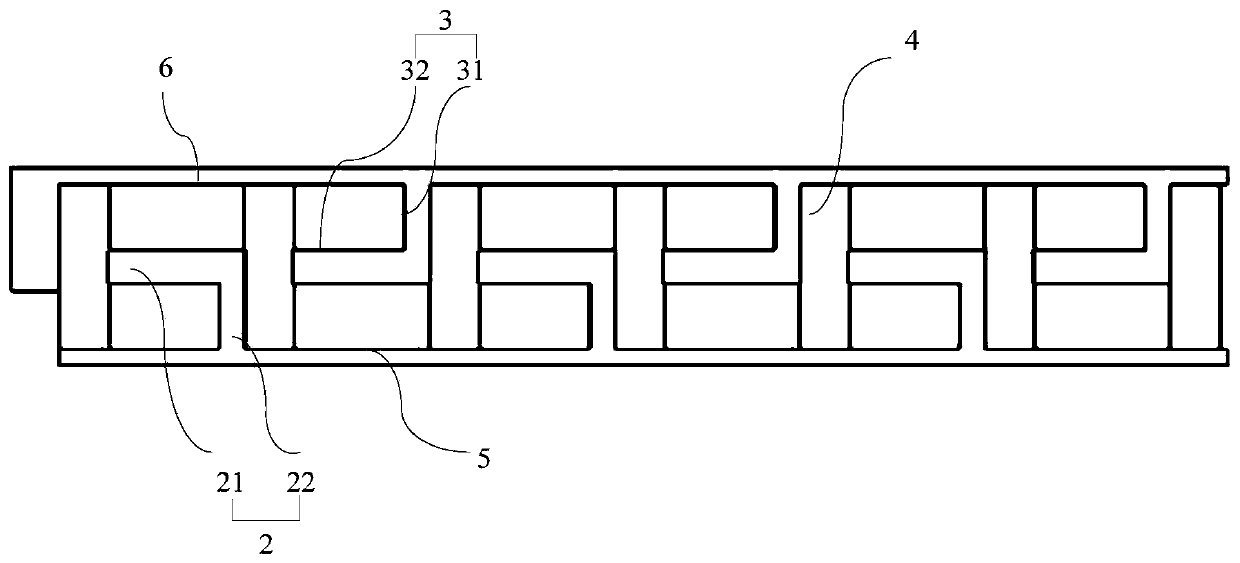

Polytetrafluoroethylene flexible copper-clad plate containing glass fabric and preparation method thereof

PendingCN114670512AShort processSave equipment and energyPrinted circuit detailsSynthetic resin layered productsCopper foilMesh grid

The invention discloses a polytetrafluoroethylene flexible copper-clad plate containing glass fabric and a preparation method of the polytetrafluoroethylene flexible copper-clad plate. The structure of the polytetrafluoroethylene flexible copper-clad plate containing the glass fabric sequentially comprises an upper copper foil layer, an upper fusible polytetrafluoroethylene layer, an upper mixed layer, a glass fabric layer, a lower mixed layer, a lower fusible polytetrafluoroethylene layer and a lower copper foil layer from top to bottom, wherein the upper mixing layer and the lower mixing layer are prepared by blending polytetrafluoroethylene and fusible polytetrafluoroethylene; and the glass fabric has a grid structure. The mechanical property of the prepared polytetrafluoroethylene flexible copper-clad plate containing the glass fabric is effectively improved, the stability is relatively good, meanwhile, relatively high electrical property is also ensured, and the application prospect is good.

Owner:ALLSTAE TECH ZHONGSHAN +1

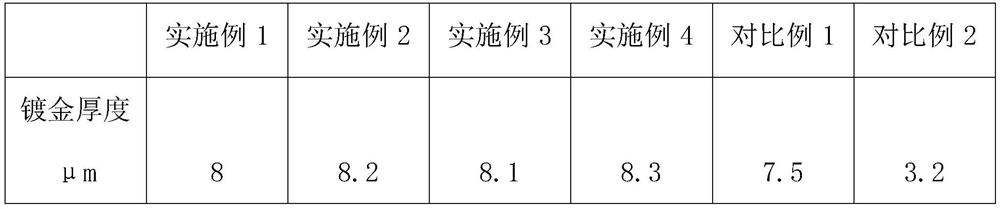

PCB secondary circuit gold plating process

InactiveCN111885844AReduce defective rateLow costDevelopersConductive pattern reinforcementGold layerGold plating

