Patents

Literature

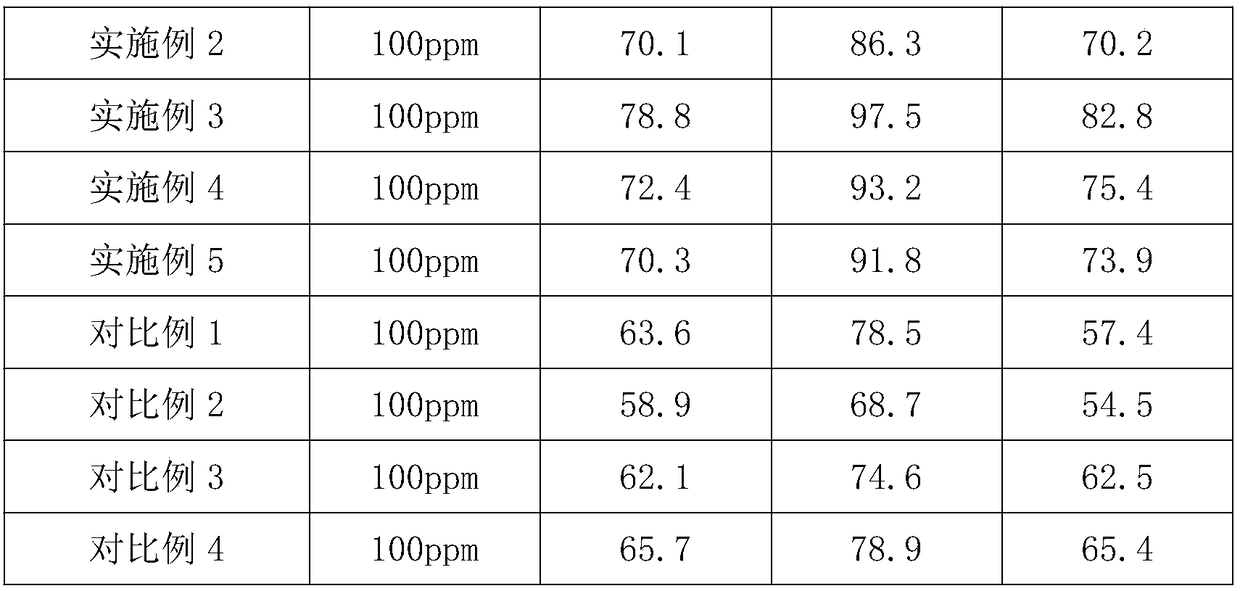

34results about How to "No coalescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated particulate preparation method

The invention discloses a coated particulate preparation method, comprising the following steps: firstly, particulates in movement are coated with coating solution to cure the solution to form films; the coating rate and curing rate are controlled to ensure that the particulates reach the designed coating quantity while avoiding accumulation; then, the organic polymer films outside the coating films of particulates in movement are cured; inert organic substance is added to form continuous inert liquid membranes outside the organic polymer films before the particulates are likely to accumulate on the adopted coating film curing process conditions; then, the organic polymer films outside the particulates are continuously cured to lose autohension or so that the whole coating films are cured fully; and finally, the particulates coated films are cooled to the room temperature to obtain the coated particulates. The preparation method of the invention has high coating efficiency and good coating integrity and coating process.

Owner:NANJING UNIV OF SCI & TECH

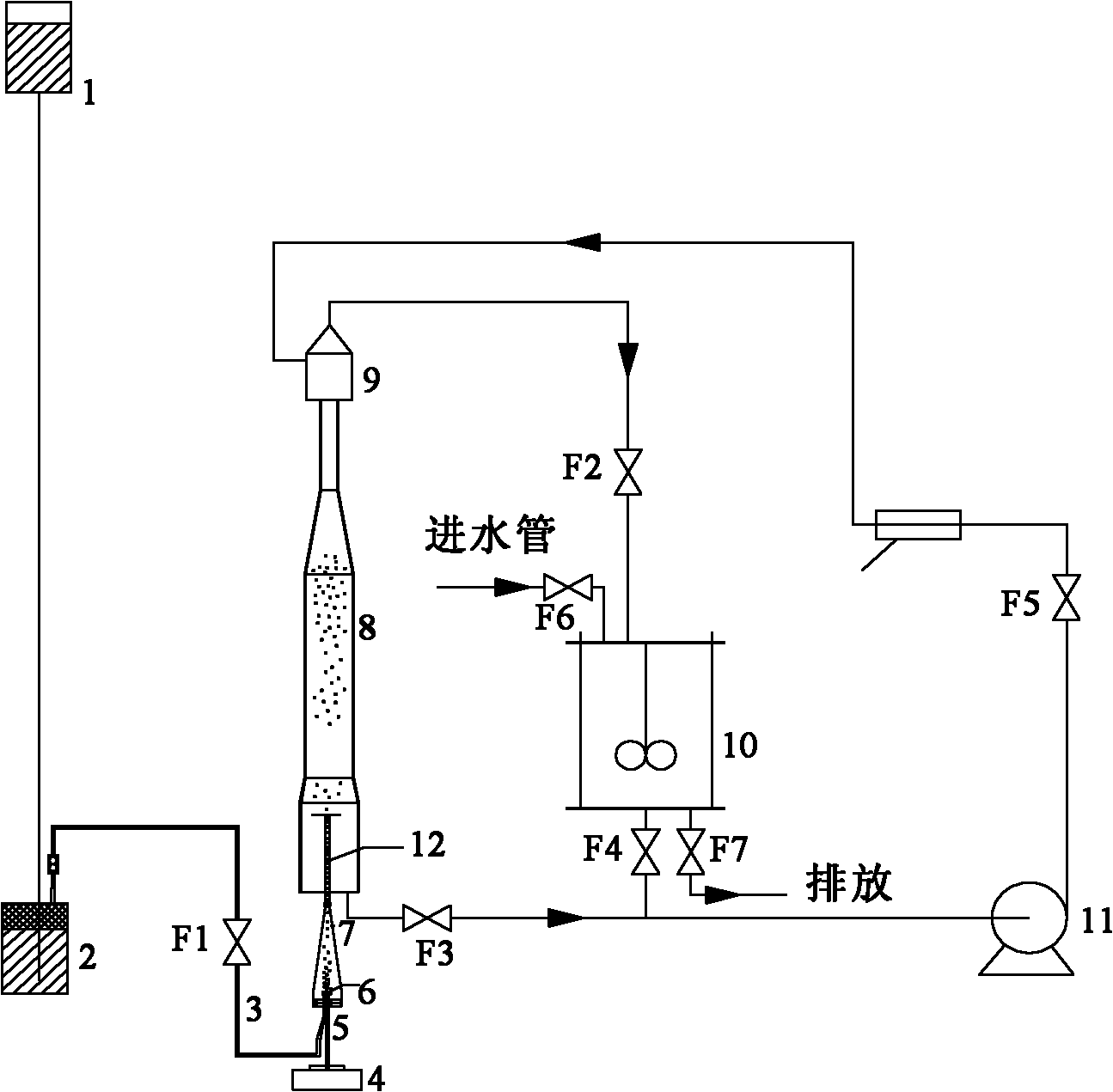

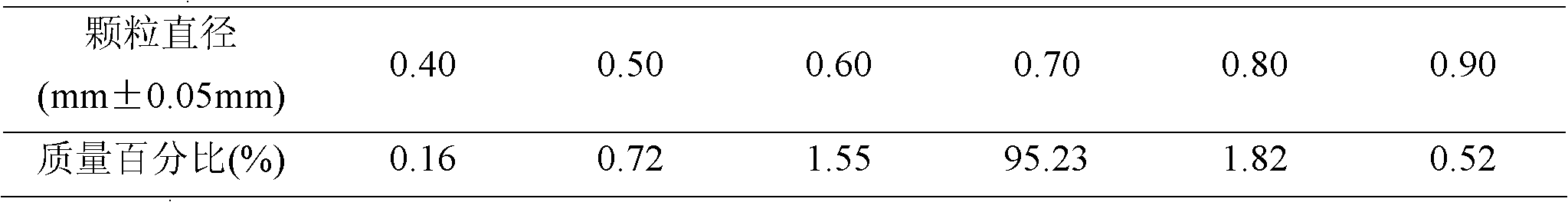

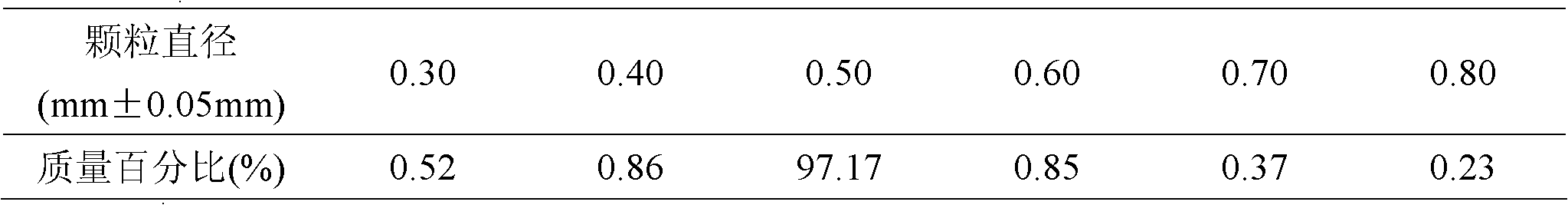

Equipment and method for producing uniform particle ion exchange resin beads

ActiveCN102086240AUniform particle sizeMaintain Particle Size UniformityMicroballoon preparationMicrocapsule preparationWastewaterOil phase

The invention discloses equipment and a method for producing uniform particle ion exchange resin beads. The equipment comprises a head tank 1, an oil phase storage tank 2, a vibration generator system 4, a nozzle 6, a fluidized polymerization reactor 8, an aqueous phase liquid distributer 9, a maturation tank 10 and an aqueous phase circulating pump 11; and the ion exchange resin beads produced by the equipment have uniform particle size. When the method is used for producing the ion exchange resin bead products, the production capacity of the equipment can be adjusted by changing the number of orifices of the nozzle and the mass fraction of the target particle size of + / -0.05mm is more than 95 percent without sieving; and in the method, the aqueous phase can be recycled, so that the wastewater discharge is reduced; therefore, sewage discharge in the reaction process is greatly reduced.

Owner:TIANJIN UNIV

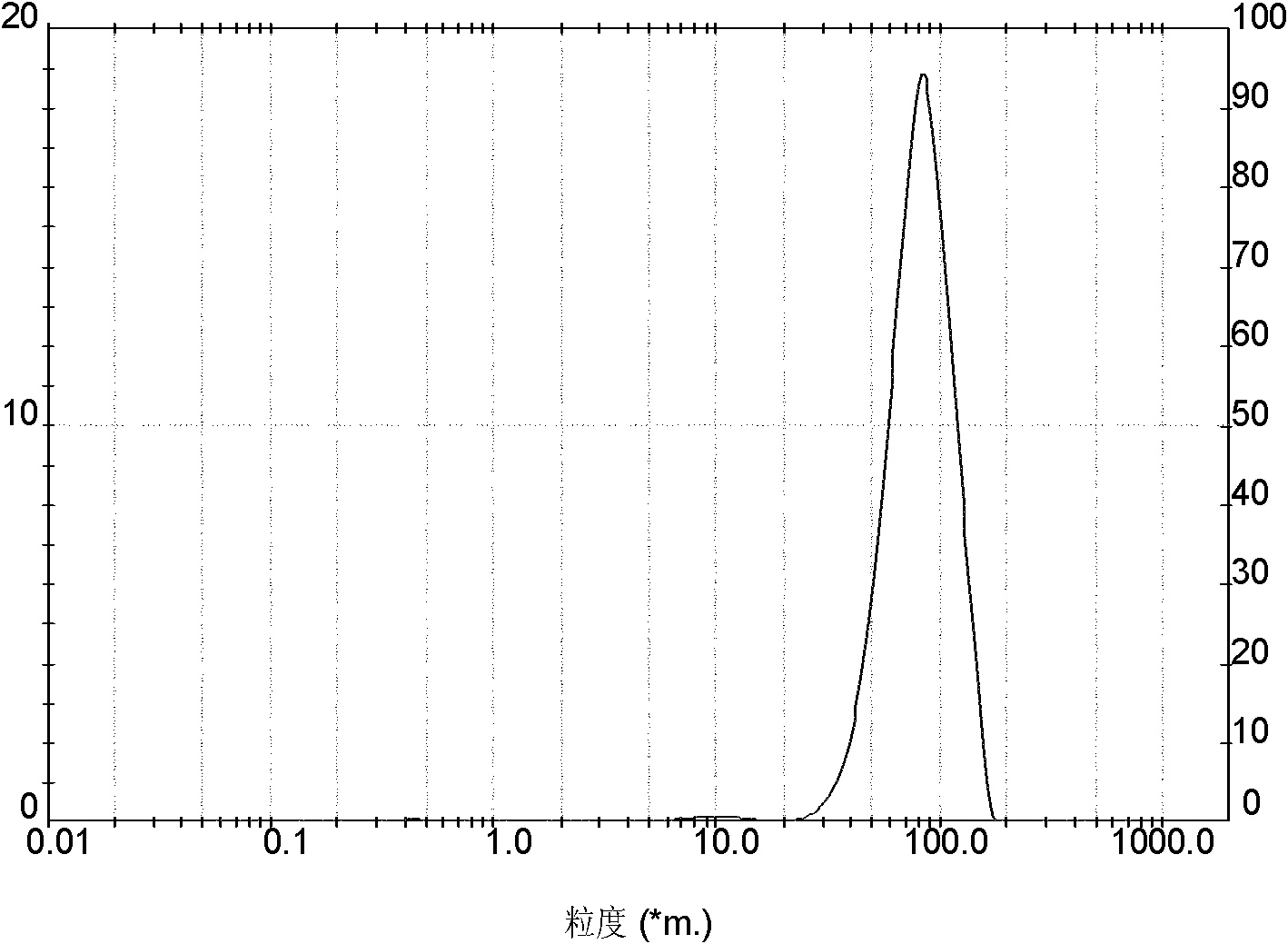

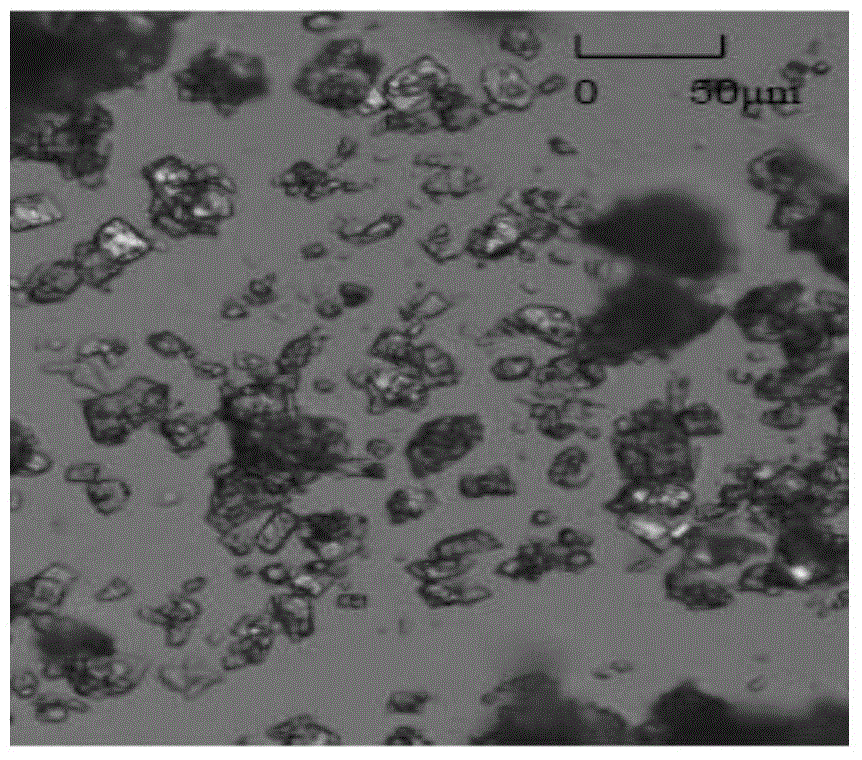

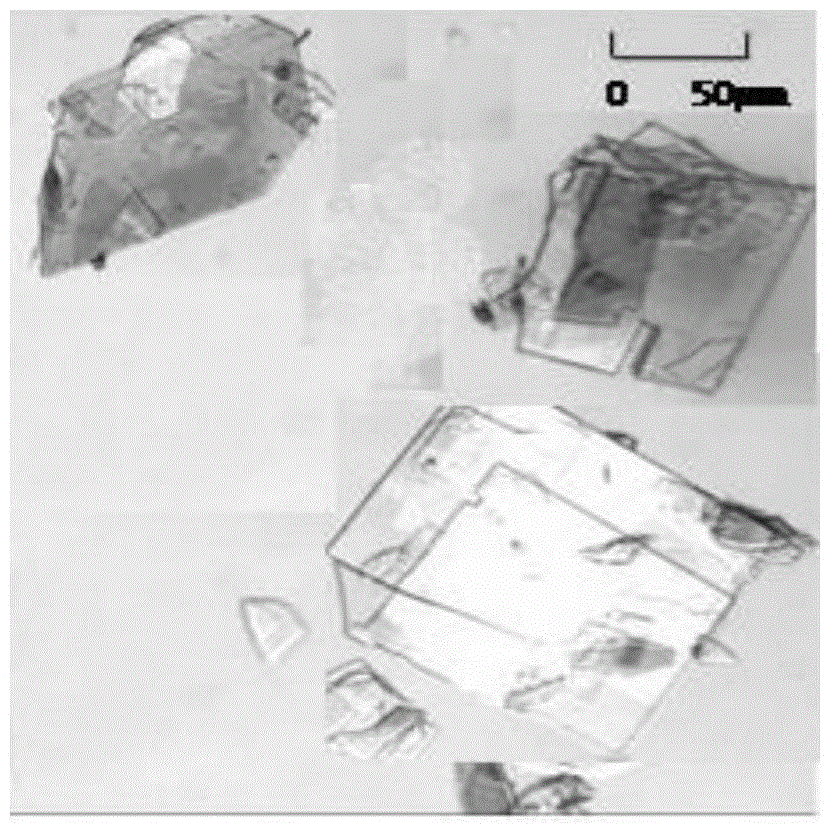

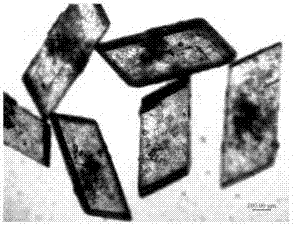

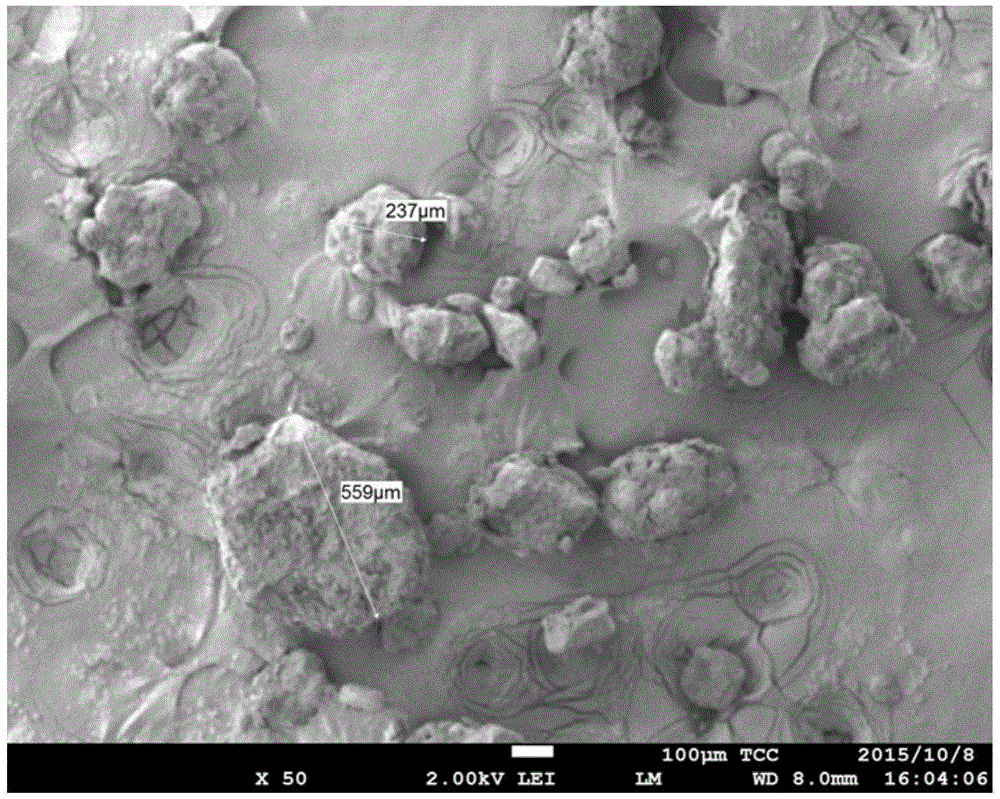

Crystallization method of cefadroxil monohydrate and crystals

ActiveCN102134250AInhibit the rate of crystallizationPrevent coalescenceOrganic chemistryGranularityCEFADROXIL MONOHYDRATE

The invention relates to a method for producing crystals of cefadroxil monohydrate, comprising the following steps: adding an N, N-dimethyl formamide solvent compound of cefadroxil to a mixed solvent of N, N-dimethyl formamide and water, wherein the mass ratio of the cefadroxil solvent compound to the mixed solvent is 1:1-1:2, stirring to obtain a suspending liquid, and keeping the temperature at15-30 DGE C and the pH value of the solution at 6.0-7.5 during feeding; after the cefadroxil solvent compound is totally changed into the cefadroxil monohydrate, reducing the pH value of the suspending liquid to 4.5-5.0 within 1-20 minutes, keeping the temperature at 10-18 DEGC, and stirring for crystal cultivation for 10-90 minutes; and filtering, washing and drying after crystal cultivation is finished to obtain a product, the square platy crystal-form cefadroxil monohydrate. The square platy crystal-form cefadroxil monohydrate obtained by the method has uniform particle size distribution, does not generate coalescence, and is applicable to industrial production.

