Preparation method of high-viscosity material particles of extracts

An extract-based, high-viscosity technology, which is applied in the field of wet granulation preparation, can solve the problems of large particle powder, inconvenient granulation, inconvenient operation, etc., and achieve uniform particle shape, convenient formula deployment, and obvious optimization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing extract-like high-viscosity material particles is characterized in that it mainly includes the following steps:

[0020] Step ①: Prepare solid slurry; in step ①, use a non-viscous and less viscous base material and put it into a high-speed wet mixing granulator, add a wetting agent, and wet the base material to form a solid slurry; The base material is one or a combination of at least two of silicon dioxide, glucosamine hydrochloride, glucose, anhydrous calcium hydrogen phosphate powder, microcrystalline cellulose, malic acid, sodium chloride, potassium chloride; The wetting agent is one or a combination of purified water, ethanol, and isopropanol; the amount of the wetting agent is 0.3 to 3 times the amount of the base material;

[0021] Step ②: Stirring and mixing of high-viscosity main ingredients;

[0022] Step ③: Add solid slurry in step ②, and granulate;

[0023] Step ④: drying, dry material granulation;

[0024] Step ⑤: Sieve test; in st...

Embodiment 1

[0028] formula:

[0029] Chrysanthemum extract: 200 parts (high viscosity);

[0030] Radix Seed Extract: 300 parts (very viscous);

[0031] Silica: 50 parts;

[0032] 1. Put 50 parts of silicon dioxide into a high-speed wet mixing granulator, add an appropriate amount of water to disperse and chop, and form a solid slurry to release;

[0033] 2. Put the extract in the formula into the high-speed wet mixing granulator for mixing, put in the solid slurry released earlier, and at the same time quickly close the machine cover, open the granulation system for granulation until satisfactory granules are produced;

[0034] 3. After the prepared granular soft material is fluidized and dried, the dry material is fully granulated;

[0035] 4. Carry out sub-sieving test, test with 20, 40, 60, 80, and 100 mesh sieves respectively, 2.5% for 20 mesh upper sieve, 35.8% for 20~40 mesh, 21.5% for 40~60 mesh, 21.5% for 60~80 mesh 16.6%, 9.2% for 80-100 mesh, 14.4% for 100-mesh sieve, the fi...

Embodiment 2

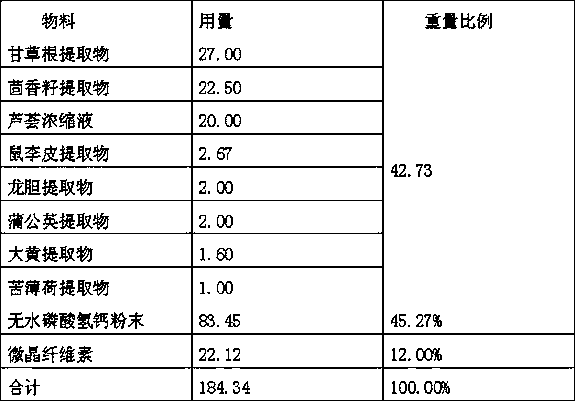

[0039]

[0040] 1. Put 45.27 parts of anhydrous calcium hydrogen phosphate powder and 12 parts of microcrystalline cellulose into a high-speed wet mixing granulator to stir and mix, and at the same time add an appropriate amount of water to disperse and chop to form a solid slurry;

[0041] 2. Mix the various extracts in the table formula evenly in the mixer first, release 42.73 parts, put them into the solid slurry of anhydrous calcium hydrogen phosphate powder and microcrystalline cellulose, and turn on the granulation system in time for granulation. until satisfactory particles are made;

[0042] 3. After the prepared granular soft material is fluidized and dried, the dry material is fully granulated;

[0043] 4. Carry out sub-sieving test, use 20, 40, 60, 80, and 100 mesh sieves to test respectively, 20 mesh upper sieve is 4.0%, 20~40 mesh is 36.2%, 40~60 mesh is 21.5%, 60~80 mesh It is 14.2%, 80-100 mesh is 8.2%, and 100-mesh sieve is 15.9%. The fineness distribution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com