The invention discloses a PCB secondary circuit gold plating process, which comprises the following steps of: grinding and cleaning a PCB through a horizontal line to remove an oxide layer on the surface of the PCB, printing a layer of photosensitive solder resist ink on the surface of the PCB in a silk screen skip printing manner, transferring the PCB into a 65 DEG C oven, baking the photosensitive solder resist ink for 2 hours, and feeding the PCB into an exposure machine for exposing for 20 seconds; then transferring into a sodium carbonate solution with the mass fraction of 1% for cleaning, removing the unexposed photosensitive solder resist ink to expose a gold plating area pattern, and then feeding into a oven at 135-140 DEG C for drying the PCB for 30 minutes. According to the invention, the conductive windows are formed during two times of gold plating, the positions of the conductive windows can be adjusted according to actual requirements, the reject ratio of gold staining ofthe conductive windows is reduced by forming the conductive windows, the gold salt cost is saved, and the purpose of thickening a gold layer can be achieved through two times of gold plating.

Owner:深圳市明正宏电子有限公司

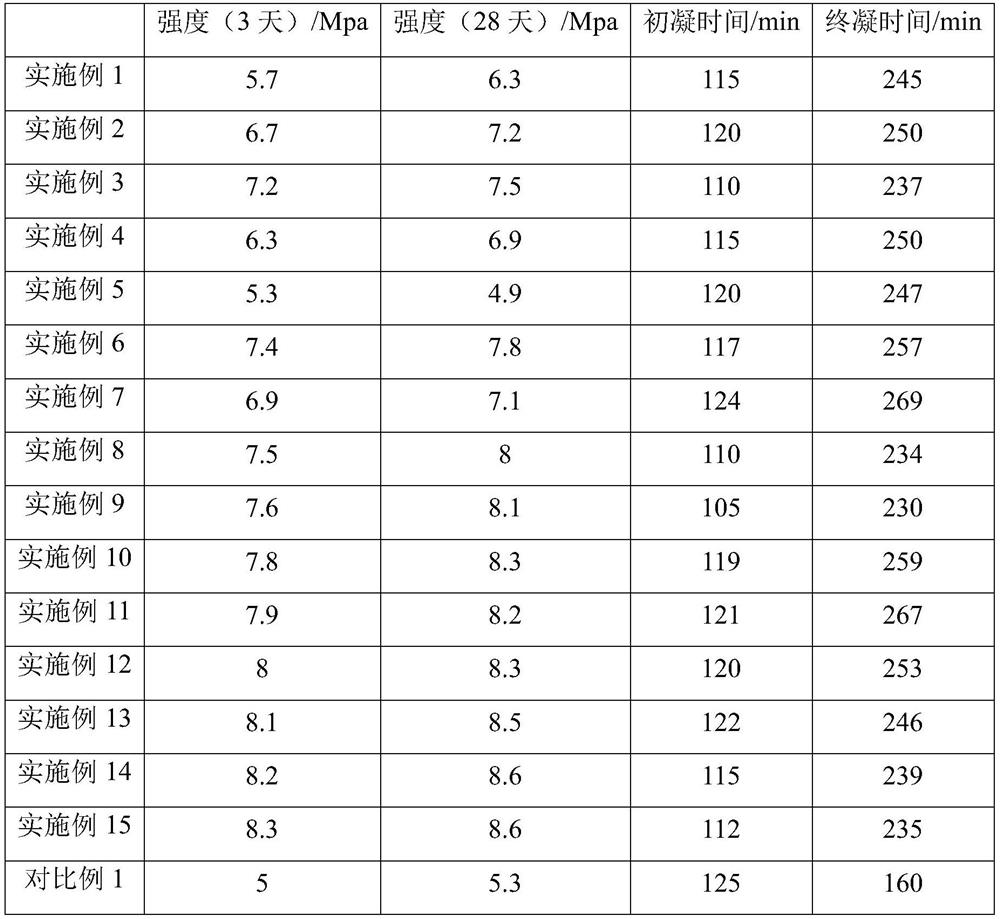

Quick-setting liquid soil and preparation method thereof

ActiveCN114685137AHigh strengthProlong clotting timeSolid waste managementSoil scienceEnvironmental engineering

The invention relates to the field of construction and building materials, and particularly discloses quick-setting liquid soil and a preparation method thereof. The liquid soil is prepared from the following raw materials in parts by weight: soil, cement, fly ash, a water reducing agent, water glass, water, quick lime, zeolite powder and triethanolamine, and the finished liquid soil is obtained by uniformly mixing the raw materials; in addition, the preparation method has the advantage of improving the strength of the liquid soil.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

