Patents

Literature

33results about How to "Achieve thickening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

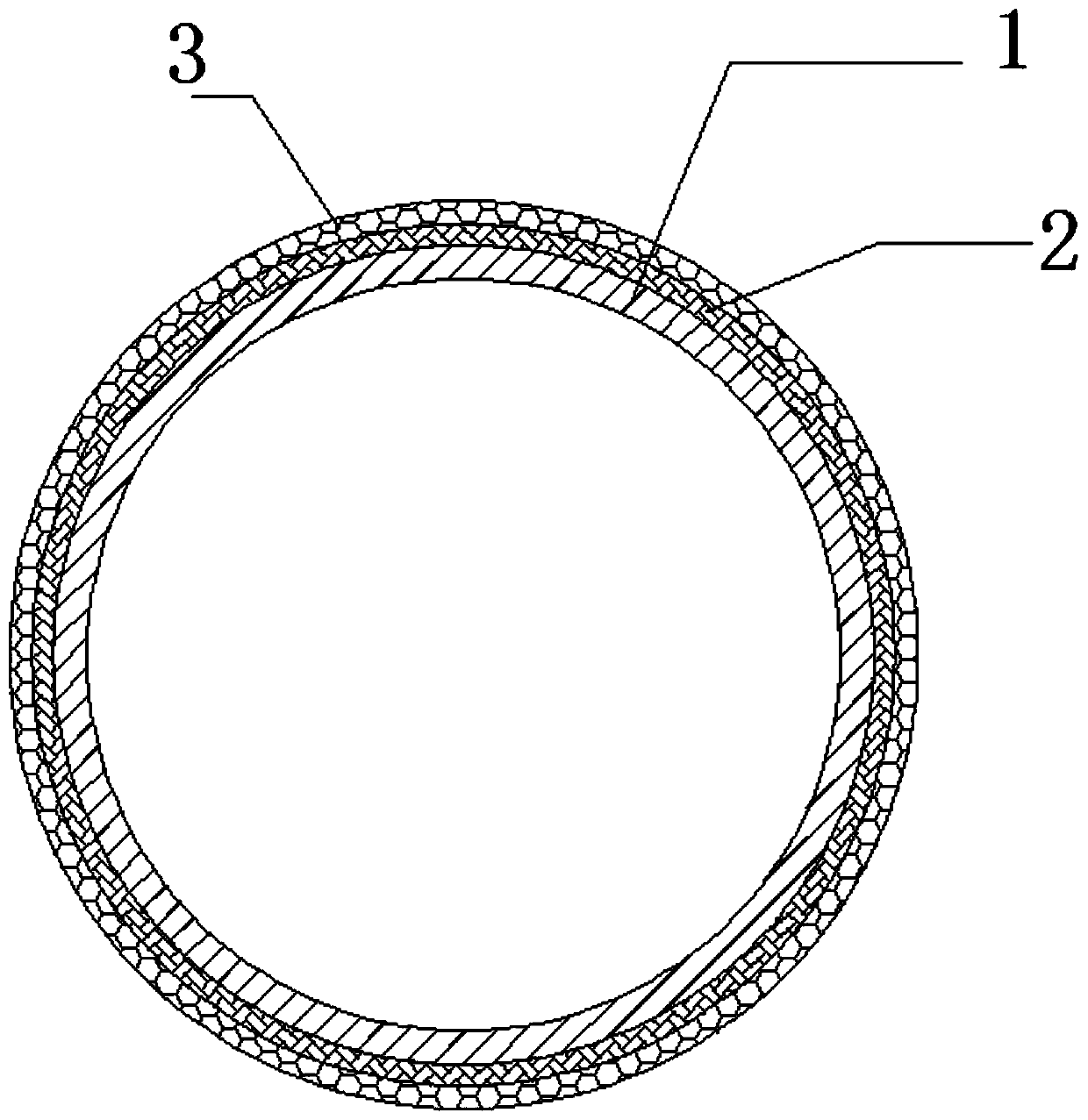

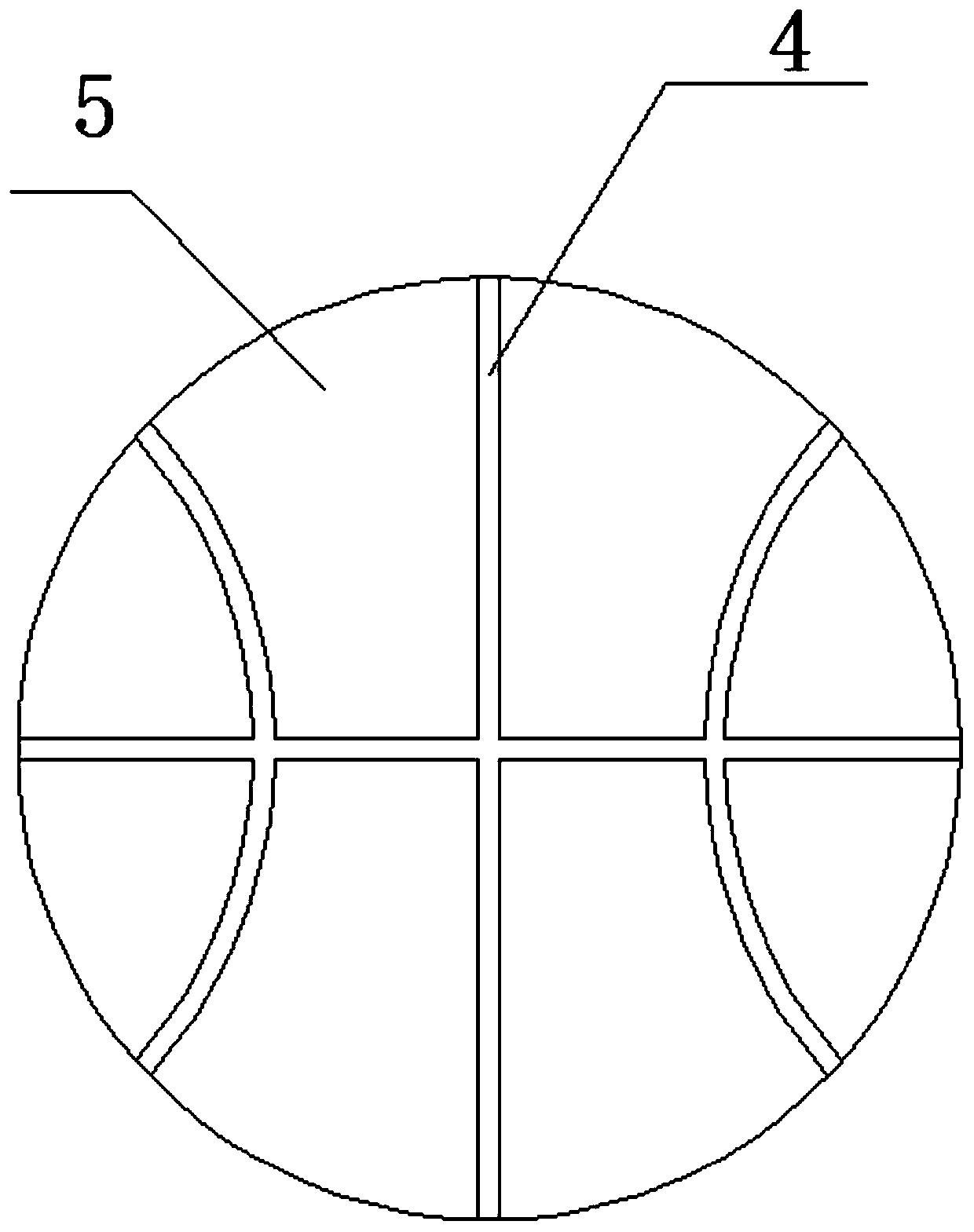

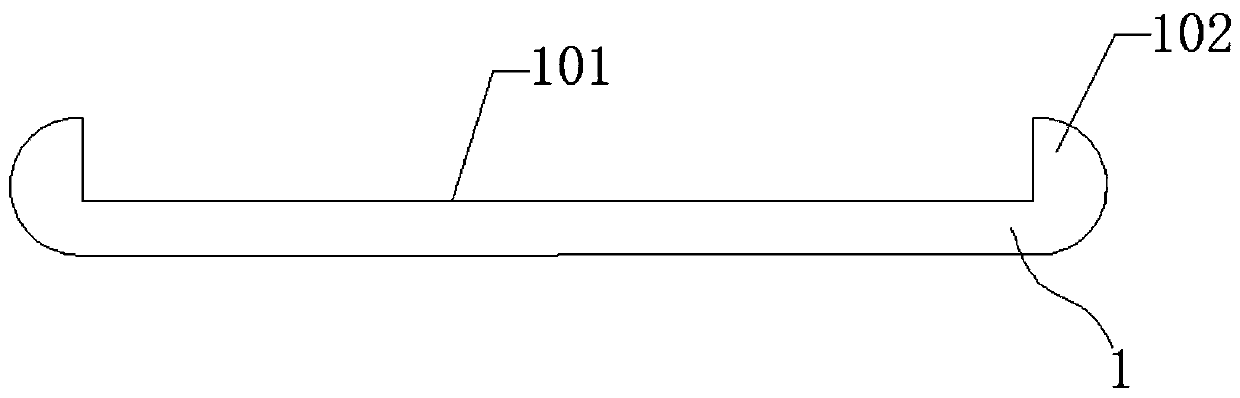

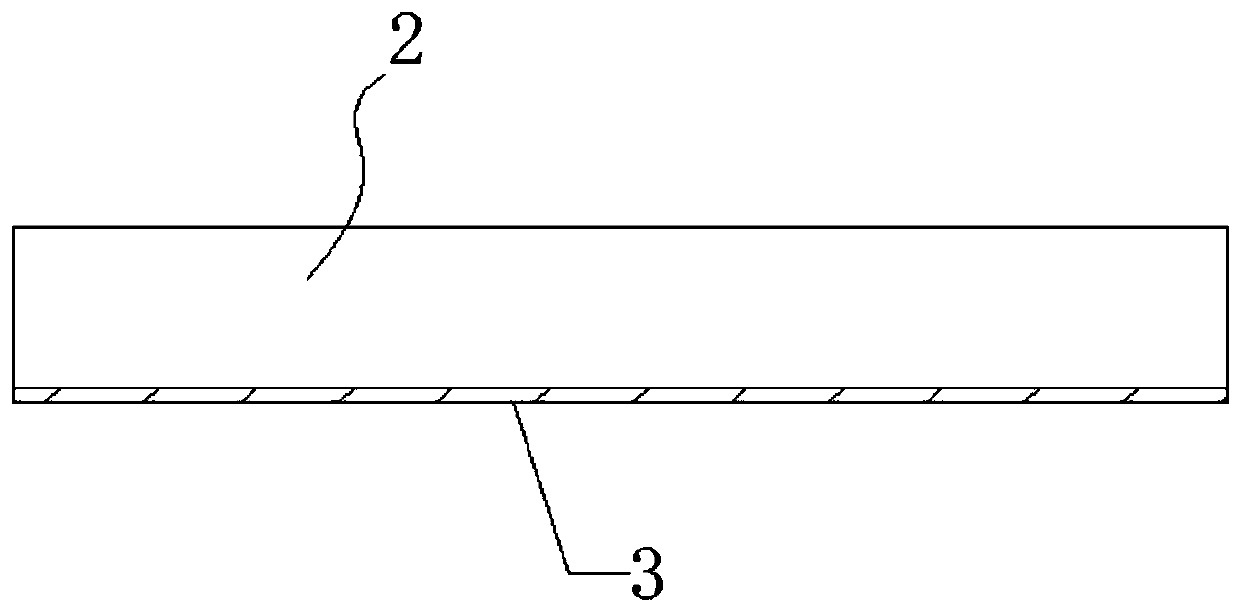

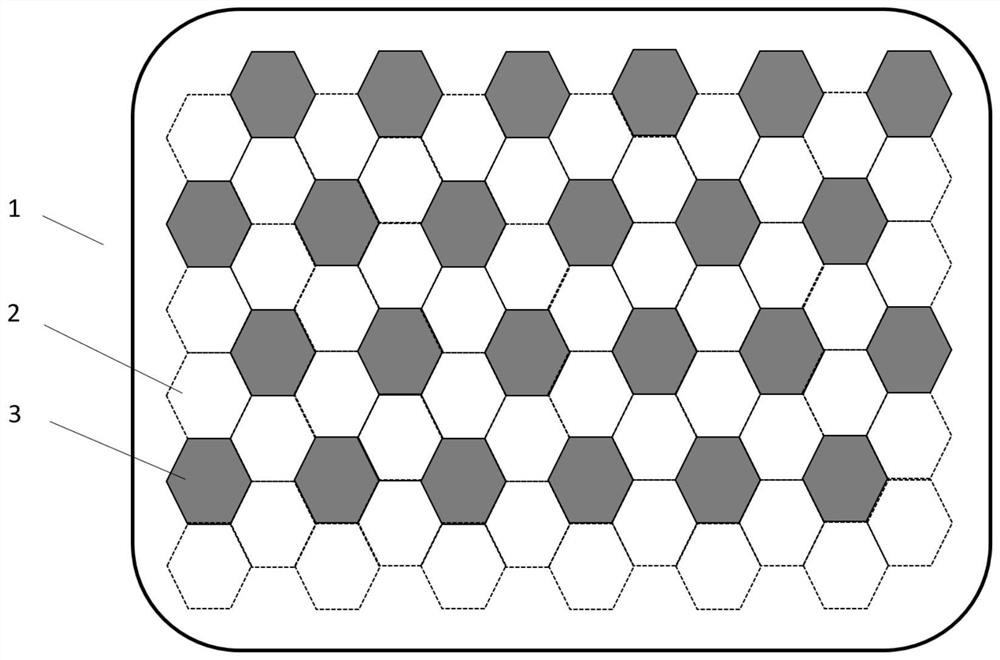

Foamed middle tube, leather stuck ball and manufacturing method

PendingCN110393902AIncrease elasticityGood flexibilityHollow inflatable ballsLayered productsYarnVulcanization

The invention discloses a foamed middle tube, a leather stuck ball and a manufacturing method. The foamed middle tube comprises a liner, a liner deformation preventing layer and a foam layer, whereinliner deformation preventing layer is coated on the outer surface of the liner; and the foam layer is coated on the outer surface of the liner deformation preventing layer. According to the foamed middle tube, the foam layer is directly stuck to the liner deformation preventing layer, so that based on the characteristic that the foam layer is light in weight, the weight of the liner can be increased by using the middle tube with the same weight, and the thickness of the liner made from the same material can be increased, so that the airtightness of the liner is improved; the foamed middle tubecan be applied to a volleyball with the relatively light weight, and also can meet the requirement of the liner with a complex structure; in addition, the ball has better bounce and flexibility without the constraint of a middle rubber layer; meanwhile, the original flexibility of yarns or patches and foam can be kept, the sense of flapping touch is softer and more comfortable; the foamed rubbermiddle tube layer is replaced with the foam layer, a vulcanization technology and a polishing process during a manufacturing process can be avoided, and bad and nonuniform foaming during a vulcanization process also can be avoided.