Owner:TIANJIN UNIV

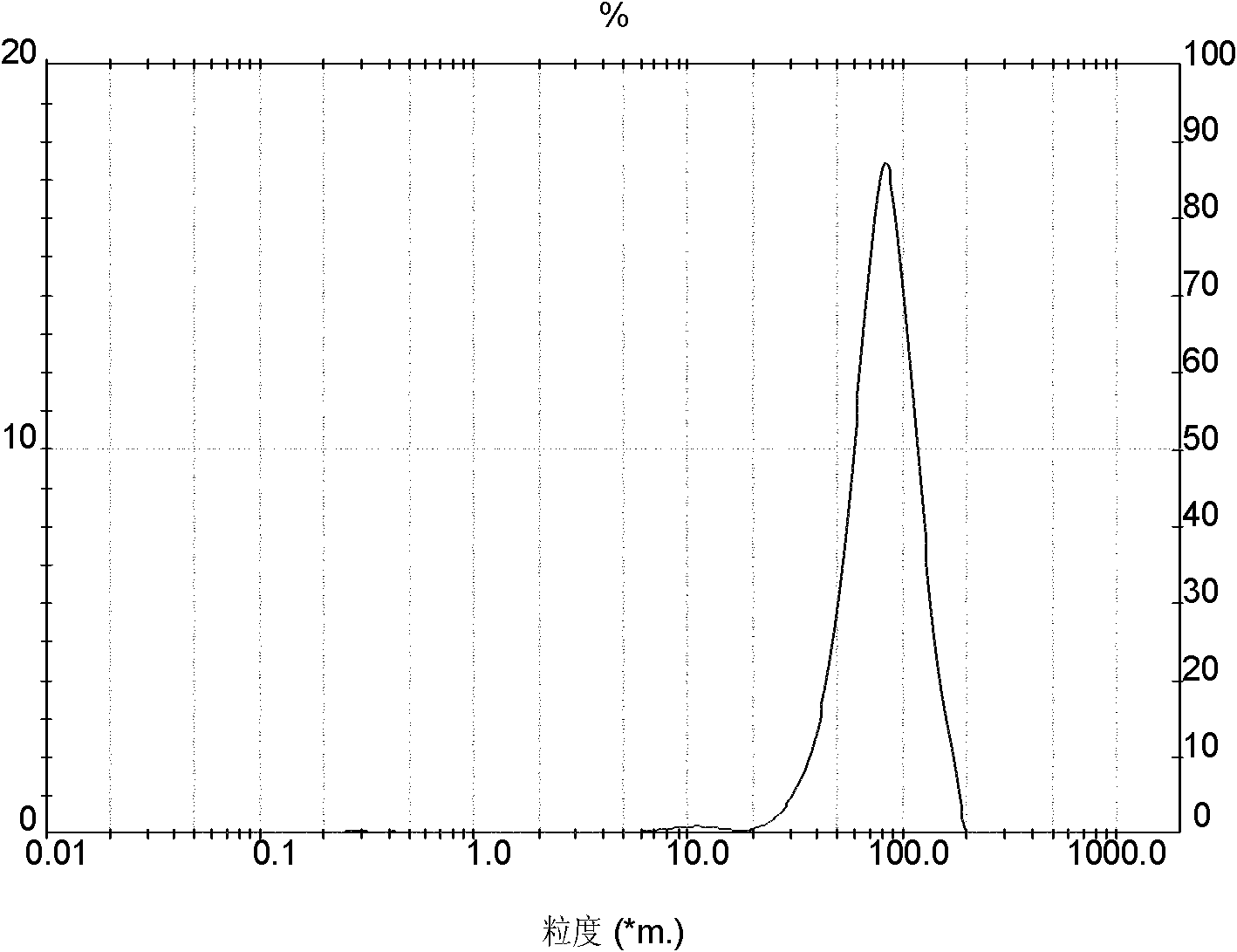

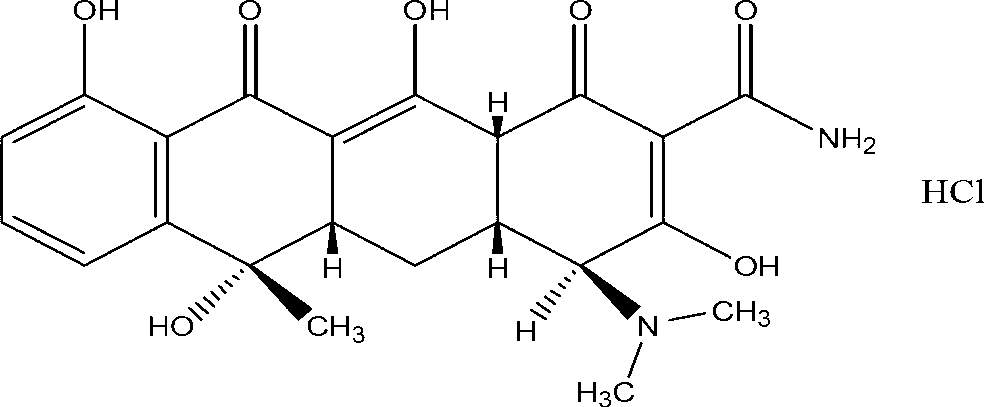

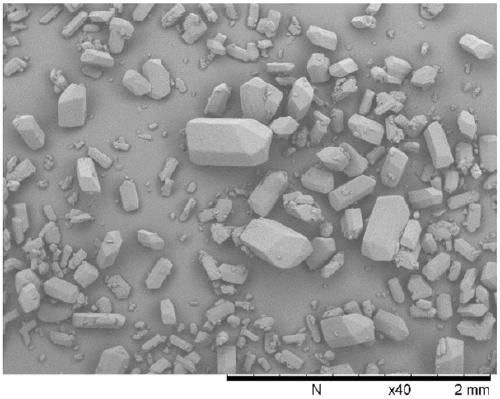

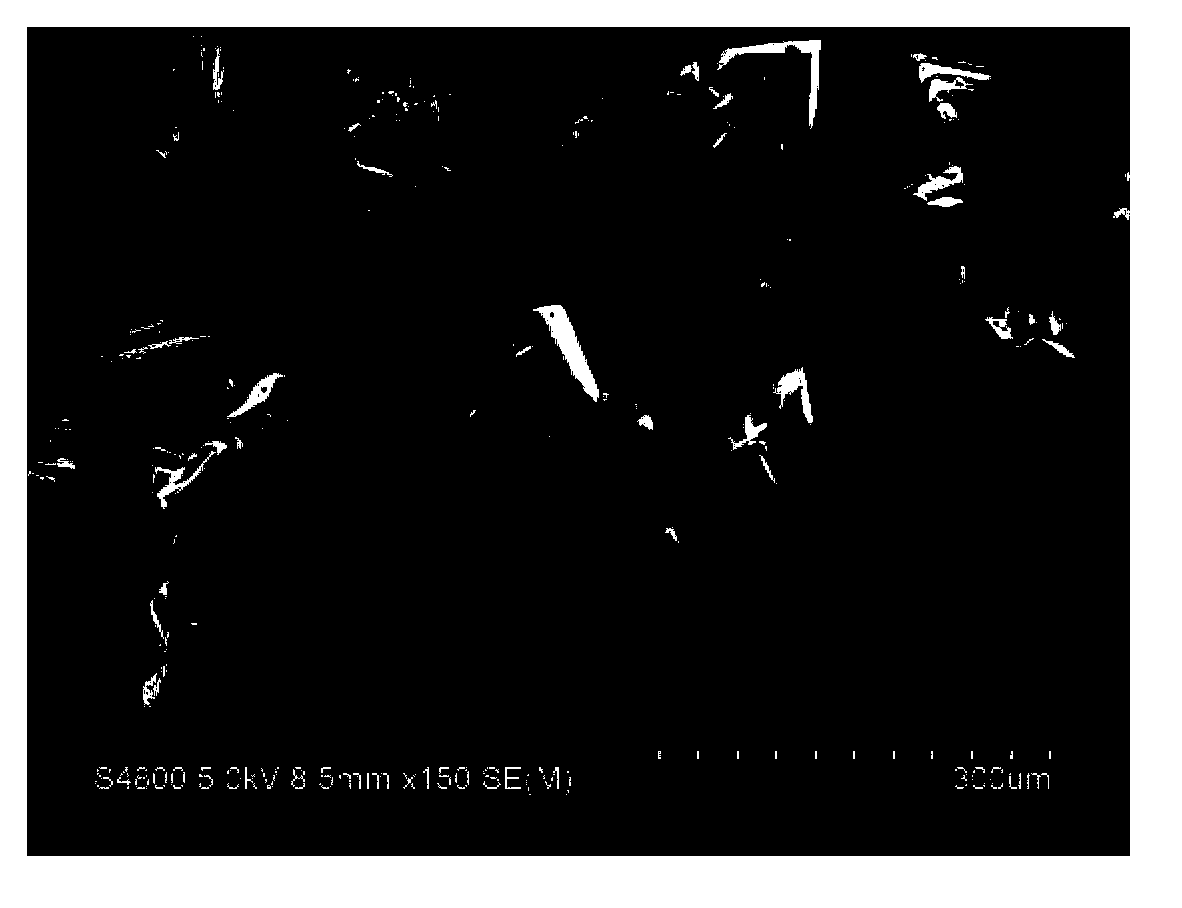

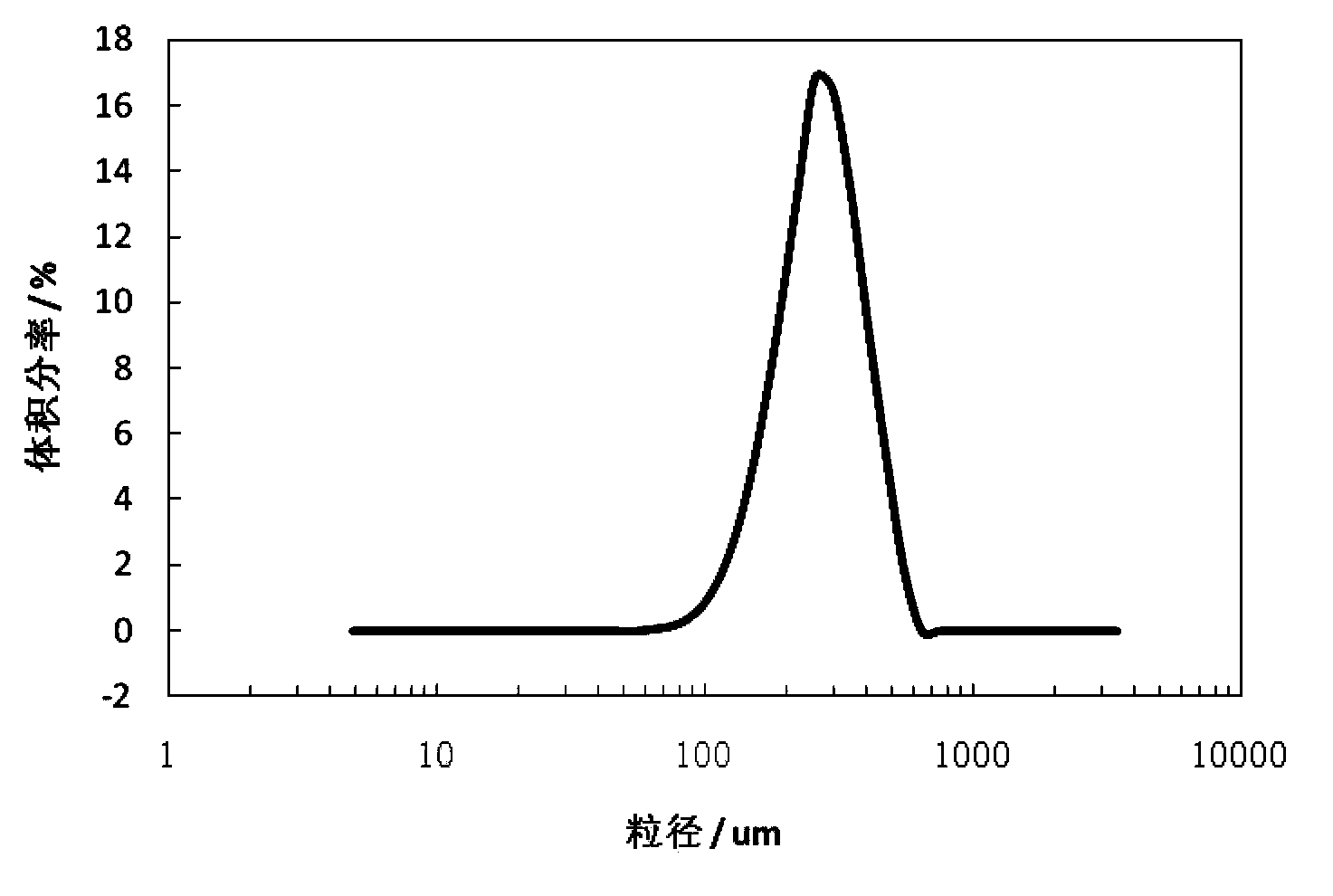

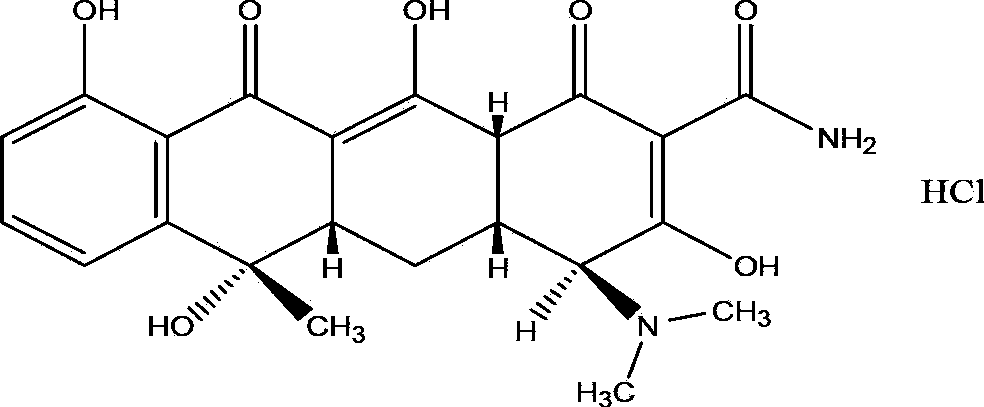

Method for preparing high-purity tetracycline hydrochloride

ActiveCN102993043AUniform particle size distributionSimple filterOrganic compound preparationCarboxylic acid amides preparationAlcoholTetracycline Hydrochloride

The invention relates to a method for preparing high-purity tetracycline hydrochloride. Tetracycline urea double salt and hydrochloric acid serve as raw materials, and reaction of the tetracycline urea double salt and hydrochloric acid and crystallization of tetracycline hydrochloride are simultaneously performed. The method comprises the following steps of: mixing the double salt with an organic alcohol mixed solvent according to a ratio, adding hydrochloric acid at the temperature of 5-20 DEG C, continuously stirring and filtering; transferring the filtrate into a crystallizer, raising the temperature, adding a seed crystal when the system temperature reaches 27-32 DEG C, further raising the temperature to 40-50 DEG C, and growing the grain at constant temperature; reducing the temperature of the suspension to 5-20 DEG C; and filtering, washing and drying the obtained crystal mush, thereby obtaining a tetracycline hydrochloride crystal product. The reaction and crystallization processes in the solvent system are screened and optimized, the tetracycline hydrochloride crystal which is uniform in particle size distribution, zero in coalescence and complete in crystalline form and has the purity of more than 98.0 percent is obtained, and the process yield is more than 88.0 percent. The problems that the product is non-uniform in particle size distribution and severe in coalescence so that the purity of the product is reduced are solved, and the product quality is obviously improved.

Owner:TIANJIN UNIV

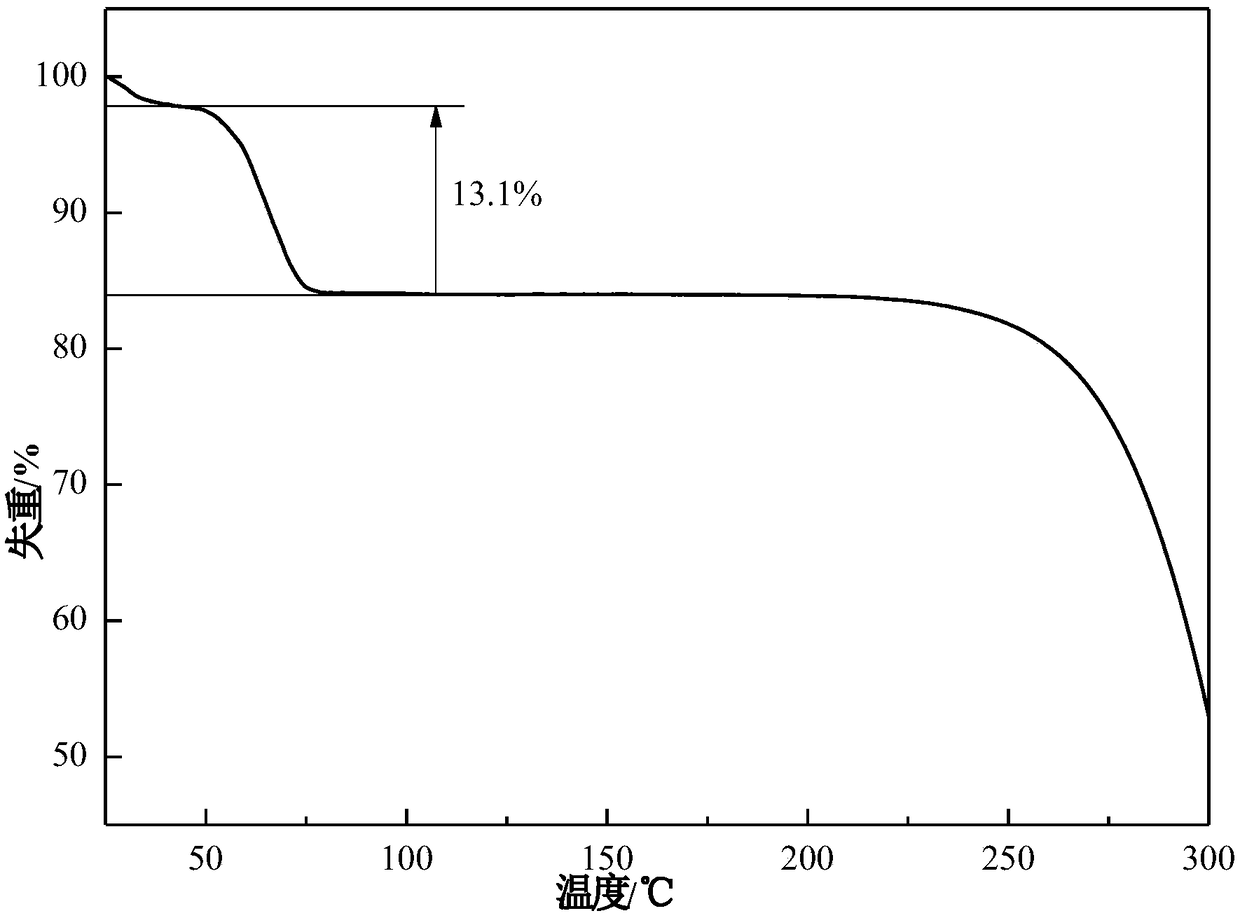

Hydrate of micheliolide dimethylamine fumarate, preparation method and application thereof

ActiveCN111303100AIncrease the average particle sizeNo coalescenceOrganic active ingredientsOrganic chemistry methodsDimethylaminesPatent medicine

The invention relates to a hydrate of micheliolide dimethylamine fumarate, a preparation method and application thereof, wherein the hydrate is a crystal form D, is high in crystallinity, smooth in particle surface, free of coalescence, high in bulk density and good in flowability, and has good stability and good reproducibility. The preparation method comprises the following steps: under stirringeffect, adding dimethylamine micheliolide and fumaric acid into a mixed solvent system with a constant temperature of 30-70 DEG C, carrying out reaction crystallization; and filtering after the reaction is finished, and drying the filtered solid at normal pressure to obtain the micheliolide dimethylamine fumarate crystal form D. The preparation method is simple, the product yield is high, and themethod is suitable for later preparation of patent medicines, and is beneficial to large-scale production.

Owner:ACCENDATECH +1

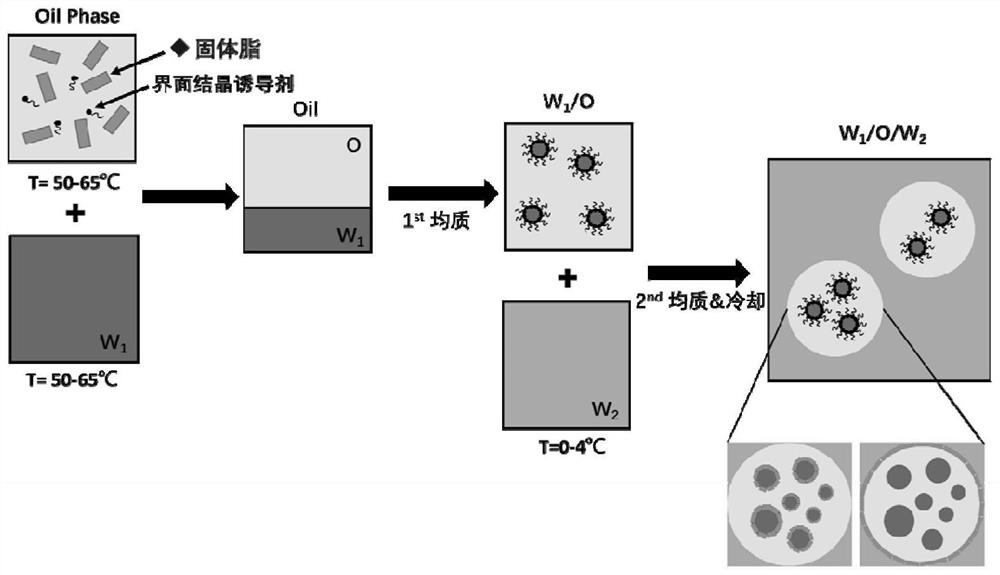

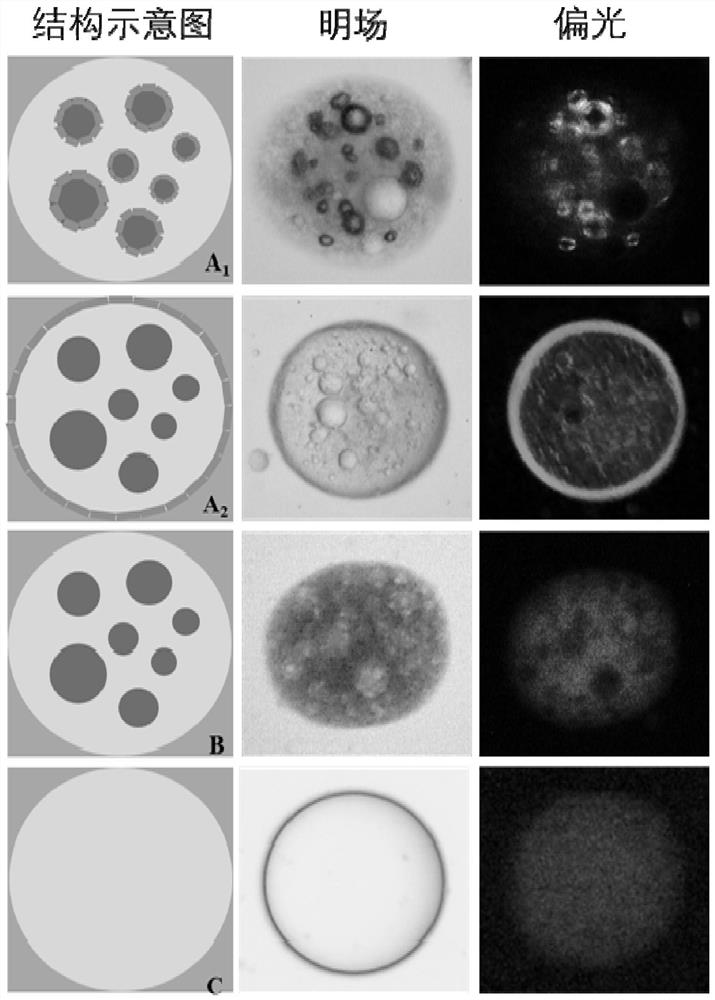

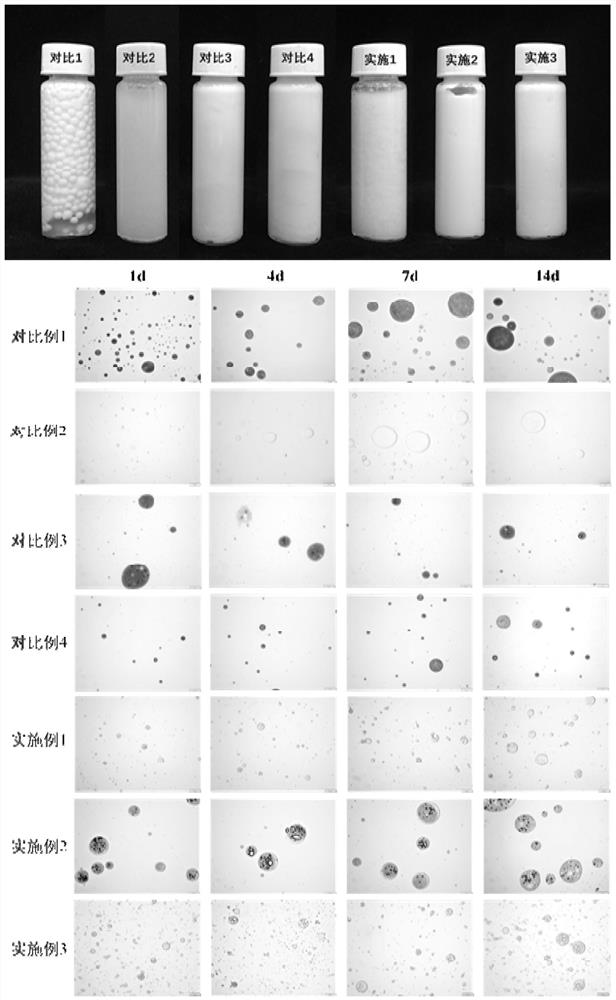

Pickering double emulsion with interface stabilized by solid lipid as well as preparation and application of Pickering double emulsion

ActiveCN112314714ASave oil consumptionInhibits lipid digestionEdible oils/fats ingredientsLipidic food ingredientsIn vitro digestionStabilizing Agents

The invention discloses a Pickering double emulsion with an interface stabilized by solid lipid, as well as a preparation method of the Pickering double emulsion and an application of the Pickering double emulsion to low-lipid foods. According to the interface provided by the invention, lipid crystals are formed in situ at the interface through the emulsifying property of solid lipid and the template effect of a lipophilic interface crystallization inducer, the lipid crystals are used for assisting in stabilizing the emulsion, the overall stability of the emulsion is enhanced, based on the condition that the consumption of an emulsifying agent, a stabilizing agent and gelata is reduced, a coalescence phenomenon does not occur after the emulsion is placed for one month, and instability caused by a processing or compounding process can be effectively improved. Through in vitro digestion experiments, the inventor find that the solid lipid interface layer of the prepared Pickering double emulsion W1 / O / W2 partially inhibits the digestion of lipase to liquid oil, the emulsion has the characteristic of low lipid digestibility, and the application of the food-grade Pickering emulsion in the fields of food processing and low-lipid food can be widened.