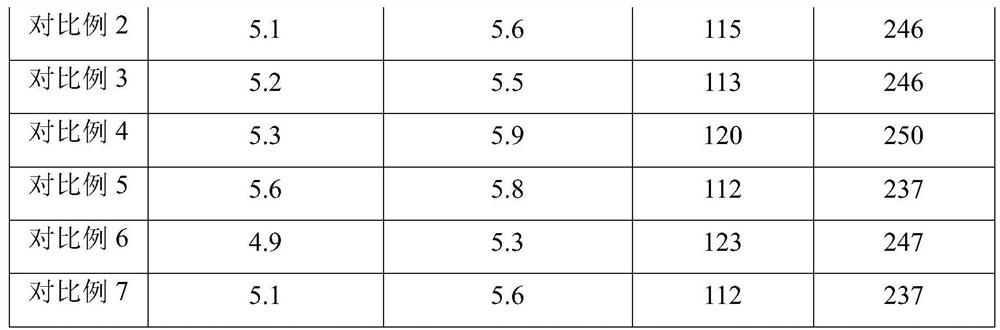

Preparation method of high-viscosity material particles of extracts

The invention discloses a preparation method of high-viscosity material particles of extracts. The preparation method mainly comprises following steps: step 1, preparation of solid slurry; step 2, stirring and mixing for a high-viscosity main material; step 3, addition of the solid slurry to the high-viscosity main material and granulation. Specifically, firstly, a base material is wetted by a wetting agent, the base material is a non-viscous material or a material with a little viscosity, the solid slurry is formed and then added to the high-viscosity main material or the high-viscosity mainmaterial is added to the solid slurry, and with the adoption of a high-speed wet mixed granulation mode, solids and liquids after dispersive mixing are contacted to be sticky and are bonded to form particles; the formed particles are uniform in shape, high in granulating ratio, tightly combined, high in production efficiency and high in capacity; tablets prepared from the particles are high in hardness, fast to disintegrate and remarkable in effect.

Owner:JIANGSU ALAND NOURISHMENT

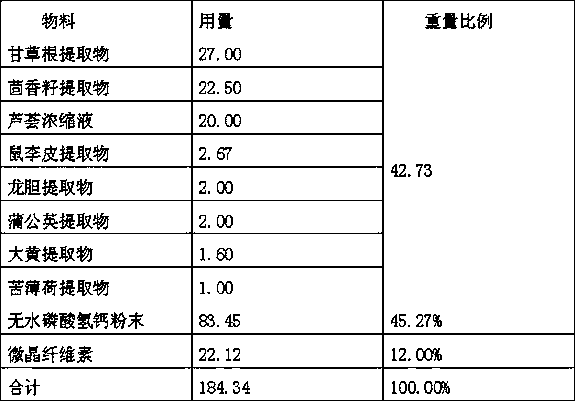

Composite rubber composition for automobile tire and preparation method thereof

The invention provides a composite rubber composition for an automobile tire, and relates to the technical field of automobile tire material. The composite rubber composition for the automobile tire is prepared from the following components in parts by weight: 40 to 55 parts of natural rubber, 50 to 70 parts of synthetic rubber, 10 to 50 parts of styrene thermoplastic elastomer, 5 to 20 parts of tackifier, 50 to 60 parts of carbon black, and 4 to 8 parts of vulcanizer. The composite rubber composition has the advantages that the cost is low, the environment-friendly effect is realized, and theabrasion-resistant and explosion-resistant properties are better. A preparation method of the composite rubber composition comprises the following steps of mixing and blending the natural rubber, thestyrene thermoplastic elastomer and the synthetic rubber, sequentially adding the tackifier and the carbon black, mixing, heating and forming; finally, adding the vulcanizer into the formed rubber atthe temperature of 100 to 200 DEG C to vulcanize. The preparation method has the advantages that the raw materials are fully used, and the operability is stronger.