Owner:陈红维

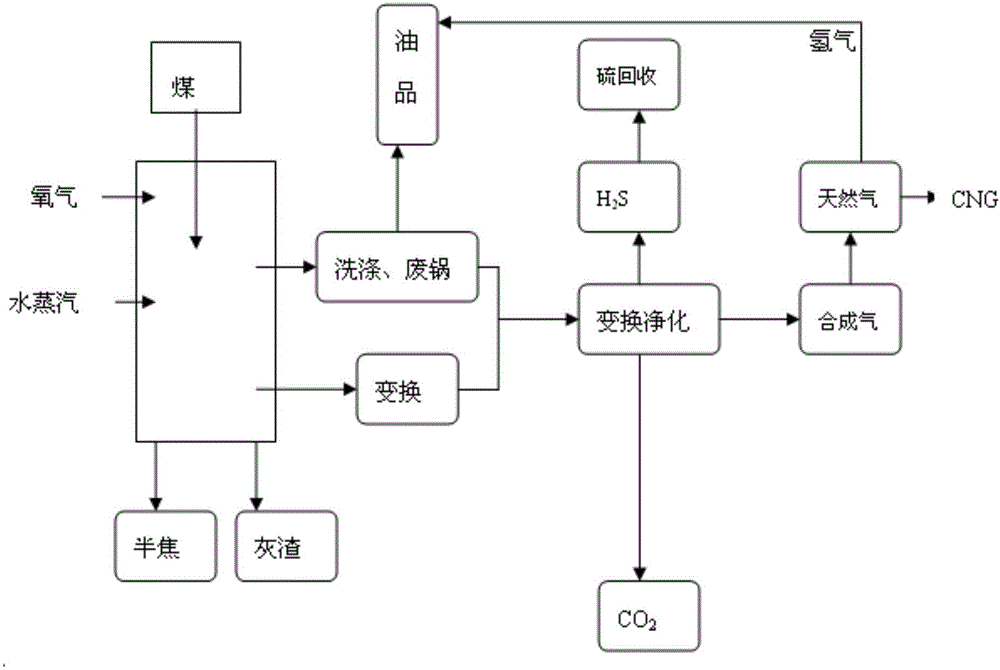

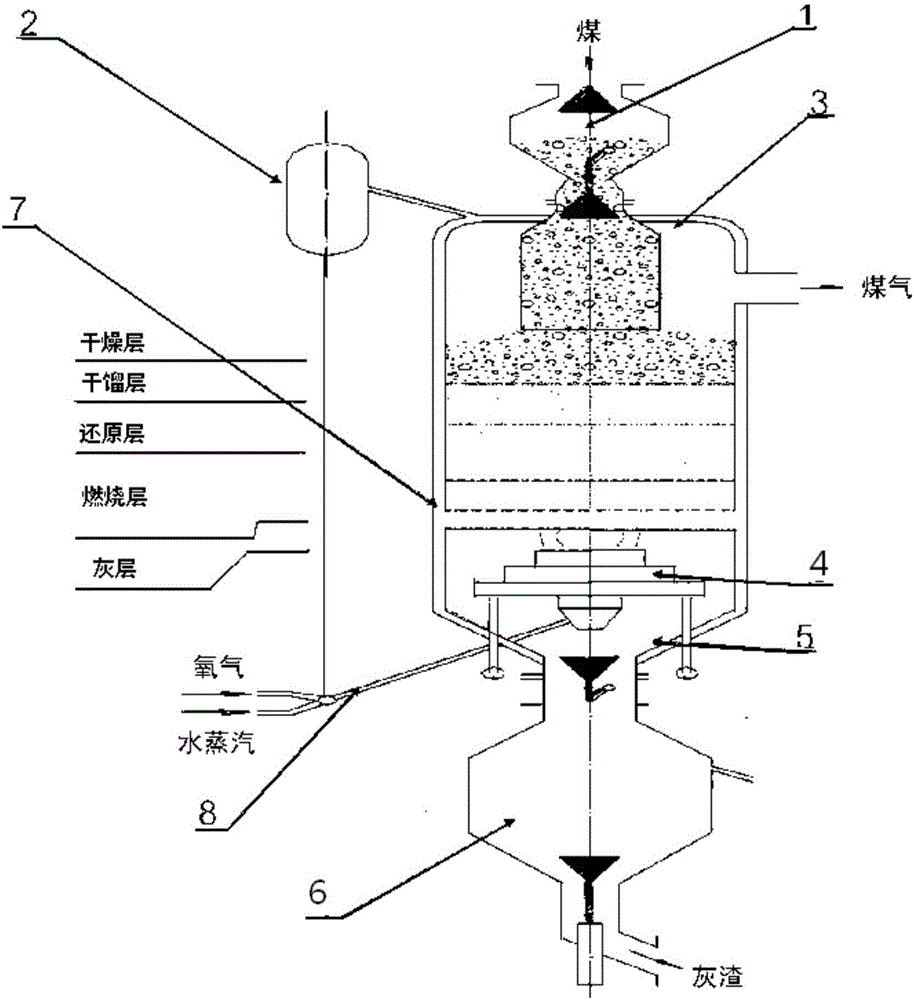

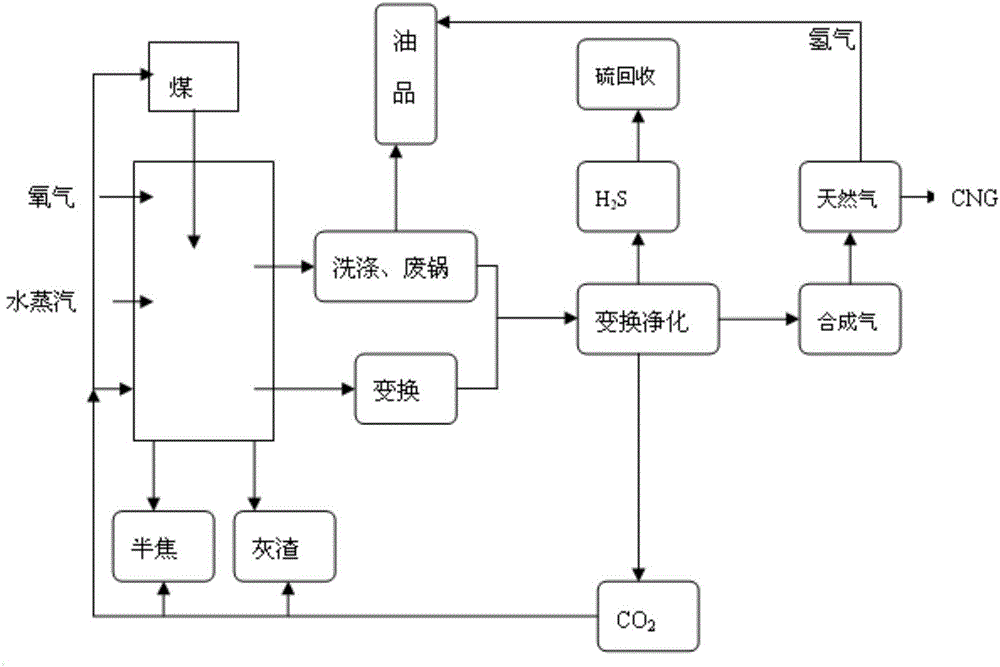

Method and system for preparing gas by fixed bed gasifier

InactiveCN106635168AAchieve thickeningConducive to energy saving and emission reductionChemical industrySpecial form destructive distillationHeat carrierFixed bed

The invention provides a method and a system for preparing gas by a fixed bed gasifier. The method for preparing gas comprises steps as follows: a coal lock containing feed coal is pressurized by the first part of carbon dioxide exhaust gas; the second part of the carbon dioxide exhaust gas is introduced into the fixed bed gasifier before a vapor inlet of a gasification agent pipe; an introduced gasification agent, the second part of the carbon dioxide exhaust gas and the pressurized feed coal react in the fixed bed gasifier, and crude gas and gasified ash are obtained. The carbon dioxide exhaust gas is mainly used as the raw material and introduced into the gasifier, and CO can be prepared by a reduction reaction; a heat storage type heat carrier CO2 performs gas stripping on volatile matter of coal at the dry distillation stage, and effects of thickening of a dry distillation bed and high yield of coal tar can be realized. Therefore, the system has the functions of preparation of a large amount of oil and gas, recovery of carbon dioxide exhaust gas and the like, and is beneficial to energy conservation and emission reduction.

Owner:COMPREHENSIVE TECH SERVICE CENT YILI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

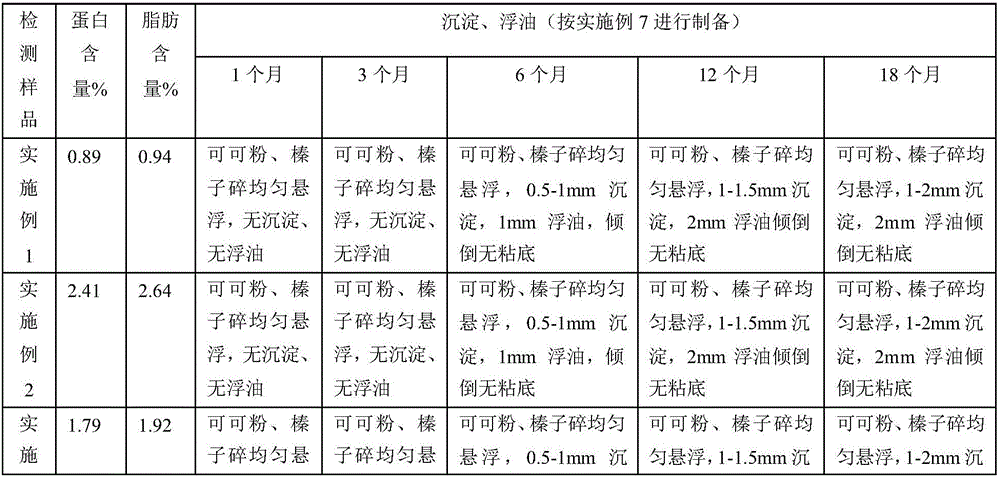

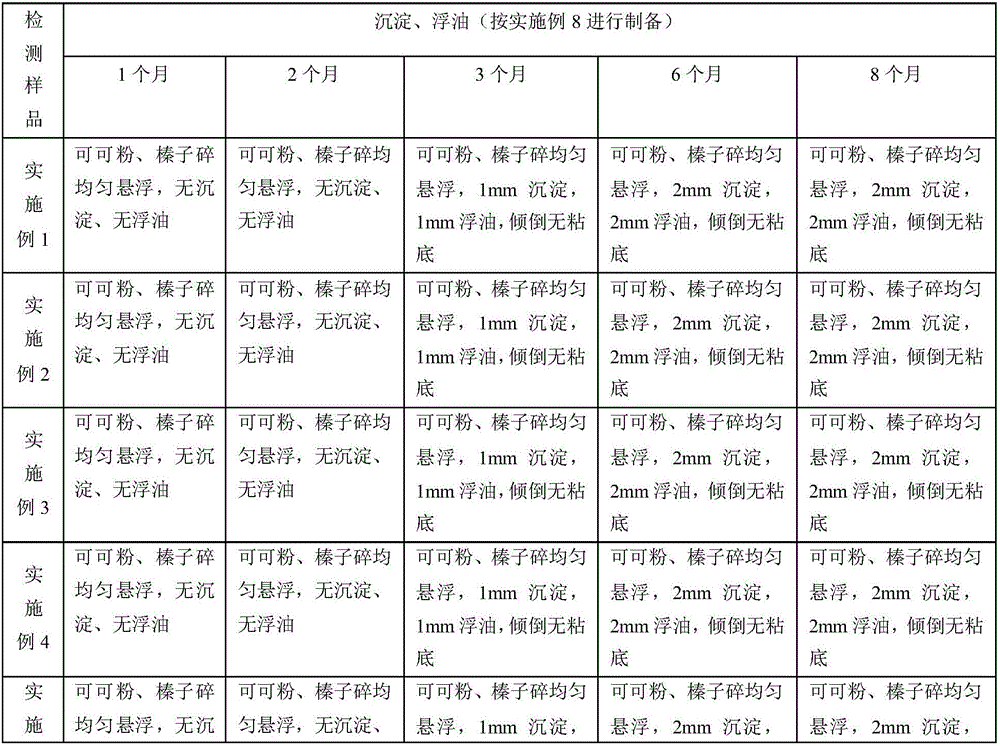

Hazelnut, chocolate and milk compound protein drink and production technology thereof

InactiveCN106106749AGuaranteed shelf life stabilityRich tasteMilk preparationButter cocoaCocoa Powders

The invention provides a hazelnut, chocolate and milk compound protein drink and belongs to the technical field of vegetable protein drinks. The drink comprises the components, by weight, of 30-80 parts of milk, 3-7 parts of white sugar, 0.2-6 parts of hazelnut sauce, 1-5 parts of grain powder, 1-3 parts of grated hazelnuts, 0.1-3 parts of cocoa powder, 0.1-2 parts of cocoa butter, 0.1-0.5 part of compound emulsification thickening agent, 0.01-0.1 part of essence and the balance of water. The invention further provides a production technology of the drink. According to the hazelnut, chocolate and milk compound protein drink, various nutritional ingredients of the milk, hazelnuts, grain powder and the like are added, so that the milk protein and the hazelnut protein are reasonably matched, dietary fiber is added, the product stability problem can be solved by adding small amount of emulsification thickening agent, the technology is suitable for current vegetable protein general technologies, and the requirement of stable product shelf life under different packages is met.