Owner:SOUTH CHINA AGRI UNIV

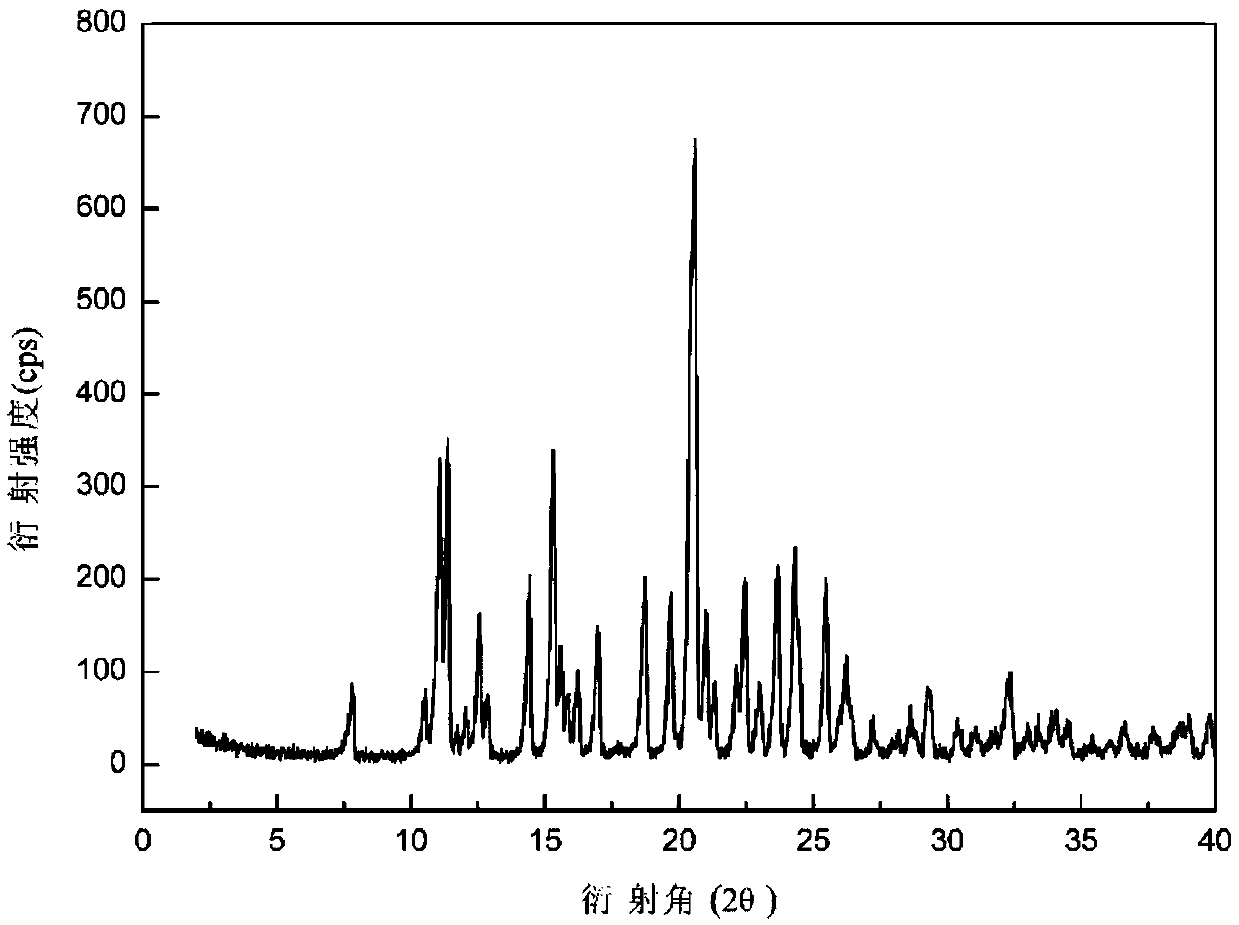

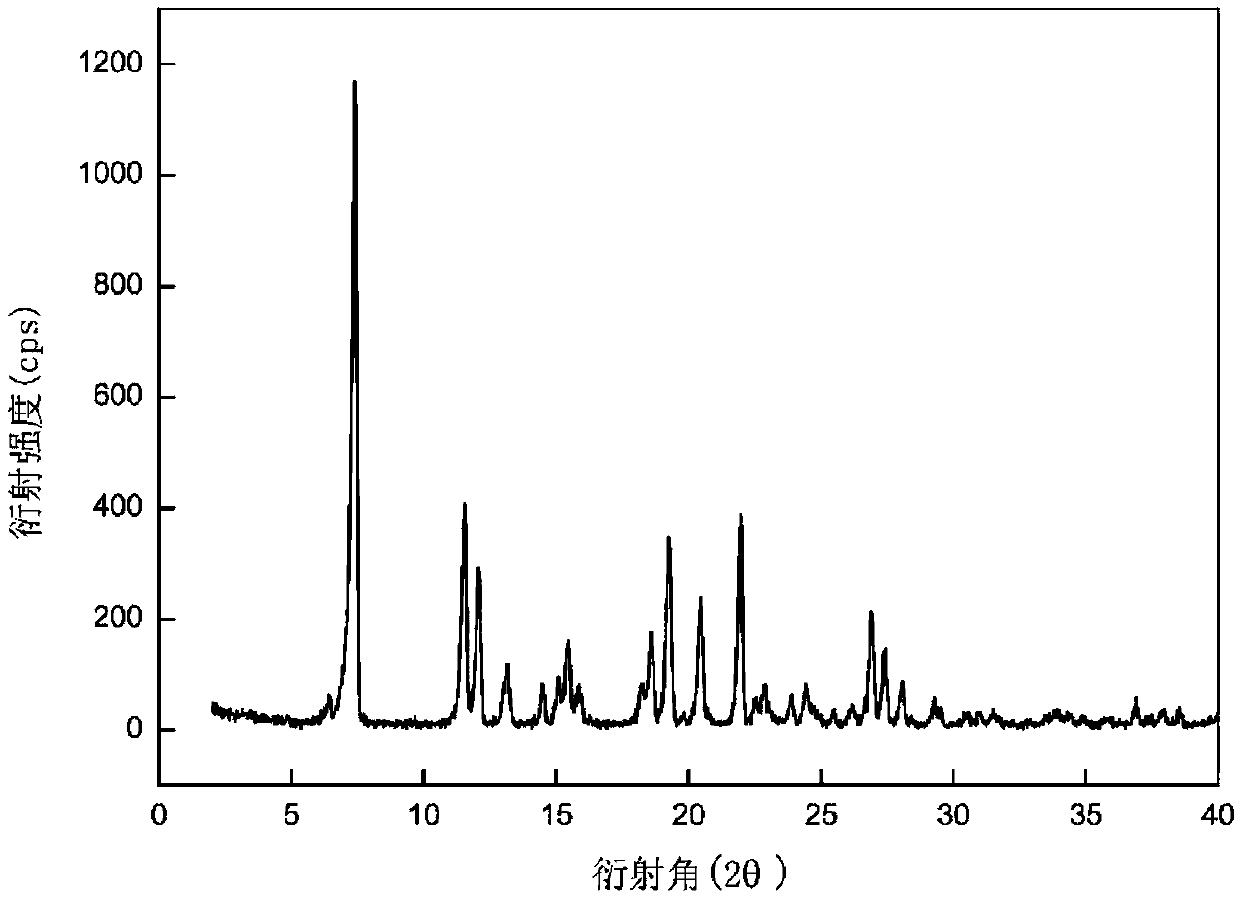

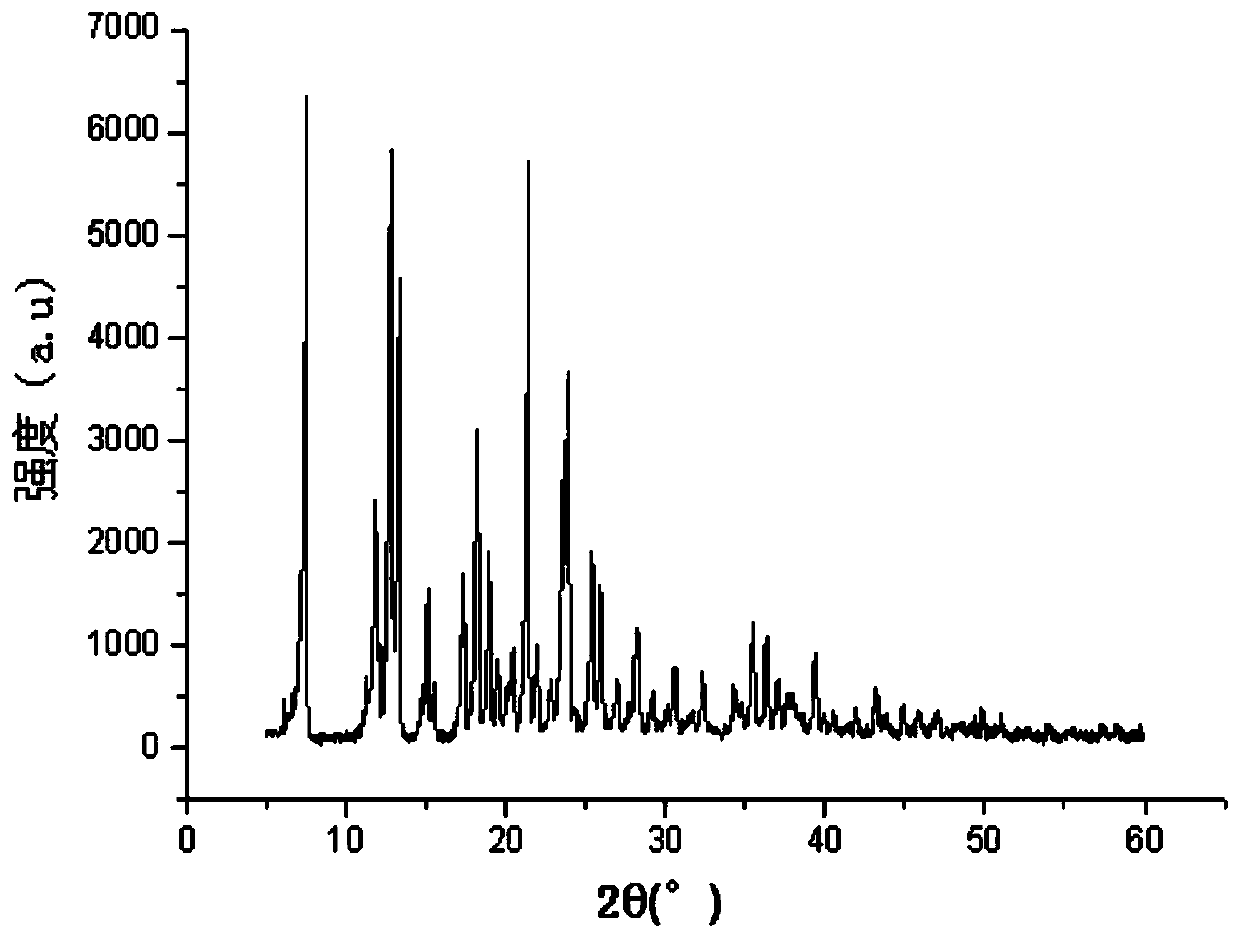

Dimethylaminomicheliolide fumarate crystal form C and preparation method thereof

ActiveCN111303097AFix stability issuesSolve processabilityOrganic chemistry methodsPhysical chemistryCrystal habit

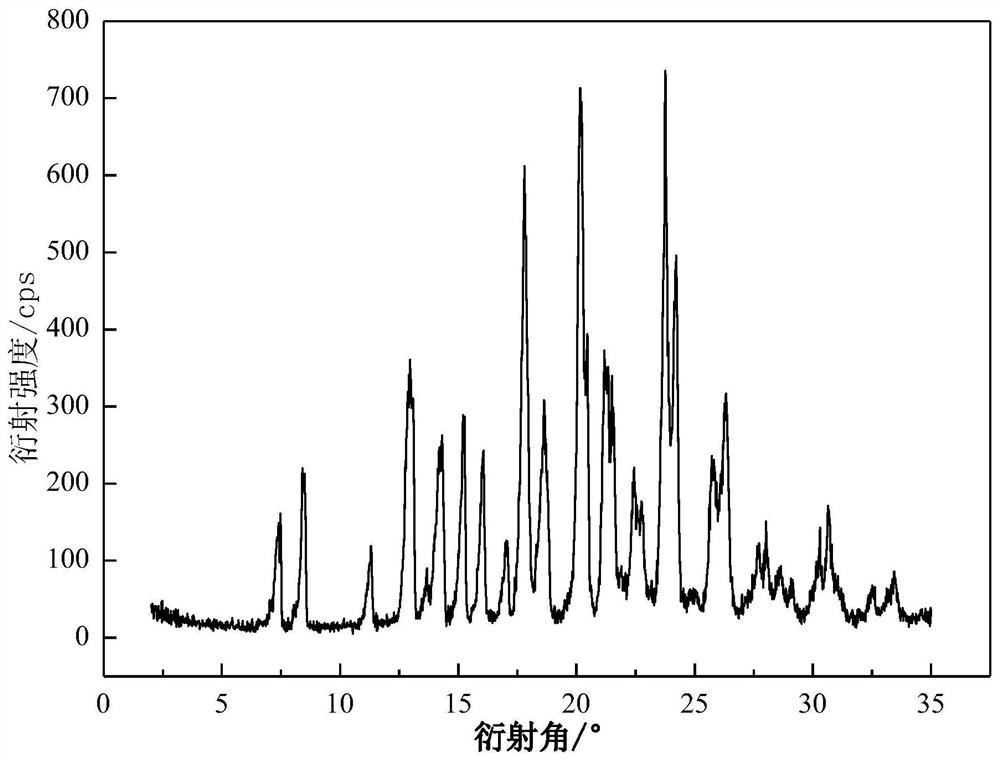

The invention relates to a dimethylaminomicheliolide fumarate crystal form C and a preparation method thereof, wherein X-ray powder diffraction results show that the crystal form C has characteristicpeaks at 2[theta] of 6.4+ / -0.2 DEG, 7.4+ / -0.2 DEG, 11.6+ / -0.2 DEG, 12.1+ / -0.2 DEG, 13.1+ / -0.2 DEG, 14.5+ / -0.2 DEG, 15.1+ / -0.2 DEG, 15.5+ / -0.2 DEG, 15.9+ / -0.2 DEG, 18.3+ / -0.2 DEG, 18.6+ / -0.2 DEG, 19.3+ / -0.2 DEG, 19.8+ / -0.2 DEG, 20.5+ / -0.2 DEG, 22.0+ / -0.2 DEG, 22.5+ / -0.2 DEG, 22.9+ / -0.2 DEG, 23.9+ / -0.2 DEG, 24.4+ / -0.2 DEG, 25.5+ / -0.2 DEG, 26.2+ / -0.2 DEG, 26.9+ / -0.2 DEG, 27.4+ / -0.2 DEG, 28.1+ / -0.2 DEG, 29.3+ / -0.2 DEG, 29.5+ / -0.2 DEG, 30.6+ / -0.2 DEG, 31.0+ / -0.2 DEG and 31.5+ / -0.2 DEG, wherein the characteristic peak at 6.4+ / -0.2 DEG is an initial peak, and the relative intensity of the characteristic peak at 7.4+ / -0.2 DEG is 100%. According to the invention, the preparation process is constant-temperature suspension crystal transformation preparation, the process method is simple, easy to operate and good in reproducibility, the purity of the obtained product is 99% or above, the yield is higher than 90%, the stability is good, the bulk density is high, the surface is smooth, the completerod-like crystal habit is achieved, and the method is suitable for large-scale production.

