PCB secondary circuit gold plating process

A secondary circuit and process technology, applied in the field of PCB board manufacturing, can solve problems affecting product quality and cost, business competition success or failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] PCB secondary circuit gold plating process, including the following steps:

[0027] The first step is to grind and clean the PCB through a horizontal line to remove the oxide layer on the surface, and then print a layer of photosensitive solder resist ink on the surface of the PCB by screen printing, and then transfer it to a 65°C oven to dry the photosensitive solder resist ink. Bake for 2 hours, then put the PCB into an exposure machine for exposure for 20 seconds, then transfer it to a 1% sodium carbonate solution for cleaning, remove the unexposed photosensitive solder resist ink, and expose the gold-plated area pattern, and then send it to an oven at 135°C for drying 30min;

[0028] The second step is to pass the PCB through acid degreasing and micro-etching solution respectively to remove the oxide layer on the surface, and then open the skylight on the PCB surface corresponding to the position of the gold finger in the first gold-plated area on the PCB so that th...

Embodiment 2

[0037] PCB secondary circuit gold plating process, including the following steps:

[0038] The first step is to clean the PCB through a horizontal line to remove the oxide layer on the surface, and then print a layer of photosensitive solder resist ink on the surface of the PCB by screen printing, and then transfer it to a 65°C oven to dry the photosensitive solder resist ink. Bake for 2 hours, then send the PCB into an exposure machine for exposure for 20 seconds, then transfer it to a sodium carbonate solution with a mass fraction of 1% for cleaning, remove the unexposed photosensitive solder resist ink, and expose the pattern of the gold-plated area, and then send it to an oven at 135°C for drying 30min;

[0039] In the second step, the PCB is respectively subjected to acid degreasing and micro-etching solutions to remove the oxide layer on the surface, and then a skylight is opened on the PCB surface corresponding to the position of the gold finger in the first gold-plated...

Embodiment 3

[0048] PCB secondary circuit gold plating process, including the following steps:

[0049] The first step is to clean the PCB through a horizontal line to remove the oxide layer on the surface, and then print a layer of photosensitive solder resist ink on the surface of the PCB by screen printing, and then transfer it to a 65°C oven to dry the photosensitive solder resist ink. Bake for 2 hours, then send the PCB into an exposure machine for exposure for 20 seconds, then transfer it to a sodium carbonate solution with a mass fraction of 1% for cleaning, remove the unexposed photosensitive solder resist ink, and expose the pattern of the gold-plated area, and then send it to an oven at 135°C for drying 30min;

[0050] In the second step, the PCB is respectively subjected to acid degreasing and micro-etching solutions to remove the oxide layer on the surface, and then a skylight is opened on the PCB surface corresponding to the position of the gold finger in the first gold-plated...

PUM

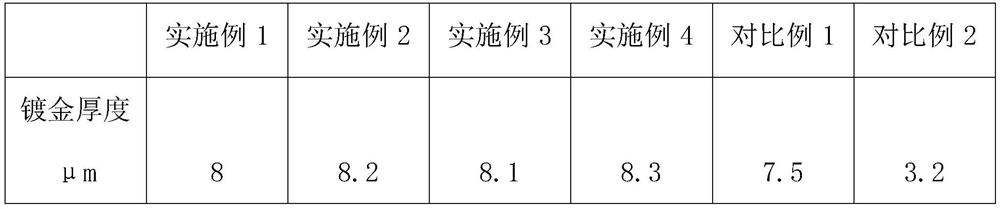

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com