Owner:HEBEI BROS ILONG FOOD TECH LLC

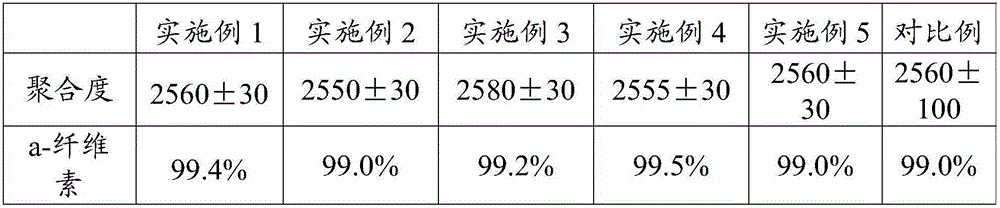

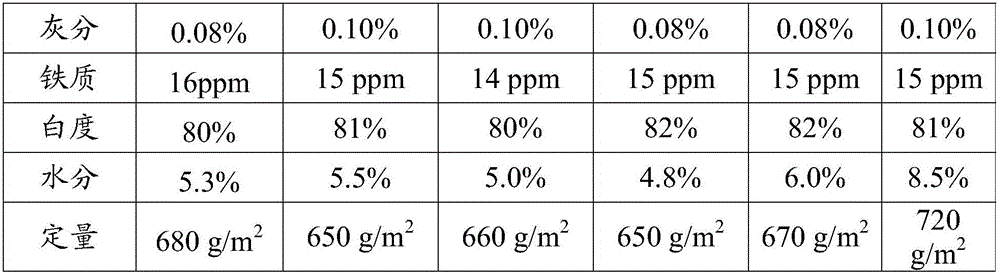

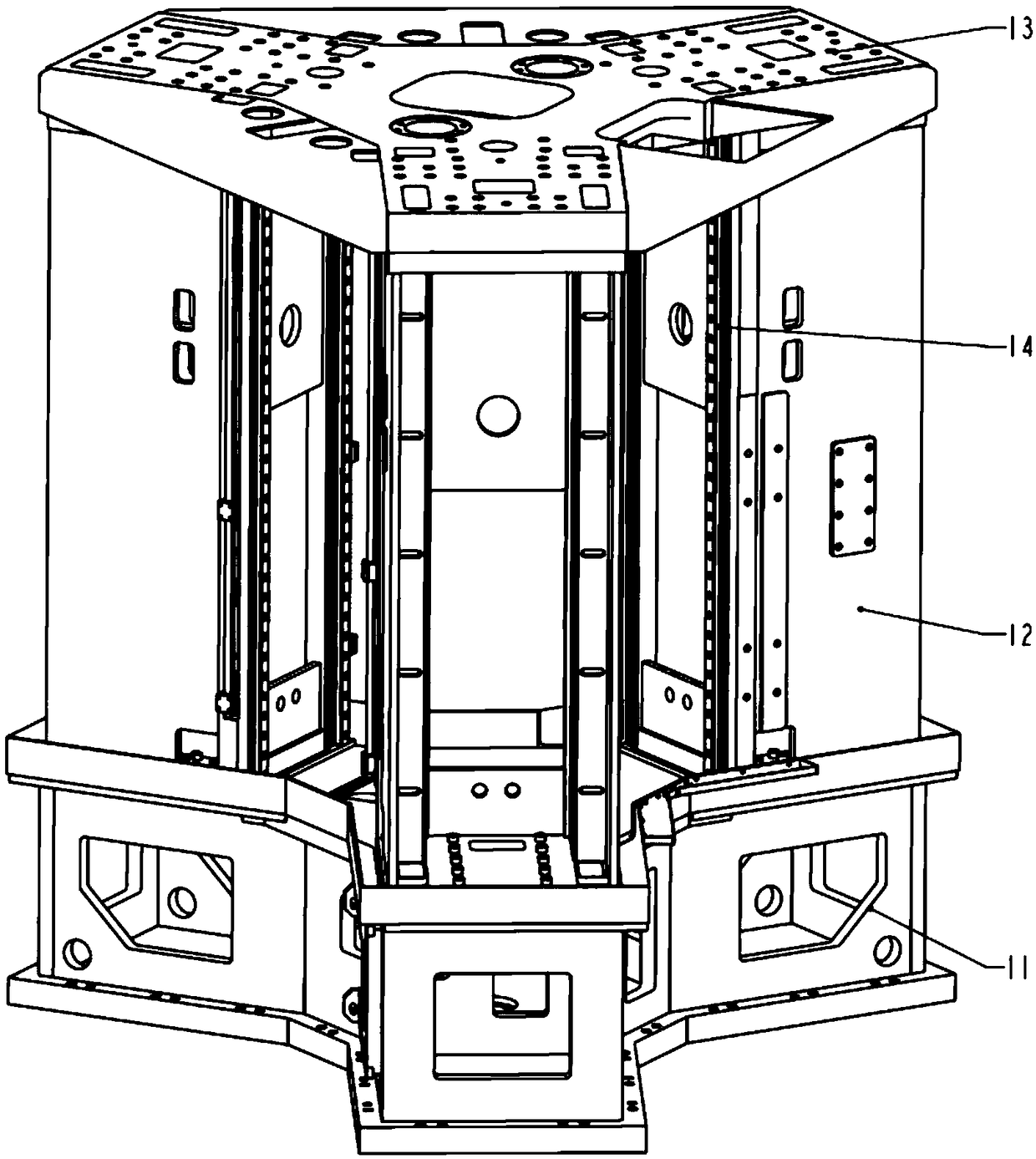

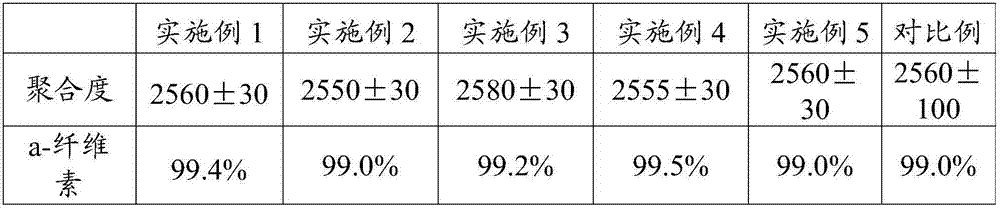

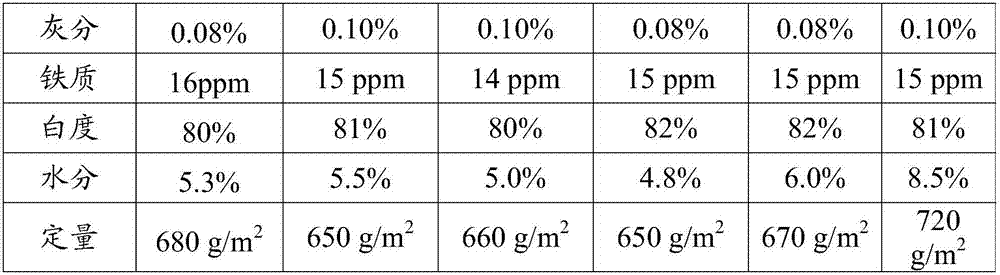

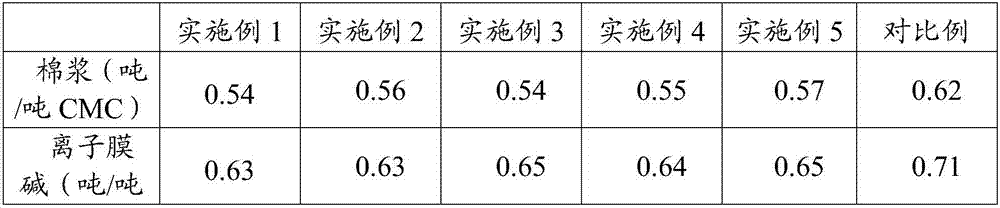

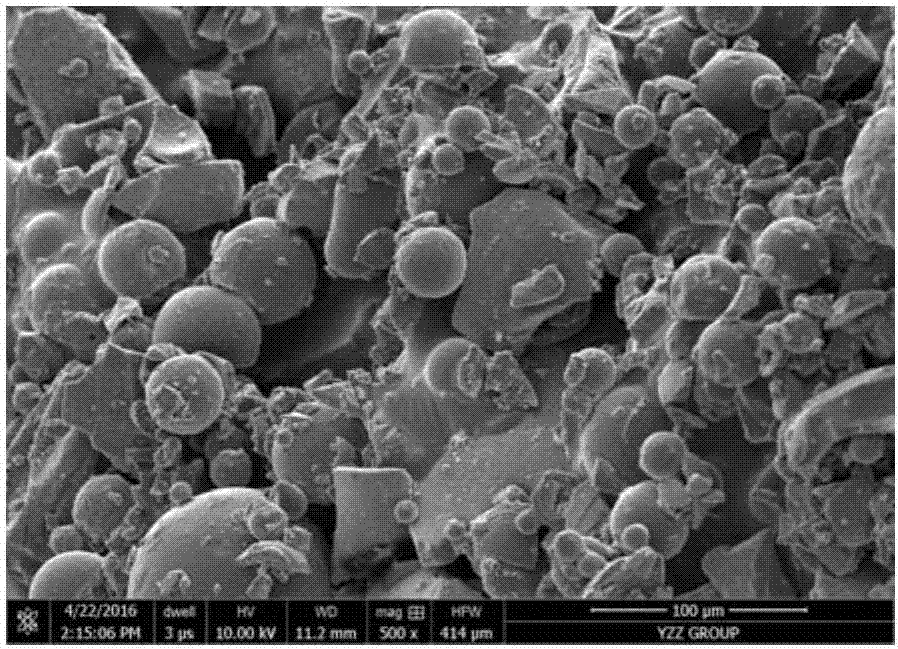

Cotton pulp and preparation method thereof, as well as carboxymethylcellulose and preparation method thereof

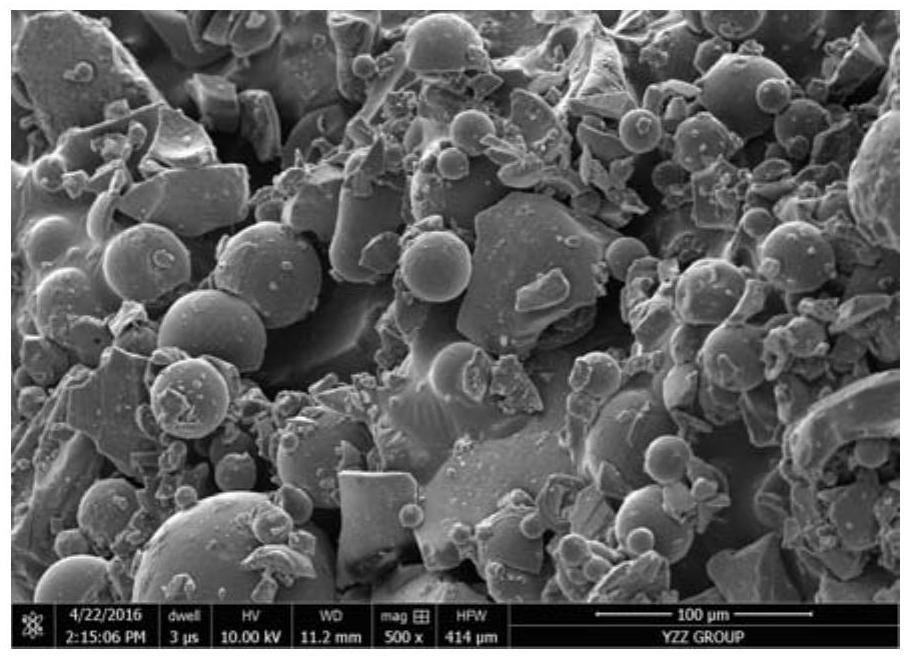

ActiveCN105821701AQuality improvementHigh reactivityPulping with inorganic basesNon-woody plant/crop pulpCarboxymethyl celluloseCotton fibre

The invention provides a preparation method of cotton pulp. The method comprises the following steps: mixing alkali liquor and cotton linters subjected to impurity removal, and performing continuous boiling, washing, pulping, degritting, primary concentration, chlorine alkalization, bleaching, acid treatment, water washing, degritting, secondary concentration and papermaking, so as to obtain the cotton pulp. The mass ratio of alkali in the alkali liquor to the absolute-dry cotton linters is (13 to 15): 100; the temperature for continuous boiling is 108 to 115 DEG C; the period for continuous boiling is 55 to 65min. According to the method, cotton pulp is prepared through a high alkali content, low temperature and short time continuous coiling mode, materials are uniformly heated in a tube, uniform permeation of alkali liquor is achieved, and the product polymerization degree is uniform; cotton fiber primary walls and secondary walls can be destroyed furthest, so that the degree of crystallinity of cotton pulp fiber is reduced, the amorphous region rises, and the reaction activity of the cotton pulp is improved. Through the adoption of the cotton pulp with high reaction activity, high-quality carboxymethylcellulose can be prepared.

Owner:ANHUI SNOW DRAGON FIBER TECH

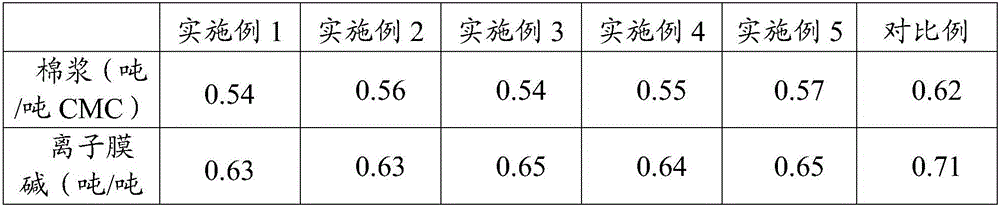

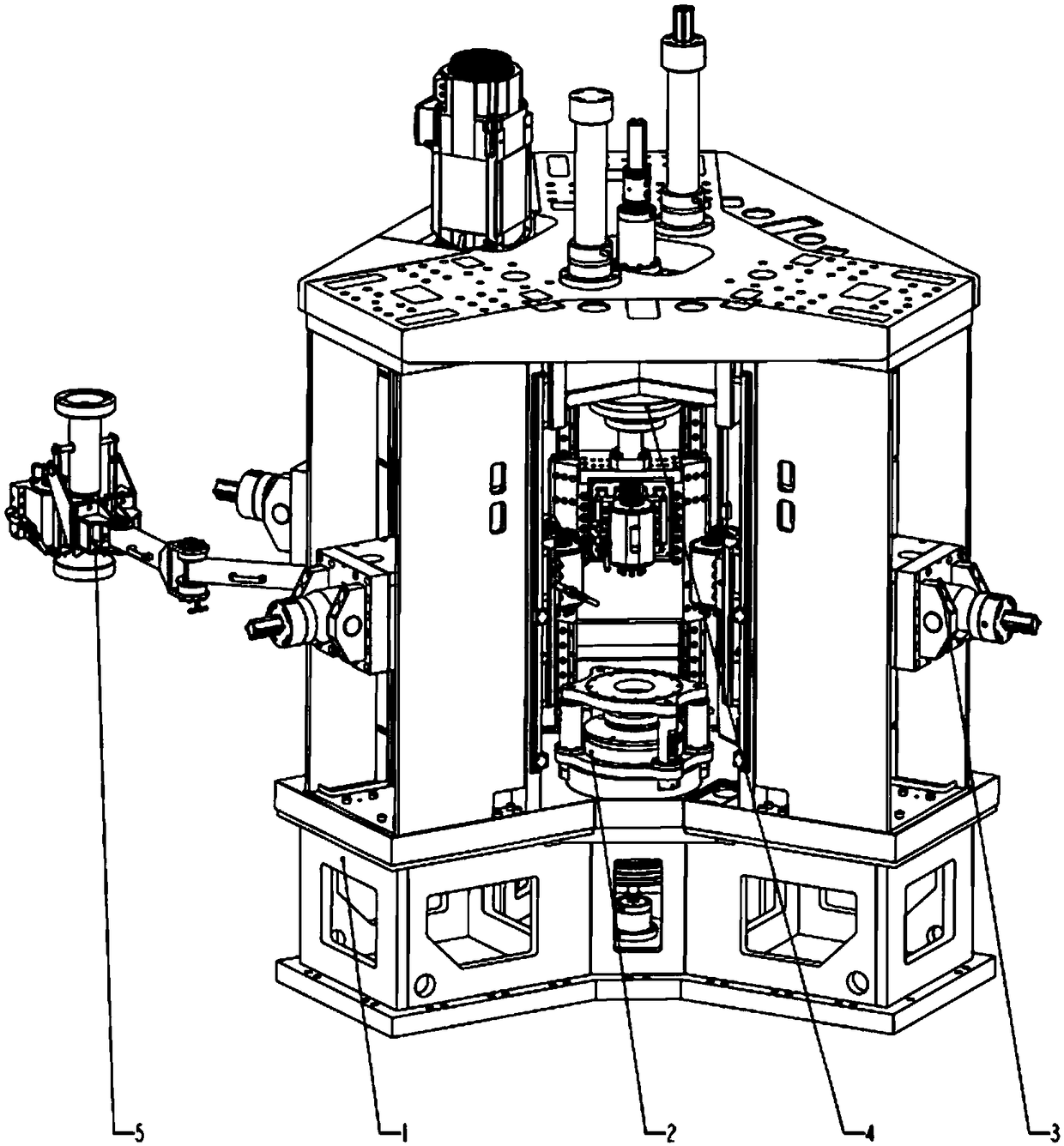

Vertical spinning machine

The invention relates to a vertical spinning machine comprising a machine body component, a main shaft component, a spinning wheel component, a tail jack component and a mechanical arm component as well as electronic control, hydraulic, lubrication, cooling and protection systems; the spinning wheel component of the vertical spinning machine is composed of three groups of spinning wheels distributed by 120 DEG, and a group of auxiliary spinning wheels; and each group of spinning wheels can achieve axial and radial servo feed motion alone. According to the vertical spinning machine stated in the invention, new technological methods, such as stagger spinning, local thickening and splitting, can be achieved, and the process flow is simplified; and the processing efficiency is improved, and the manufacturing cost is saved. The batch production of automobile clutch shell parts can be achieved, and the defects of existing equipment for producing such parts in China are overcome; and the gapbetween the automobile manufacturing field and foreign technical level is narrowed.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