Owner:ACCENDATECH +1

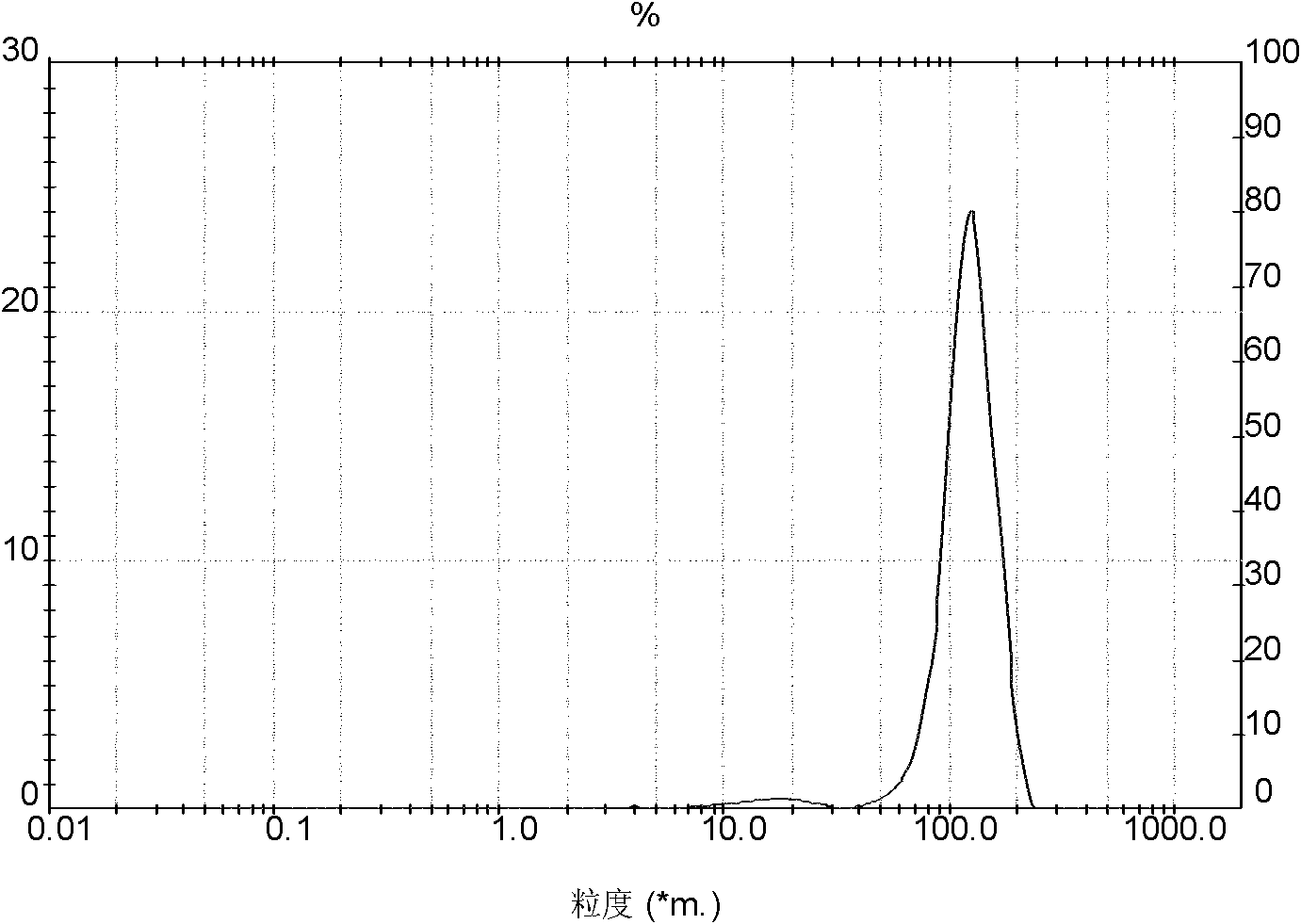

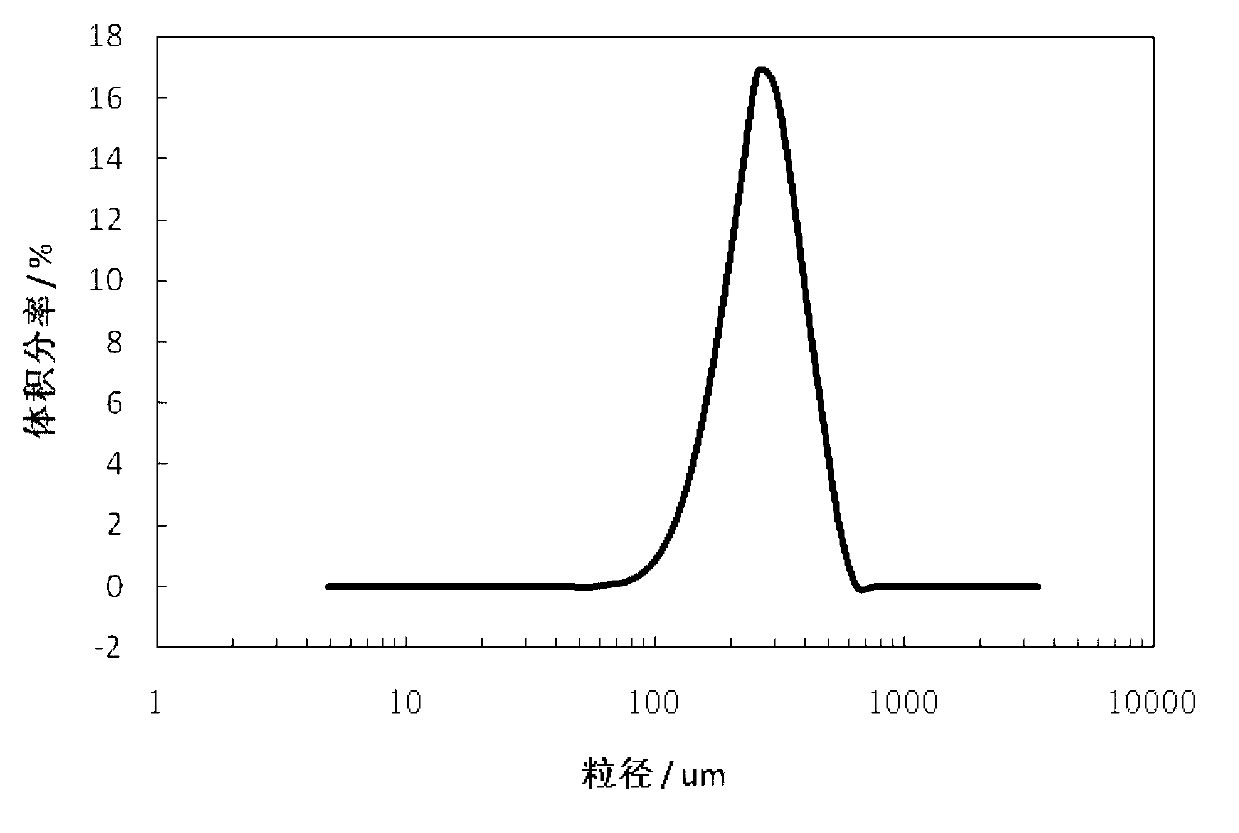

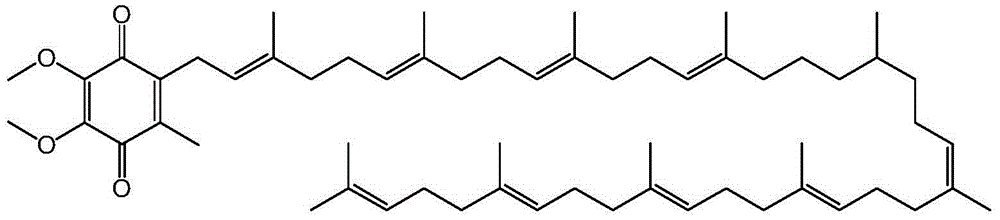

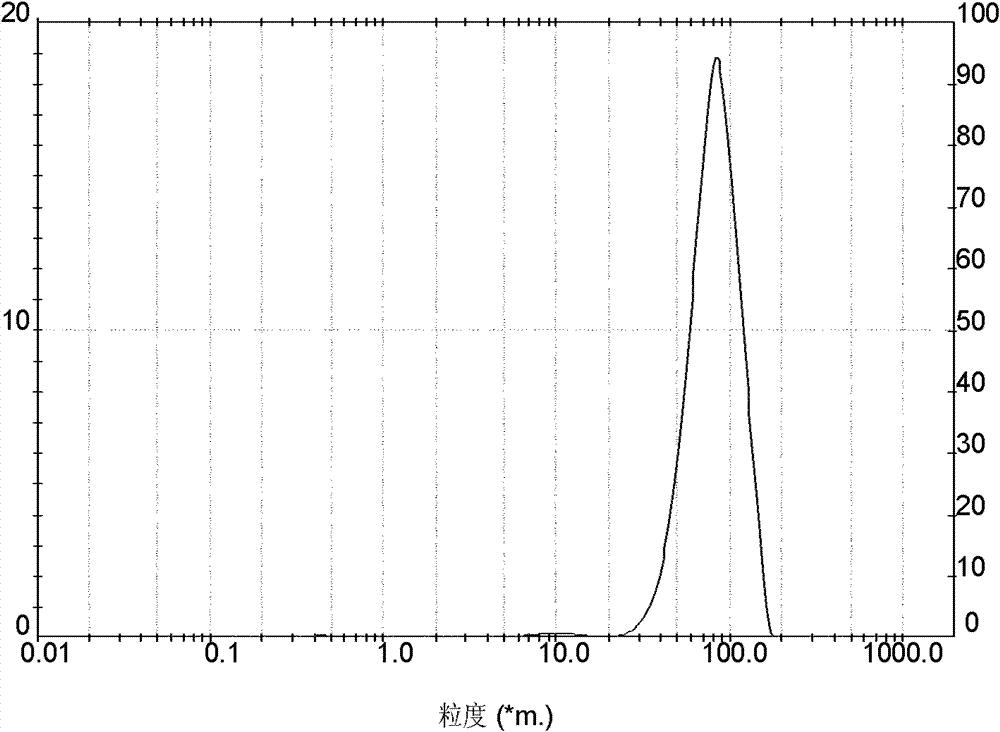

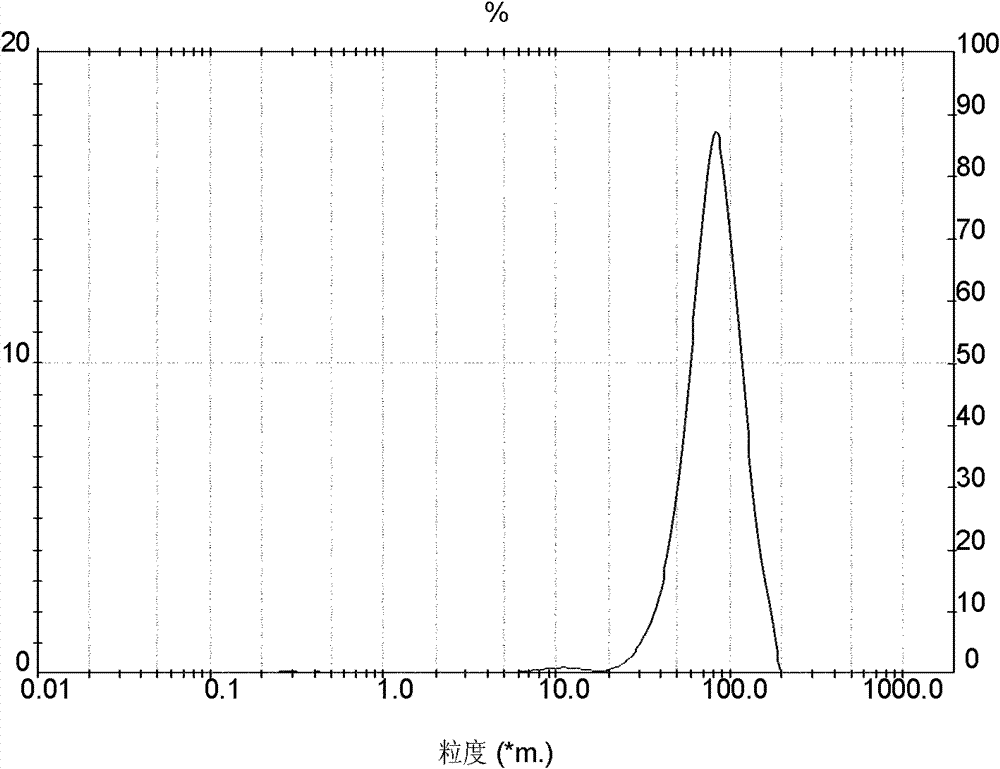

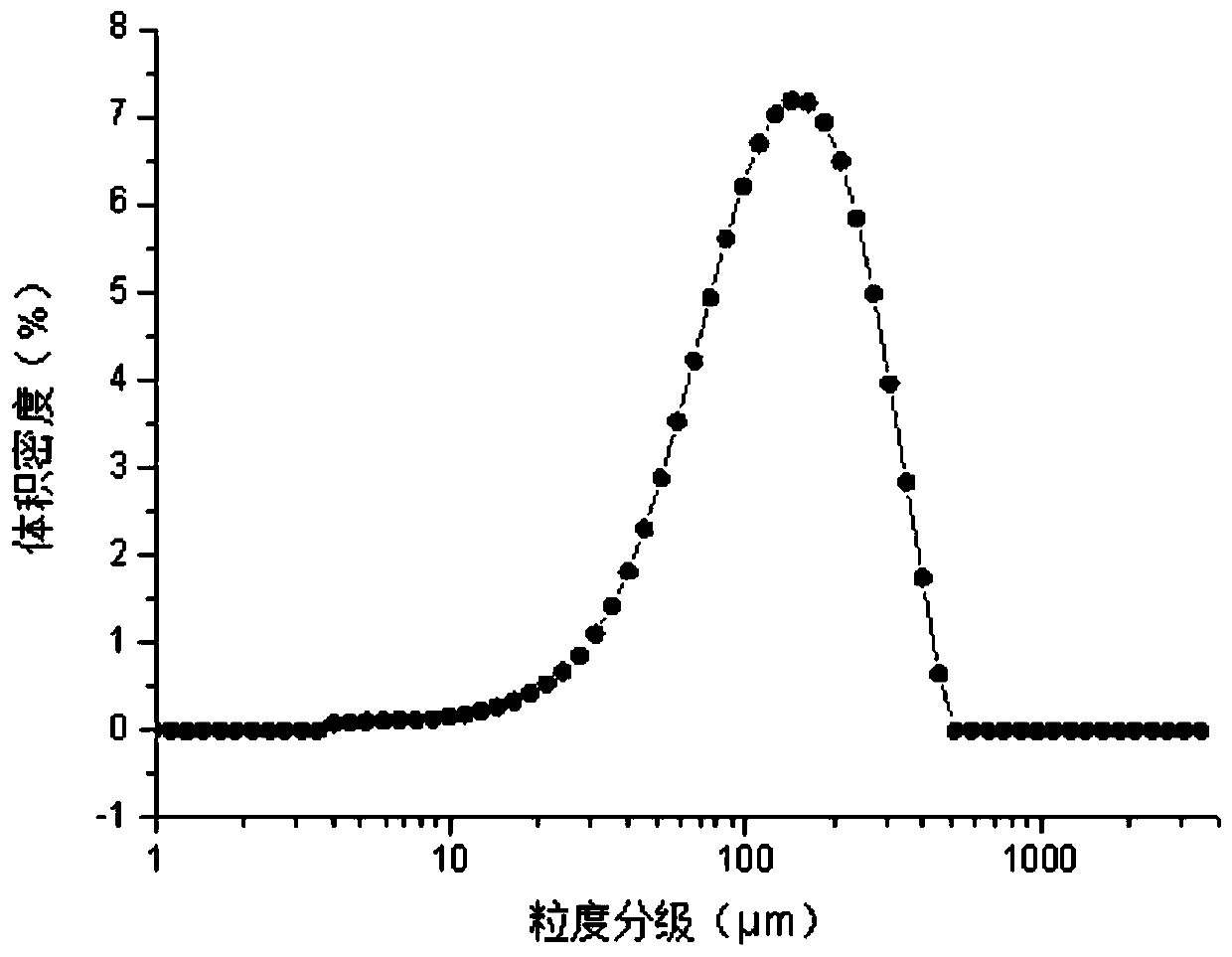

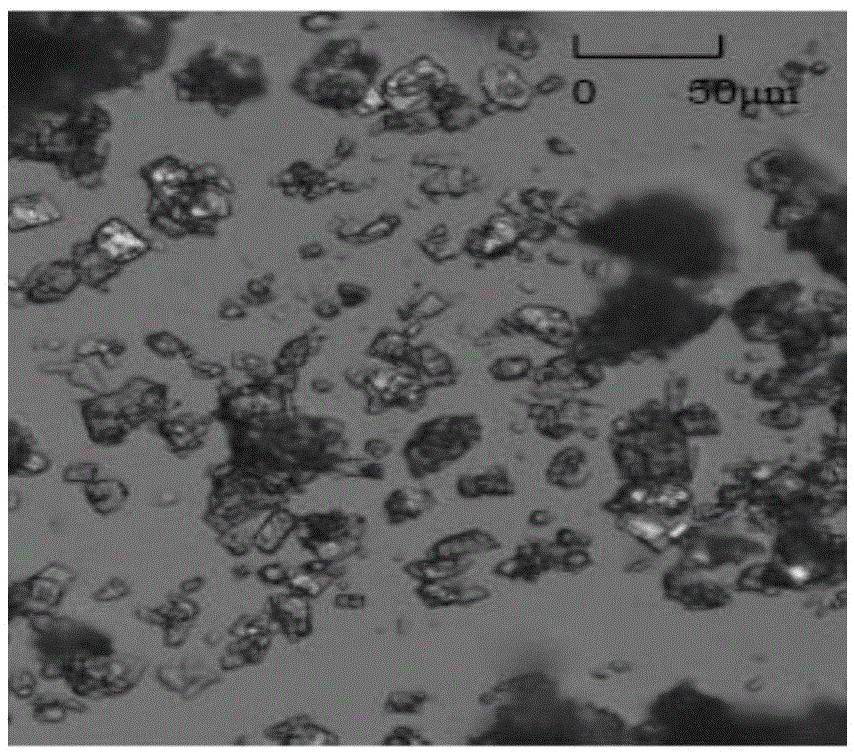

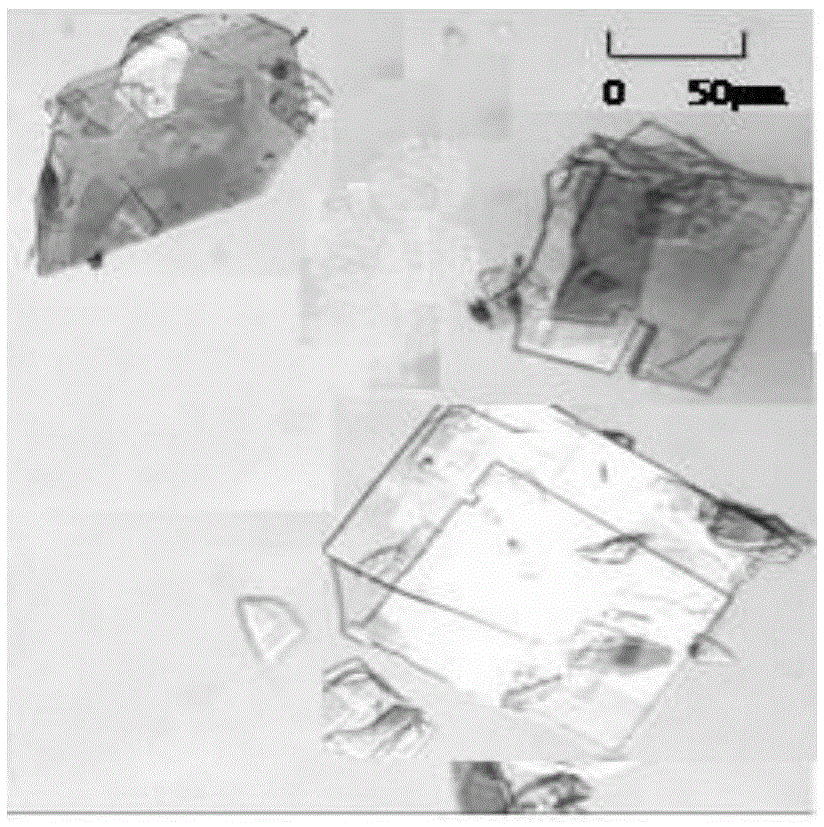

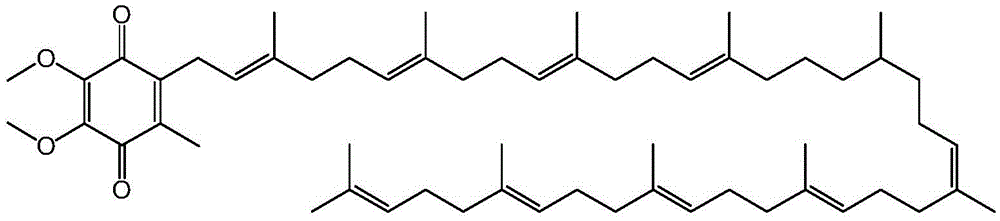

Ultrasonic-assisted coenzyme Q10 crystallizing method

ActiveCN104402697AHigh purityImprove production efficiencyQuinone separation/purificationUltrasonic assistedOrganic solvent

The invention relates to an ultrasonic-assisted coenzyme Q10 crystallizing method which comprises following steps: adding coenzyme Q10 with a purity being 90-95% to an organic solvent, wherein a mass ratio of the raw material to the organic solvent is 20-40:100; stirring the mixture and increasing the temperature to 50-60 DEG C for completely dissolving the coenzyme Q10 to form a uniform solution; performing a cooling crystallization process; decreasing the temperature of the solution to 36-40 DEG C with the ultrasonic-assisted crystallization being carried out for 5-20 min; decreasing the temperature of the solution to 13-20 DEG C; and performing filtration, a washing operation and a drying operating to obtain a coenzyme Q10 crystal product. The method is short in crystallization time. The coenzyme Q10 crystal product has a large granularity of about 70 [mu]m and is uniform in distribution. The solution is easy to filter and dry, is good in flowability and is free of coalescence. A single-way crystallization yield is higher than 90%. The purity of the coenzyme Q10 crystal product is higher than 99.0%. The method is convenient to operate, is low in cost, is less in energy consumption, is free of generation of harmful wastes and is suitable for industrial production.

