A kind of high-efficiency instant multi-component copolymer dispersion liquid and preparation method thereof

A multi-component copolymer and dispersion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor stability, low suspended solid content, poor suspension dispersibility, etc., and achieve low apparent viscosity and solid content High, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

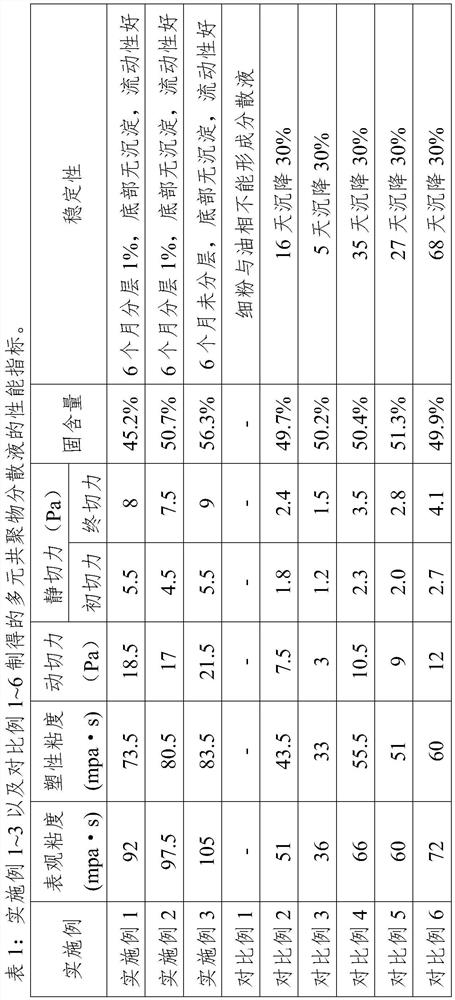

Examples

preparation example Construction

[0040] In a second aspect, the present invention provides a method for preparing the high-efficiency instant multi-polymer dispersion described in the first aspect of the present invention, said method comprising the steps of:

[0041] (1) Grinding the multi-component copolymer particles to obtain a multi-component copolymer fine powder; in the present invention, for example, performing low-temperature grinding on the multi-component copolymer particles, for example, performing the low-temperature grinding at a temperature not higher than 0° C., to obtain the obtained The above-mentioned multi-polymer fine powder is preferably obtained through low-temperature grinding to obtain a multi-polymer ultrafine powder with a particle size below 75 μm; as we all know, during the grinding and pulverization of conventional polymers, the polymer temperature is relatively high, and crosslinking reactions will occur, which may affect The solubility of the product has a certain impact, and wh...

Embodiment 1

[0070] The high-efficiency instant multi-polymer dispersion liquid in the present embodiment is made up of the component of following percentage by weight:

[0071] Multi-component copolymer ultra-fine powder (linear ultra-high molecular weight polyacrylamide ultra-fine powder): 45%;

[0072] Modified hectorite: 1.5%;

[0073] Dimerized fatty acid diethanolamide: 0.5%;

[0074] AEO-5: 0.5%;

[0075] Cetyltrimethylammonium chloride: 0.5%

[0076] Triethylene glycol monobutyl ether: 0.5%;

[0077] Emulsifier: 2%; wherein, the emulsifier is compounded by span80 and tween80, and the compounding ratio (mass ratio) is span80:tween80=2:1;

[0078] White oil (industrial 3# white oil): 49.5%;

[0079] The preparation method of the efficient instant multi-component copolymer dispersion liquid in the present embodiment comprises the steps:

[0080] ①Preparation of superfine powder: Low-temperature grinding of multi-component copolymer particles until the particle size is less than ...

Embodiment 2

[0089] The high-efficiency instant multi-polymer dispersion liquid in the present embodiment is made up of the component of following percentage by weight:

[0090] Multi-component copolymer ultra-fine powder (linear ultra-high molecular weight polyacrylamide ultra-fine powder): 50%;

[0091] Modified hectorite: 2%;

[0092] Fatty acid diethanolamide: 1%;

[0093] AEO-6: 1%;

[0094] Octadecyltrimethylammonium bromide: 1%

[0095] Triethanolamine: 1%;

[0096] Emulsifier: 3%; wherein, the emulsifier is compounded by span80 and tween80, and the compounding ratio (mass ratio) is span80:tween80=2:1;

[0097] White oil (industrial 3# white oil): 41%;

[0098] The preparation method of the efficient instant multi-component copolymer dispersion liquid in the present embodiment comprises the steps:

[0099] ①Preparation of superfine powder: Low-temperature grinding of multi-component copolymer particles until the particle size is less than 75 μm, to obtain super-fine multi-comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com