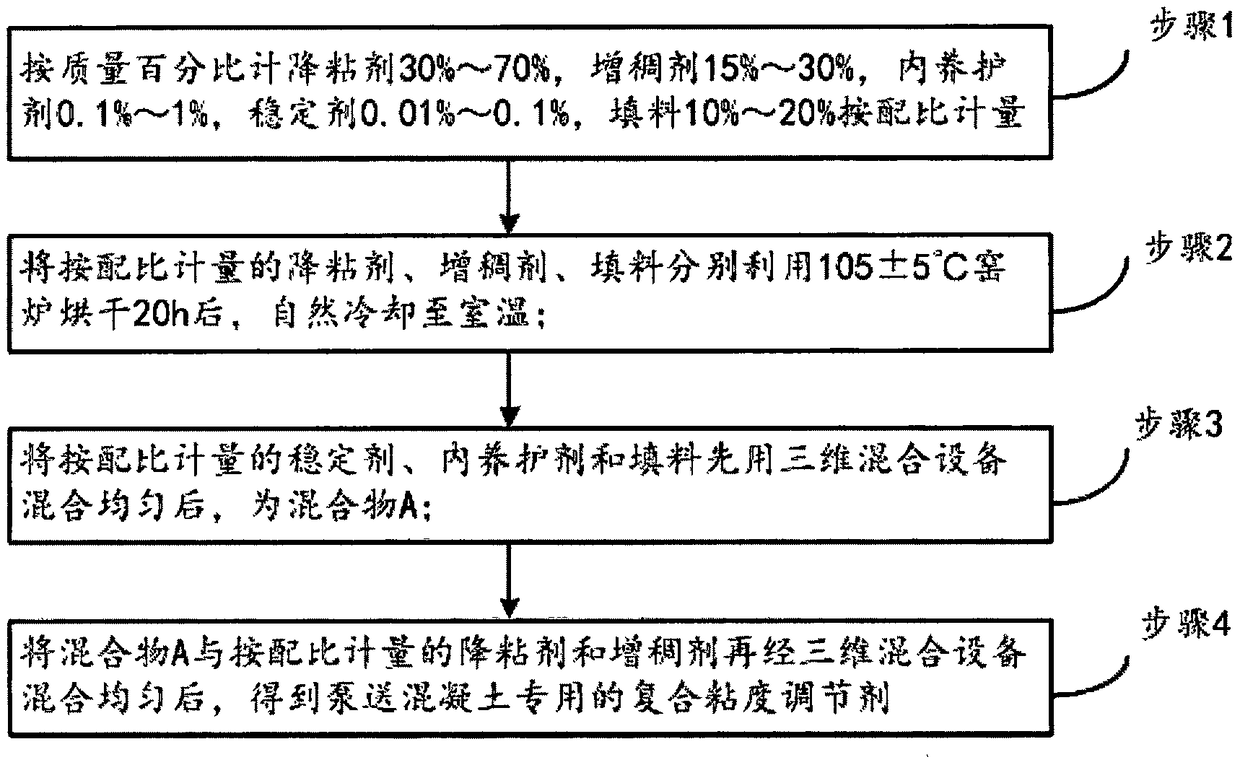

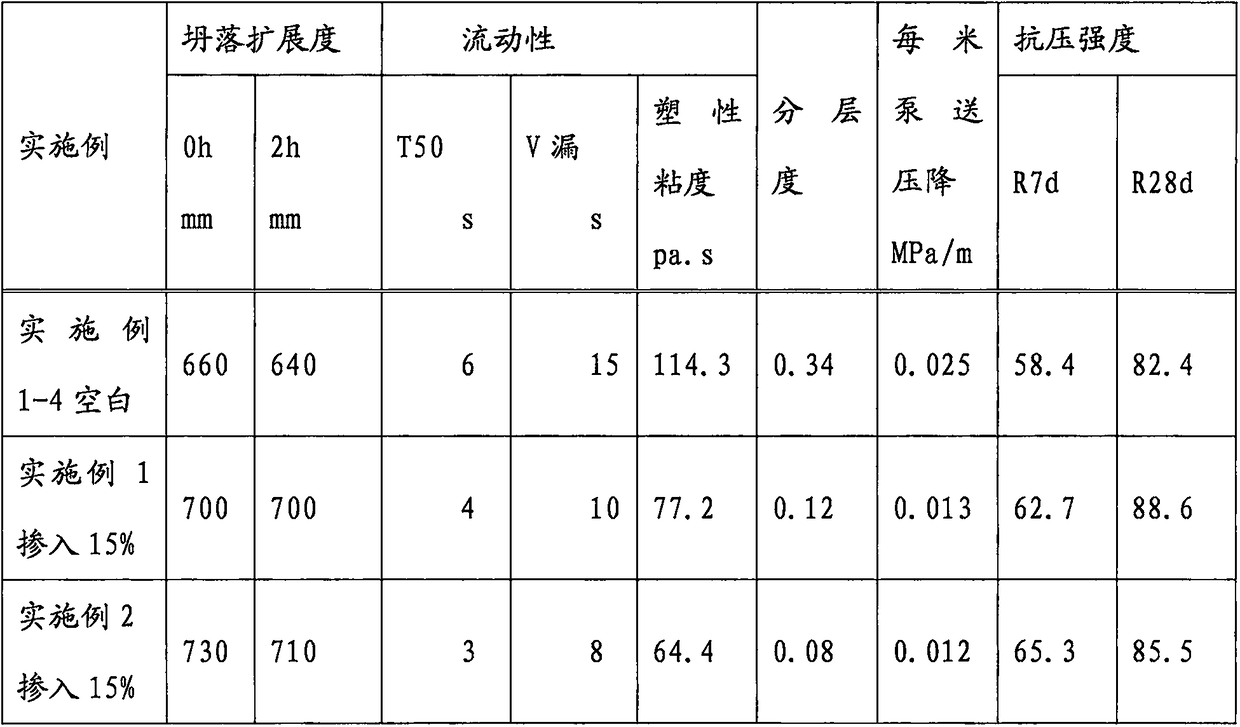

Special composite velocity adjusting agent, adjusting agent preparation method and application method

The invention discloses a special composite velocity adjusting agent for high-lift pumped concrete, an adjusting agent preparation method and an application method. The special composite velocity adjusting agent for the high-lift pumped concrete comprises the following components in percentage by mass: 30-70% of a viscosity reducer, 15-30% of a thickening agent, 0.1-1% of an inner maintenance agent, 0.01-0.1% of a stabilizer and 10-20% of packing. The special composite velocity adjusting agent is stable in property and simple to use, is directly put into concrete in a dry powder mode, is capable of effectively adjusting plasticization viscosities and homogeneity of a pumped concrete mixture after being uniformly stirred, is capable of preventing phenomena such as easy separation, water secretion and layering of large flowing pumped concrete, is particularly beneficial to pumping application of the high-lift (ultrahigh elevation) pumped concrete, and is capable of reducing pumping pipeline pressure along the way and preventing accidents such as pipeline blocking and pipeline explosion caused by large pumping resistance.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

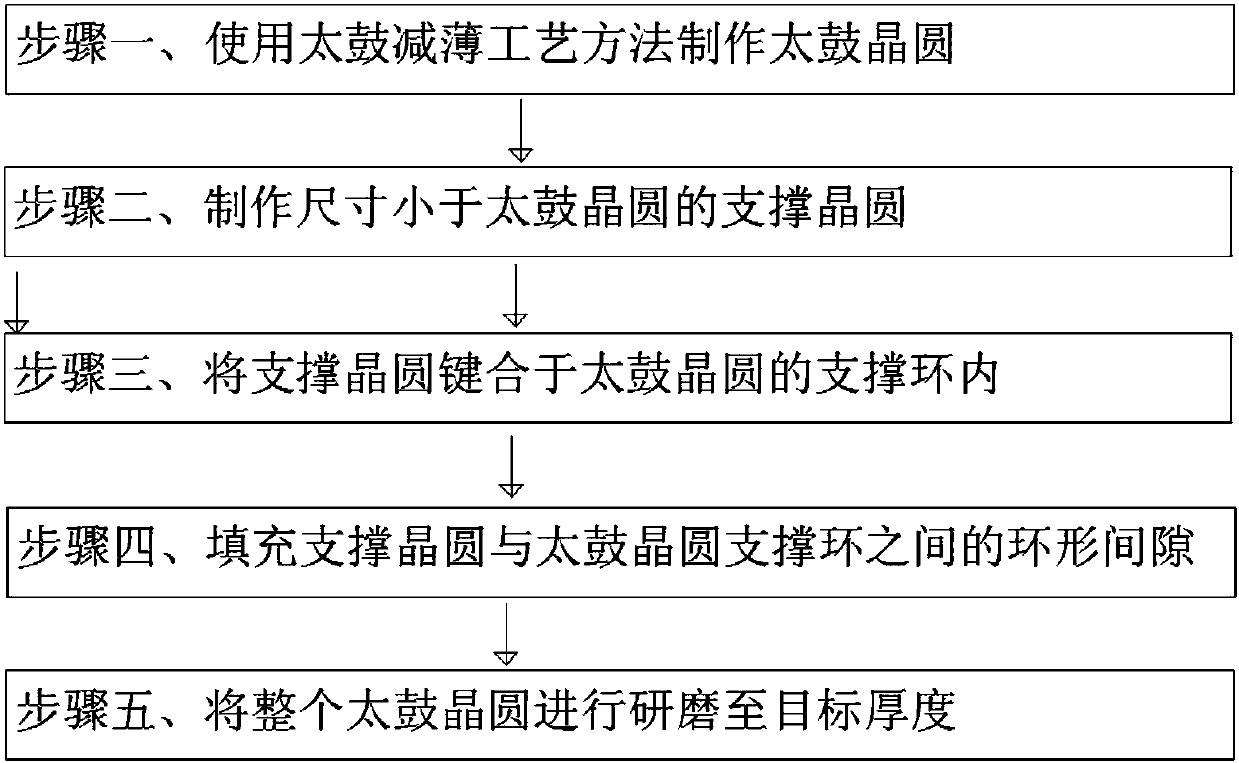

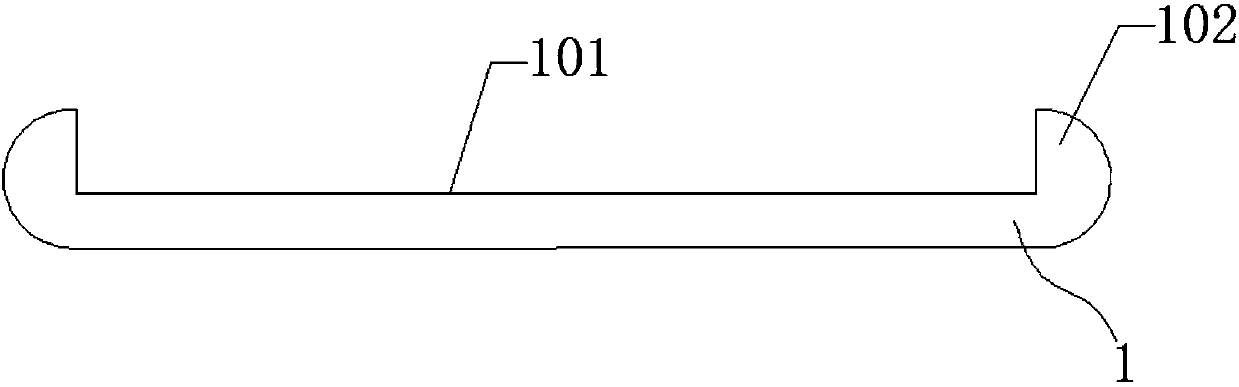

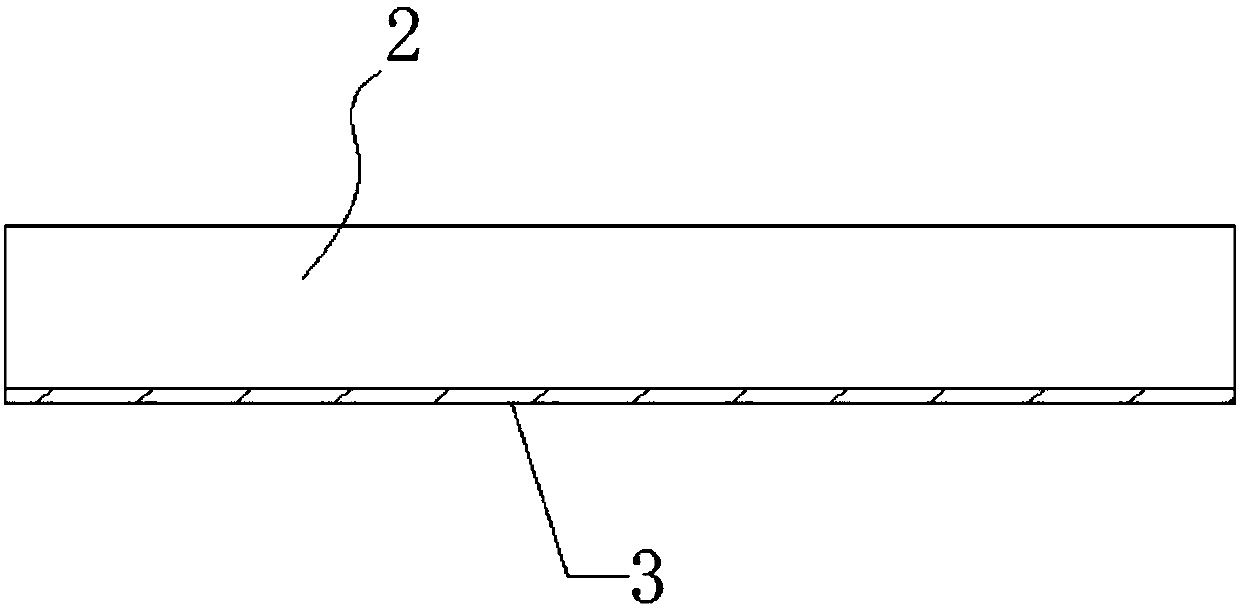

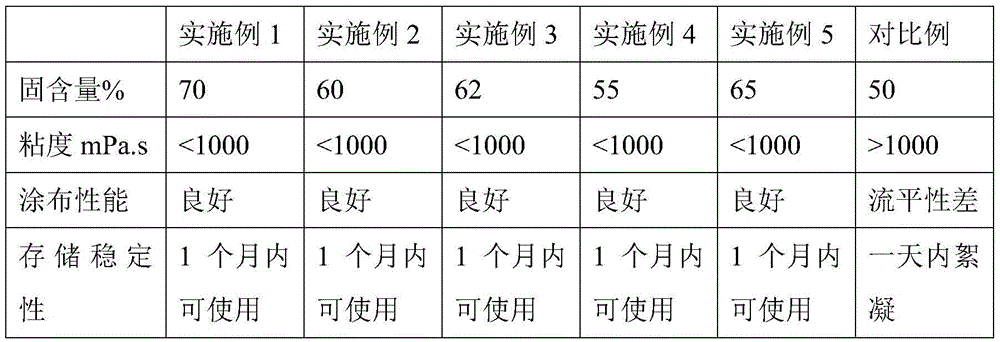

Taiko-wafer-based wafer-level packaging structure and method

ActiveCN107910288AAchieve thickeningSolid-state devicesSemiconductor/solid-state device manufacturingPetroleum engineeringWafer-level packaging

The invention discloses a Taiko-wafer-based wafer-level packaging structure and method. A support wafer is arranged at the center of a Taiko wafer after reduction based on a Taiko reduction process ina bonding manner, so that thickening of the center of the Taiko wafer is realized and thus the wafer-level packaging process is carried out continuously. With the method disclosed by the invention, usage of a special Taiko wafer support ring removing device is avoided and thus the wafer-level packaging of the Taiko wafer can be realized at a standard packaging production line.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

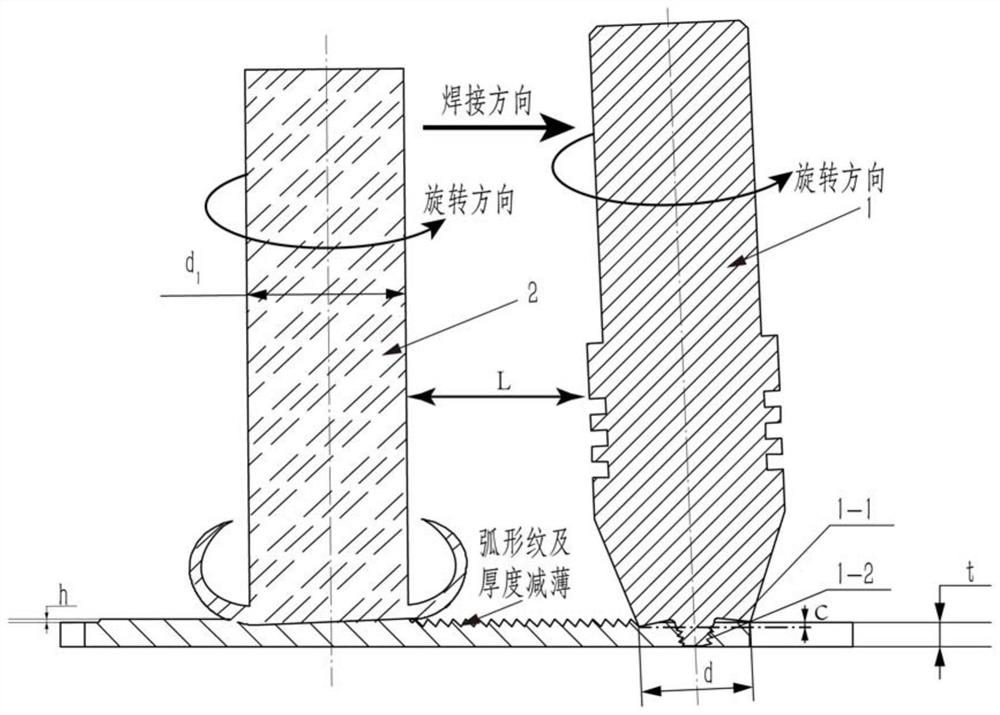

A Friction Stir Welding Method for Suppressing Weld Thinning and Thickening Weld

ActiveCN109967855BIncrease the area of actionAct as surface rougheningNon-electric welding apparatusOrganic solventSurface oxidation

The invention provides a friction stir welding method for restraining welded joint thinning and thickening a welded joint. The friction stir welding method includes the steps that firstly, cleaning isconducted before welding, an oxide film on the surface of a sheet to be welded is removed by mechanical polishing, and then organic solvents or cleaning agents are adopted to wipe the surface of thesheet to be welded to remove sundries; secondly, materials and shapes of a stirring head and a consumptive friction head are selected, the material and the shape of the stirring head are determined according to the properties and the thickness of the sheet to be welded, the consumptive friction head is made of the same material as the sheet to be welded, and the diameter of the consumptive friction head is equal to or larger than that of shaft shoulders of the stirring head; thirdly, positioning is conducted, the relative position of the sheet to be welded is adjusted to make the axis of the stirring head and the axis of the consumptive friction head face the center line of a to-be-welded position of the sheet to be welded, and the consumptive friction head is arranged directly behind thestirring head; and fourthly, welding is carried out. The friction stir welding method eliminates welded joint thinning and achieves welded joint thickening, so that the service life of the welded joint is remarkably prolonged.