Owner:TIANJIN UNIV

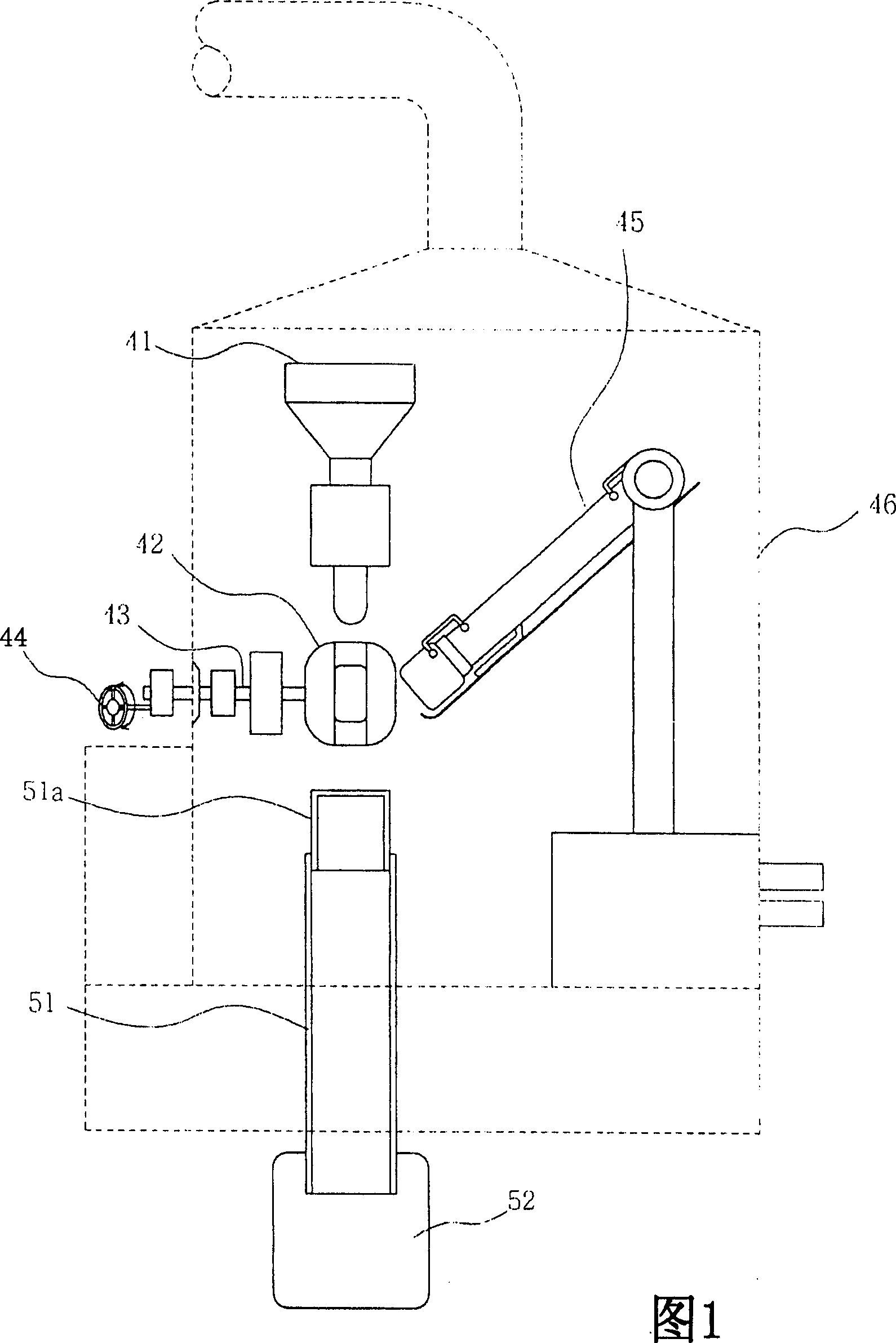

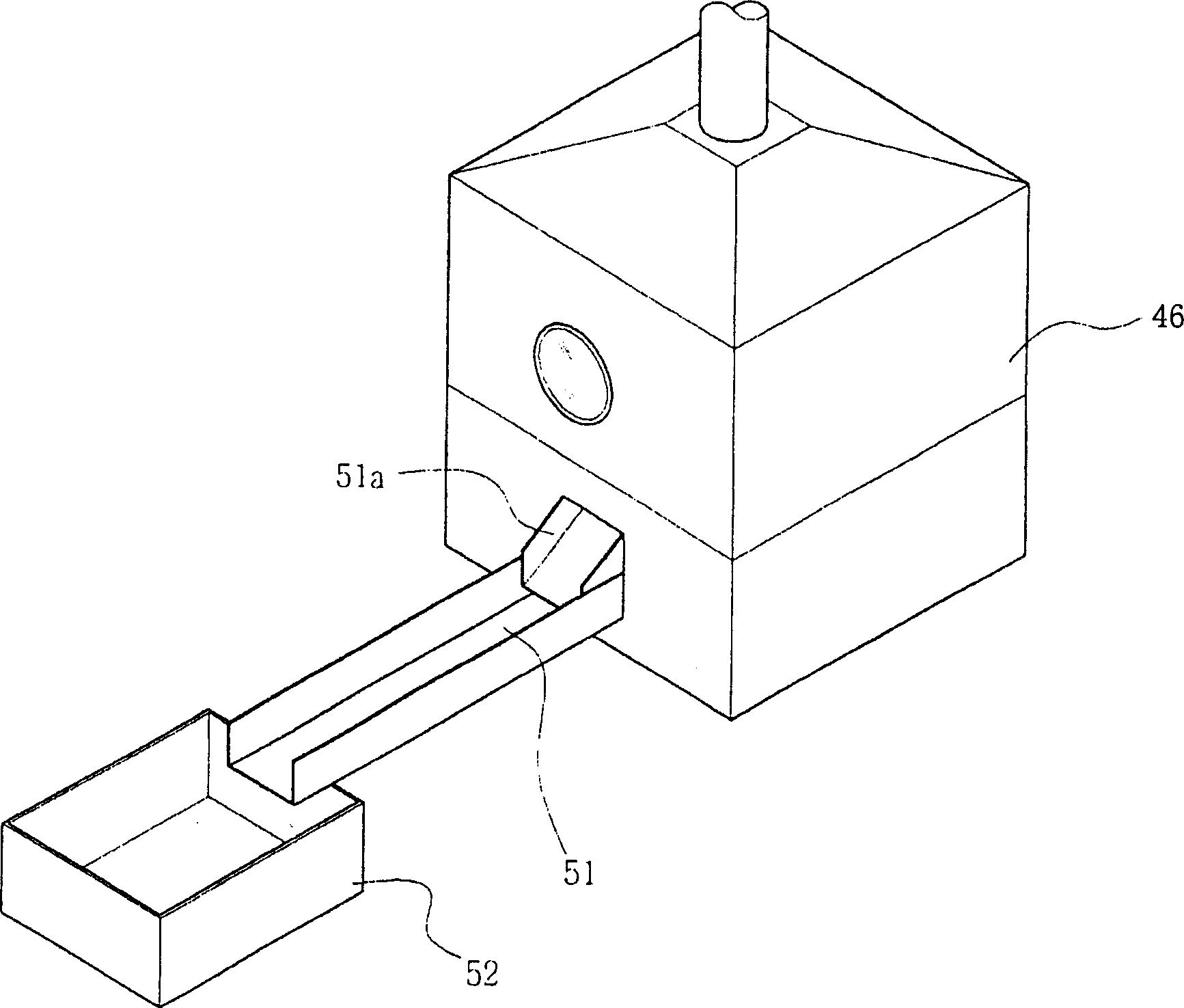

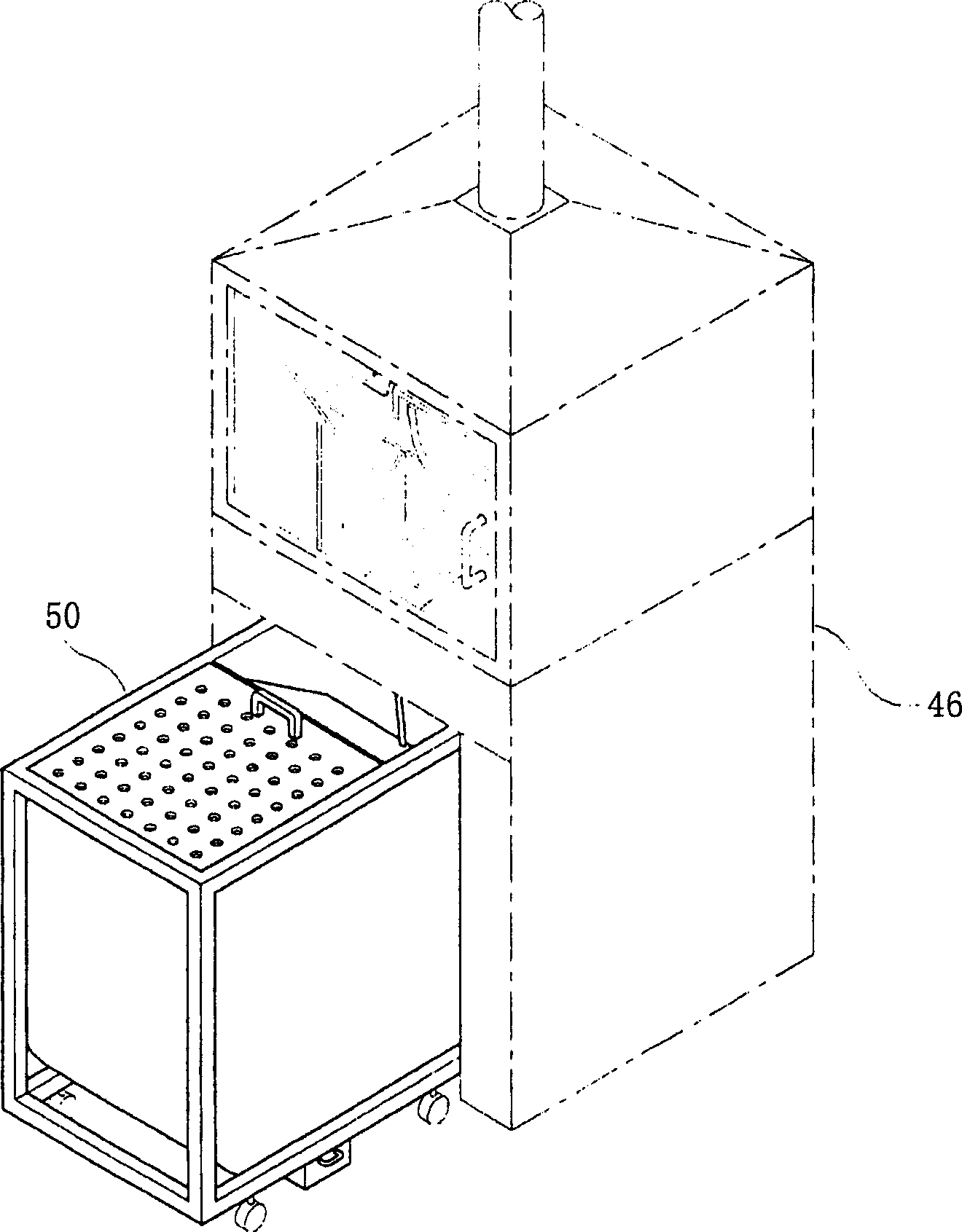

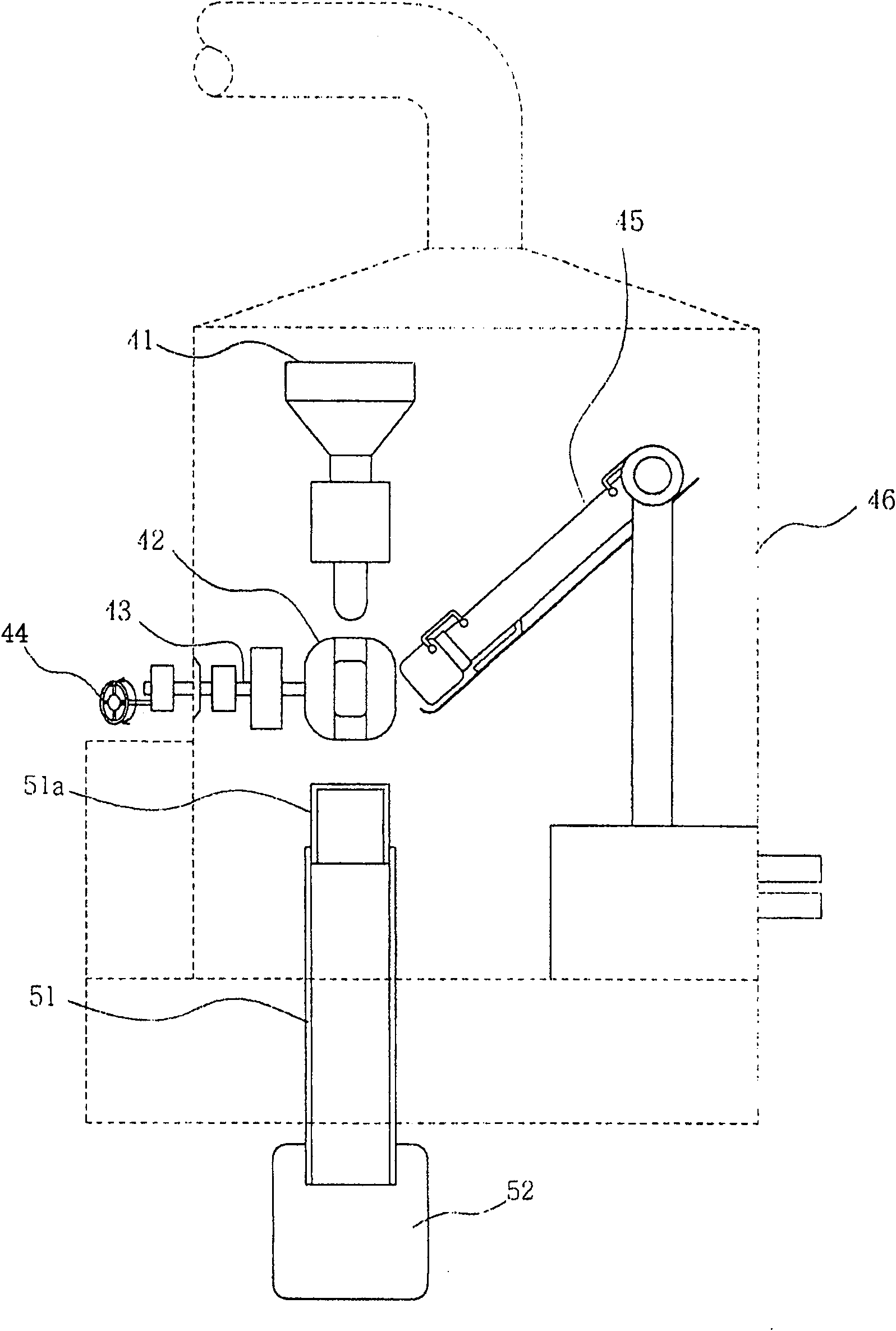

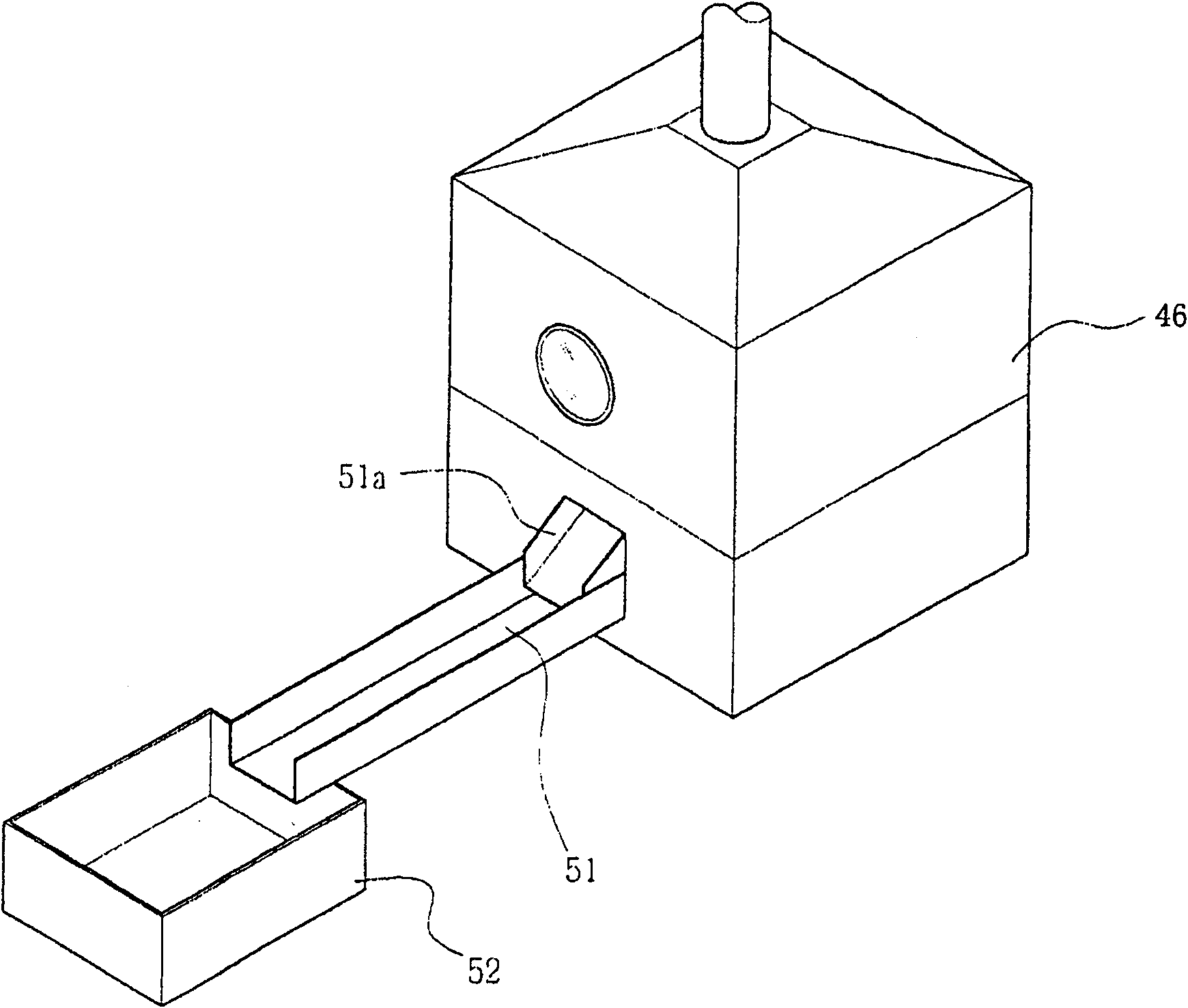

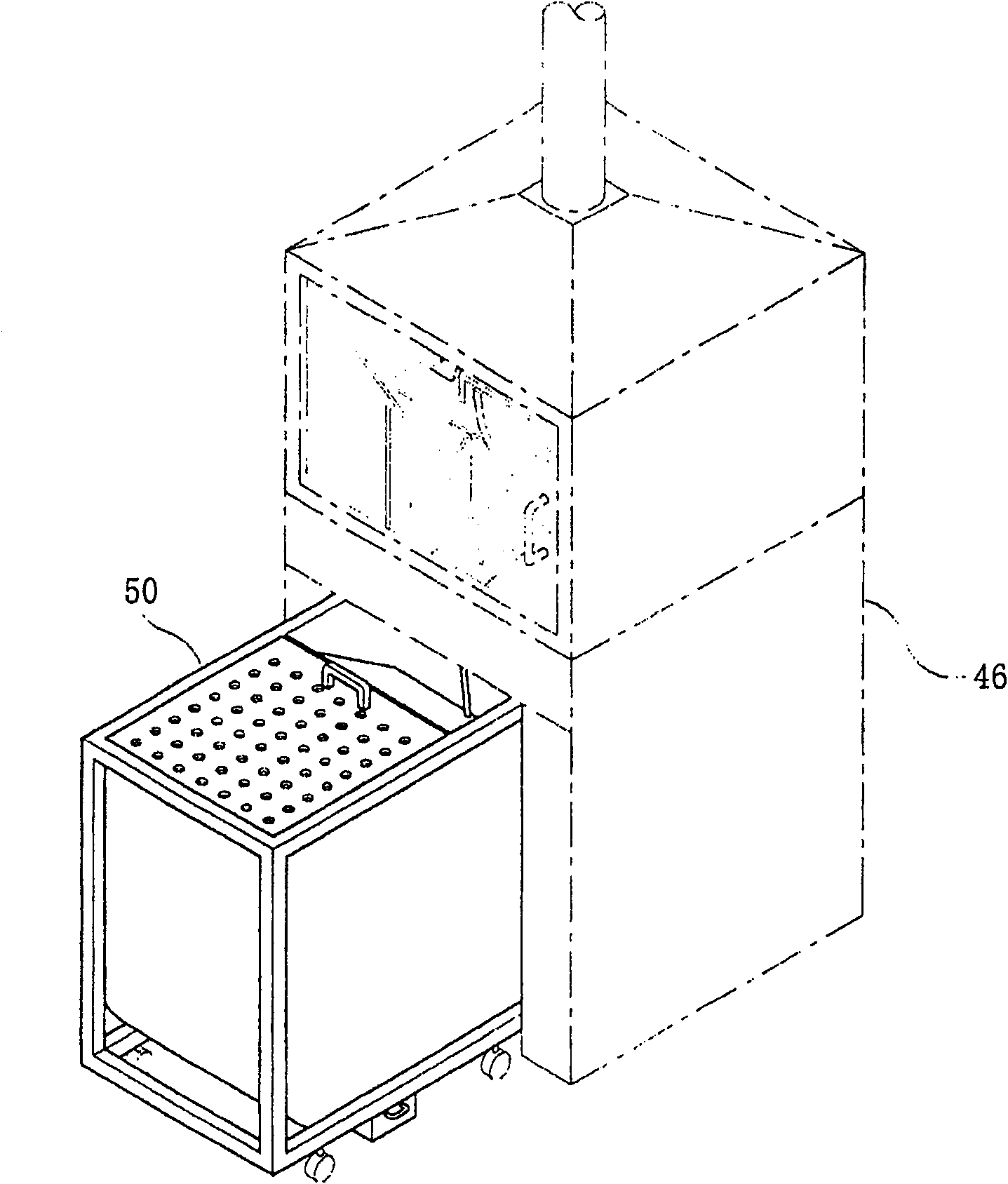

Apparatus for preparing cremated body crystalline grain

InactiveCN1915202ANo coalescenceShorten the timeSolid waste managementCremation furnacesEngineeringHeating furnace

The present invention relates to an apparatus for preparing cremated body crystalline grain which manufactures the collected bone powder into crystallized bones in the form of small bells. This crystallized bone manufacturing machine includes: a bone powder hopper and a heating furnace which is supported on one side of the housing by a supporting shaft, the supporting shaft is provided with a rotating handle on one end and a heating mechanism is disposed to surround the heating furnace as a heat source. The apparatus further includes: a spindle plate provided on the lower side of a discharge port of the heating furnace; an oscillating container of the spindle plate; a support bracket, one end of which is supported and fixed in a housing to support the spindle plate and the oscillating container; a cooling collector arranged on the right bottom of the oscillating container, and a plurality of blowers to cool and collect the generated crystallized bones passing the spindle plate and the oscillating container.

Owner:裴在烈

High-temperature high-salt resistant nano emulsion viscosity-reducing agent

InactiveCN100516164CImprove seepage capacityNo coalescencePipeline systemsDrilling compositionAdjuvantReducer

The invention relates to a high-temperature and high-salt-resistant nano-emulsion viscosity reducer used for heavy oil exploitation and transportation. It uses surfactants, and at the same time adds alkaline additives and nano additives to significantly improve the effect of emulsification and viscosity reduction. The viscosity reducer is composed of non-ionic surfactant, anionic surfactant, modified nano additive, NaOH, accelerator and water. The preparation method is: add 5-7% of OP-10, 2-5% of accelerator, 0.5-2% of modified nano additives at normal temperature and pressure, and stir evenly; then add anionic surfactant 30-45 %, add O1~3% flatly; finally add NaOH 20~30% and water 20~40%, and then stir continuously at a speed of 60~120r / min for 60~90min to obtain this nanoemulsion viscosity reducer product. The viscosity reducer system has good stability and will not coalesce during storage; the formed oil-in-water particles are smaller and more uniform, which improves the seepage capacity; it can greatly reduce interfacial tension and improve oil displacement efficiency, and can be used for heavy oil recovery and delivery fields.

Owner:SOUTHWEST PETROLEUM UNIV

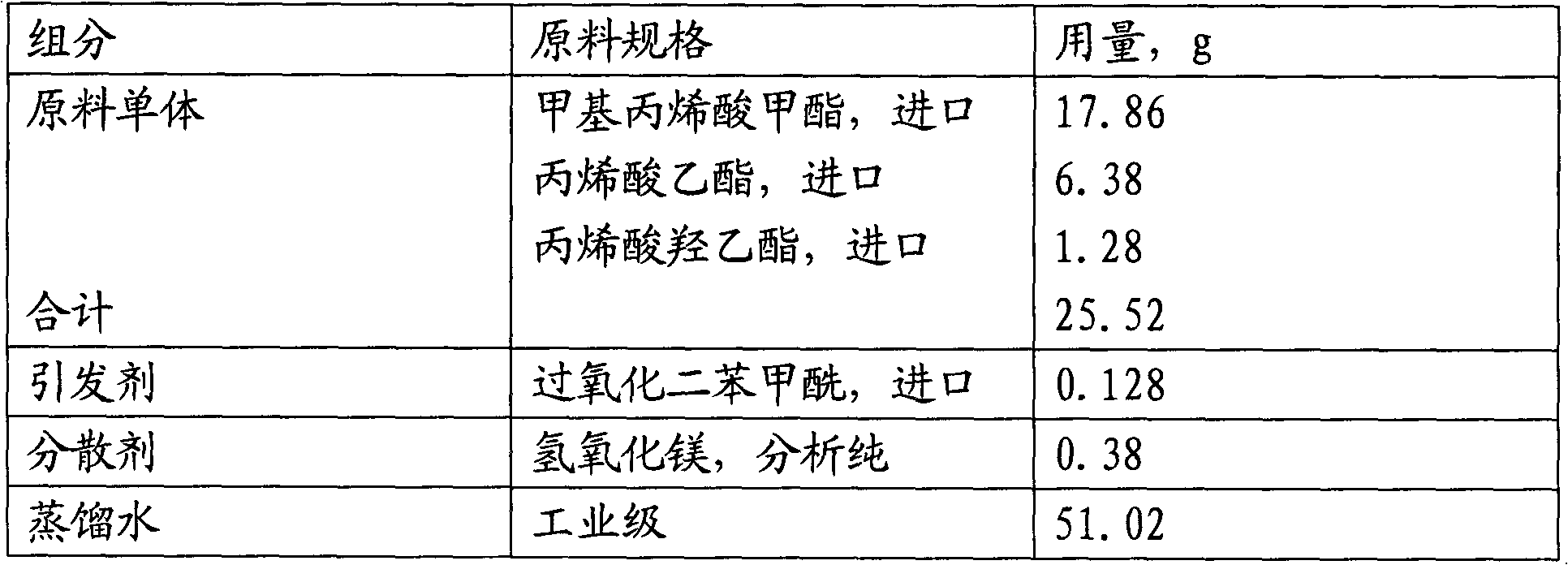

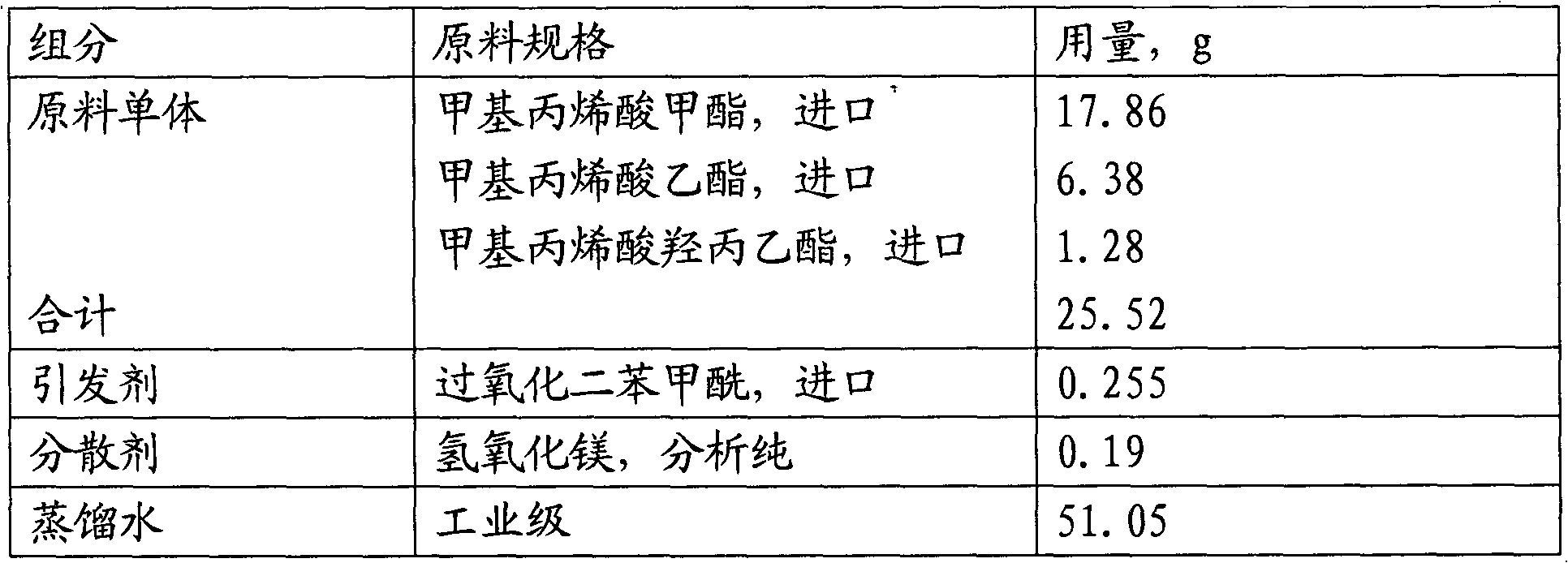

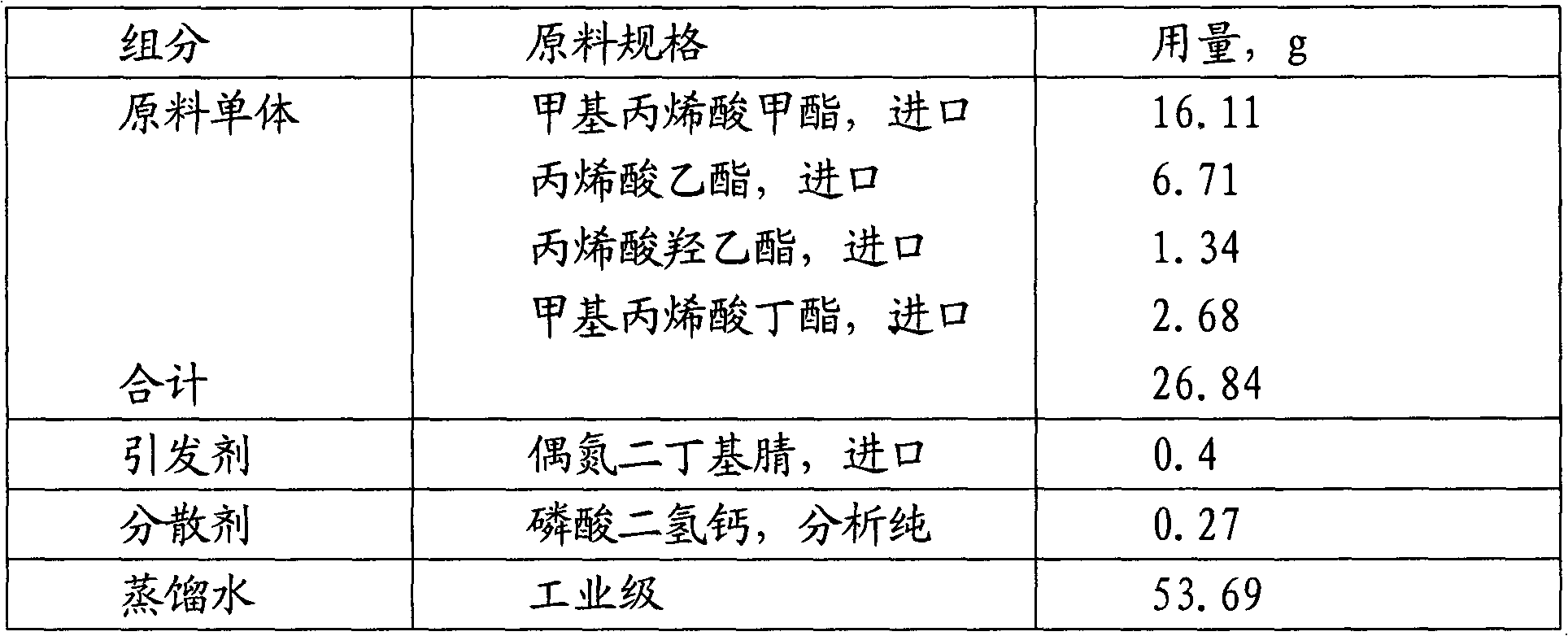

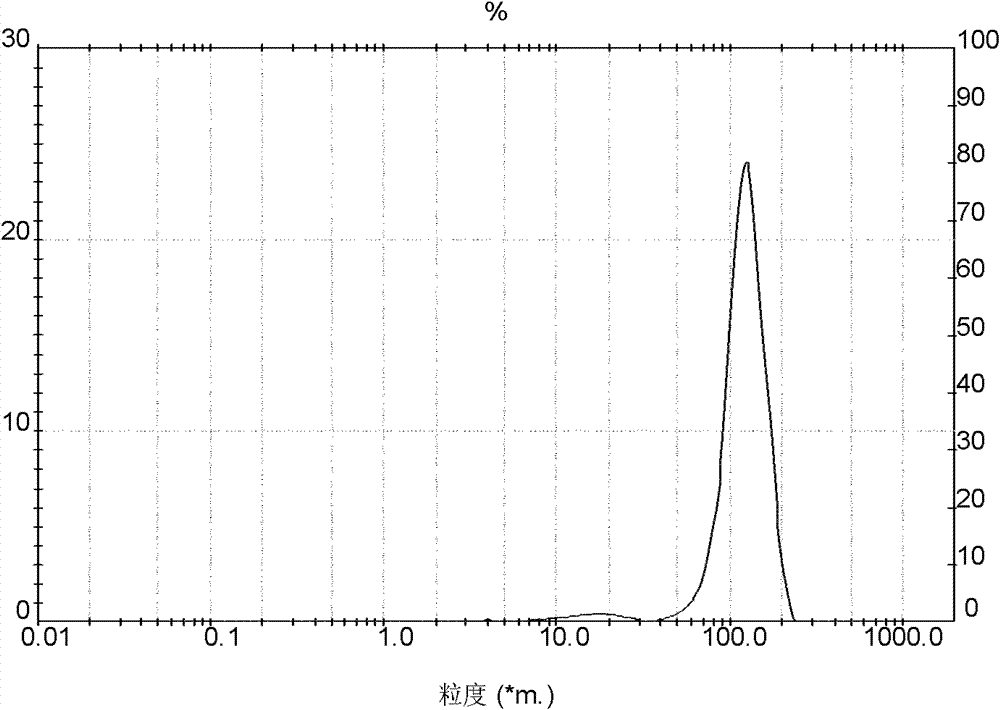

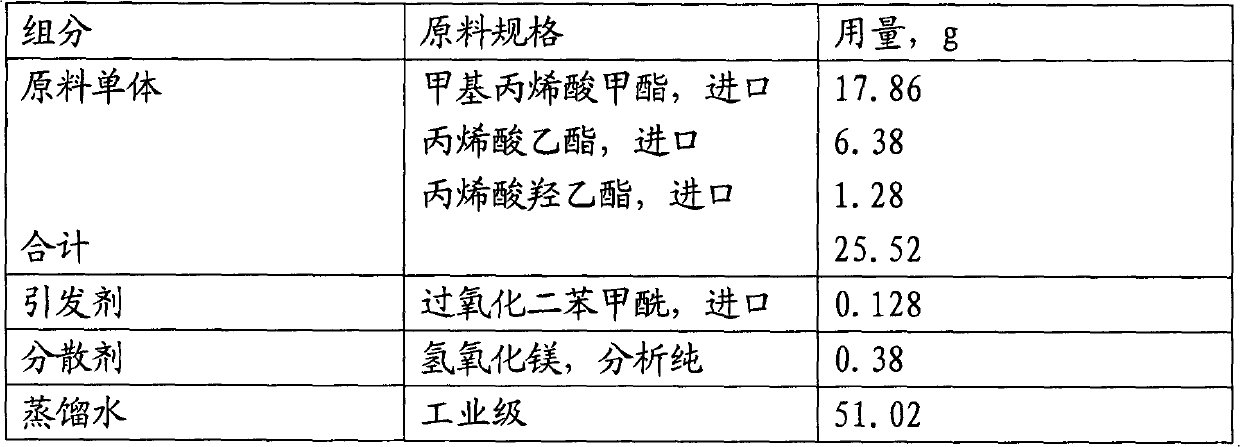

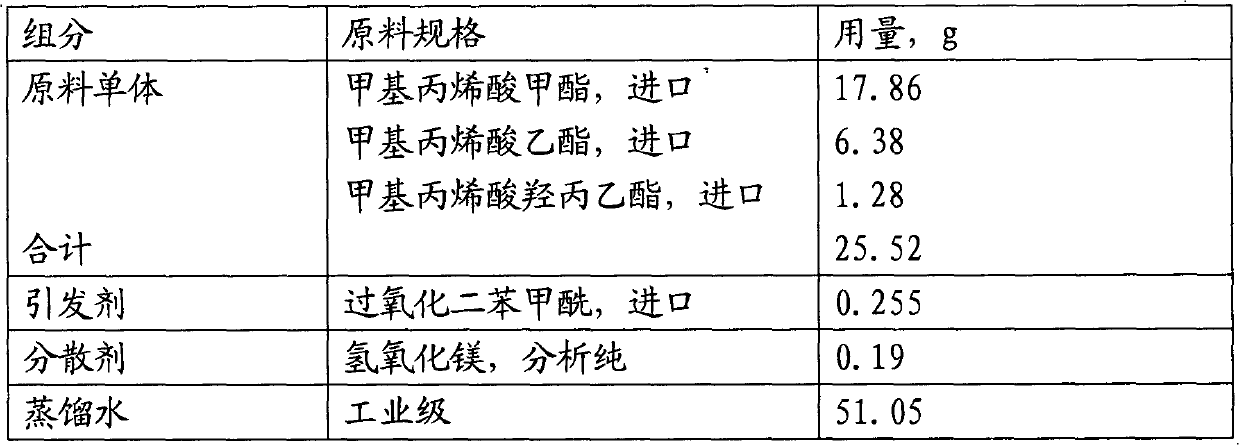

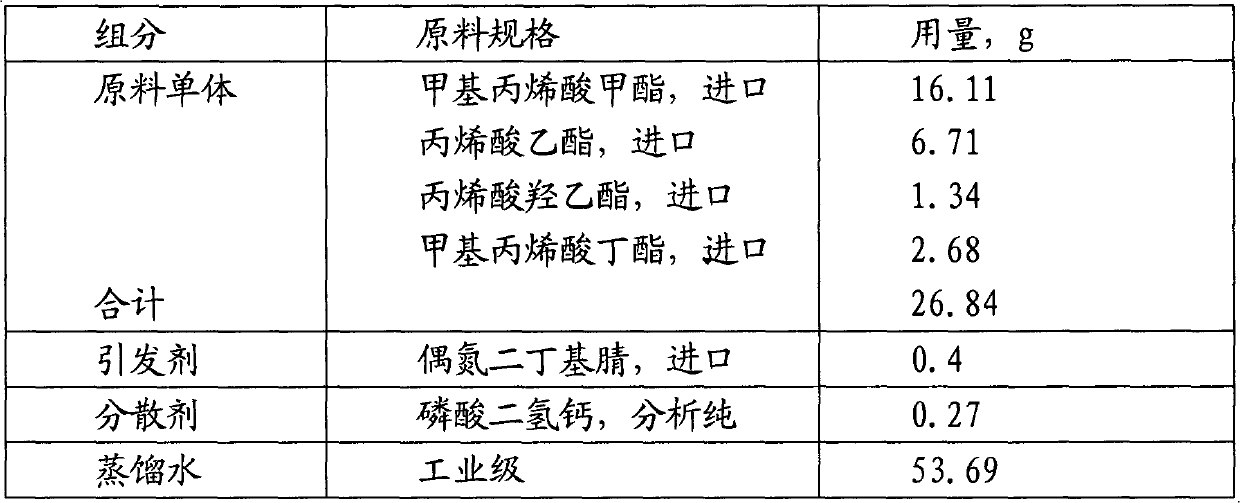

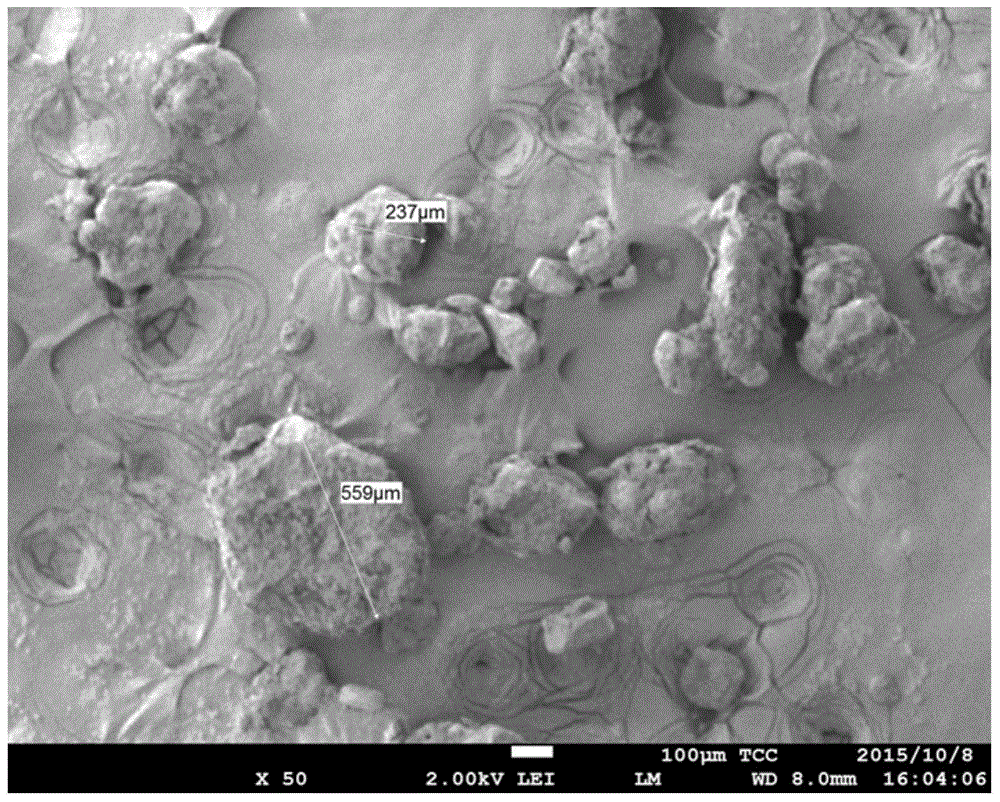

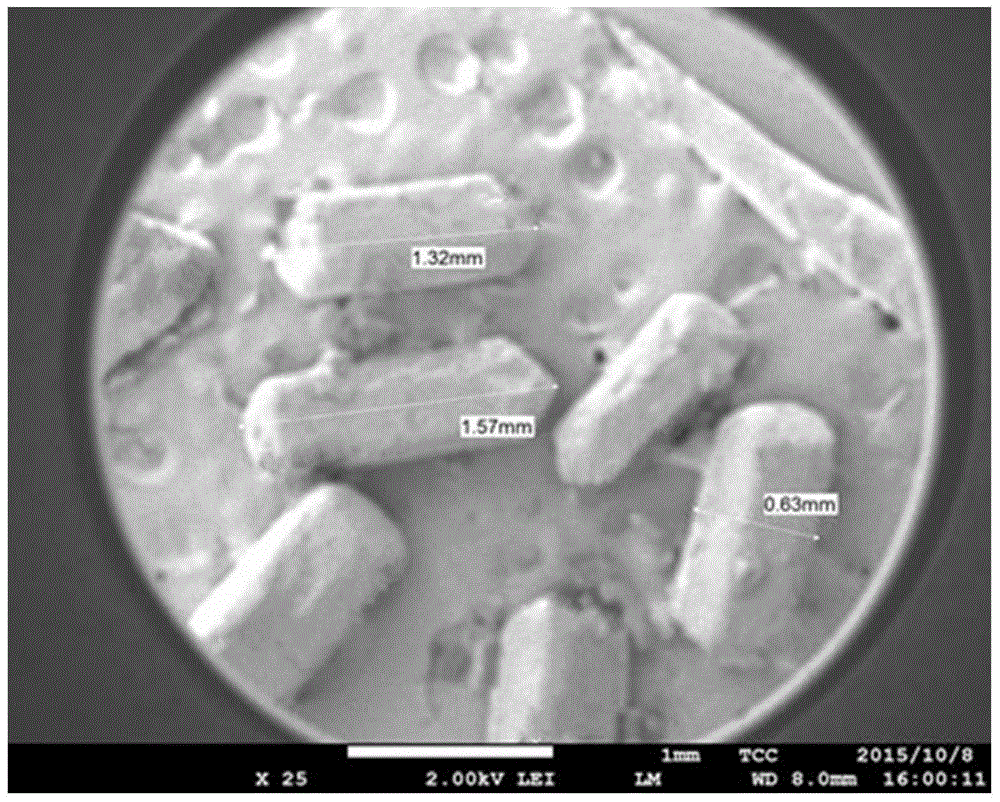

High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

ActiveCN102443098AHigh molecular weightOvercome the disadvantage that the molecular weight is not easy to increaseCoatings(Hydroxyethyl)methacrylateAcrylic resin