Owner:平潭诚信智创科技有限公司

Mixer and anchoring device

Owner:PINGAN COAL MINING ENG RES INST CO LTD +2

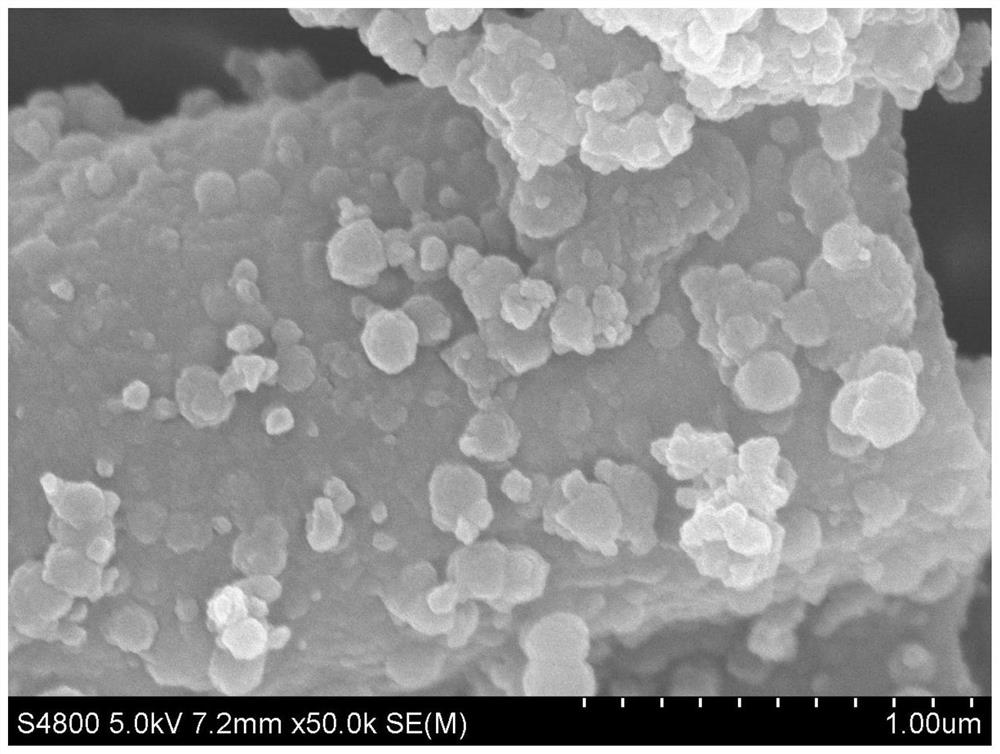

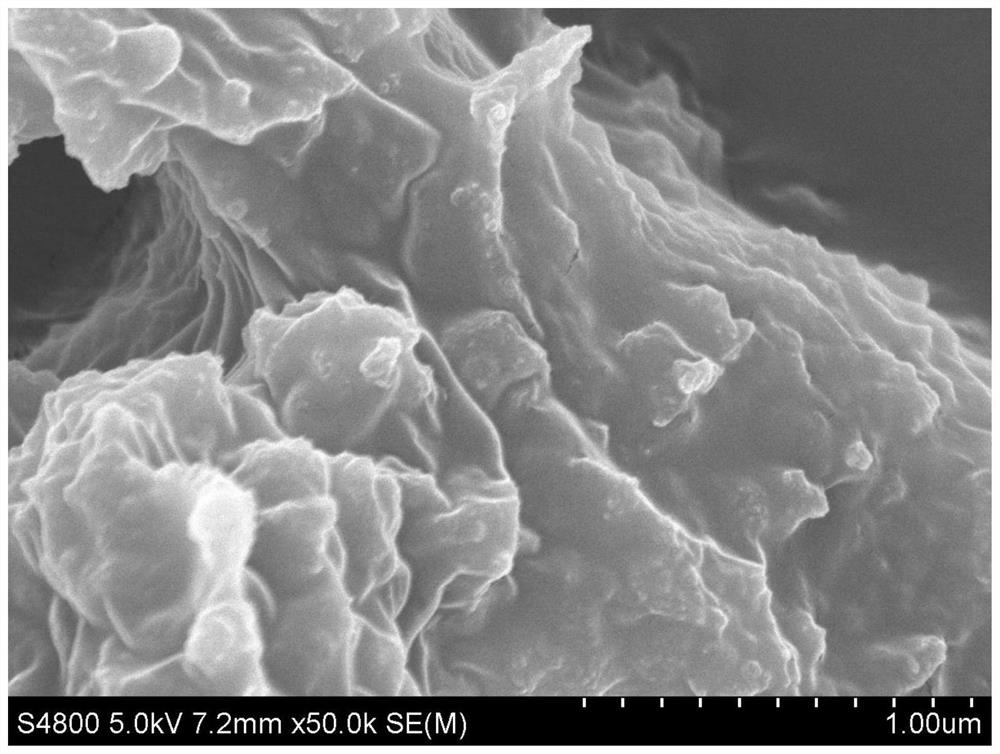

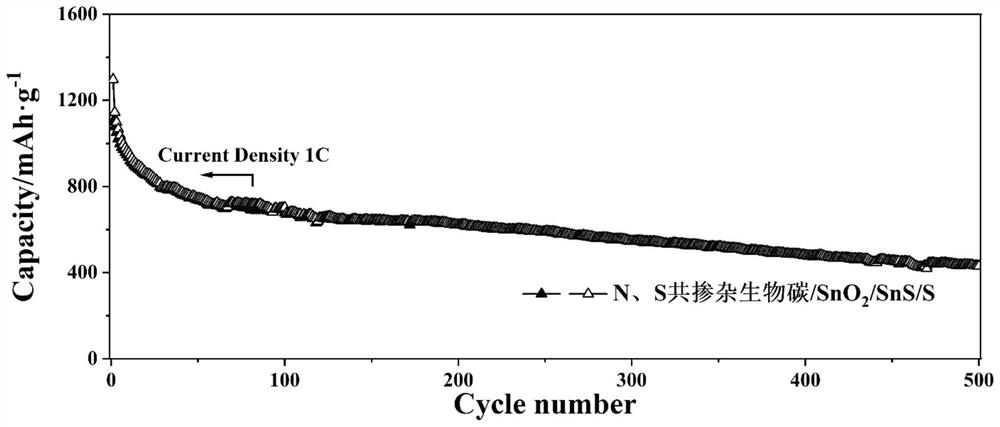

Nitrogen and sulfur co-doped biocarbon/SnO2/SnS/S composite material, preparation method and application

PendingCN114725343AStrong specific surface areaEnhanced fast adsorption capacityNegative electrodesLi-accumulatorsSulfideSolvothermal reaction

The invention discloses a nitrogen and sulfur co-doped biochar / SnO2 / SnS / S composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: performing heat treatment on biomass with a tubular structure to obtain biochar; carrying out solvothermal reaction on the biochar by taking mixed acid as a solvent; adding acid liquor into the obtained product, and carrying out solvothermal reaction to obtain biological carbon rich in oxygen-containing functional groups; mixing the nitrogen-sulfur co-doped biochar with thiourea, and carrying out heat treatment in a mixed atmosphere of NH3 and H2S to obtain nitrogen-sulfur co-doped biochar; mixing with an inorganic tin source, and carrying out hydrothermal reaction to obtain a nitrogen and sulfur co-doped biochar / SnO2 composite material; and mixing with thiourea, and carrying out heat treatment to obtain a final product. According to the invention, the rapid adsorption and conversion capability on polysulfide is realized, the capacity of the lithium-sulfur battery is improved, meanwhile, the stability of the composite structure in the circulation process is ensured, and the capacity loss caused by structural damage is reduced.

Owner:XIAN AERONAUTICAL UNIV