Owner:HARBIN INST OF TECH

Acidic bathroom detergent

ActiveCN101372649BEfficient removalImprove acid resistanceOrganic detergent compounding agentsSurface-active detergent compositionsThioureaActive component

The invention relates to the cleaning and washing field of sanitary facilities. A thickening acidic bathroom cleaner disclosed by the invention comprises the following main active components by mass portions: 10-20 portions of a nonionic surfactant, 0.5-5.5 portions of an anionic surfactant, 2-5 portions of methanesulfonic acid, 0.3-1.0 portion of thiourea and 2-15 portions of oxydol. The cleanercan effectively remove human excrement and urine scale without corrosiveness, and has the functions of decontamination, cleaning, sterilization and deodorization.

Owner:BEIJING REWARD HOME CARE CHEM

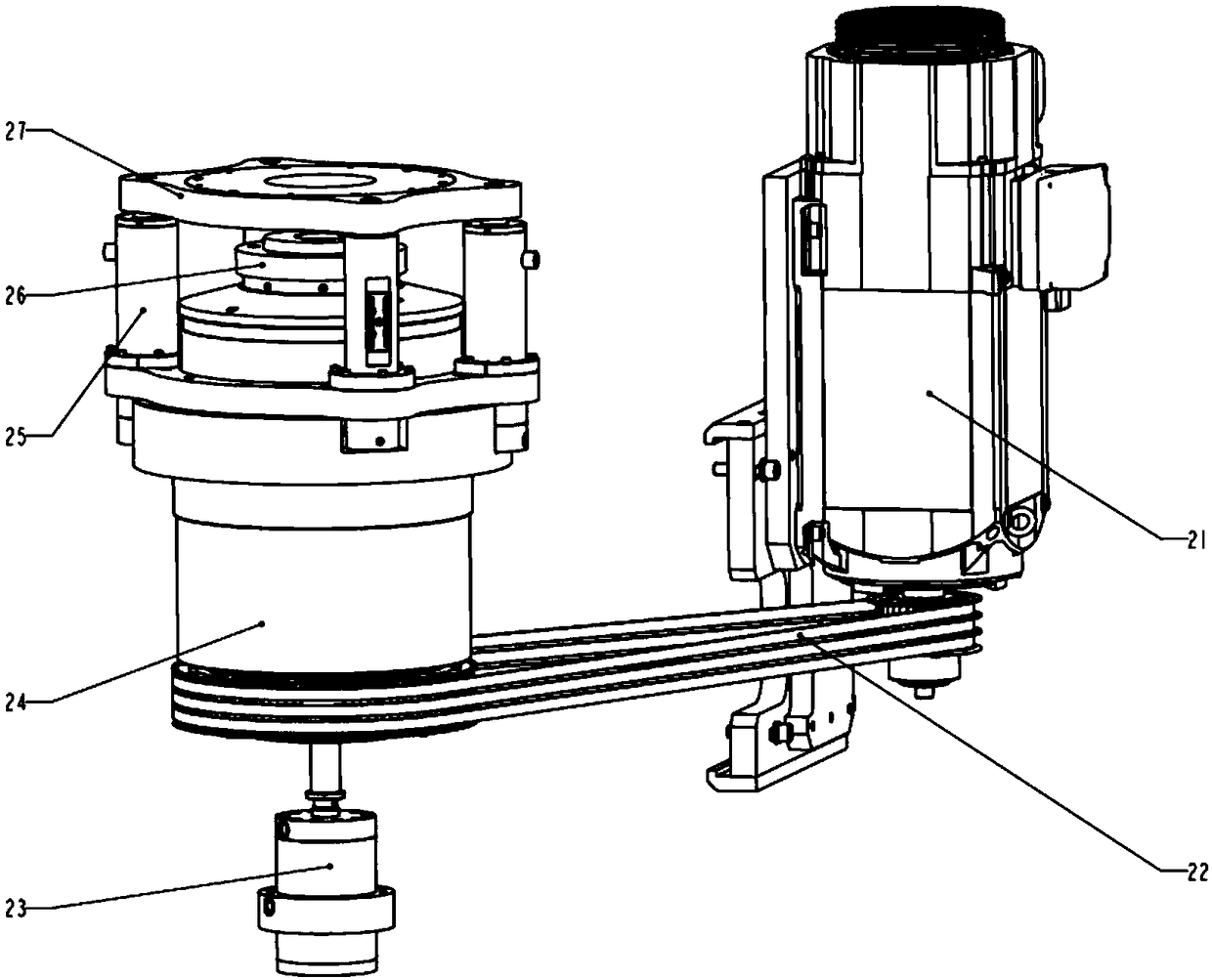

Carbon dioxide thickening fracturing system and technological method thereof

PendingCN113738333AAchieve thickeningReduce the impactFluid removalDrilling compositionPhysicsGeotechnical engineering

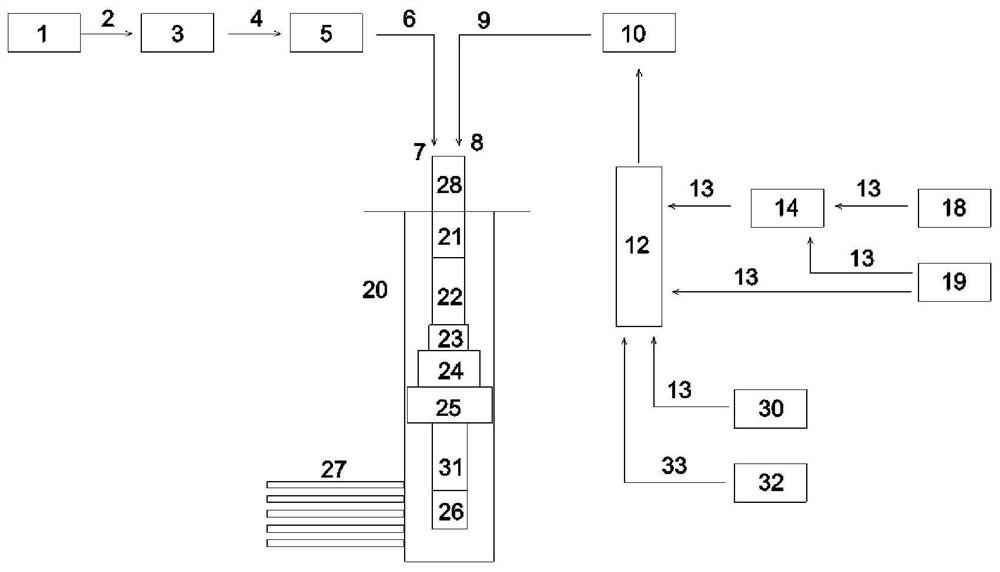

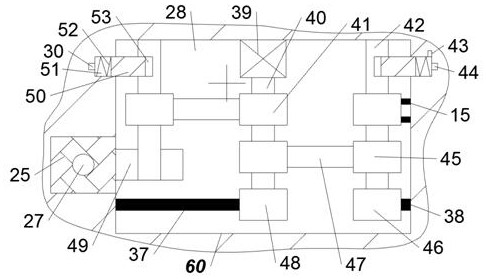

The invention provides a carbon dioxide thickening fracturing system, which is suitable for the field of fracturing transformation. The carbon dioxide thickening fracturing system comprises an output system, a fracturing fluid treatment system and a liquid CO2 treatment system, wherein the fracturing fluid treatment system comprises a liquid CO2 thickening agent stock solution treatment system and a fracturing fluid thickening system. A technological method comprises the following step that an extension short joint 21, a safety joint 23, a low-temperature high-pressure air-tight sealing hydraulic anchor 24, a low-temperature high-pressure air-tight sealing anchoring type packer 25, a sand blasting nozzle 26 and a fracturing well completion oil pipe 22 are put into a well together through a well repairing machine. According to the carbon dioxide thickening fracturing system, thickening of liquid carbon dioxide, fracture forming of the thickened liquid carbon dioxide, sand carrying of the thickened liquid carbon dioxide and liquid together and the like are achieved by designing fracturing fluid and liquid carbon dioxide pumping programs, the influence of liquid on a reservoir can be effectively reduced, the flowback rate is increased, the reservoir transformation effect is guaranteed to the maximum extent, and the single well yield is increased.

Owner:YANAN SHUANG FENG GRP

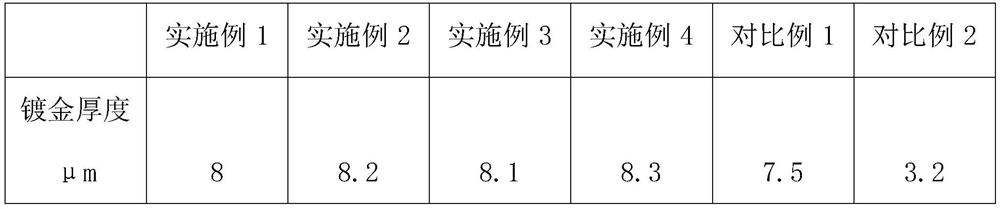

PCB secondary circuit gold plating process

InactiveCN111885844AReduce defective rateLow costDevelopersConductive pattern reinforcementGold layerGold plating

The invention discloses a PCB secondary circuit gold plating process, which comprises the following steps of: grinding and cleaning a PCB through a horizontal line to remove an oxide layer on the surface of the PCB, printing a layer of photosensitive solder resist ink on the surface of the PCB in a silk screen skip printing manner, transferring the PCB into a 65 DEG C oven, baking the photosensitive solder resist ink for 2 hours, and feeding the PCB into an exposure machine for exposing for 20 seconds; then transferring into a sodium carbonate solution with the mass fraction of 1% for cleaning, removing the unexposed photosensitive solder resist ink to expose a gold plating area pattern, and then feeding into a oven at 135-140 DEG C for drying the PCB for 30 minutes. According to the invention, the conductive windows are formed during two times of gold plating, the positions of the conductive windows can be adjusted according to actual requirements, the reject ratio of gold staining ofthe conductive windows is reduced by forming the conductive windows, the gold salt cost is saved, and the purpose of thickening a gold layer can be achieved through two times of gold plating.

Owner:深圳市明正宏电子有限公司

Electrochemical copper plating method based on fully-additive process

PendingCN113463143AIncrease productivitySavings in the process of transshipmentCellsLiquid/solution decomposition chemical coatingEtchingCopper plating

The invention belongs to the technical field of PCBs (printed circuit boards), and provides an electrochemical copper plating method based on a fully-additive process. The electrochemical copper plating method is characterized by comprising the following steps of drilling, glue residue removal, film drying, electrochemical copper plating and etching, wherein the electrochemical copper plating process specifically comprises the steps of: S1, adopting a catalytic reduction system, adjusting an electrochemical copper plating reaction system, and forming a uniform and compact copper layer on the surface of a base material or a hole in a copper deposition manner; and S2, in an existing plating solution system, achieving copper layer thickening by taking copper as a soluble anode and titanium as a cathode through electroplating. According to the electrochemical copper plating method, the copper plating rate can be increased, the copper plating binding force and the ductility of the copper layer can be guaranteed, the generation of a redox reaction byproduct Cu2O is controlled through a new graft polymerization catalysis system, the generation probability of disproportionated reaction is reduced, and the reaction rate and stability of an electrochemical copper plating system in a non-current plating layer are controlled.

Owner:GUANGDONG CHAMPION ASIA ELECTRONICS CO LTD

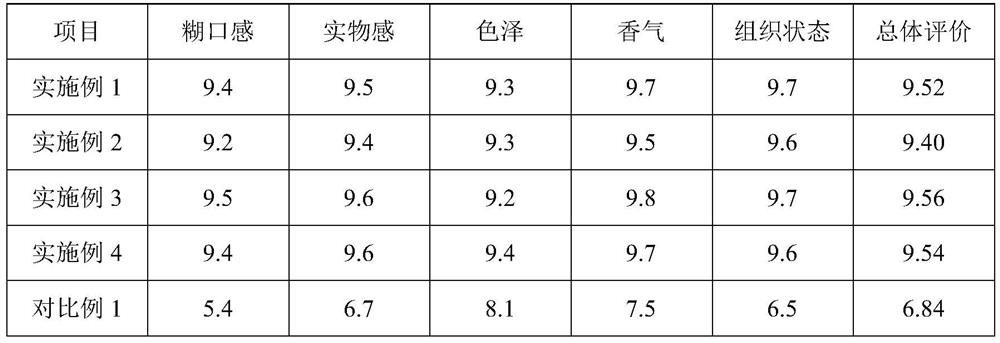

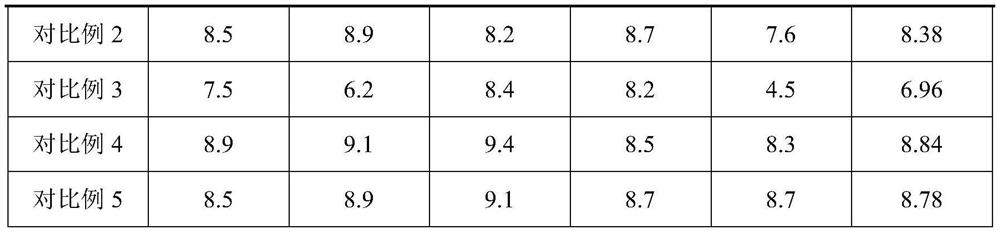

Citrus fiber-containing cheese guacamole and preparation method thereof

ActiveCN111990621AAchieve thickeningImprove the taste of pasteClimate change adaptationFood ingredient functionsBiotechnologySweet Peppers

The invention discloses citrus fiber-containing cheese guacamole and a preparation method thereof. The cheese guacamole comprises raw materials of cheese, avocado puree, tomatoes, sweet pepper sauce,dehydrated vegetable, soybean oil, water, cream, white granulated sugar, edible salt, yolk powder, maltodextrin, xanthan gum, citrus fiber, spices and the like. The preparation method comprises the following steps: firstly, re-dehydrating the dehydrated vegetable, then adding the xanthan gum and the white granulated sugar to the water, heating sol to prepare an xanthan gum solution, pulping the tomatoes to obtain tomato pulp, adding the cheese, the cream and the yolk powder to the soybean oil, performing heating and stirring for dissolution, and then uniformly mixing the dissolved materials with the xanthan gum solution, the tomato pulp, the re-dehydrated dehydrated vegetable, the sweet pepper sauce, the maltodextrin and the citrus fiber to obtain a mixture; and finally, adding the remaining components to the mixture to obtain the cheese guacamole. According to the cheese guacamole, the sense of eating, the sense of substance, the color, the aroma and the tissue state are improved overall by mutual cooperation of the components.