The invention relates to a high molecular weight acrylic resin for a polyvinylidene fluoride coiled material finish paint. The acrylic resin is combined with polyvinylidene fluoride resin as a coiled material finish paint base-material, is a bead-shape transparent particle and has a number-average molecular weight Mn higher than 90 thousand and molecular weight distribution Mw / Mn less than 2.0. The resin of the invention is prepared by a suspension polymerization method from material monomers of 50-80 wt% of methyl methacrylate and / or methyl acrylate, 10-40 wt% of ethyl acrylate and / or methyl methacrylate and 0-40 wt% of one or more selected from acrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, methacrylic acid, hydroxyethyl methacrylate, hydroxypropyl methacrylate, butyl acrylate and butyl methacrylate. The high molecular weight acrylic resin of the invention can be combined with a PVDF resin, and a prepared finish paint film has comprehensive properties the same as an imported one and better performances on MEK-resistant wiping frequency and artificial ageing resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Crystallization method of cefadroxil monohydrate and crystals

ActiveCN102134250BUniform particle size distributionNo coalescenceOrganic chemistryCEFADROXIL MONOHYDRATEGranularity

The invention relates to a method for producing crystals of cefadroxil monohydrate, comprising the following steps: adding an N, N-dimethyl formamide solvent compound of cefadroxil to a mixed solvent of N, N-dimethyl formamide and water, wherein the mass ratio of the cefadroxil solvent compound to the mixed solvent is 1:1-1:2, stirring to obtain a suspending liquid, and keeping the temperature at 15-30 DGE C and the pH value of the solution at 6.0-7.5 during feeding; after the cefadroxil solvent compound is totally changed into the cefadroxil monohydrate, reducing the pH value of the suspending liquid to 4.5-5.0 within 1-20 minutes, keeping the temperature at 10-18 DEGC, and stirring for crystal cultivation for 10-90 minutes; and filtering, washing and drying after crystal cultivation is finished to obtain a product, the square platy crystal-form cefadroxil monohydrate. The square platy crystal-form cefadroxil monohydrate obtained by the method has uniform particle size distribution, does not generate coalescence, and is applicable to industrial production.

Owner:TIANJIN UNIV

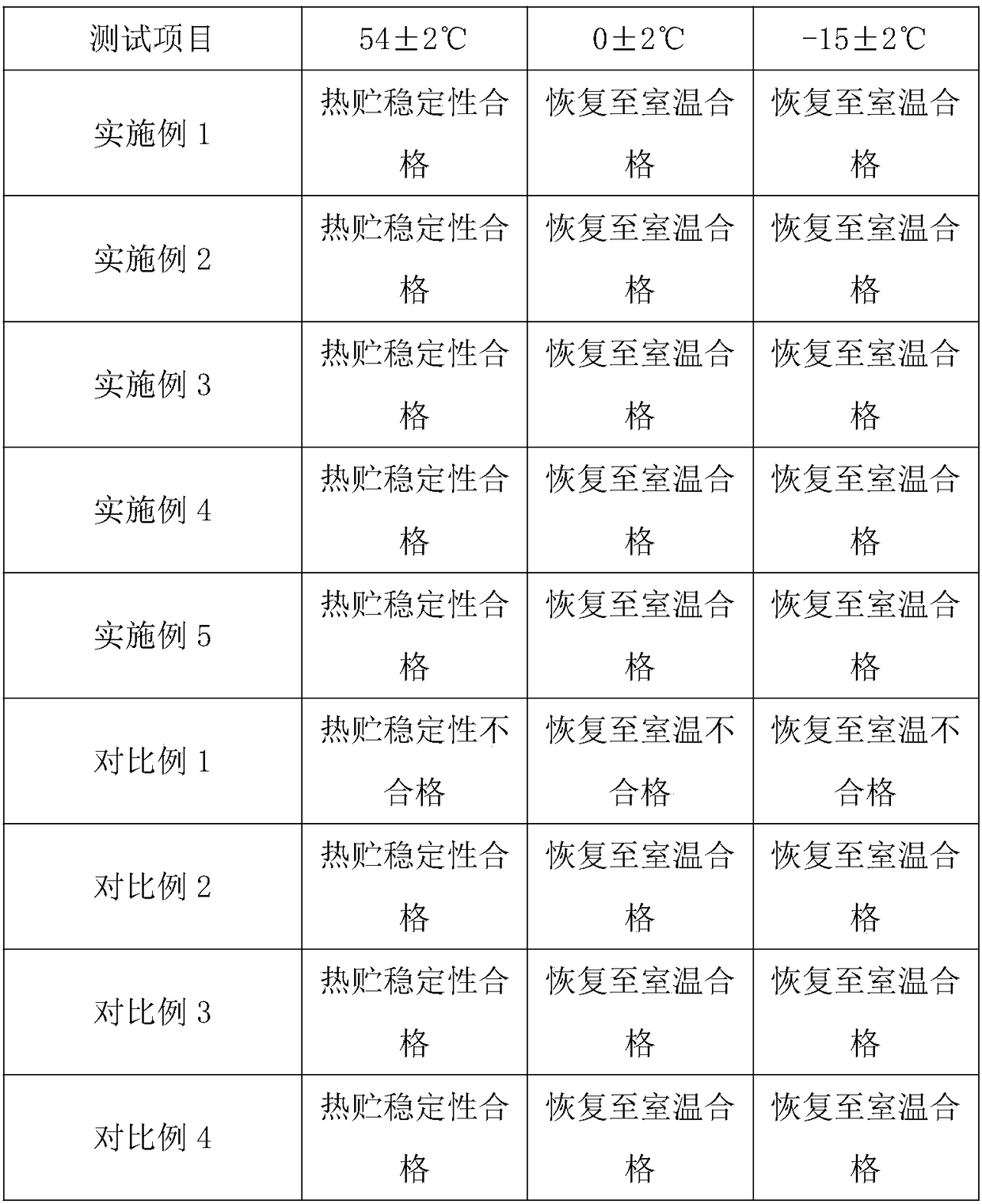

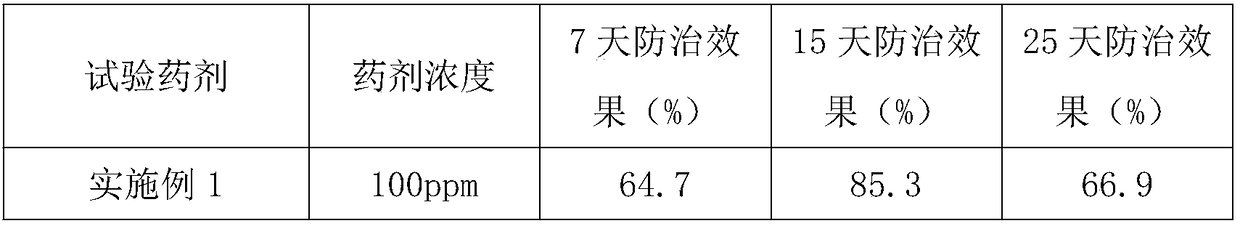

Pleocidin synergistic water emulsion and preparation method thereof

InactiveCN109221133ALong validity periodImprove stabilityBiocideAnimal repellantsOrganic solventAnti freezing

The invention relates to the technical field of pesticide preparations and specifically relates to a pleocidin synergistic water emulsion and a preparation method thereof. The water emulsion is prepared from the following raw materials in parts by weight: 1-15 parts of pleocidin, 10-25 parts of capsule shell material, 10-15 parts of organic solvent, 3-7 parts of emulsifying agent, 1-5 parts of synergist, 0.5-2.5 parts of wetting dispersant, 1-3 parts of surfactant, 1-3 parts of thickening agent, 2-4 parts of anti-freezing agent, 3-5 parts of penetrant, 0.3-0.7 part of defoaming agent and 50-70parts of deionized water. The pleocidin synergistic water emulsion disclosed by the invention is good in fast-acting property, efficient in dispersion, stable and durable in pesticide effect, long instorage validity, capable of reducing the consumption of a poisonous and harmful solvent, environment-friendly and safe.

Owner:JIXI NONGHUA BIOTECH

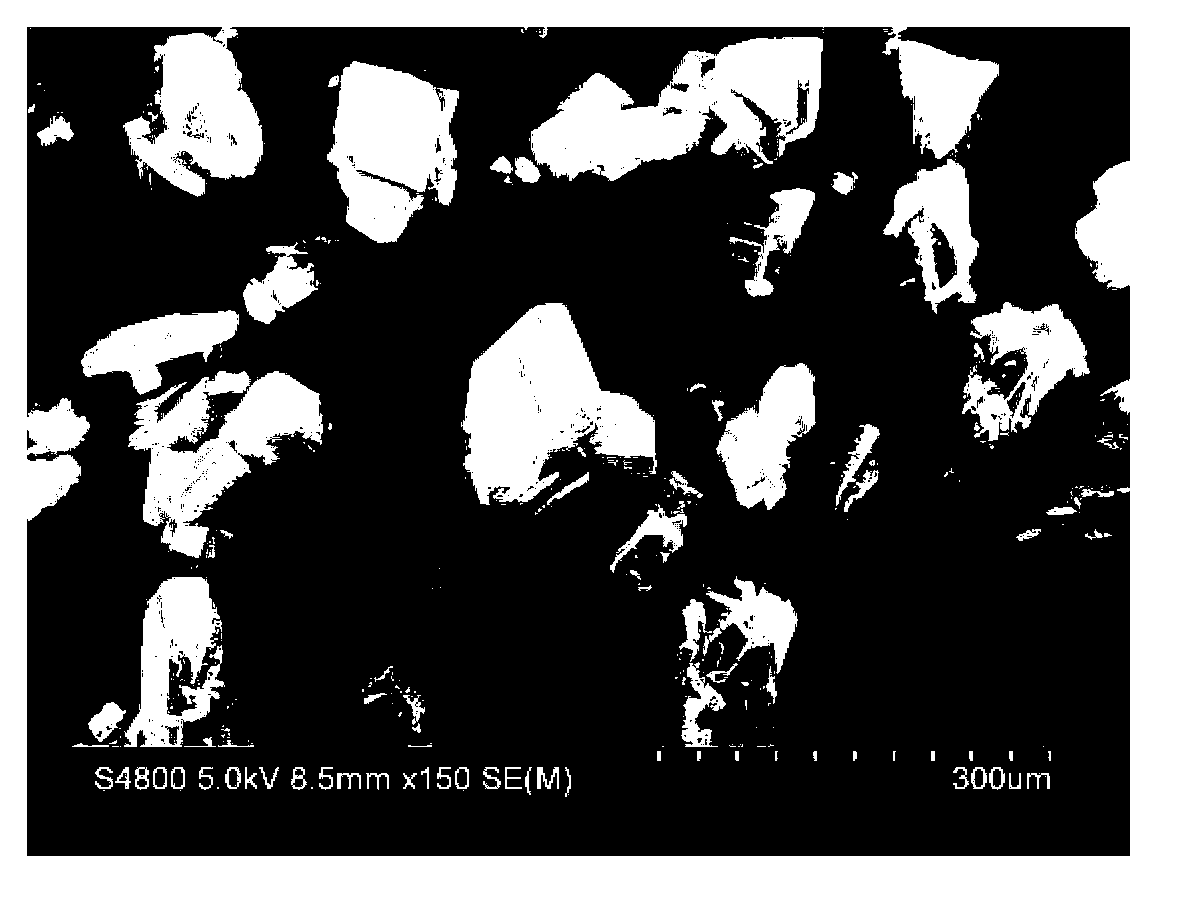

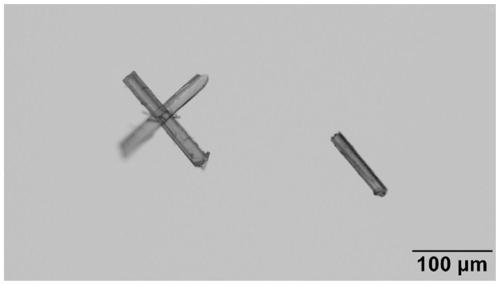

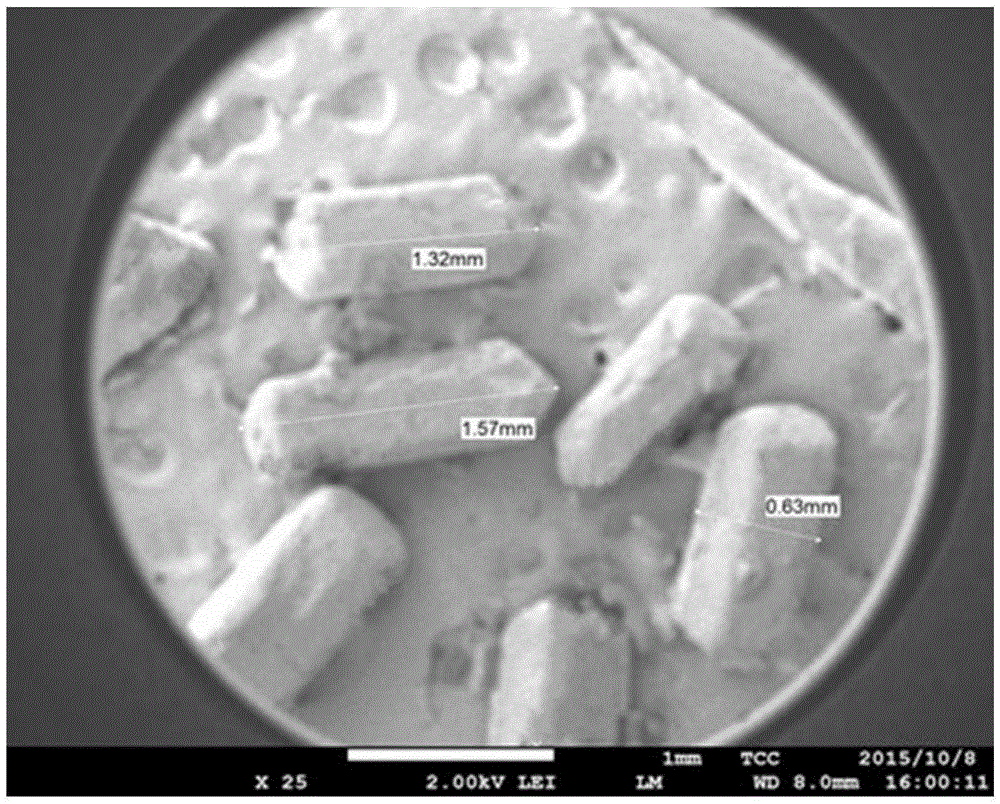

Method for crystallizing phenylacetyl-7-amino-3-deacetoxycephalosporanic acid controllable in particle size and crystal habit

The invention provides a method for crystallizing phenylacetyl-7-amino-3-deacetoxycephalosporanic acid controllable in particle size and crystal habit. The method includes the following steps that a phenylacetyl-7-amino-3-deacetoxycephalosporanic acid crude product is added into ammonia water and uniformly mixed, and the mixture is filtered to obtain a phenylacetyl-7-amino-3-deacetoxycephalosporanic acid solution; hydrochloric acid is added into the phenylacetyl-7-amino-3-deacetoxycephalosporanic acid solution under the stirring condition at the temperature of 5-30 DEG C and at the speed of 90-180 r / min, the pH value is adjusted to be 1.5-3.0, crystal growing is conducted for 1-5 hours, and the phenylacetyl-7-ADCA is obtained. The purity of the phenylacetyl-7-ADCA prepared through the preparation method of the phenylacetyl-7-ADCA can reach 99.7%, the phenylacetyl-7-ADCA is in a long bar shape or a needle shape in the aspect of crystal habits, and the phenylacetyl-7-ADCA has the advantages of being complete in crystal habit, high in purity, good in liquidity, not prone to coalescence and the like, and has wide application prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

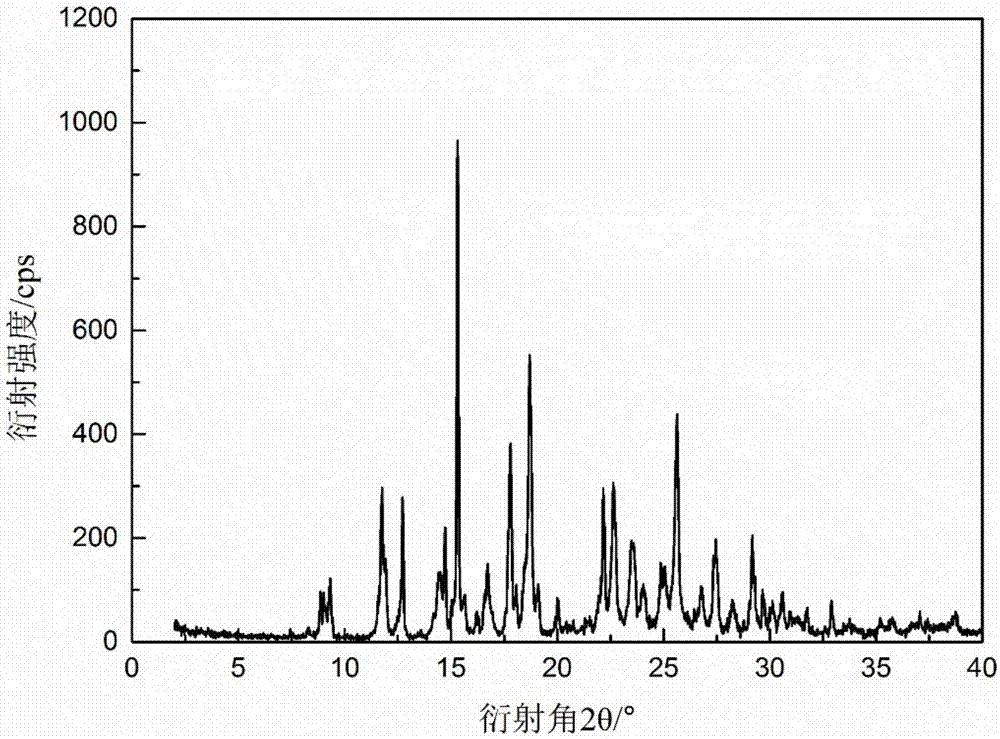

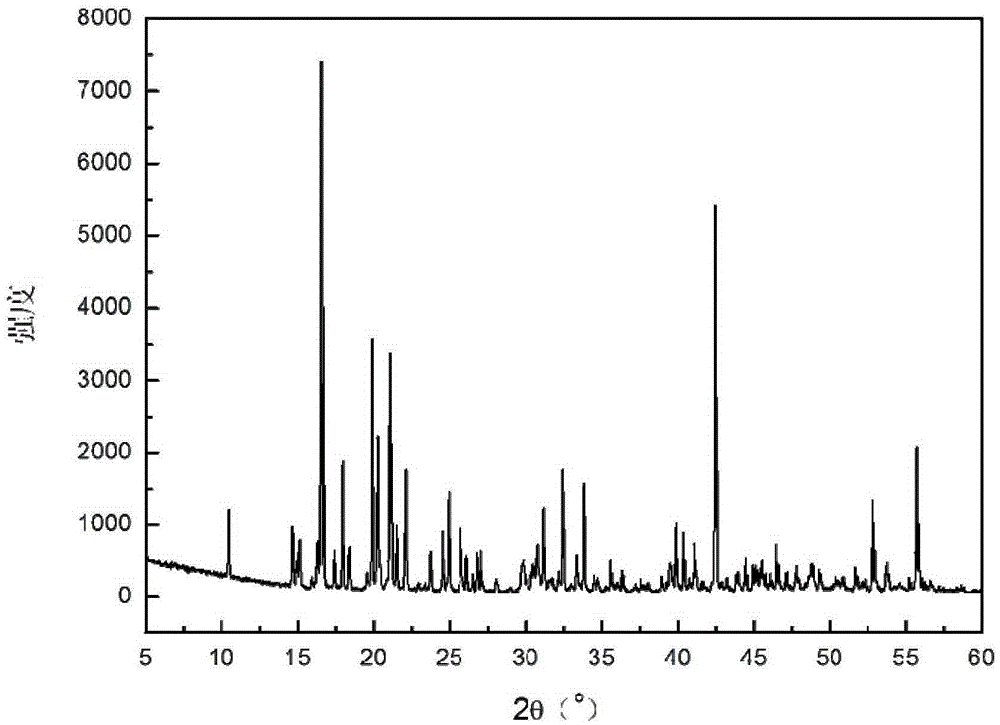

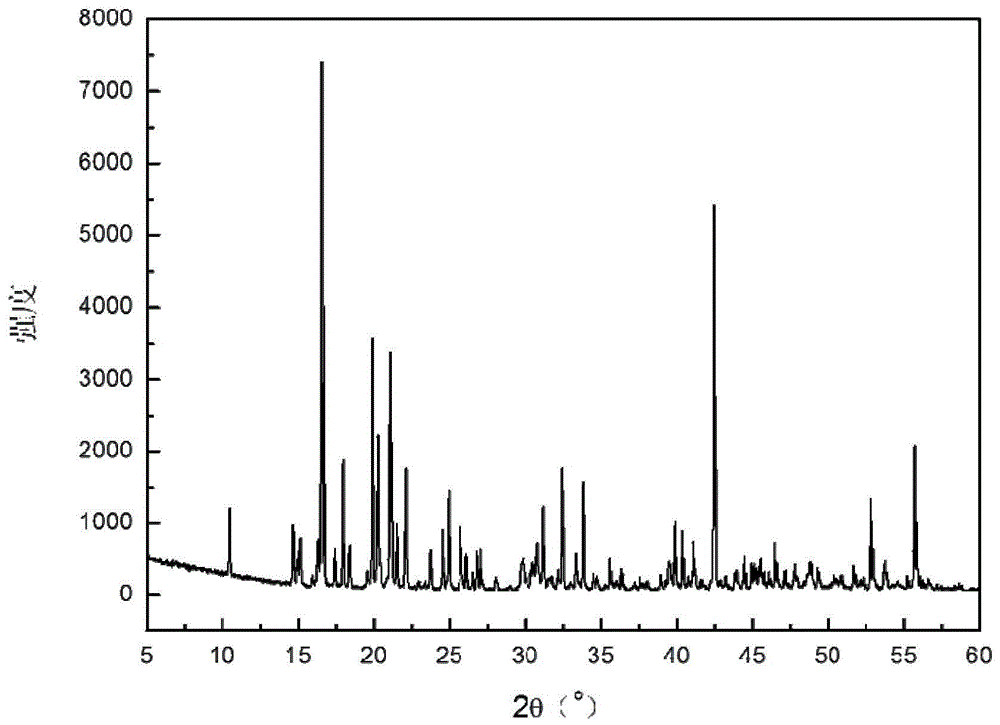

Pyraclostrobin crystal form and preparation method thereof

The invention relates to a pyraclostrobin crystal form and a preparation method thereof. The pyraclostrobin crystal form is characterized in that X-ray powder diffraction shows characteristic peaks when 2theta is 8.8+ / -0.1 degrees, 9.0+ / -0.1 degrees, 9.2+ / -0.1 degrees, 11.8+ / -0.1 degrees, 12.7+ / -0.1 degrees, 14.7+ / -0.1 degrees, 15.3+ / -0.1 degrees, 17.8+ / -0.1 degrees, 18.7+ / -0.1 degrees, 22.2+ / -0.1 degrees, 22.6+ / -0.1 degrees, and 25.6+ / -0.1 degrees. The preparation method comprises the following steps: dissolving a pyraclostrobin crude product in dichloromethane or a mixed solvent containing the dichloromethane; stirring and dissolving until a solution becomes clear; precipitating a crystal by evaporating or cooling and crystalizing; filtering crystal mush, washing and drying to obtain the pyraclostrobin crystal form. The method disclosed by the invention is easy to operate, the yield of a crystalizing process is 90 to 98 percent, the HPLC (High Performance Liquid Chromatography) detection purity of a product is 99.9 percent, and the product is a yellow crystal, has a flaky crystal habit, is smooth in surface and regular in edges, and has higher practical application value.