Method for preparing two-component vitrified brick backing glue

InactiveCN108485580AIncrease contact areaImprove water absorptionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseFiber

The invention relates to the technical field of preparation of building materials and in particular relates to a method for preparing two-component vitrified brick backing glue. The method disclosed by the invention comprises the following steps: treating sugarcane serving as a raw material to obtain pre-dispersed suspension, mixing the pre-dispersed suspension, cotton stalk bark fibers, ammoniumpersulfate, N,N-methylenebis acrylamide and the like, reacting, extracting with acetone, drying to obtain a component A, performing graft copolymerization on acrylic acid and sugarcane fibers, forminga three-dimensional network structure, and producing a water-absorbent resin, wherein the cotton stalk bark fibers easily crimp when meeting water, the water is difficultly squeezed out, the roughness of the vitrified brick can be improved by the cotton stalk bark fibers, and the bricks are conveniently adhered; mixing a cellulose ether and a castor oil polyurethane prepolymer, dispersing to obtain premixed emulsion, adding quick lime, carboxylic butadiene-styrene latex, fly ash and other materials into the pre-dispersed mixture, performing vacuum defoamation to obtain a component B, and performing network interpenetrating on castor oil polyurethane and methyl silicone rubber, thereby obtaining an adhesive with an IPN (Interpenetrating Polymer Network) structure. The network interpenetrating structure is compact in binding, and the application prospects are wide.

Owner:许水仙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com