Owner:河北乐檬生物科技有限公司

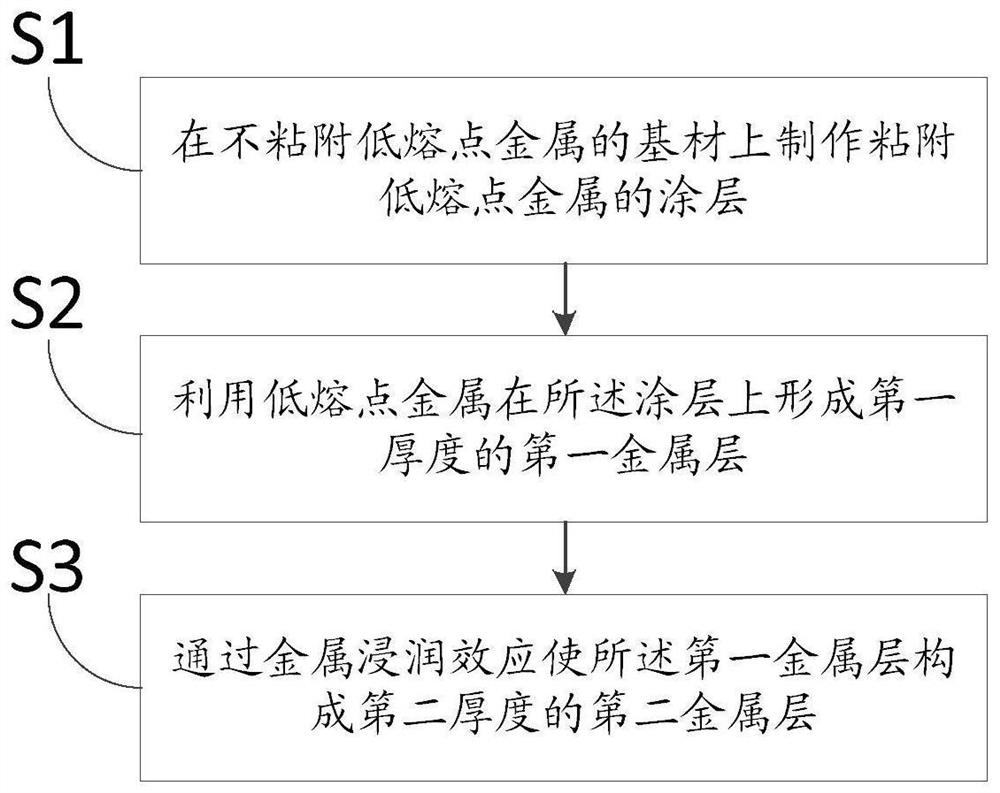

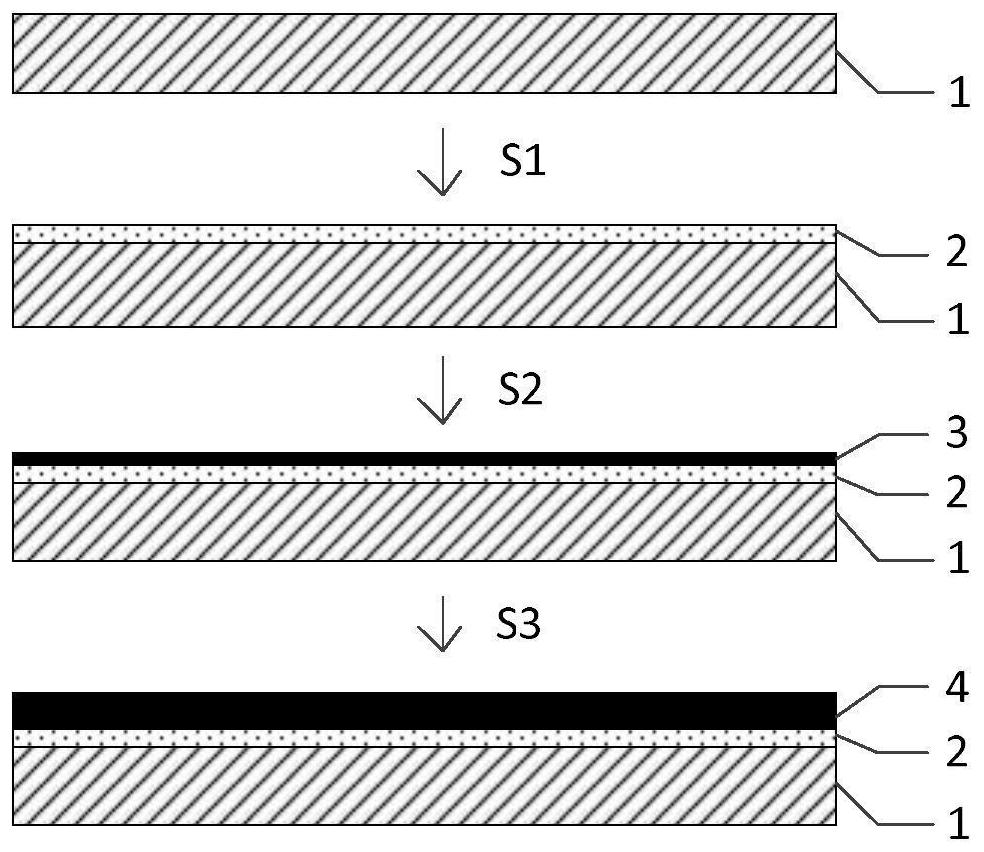

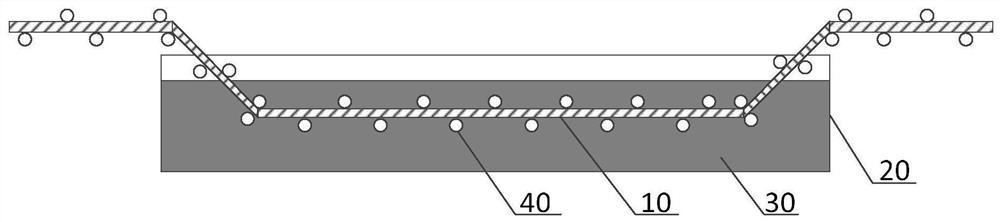

Printed electronic device and manufacturing method, manufacturing equipment and assembly line thereof

PendingCN111816366AAchieve thickeningSolve the defect of high resistance and poor conductivityApparatus for manufacturing conducting/semi-conducting layersRadiating elements structural formsElectrical resistance and conductanceAdditive layer manufacturing

The embodiment of the invention discloses a printed electronic device and a manufacturing method, manufacturing equipment and an assembly line thereof, and relates to the technical field of printed electronic additive manufacturing. The manufacturing method of the printed electronics comprises the following steps: manufacturing a coating adhered with low-melting-point metal on a base material notadhered with the low-melting-point metal, wherein the pattern of the coating is consistent with that of a target printed electron; forming a first metal layer with a first thickness on the coating byutilizing low-melting-point metal, and enabling the first metal layer to become a second metal layer with a second thickness through a metal infiltration effect, wherein the second thickness is greater than the first thickness. According to the invention, the metal infiltration effect between the low-melting-point metal and the low-melting-point metal is utilized to thicken the low-melting-point metal printed electrons, so that the defects of high resistance and poor conductivity caused by too thin low-melting-point metal printed electrons are effectively overcome.

Owner:BEIJING DREAM INK TECH CO LTD

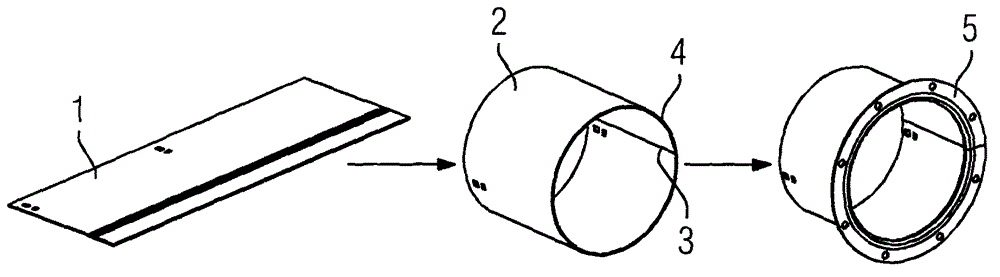

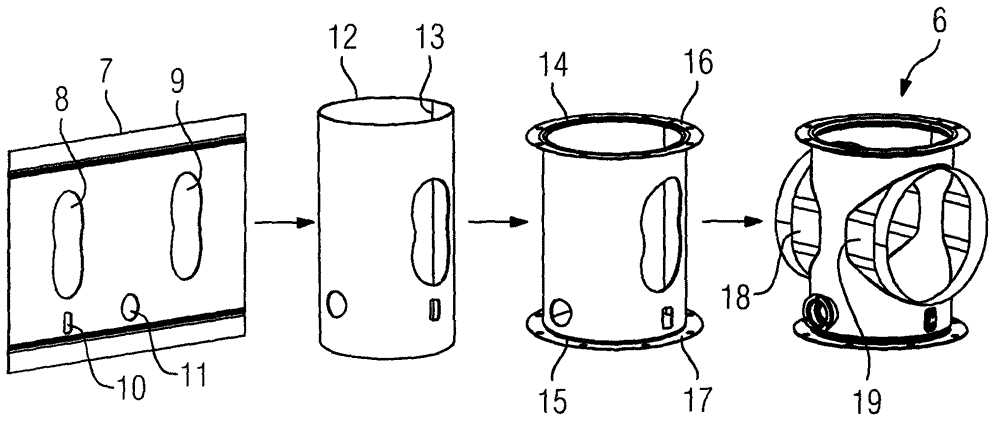

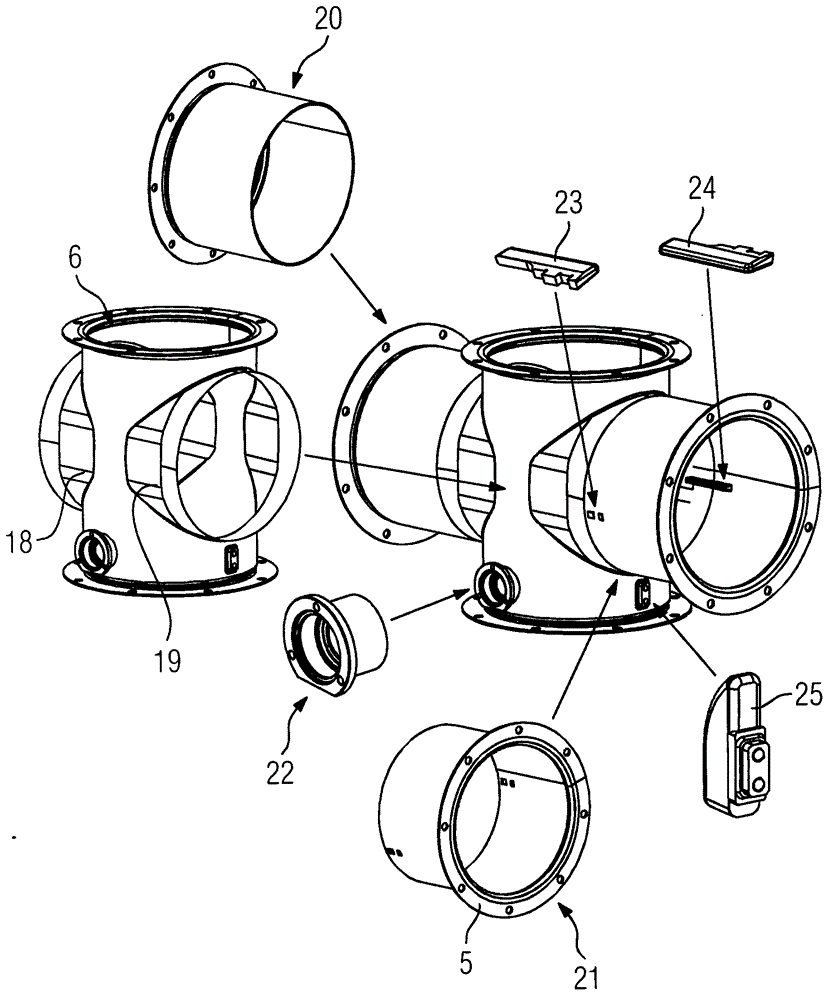

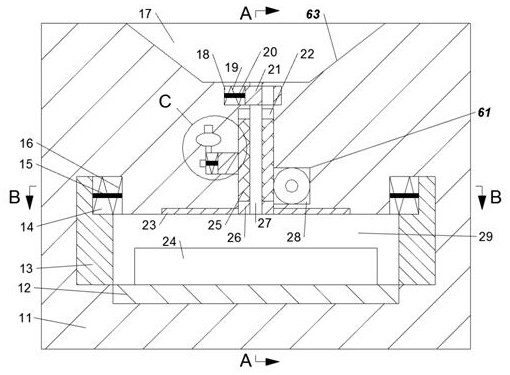

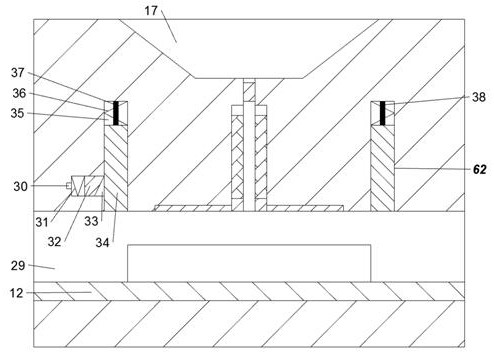

Method for manufacturing container component of sealing type switch device, and switch device

ActiveCN104550549AAchieve thickeningAchieve enhancementArrangements with metal casingHollow articlesFlangeMechanical engineering

The invention relates to a method for manufacturing a container component of a sealing type switch device, and a switch device. According to the invention, a method for manufacturing container components (6,20,21) of a sealing typoe switch device is provided. The method requires low cost. Pressure-bearing capability of teh container components are remainded; the method comprises structuring a cylindrical pipe (2,12) via welding between a rolling sheet (1,7) and abutted-sides (3,13) of the rolling sheet (1,7), and bending a flange (5,16,17) on at least one pipe end part (4) of the cylindrical pipe (2,12).

Owner:SIEMENS AG

Wood processing equipment for wood board thickening

InactiveCN112123476AAchieve thickeningConsistent thicknessMeasurement devicesWood veneer joiningPulp and paper industryWood plank

The invention discloses wood processing equipment for wood board thickening. The wood processing equipment comprises a box body, a detection cavity communicating with the outside is formed in the boxbody, a conveying belt used for conveying is fixedly connected to the lower inner wall of the detection cavity, and wood boards needing to be detected and glued is connected to the conveying belt in afriction manner; and a detection mechanism used for detecting the thicknesses of the wood boards is arranged in the upper inner wall of the detection cavity, the detection mechanism comprises a rackcavity located in the upper inner wall of the detection cavity and provided with a downward opening, the rack cavity is internally connected with a rack cavity in a sliding manner, and the lower end of the rack cavity is fixedly connected with a detection block. The device is simple in structure and convenient to use, gluing machines with the corresponding quantity can be added according to different heights of different wood boards, so that gluing thickening of the wood boards is achieved, the thicknesses of the wood boards are kept consistent, subsequent installation and use are facilitated,manual detection is not needed, and the efficiency is greatly improved while the time is saved.

Owner:东阳潘辰竹木工艺品有限公司

Method for removing titanium from converter molten iron

ActiveCN111635973ATitanium removal maximum efficiencyAvoid the risk of overturningManufacturing convertersSteelmakingIron plant

The invention belongs to the technical field of steelmaking, and particularly relates to a method for removing titanium from converter molten iron. The method comprises the following steps of: beforetapping of an iron plant, adding a titanium removing agent into molten iron of a blast furnace tapping channel; then, in the tapping process of a steel plant backflow station, adding the titanium removing agent into an iron ladle; before desulfurization of a KR desulfurization station, removing titanium removing slag; after desulfurization of the KR desulfurization station is completed, carrying out converter blowing; and after converter blowing is completed, tapping, wherein the mass ratio of the titanium removing agent to the molten iron of the blast furnace tapping channel is (1.5-1.8) kg:(0.9-1.0) t; in the tapping process of the steel plant backflow station, the adding rate of the titanium removing agent is 60-260kg / min; and the mass ratio of the titanium removing agent to the molteniron in the iron ladle is (2-8) kg: (0.9-1.0) t. According to the method, the titanium removing agent, the titanium removing slag, converter blowing and the like are optimized and controlled, so thatsteel with low titanium content and various corresponding products are obtained, and the average titanium content is controlled to be 0.0005-0.0006%.