Owner:TIANJIN UNIV +1

A method for crystallization of coenzyme q10 assisted by ultrasonic waves

ActiveCN104402697BHigh purityImprove production efficiencyQuinone separation/purificationUltrasonic assistedOrganic solvent

Owner:TIANJIN UNIV

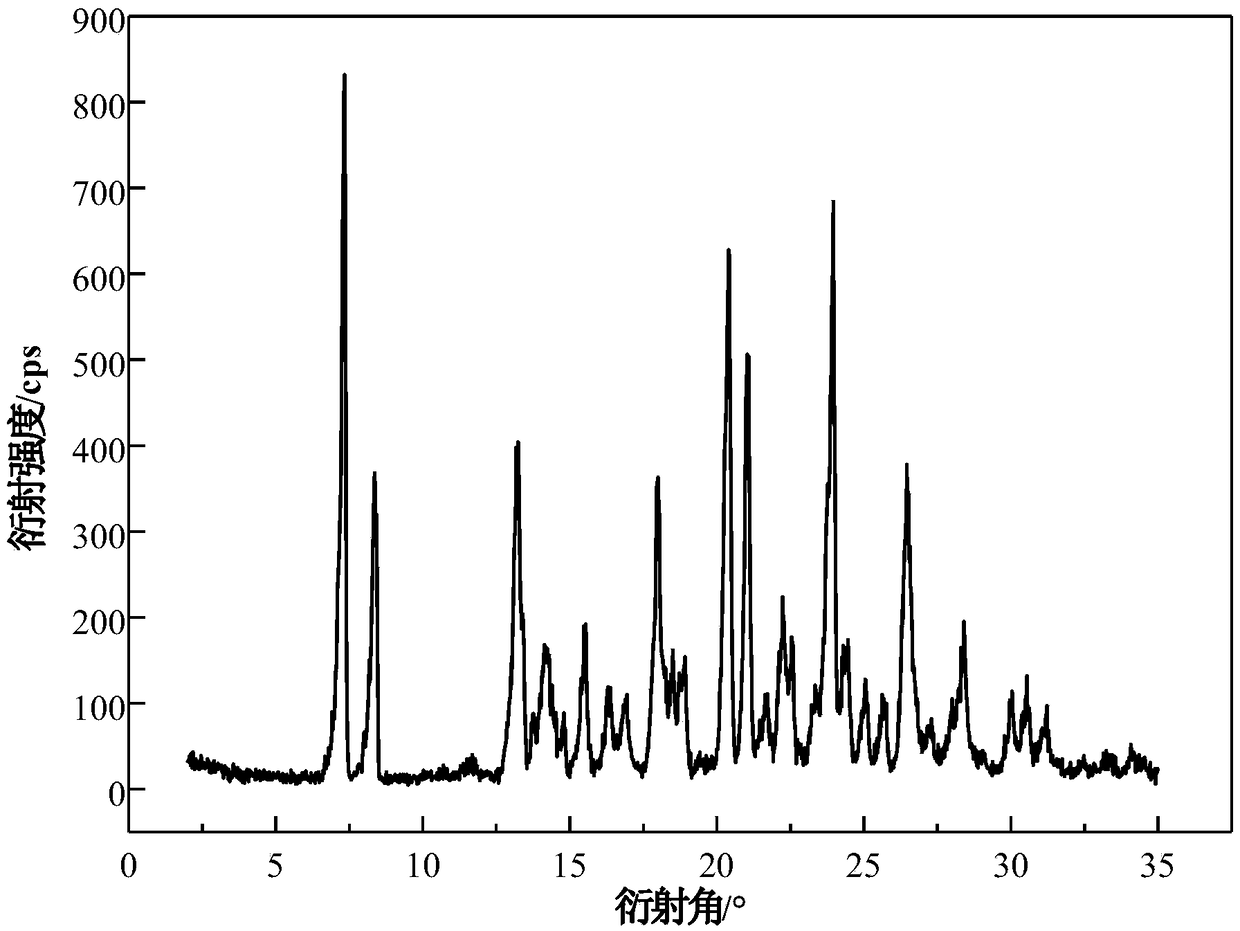

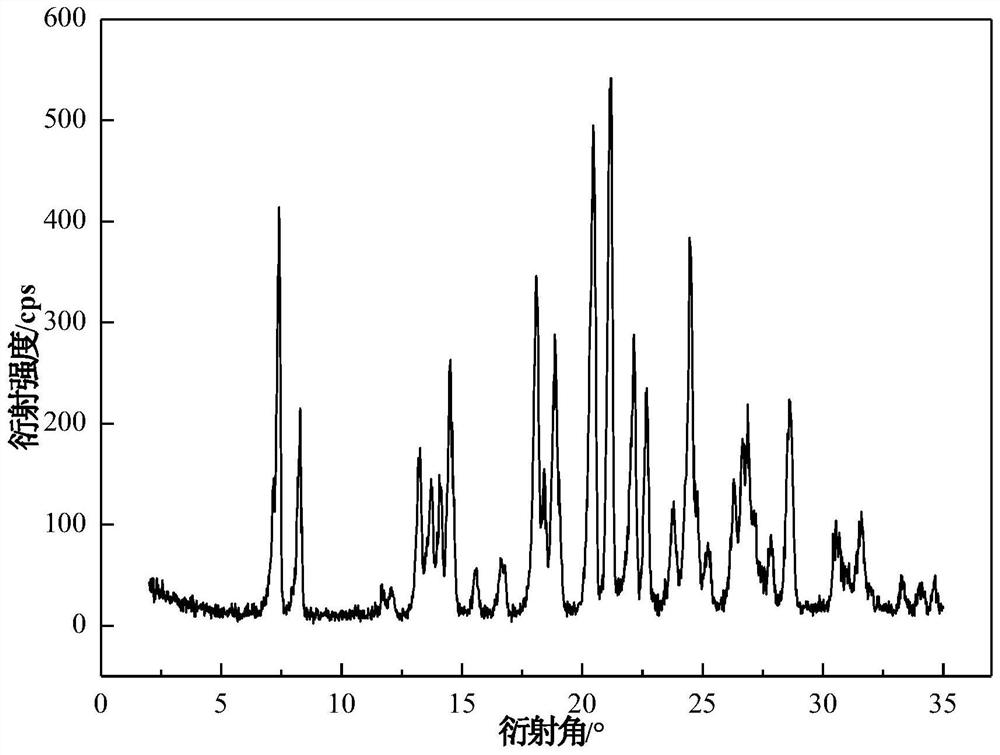

Azoxystrobin acetone solvate and preparation method thereof

The invention relates to an azoxystrobin acetone solvate and a preparation method thereof. Characteristic peaks exist at positions with the following diffraction angles represented by 2theta angles: 7.32+ / -0.20 degrees, 8.42+ / -0.20 degrees, 13.26+ / -0.20 degrees, 14.16+ / -0.20 degrees, 18.04+ / -0.20 degrees, 18.52+ / -0.20 degrees, 18.90+ / -0.20 degrees, 20.40+ / -0.20 degrees, 21.04+ / -0.20 degrees, 22.36+ / -0.20 degrees, 23.96+ / -0.20 degrees, 24.36+ / -0.20 degrees, 26.46+ / -0.20 degrees, 28.4+ / -0.20 degrees, 30.06+ / -0.20 degrees and the like, wherein the characteristic peak at the position with the diffraction angle 2theta of 7.32+ / -0.20 degrees is an initial peak, and the relative strength is 100%. The preparation method is a constant-temperature suspension rotating crystal method, operation is simple, control is easy, reproducibility is good, the problems of difficult filtering and low efficiency in production are solved, and the preparation method is suitable for industrialization.

Owner:TIANJIN UNIV

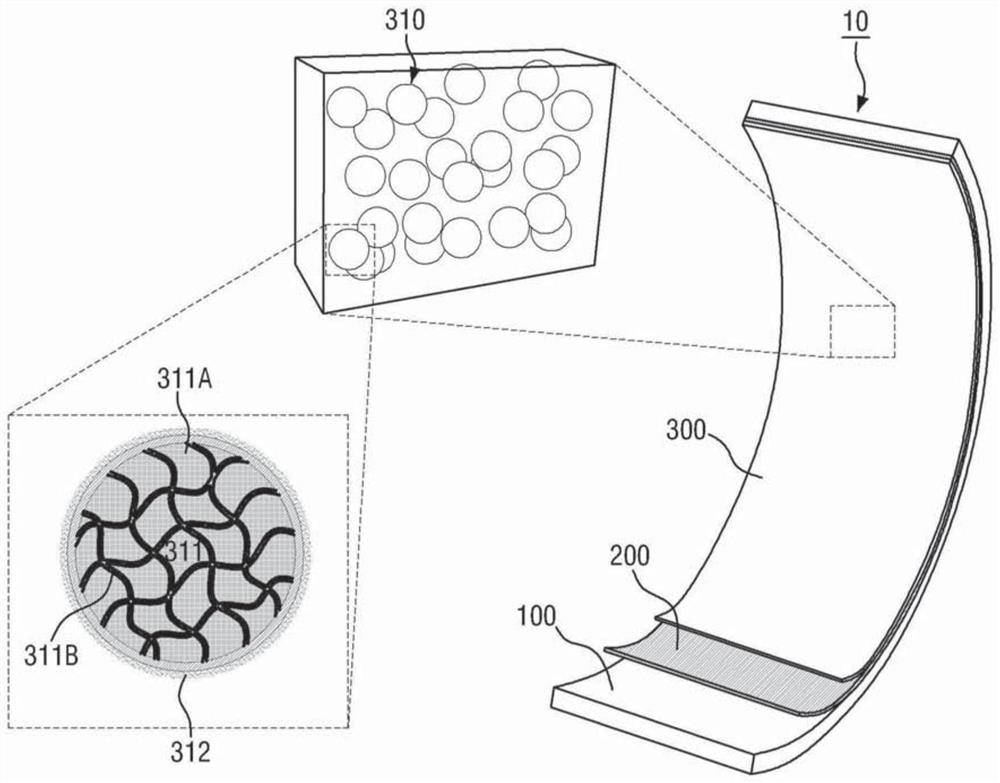

Method for manufacturing oil gel capsules and method for manufacturing contact part for vehicle, including oil gel capsules

ActiveCN112980545AImprove friction resistanceGood anti-occlusion performanceBearing componentsAdditivesActive agentProcess engineering

The present invention relates to a method for manufacturing oil gel capsules and a method for manufacturing a contact part for a vehicle, including the oil gel capsules. The present disclosure relates to manufacturing the oil gel capsules and adding the oil gel capsules to an overlay layer of the contact part for the vehicle. The present disclosure may provide a method for manufacturing the oil gel capsules and the method for manufacturing the contact part for the vehicle, including the oil gel capsules. The oil gels in the oil gel capsules manufactured by the present disclosure may respond to the temperature environment of the contact part for the vehicle, and an aggregation phenomenon of gelators or an aggregation phenomenon of surfactants may not occur even after an oil is released. Therefore, as oil gel capsules are added to an overlay layer, the present disclosure may improve low friction characteristics and seizure resistance characteristics of a contact part for a vehicle without any side effects caused by the above-described aggregation phenomenon.

Owner:HYUNDAI MOTOR CO LTD +2

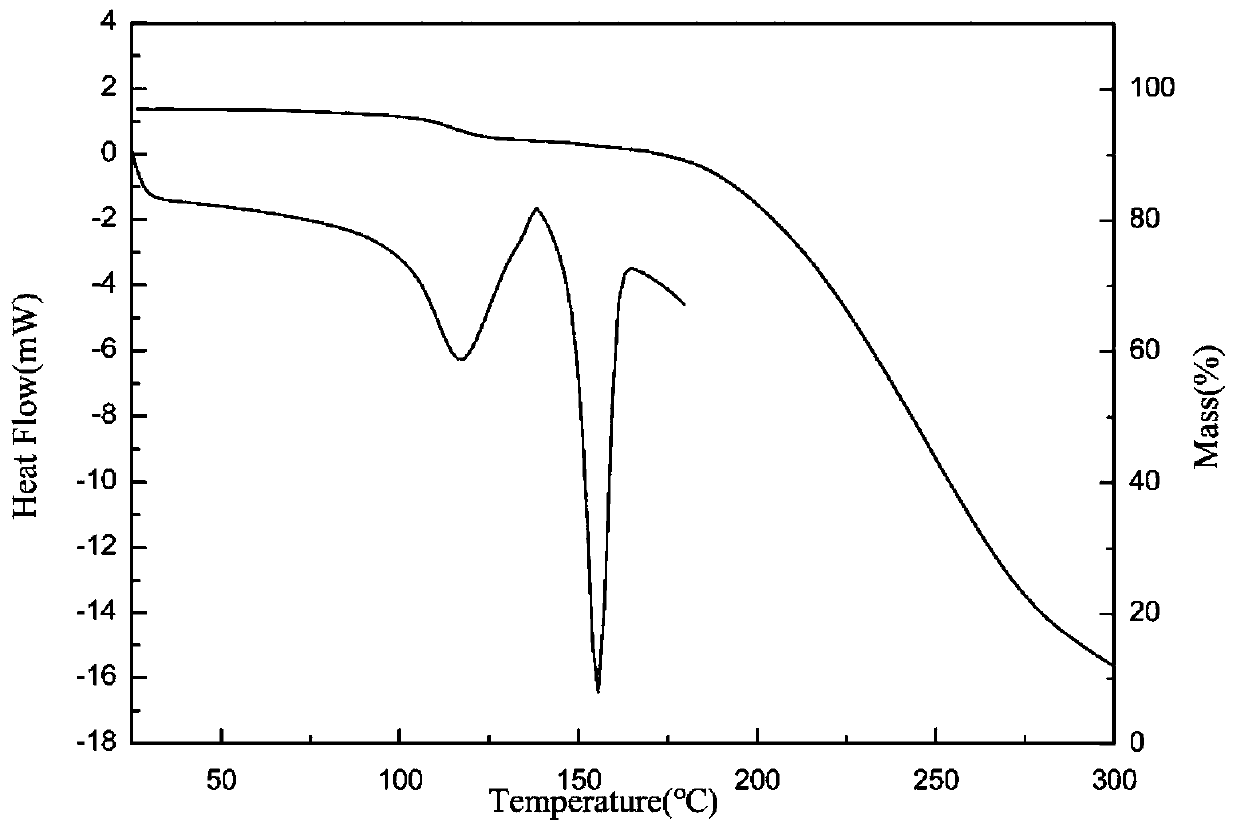

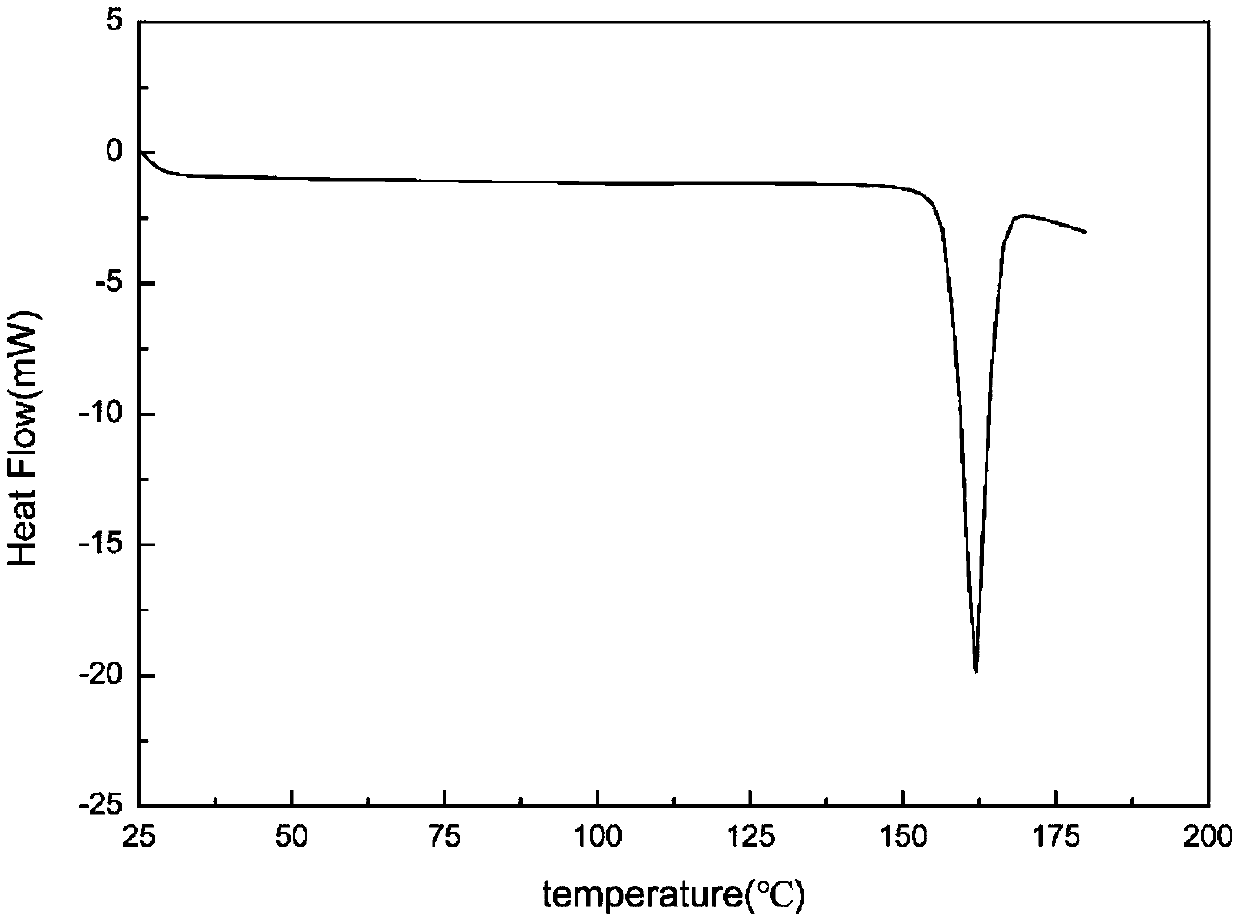

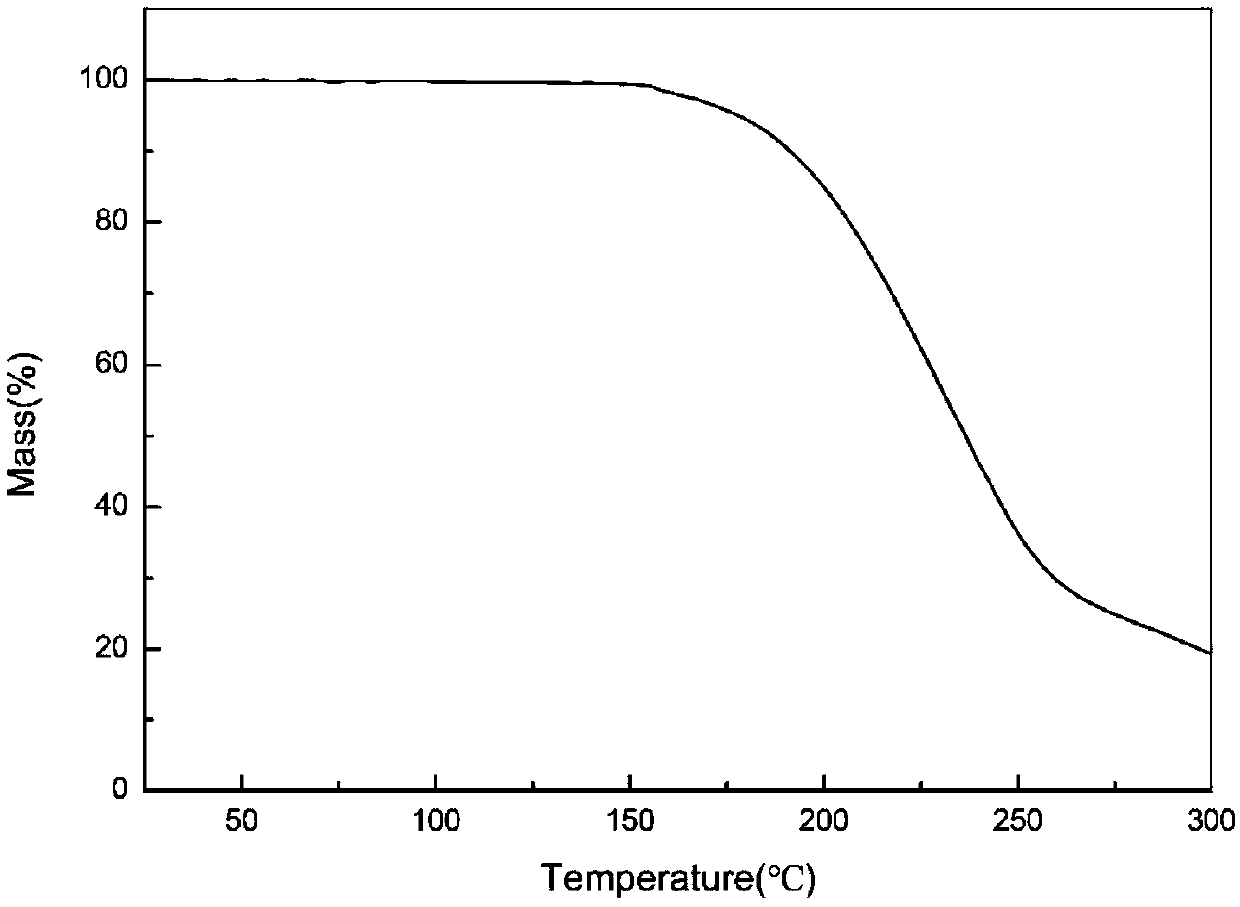

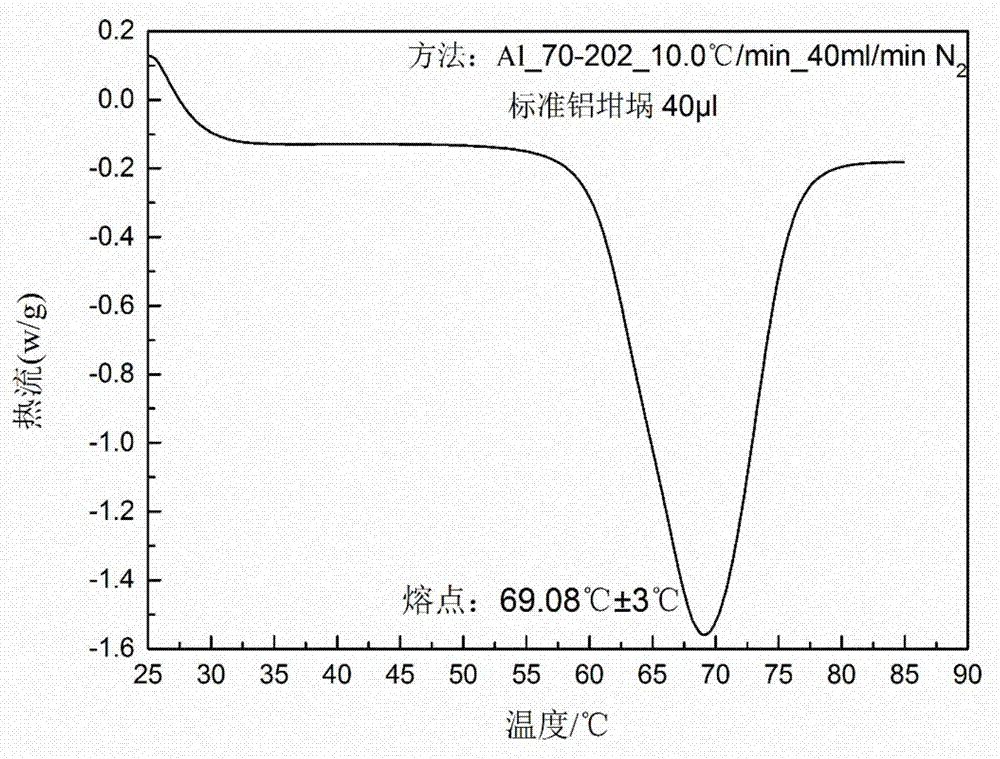

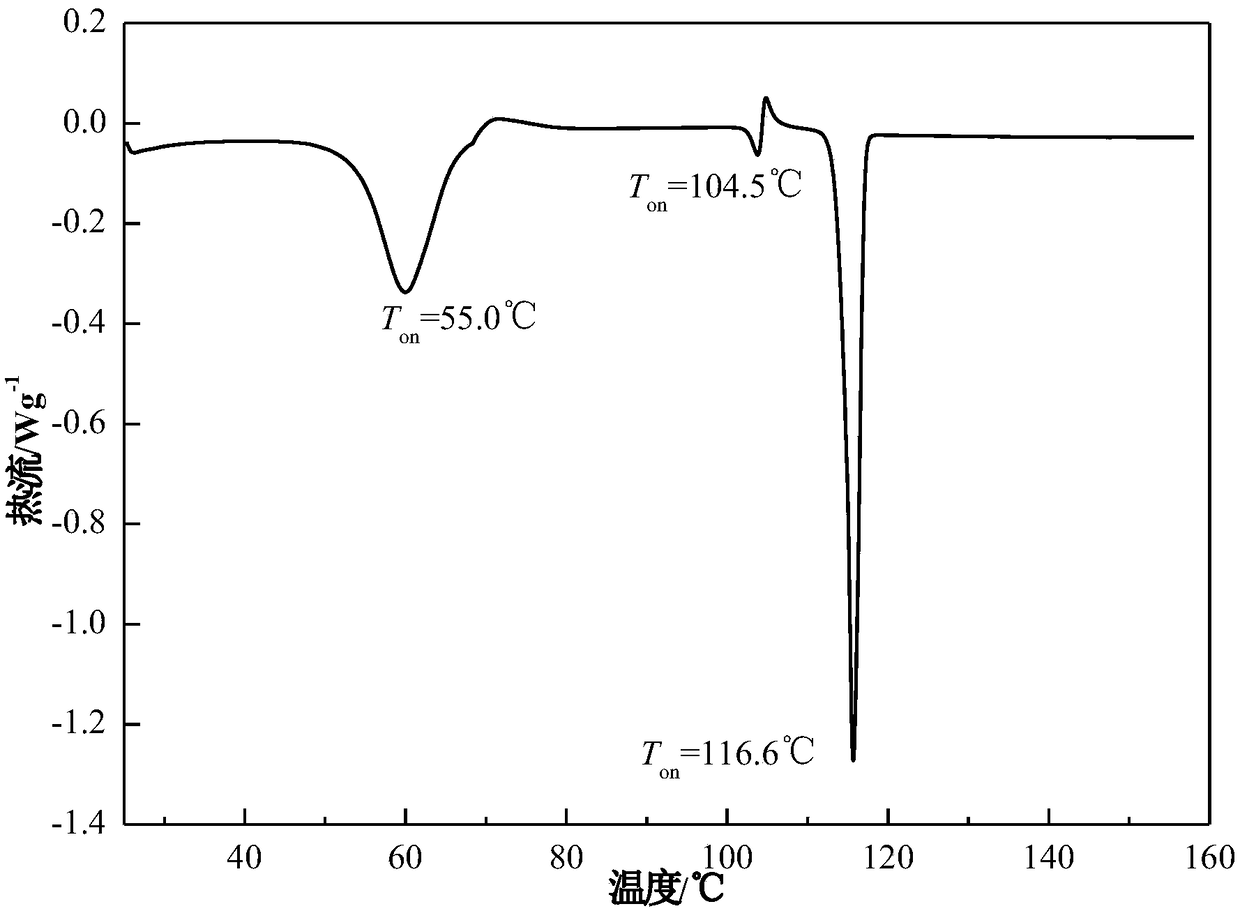

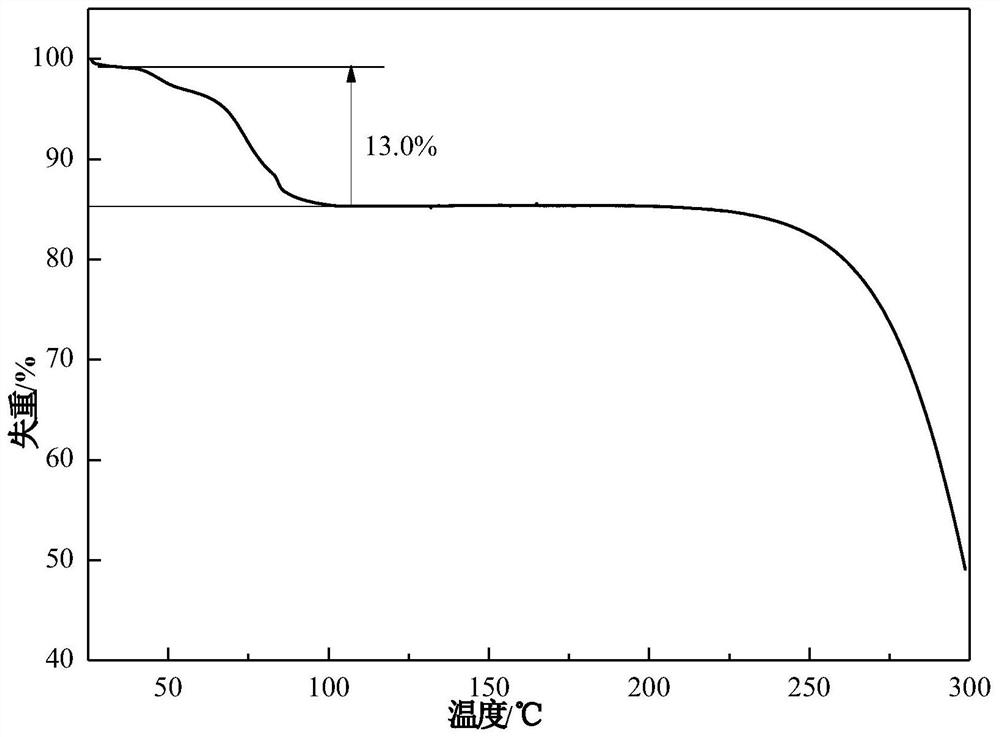

Heptahydrate crystal and preparation method

ActiveCN105271367AOperating conditions are simple and easy to controlHigh crystallinityZinc sulatesSolventMother liquor