Owner:BEIJING SHOUGANG CO LTD

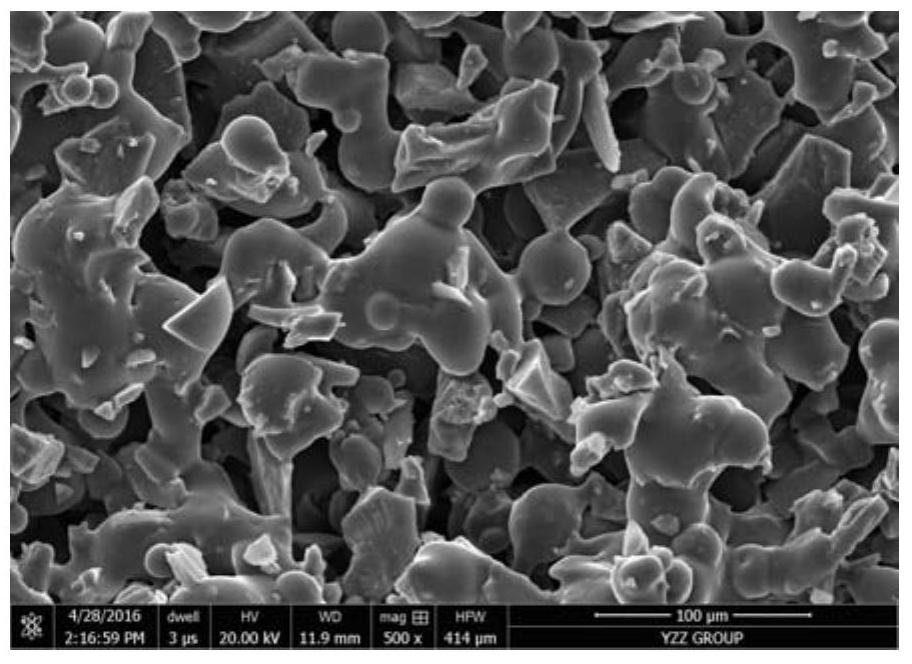

A kind of composite medical food and preparation method thereof

The invention discloses a compound medical food and a preparation method thereof. The compound medical food is composed of betaine or betaine monohydrate, modified starch, dietary fiber and an aqueous medium, wherein per liter of the aqueous medium contains 5g-200g of betaine or betaine monohydrate, 50mg-2000mg of modified starch and 5mg-200mg of dietary fiber. Experimental results show that by virtue of doping of the modified starch, a compound betaine solution has better viscosity, forms physical gel and restores to a flow state under the effect of shearing force. Furthermore, the compound medical material disclosed by the invention can be prepared under mild conditions, and the preparation method is simple. The compound medical food disclosed by the invention has certain adjuvant treatment effects on human cardiovascular diseases, nervous diseases, liver diseases and hyperhemicysteinuria and can be used for health or neurology department clinical medicine.

Owner:深圳市伟航奕宁生物科技有限公司

A kind of cotton pulp and its preparation method and a kind of carboxymethyl cellulose and its preparation method

ActiveCN105821701BQuality improvementHigh reactivityPulping with inorganic basesNon-woody plant/crop pulpFiberPapermaking

The invention provides a preparation method of cotton pulp. The method comprises the following steps: mixing alkali liquor and cotton linters subjected to impurity removal, and performing continuous boiling, washing, pulping, degritting, primary concentration, chlorine alkalization, bleaching, acid treatment, water washing, degritting, secondary concentration and papermaking, so as to obtain the cotton pulp. The mass ratio of alkali in the alkali liquor to the absolute-dry cotton linters is (13 to 15): 100; the temperature for continuous boiling is 108 to 115 DEG C; the period for continuous boiling is 55 to 65min. According to the method, cotton pulp is prepared through a high alkali content, low temperature and short time continuous coiling mode, materials are uniformly heated in a tube, uniform permeation of alkali liquor is achieved, and the product polymerization degree is uniform; cotton fiber primary walls and secondary walls can be destroyed furthest, so that the degree of crystallinity of cotton pulp fiber is reduced, the amorphous region rises, and the reaction activity of the cotton pulp is improved. Through the adoption of the cotton pulp with high reaction activity, high-quality carboxymethylcellulose can be prepared.

Owner:ANHUI SNOW DRAGON FIBER TECH

Compound medical food and preparation method thereof

The invention discloses a compound medical food and a preparation method thereof. The compound medical food is composed of betaine or betaine monohydrate, modified starch, dietary fiber and an aqueous medium, wherein per liter of the aqueous medium contains 5g-200g of betaine or betaine monohydrate, 50mg-2000mg of modified starch and 5mg-200mg of dietary fiber. Experimental results show that by virtue of doping of the modified starch, a compound betaine solution has better viscosity, forms physical gel and restores to a flow state under the effect of shearing force. Furthermore, the compound medical material disclosed by the invention can be prepared under mild conditions, and the preparation method is simple. The compound medical food disclosed by the invention has certain adjuvant treatment effects on human cardiovascular diseases, nervous diseases, liver diseases and hyperhemicysteinuria and can be used for health or neurology department clinical medicine.

Owner:深圳市伟航奕宁生物科技有限公司

A method for removing titanium from molten iron in a converter

ActiveCN111635973BTitanium removal maximum efficiencyAvoid the risk of overturningManufacturing convertersSteelmakingIron plant

Owner:BEIJING SHOUGANG CO LTD

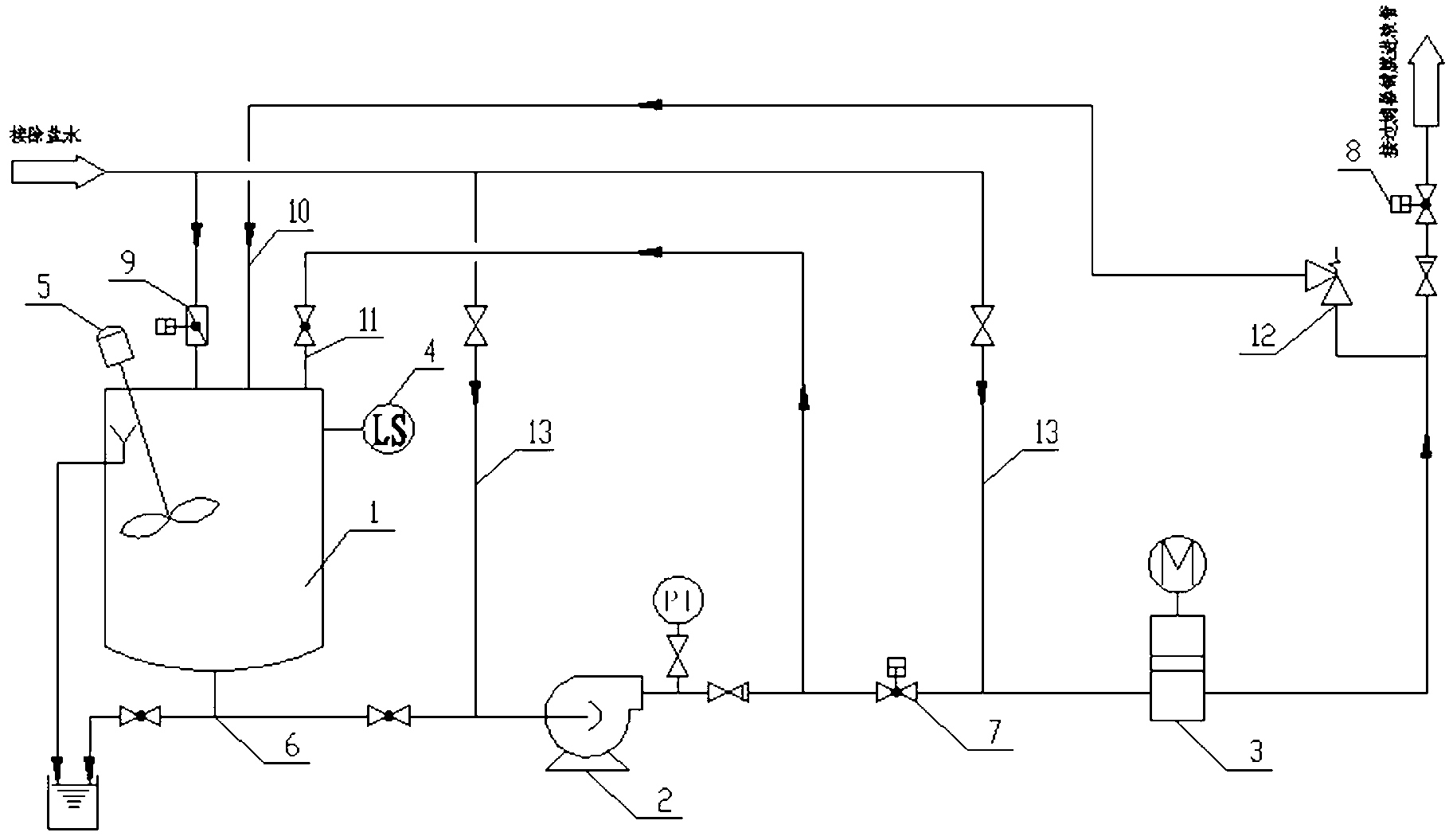

Powdery resin filter online film laying system

ActiveCN103170176AThe contradiction between not being easy and not being able to lay filmSolve the contradiction that cannot be filmedFiltration separationSmall footprintSlurry

The invention discloses a powdery resin filter online film laying system. The system is characterized in that a film laying case is provided with an inclined insert type electric stirrer and a floating ball liquid level switch. The system has the following advantages: 1, the filter element of a filter is repaired and thickened in the running process, so the running period is improved; 2, the adoption of the inclined insert type electric stirrer prevents a material liquid in the film laying case from forming a vortex, is in favor of the full and uniform mixing of the material liquid, and is also in favor of conveying the material liquid; 3, an advanced film laying pump adopts a medium pressure resistant pump shell, and is a metering pump capable of conveying a slurry, and the arrangement of a safe valve at the outlet tube of the pump is helpful for avoiding impact from a medium pressure system; 4, the powdery resin filter online film laying system is connected with the powdery filter, and has a running direction consistent with the filter, so online uniform laying and difficult shedding of a powdery resin are benefited; and 5, the powdery resin filter online film laying system has a small occupied area, solves a problem that the a filter which cannot be laid with a film under a medium pressure running condition, improves the use efficiency of the filter, reduces the running cost and reduces the manual labor.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

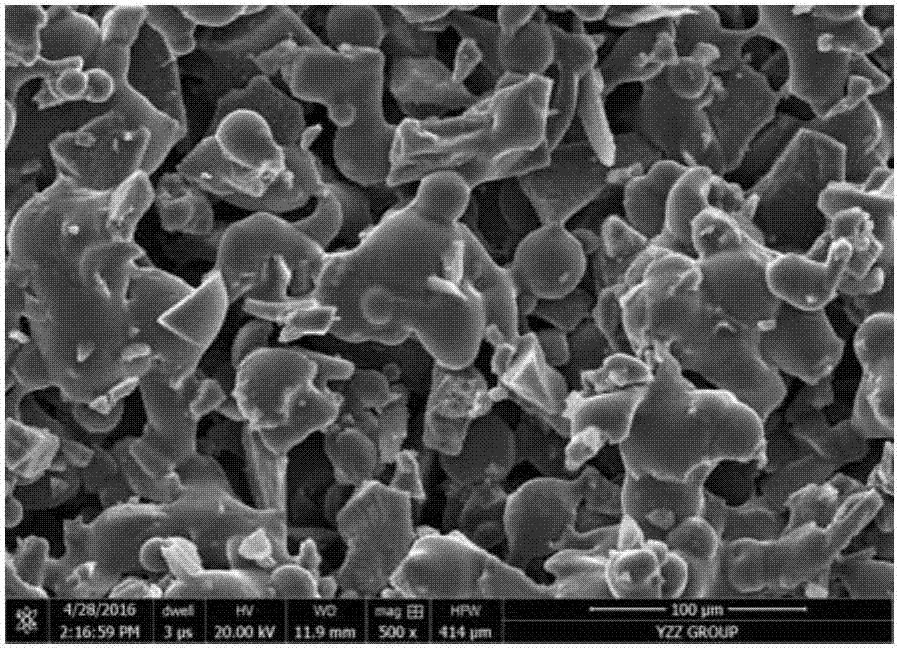

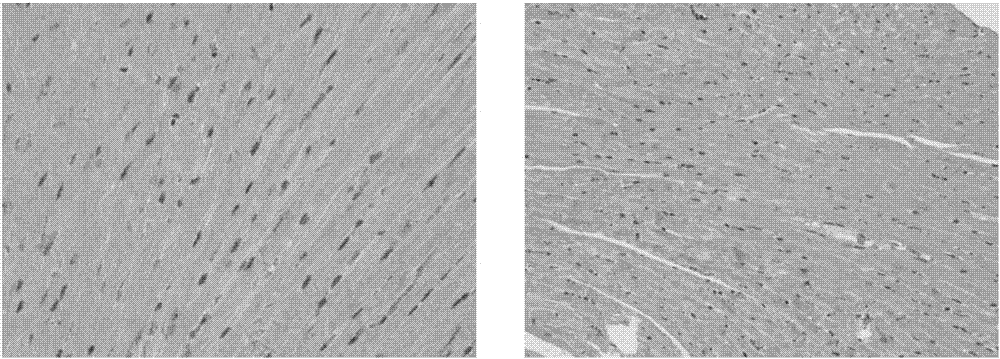

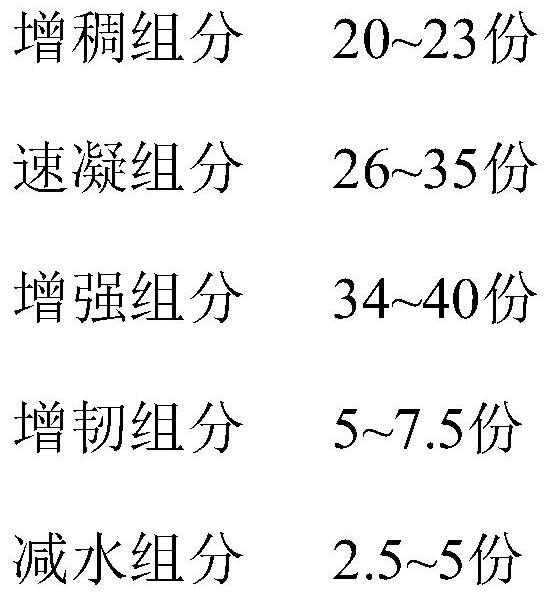

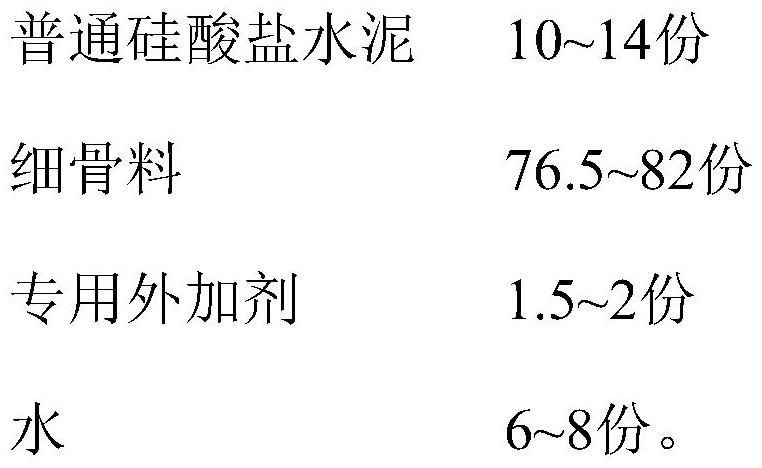

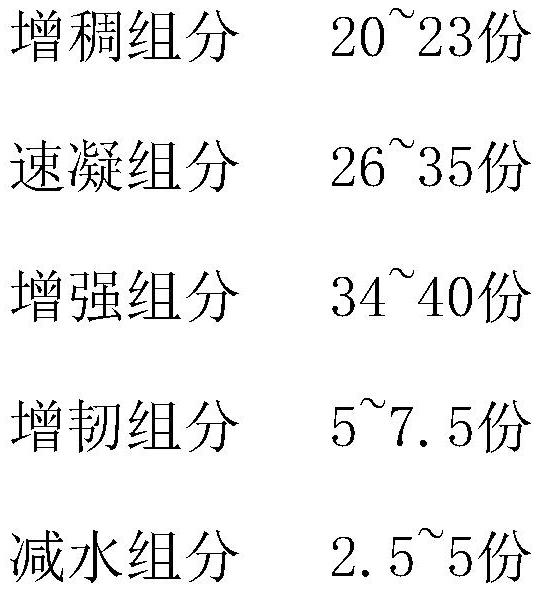

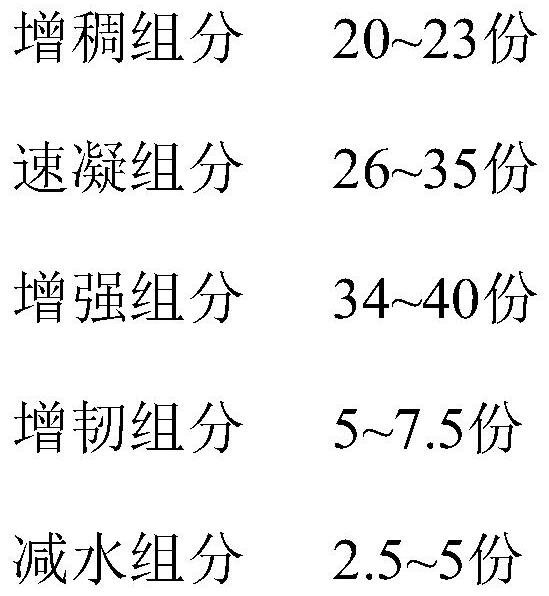

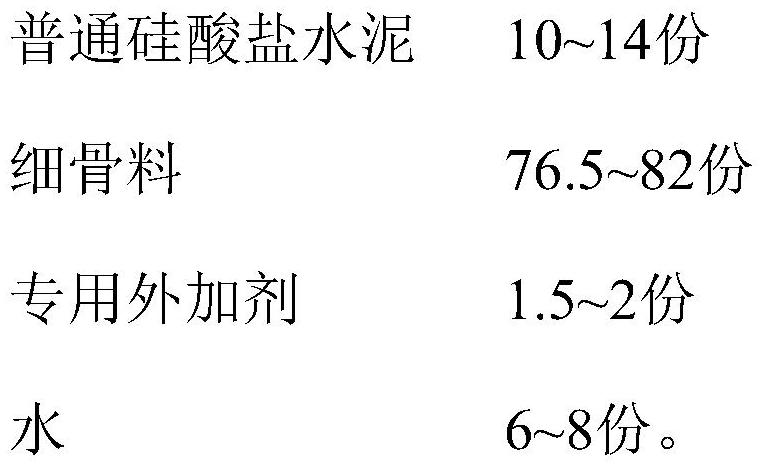

Admixture special for hydraulic structure permeable pointing mortar and preparation and use method thereof

ActiveCN112707666AEfficient recyclingLow costSolid waste managementPortland cementMechanical engineering

The invention relates to a special admixture for permeable pointing mortar of a hydraulic structure as well as a preparation method and a use method thereof. The preparation method comprises the following steps:preparing a special admixture from the following components in parts by weight: 20-23 parts of a thickening component, 26-35 parts of a quick-setting component, 34-40 parts of a reinforcing component, 5-7.5 parts of a toughening component and 2.5-5 parts of a water reducing component by feeding the components into a powder mixer, and mixing for 5-10 minutes. The use method of the prepared special admixture comprises the following steps: mixing, by weight, 1.5-2 parts of the special admixture with 10-14 parts of ordinary Portland cement, 76.5-82 parts of fine aggregate and 6-8 parts of water in the mixer for 5-10 minutes. According to the invention, falling and structural damage of the apron pointing mortar can be prevented, and the setting time of the pointing mortar material is ensured to meet the rapid setting requirement.

Owner:浙江钱塘江水利建筑工程有限公司 +1

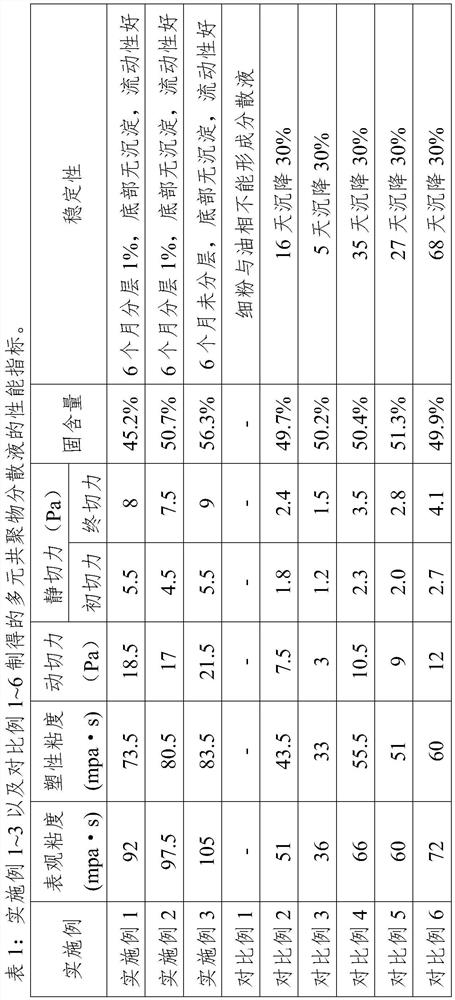

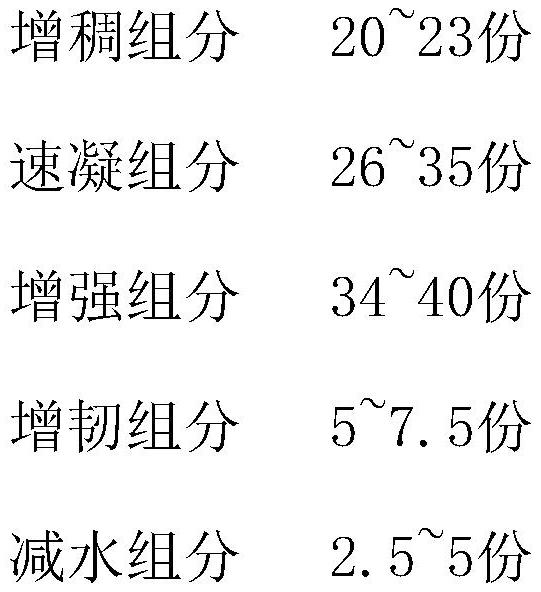

A kind of high-efficiency instant multi-component copolymer dispersion liquid and preparation method thereof

ActiveCN112662383BHigh solid contentReduce apparent viscosityDrilling compositionPolymer scienceApparent viscosity

The invention relates to a high-efficiency instant multi-component copolymer dispersion and a preparation method thereof. The dispersion liquid comprises the following components in weight percent: multi-polymer copolymer fine powder: 45-55%; rheological agent: 1.5-3%; rheological additive: 0.5%-1%; wetting agent : 0.5-1%; stabilizer: 0.5-2%; activator: 0.5-1%; emulsifier: 1.5-4%; white oil: 34-50%; the method is: grinding multi-component copolymer particles , to obtain a multi-component copolymer fine powder; add a wetting agent and a stabilizer to the multi-component copolymer fine powder for surface treatment to obtain a pre-treated fine powder; white oil, pre-treated fine powder, rheological agent, rheological additive, The activator and emulsifier are mixed and then activated to obtain the dispersion. The dispersion liquid of the present invention has high solid content and is more stable, the delamination rate is less than 2% within 6 months, the dispersion liquid has low apparent viscosity, good fluidity, and no precipitation after long-term storage.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Special admixture for hydraulic structure permeable pointing mortar and its preparation and use method

ActiveCN112707666BEfficient recyclingLow costSolid waste managementPortland cementMechanical engineering

The invention relates to a special admixture for water-permeable pointing mortar of a hydraulic structure and a preparation and use method thereof. The special admixture is composed of the following components by weight: 20-23 parts of thickening component, 26-35 parts of quick-setting component, 34-40 parts of strengthening component, 5-7.5 parts of toughening component, water-reducing component Divide 2.5 to 5 parts, feed the above components into a powder mixer and mix for 5 to 10 minutes to prepare a special admixture. The method of using the above prepared special admixture is to mix it with ordinary Portland cement, fine bone Materials and water, according to the following proportions by weight, were mixed and stirred in a mixer for 5-10 minutes to prepare: 10-14 parts of ordinary Portland cement, 76.5-82 parts of fine aggregate, 1.5-2 parts of special admixture 6-8 parts of water. The invention can prevent the apron pointing mortar from falling off and structural damage, and ensure that the setting time of the pointing mortar material meets the quick-setting requirement.

Owner:浙江钱塘江水利建筑工程有限公司 +1

High solid content aqueous ceramic slurry and processing method of lithium ion battery separator

ActiveCN104446515BAchieve thickening effectAchieve stabilityCell component detailsLatex rubberCarbon nanotube

The invention discloses a high-solid-content aqueous ceramic slurry for lithium-ion battery separators, which comprises 50-65% of a composition calculated by weight percentage and 35-50% of water; 0.1-5 parts of polymer emulsion thickener, 1-10 parts of carbon nanotubes, 0.1-5 parts of water-based dispersant, 0.1-5 parts of water-based wetting agent, 1-10 parts of water-based latex and 80-100 parts of ceramic particles. The invention also discloses a processing method of the above-mentioned high-solid-content aqueous ceramic slurry. The invention has the advantages of high solid content and good product stability.

Owner:SHENZHEN SENIOR TECH MATERIAL

Opening time adjustable wallpaper adhesive and preparation method thereof

ActiveCN101962521BAchieve thickeningAchieve water retentionMonocarboxylic acid ester polymer adhesivesStarch derivtive adhesivesCelluloseEmulsion

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

Wafer-level packaging structure and method based on Taiko wafer

ActiveCN107910288BAchieve thickeningSolid-state devicesSemiconductor/solid-state device manufacturingProduction lineEngineering

The invention discloses a Taiko-wafer-based wafer-level packaging structure and method. A support wafer is arranged at the center of a Taiko wafer after reduction based on a Taiko reduction process ina bonding manner, so that thickening of the center of the Taiko wafer is realized and thus the wafer-level packaging process is carried out continuously. With the method disclosed by the invention, usage of a special Taiko wafer support ring removing device is avoided and thus the wafer-level packaging of the Taiko wafer can be realized at a standard packaging production line.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Preparation method of cream thickening agent

InactiveCN107788501AAchieve thickeningReduce fatFood ingredient as thickening agentCream preparationFood additiveAlginic acid

The invention provides a preparation method of a cream thickening agent, and relates to the field of food additives. The preparation method comprises the following steps of (1) under normal temperature, soaking peach gum powder in water for 2 hours until the peach gum powder completely dissolves in the water to form a clear solution for standby application; (2) under normal temperature, soaking nostoc commune powder in water for 5 hours to obtain a pitchy colloid mixture, performing filtering to remove solid impurities, and adding and using a bleaching agent for bleaching treatment, so as to obtain a clear colloidal solution for standby application; and (3) under normal temperature, uniformly stirring tapioca in water, separately adding the clear solution obtained in the step (1) and the clear colloidal solution obtained in the step (2), performing uniform mixing, finally adding agar, xanthan gum and alginic acid and performing uniform mixing, so as to obtain the cream thickening agent.

Owner:绵阳市致旺食品有限公司

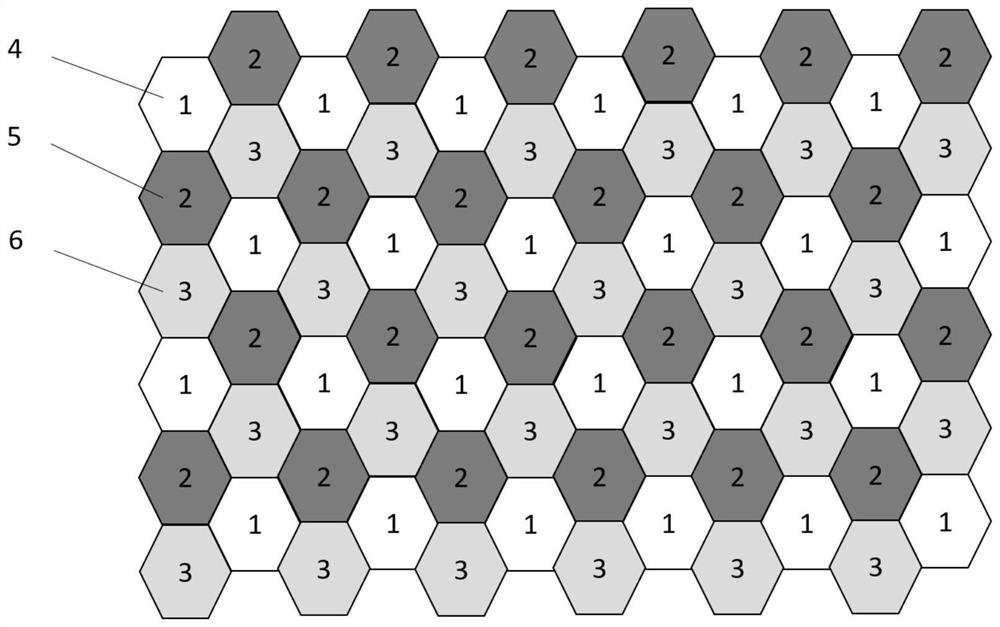

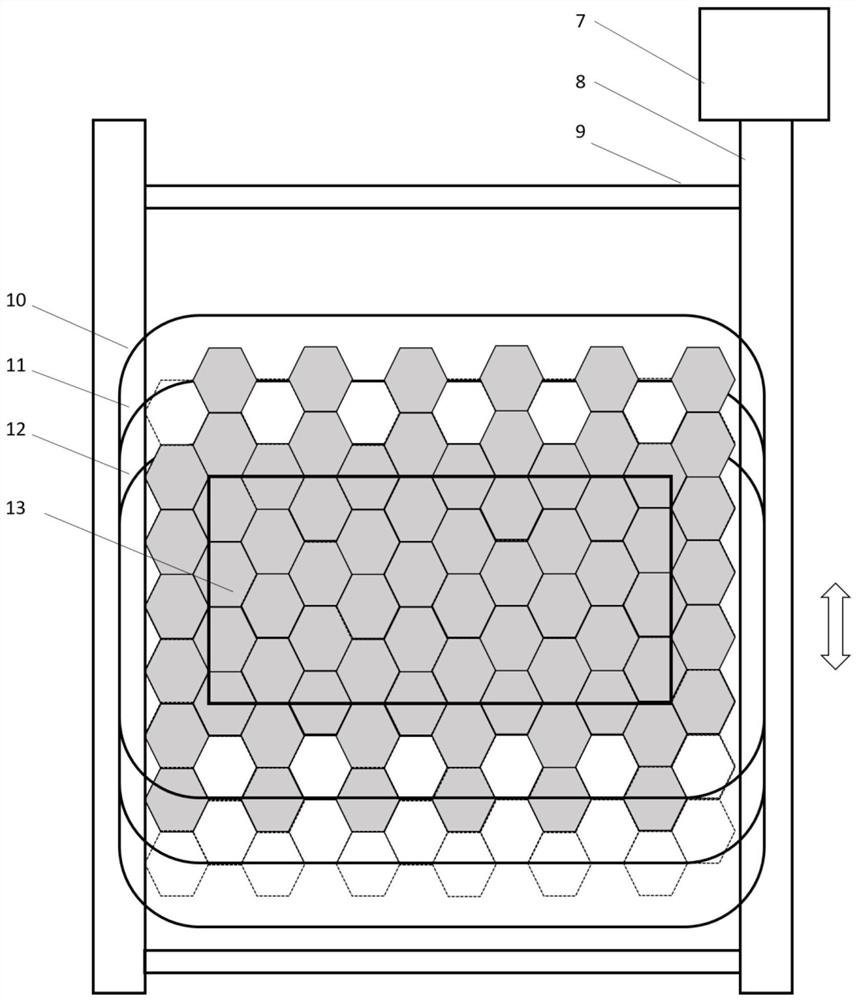

Hard coating toughening structure and toughness evaluation method

PendingCN114717515AReduce internal stressSuper thickVacuum evaporation coatingSputtering coatingSoft layerDeposition process

The invention provides a physical vapor deposition hard coating multilayer hexagonal structure design toughening and toughness evaluation method. The design of the multilayer hexagonal structure of the hard coating for toughening specifically refers to alternate deposition of a soft layer and a hard layer. In the soft layer deposition process, the regular hexagon through holes are designed in the baffles, soft layers evenly distributed in the one-third area of the base body are deposited, and the other parts are shielded by the baffles. The coating toughening design of one modulation period is completed through alternate deposition of the soft layers and the hard layers for three times, and modulation of multiple periods can be achieved according to requirements. And in one modulation period, the regular hexagonal soft layer area is not overlapped in the same area of the substrate when the soft layer is deposited each time. According to coating toughness evaluation, the coatings are deposited on the two base bodies at the same time, the end faces of the two base bodies are completely in butt joint, and it is guaranteed that the butt joint faces are smooth and have the good fitting degree. After a coating is deposited on the sample on the special clamp, the fracture moment and surface appearance of the coating are tested on a toughness testing device. And the toughness is evaluated by analyzing the fracture moment, the loading force-displacement curve and the fracture morphology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com