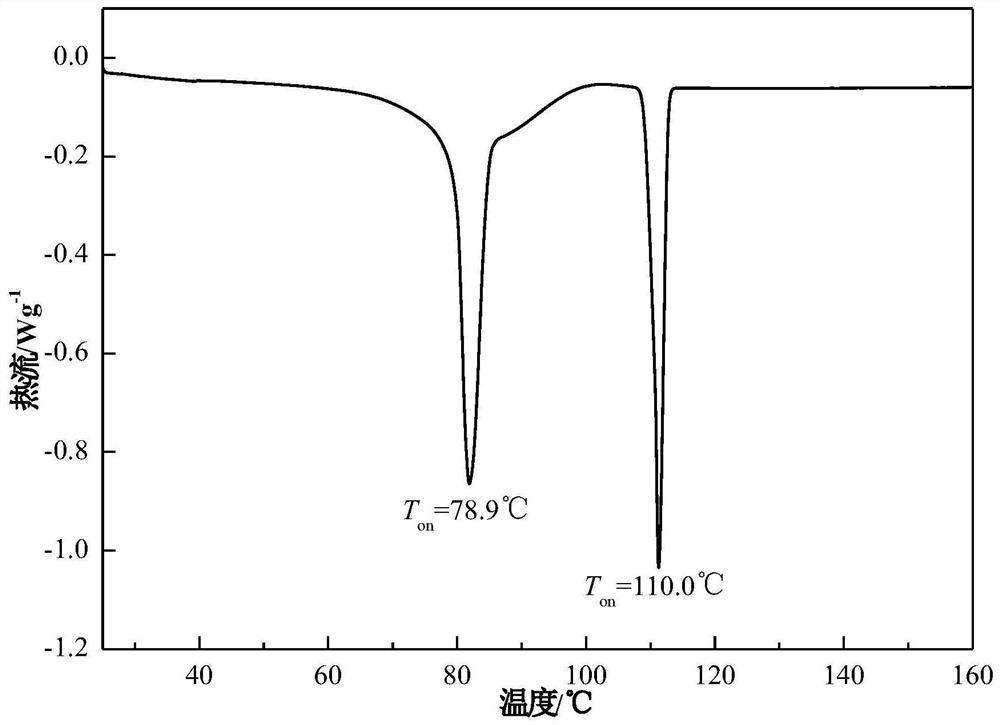

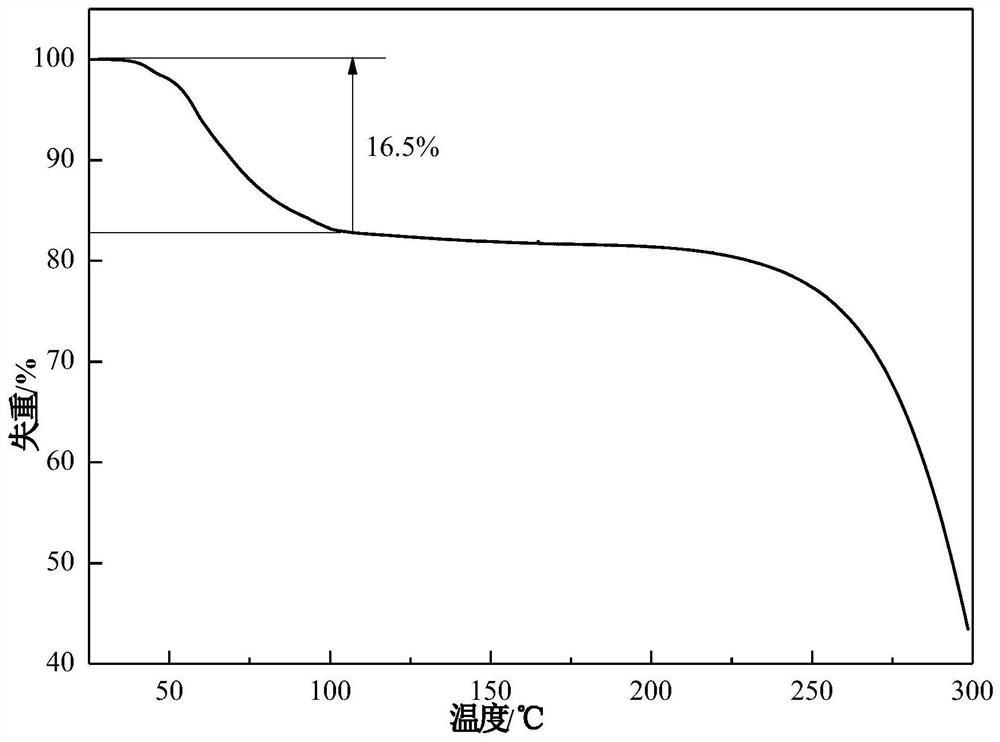

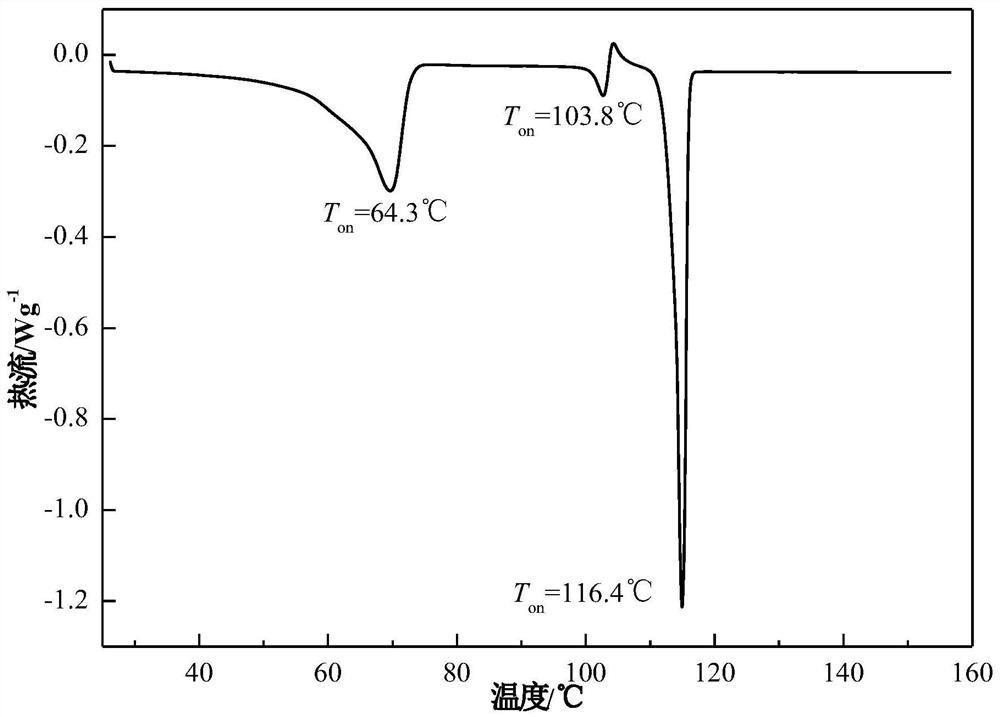

The invention provides a heptahydrate crystal and a preparation method. The preparation method includes the following steps that 1, sulfuric acid is dissolved in reaction liquid, and the reaction liquid is binary solvent and / or crystallization mother liquor of alcohol and water; 2, a zinc source is added, the molar ratio of the zinc source to sulfuric acid is controlled to be 1:1+ / -0.1), and a reaction is conducted for a certain time; 3, sulfuric acid is supplemented, the molar ratio of the supplemented sulfuric acid and the zinc source added in step 2 is controlled to be (0.05-0.25):1, and the reaction is continued for a certain time; 4, after the reaction is ended, a solution is cooled and separated, the separated solid is subjected to postprocessing, and a product of the heptahydrate crystal is obtained. The product of the heptahydrate crystal has obvious prism-shaped crystallization habit, and dewatering endothermic peaks exist at the temperature of 75+ / -1 DGE C, the temperature of 103 + / -1DEG C, the temperature of 124+ / -1 DEG C and the temperature of 276+ / -1 DEG C of a differential scanning calorimetric curve.

Owner:CHINA TIANCHEN ENG +1

Coated particulate preparation method

The invention discloses a coated particulate preparation method, comprising the following steps: firstly, particulates in movement are coated with coating solution to cure the solution to form films; the coating rate and curing rate are controlled to ensure that the particulates reach the designed coating quantity while avoiding accumulation; then, the organic polymer films outside the coating films of particulates in movement are cured; inert organic substance is added to form continuous inert liquid membranes outside the organic polymer films before the particulates are likely to accumulateon the adopted coating film curing process conditions; then, the organic polymer films outside the particulates are continuously cured to lose autohension or so that the whole coating films are curedfully; and finally, the particulates coated films are cooled to the room temperature to obtain the coated particulates. The preparation method of the invention has high coating efficiency and good coating integrity and coating process.

Owner:NANJING UNIV OF SCI & TECH

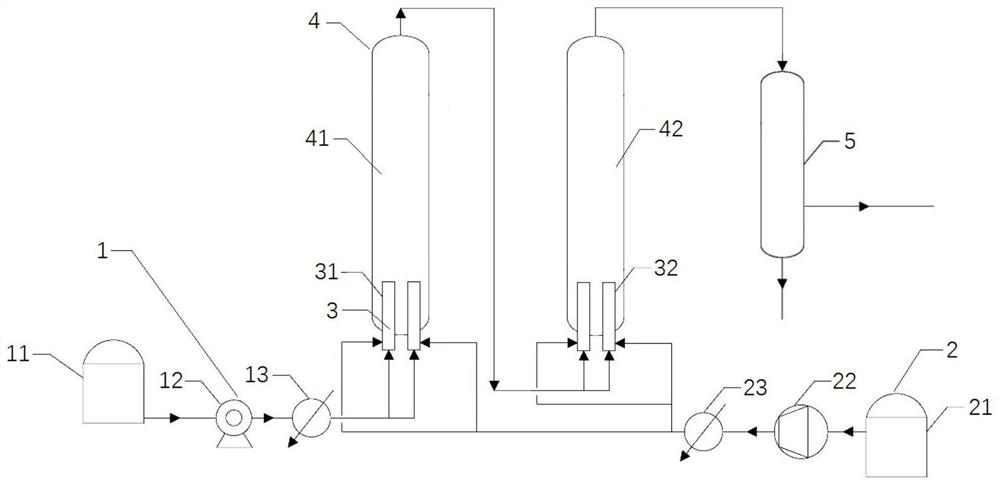

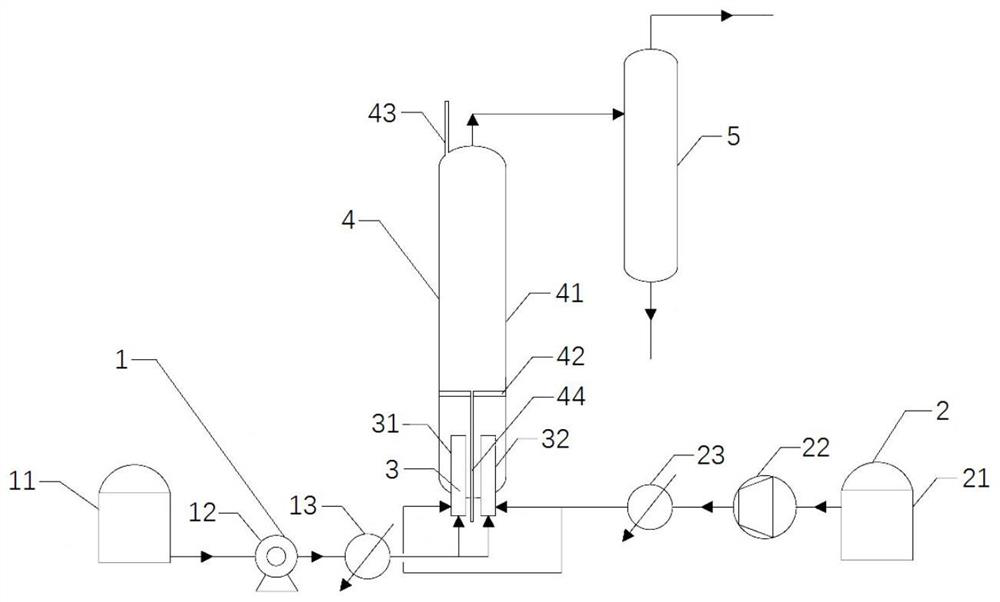

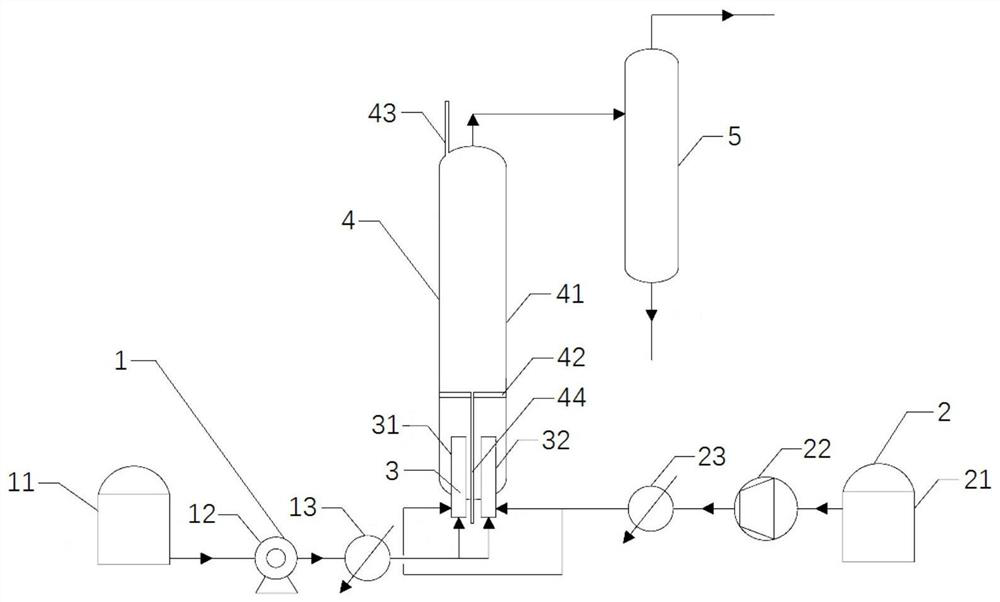

Multi-stage liquefaction system and process for coal and biomass

PendingCN112175649AIncreased phase boundary areaReduce thicknessHydrocarbon distillationLiquid hydrocarbon mixture productionEmulsionFluid phase

The invention relates to a multistage liquefaction system and process for coal and biomass. The multistage liquefaction system comprises a liquid-phase feeding unit, a gas-phase feeding unit, a micro-interface generator, at least two reactors and a separation tank. According to the invention, gas is crushed to form micron-sized bubbles, and the micron-sized bubbles are mixed with biomass keroseneslurry to form a gas-liquid emulsion, so that the phase contact area of a gas phase and a liquid phase is increased, the effect of enhancing mass transfer within a lower preset range is achieved, andthe reaction efficiency of the system is improved while the energy consumption is reduced; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, and the energy consumption of subsequent gas circulating compression is reduced while the gas material consumption is reduced; and the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

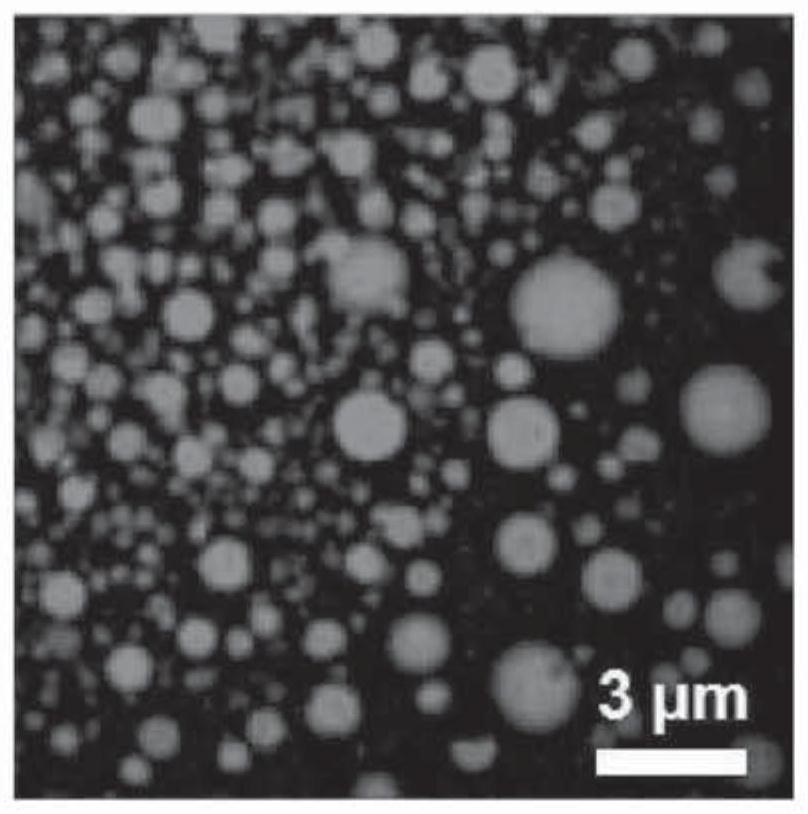

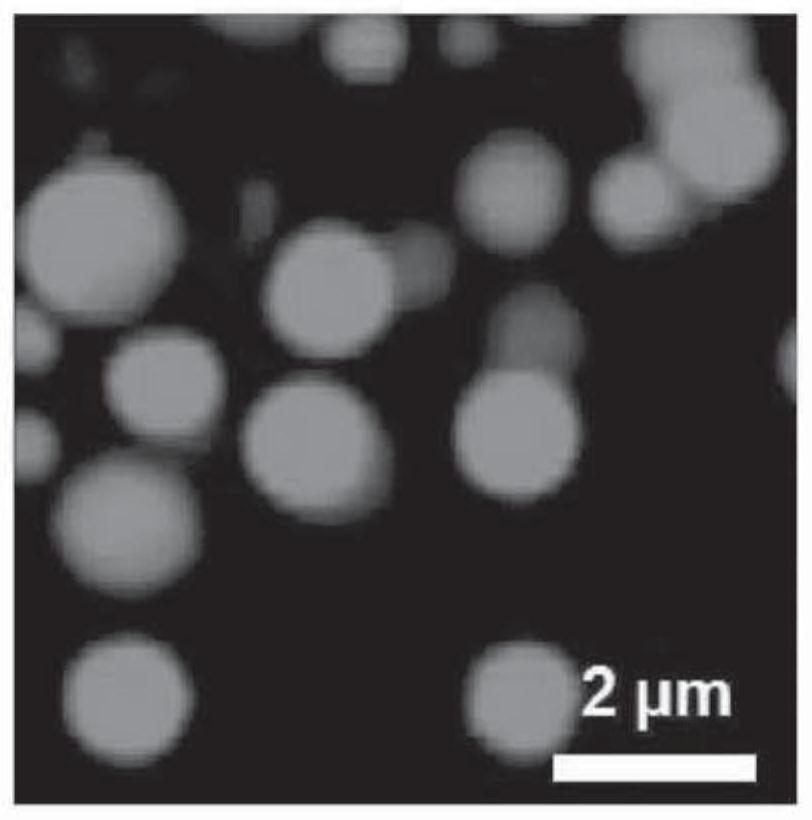

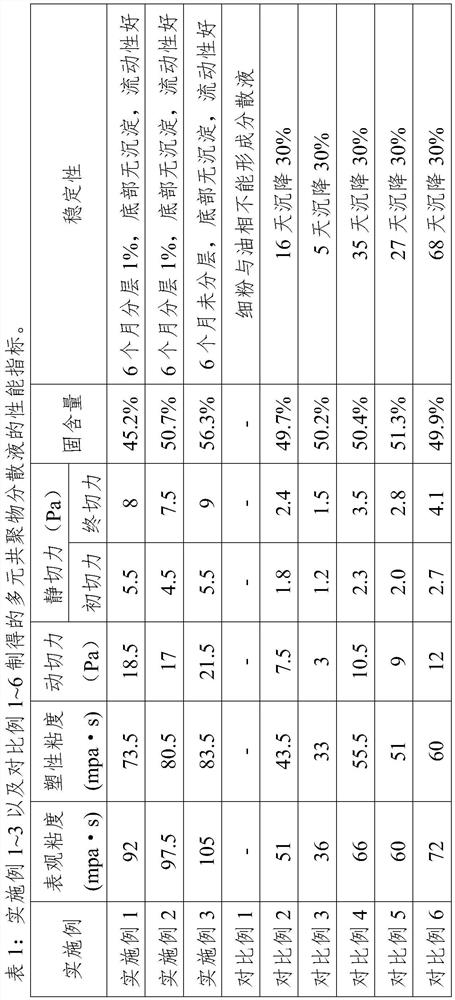

A kind of high-efficiency instant multi-component copolymer dispersion liquid and preparation method thereof

ActiveCN112662383BHigh solid contentReduce apparent viscosityDrilling compositionPolymer scienceApparent viscosity

The invention relates to a high-efficiency instant multi-component copolymer dispersion and a preparation method thereof. The dispersion liquid comprises the following components in weight percent: multi-polymer copolymer fine powder: 45-55%; rheological agent: 1.5-3%; rheological additive: 0.5%-1%; wetting agent : 0.5-1%; stabilizer: 0.5-2%; activator: 0.5-1%; emulsifier: 1.5-4%; white oil: 34-50%; the method is: grinding multi-component copolymer particles , to obtain a multi-component copolymer fine powder; add a wetting agent and a stabilizer to the multi-component copolymer fine powder for surface treatment to obtain a pre-treated fine powder; white oil, pre-treated fine powder, rheological agent, rheological additive, The activator and emulsifier are mixed and then activated to obtain the dispersion. The dispersion liquid of the present invention has high solid content and is more stable, the delamination rate is less than 2% within 6 months, the dispersion liquid has low apparent viscosity, good fluidity, and no precipitation after long-term storage.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Apparatus for preparing cremated body crystalline grain

InactiveCN100577131CNo coalescenceShorten the timeSolid waste managementCremation furnacesHeating furnacePhysics

The present invention relates to an apparatus for preparing cremated body crystalline grain which manufactures the collected bone powder into crystallized bones in the form of small bells. This crystallized bone manufacturing machine includes: a bone powder hopper and a heating furnace which is supported on one side of the housing by a supporting shaft, the supporting shaft is provided with a rotating handle on one end and a heating mechanism is disposed to surround the heating furnace as a heat source. The apparatus further includes: a spindle plate provided on the lower side of a discharge port of the heating furnace; an oscillating container of the spindle plate; a support bracket, one end of which is supported and fixed in a housing to support the spindle plate and the oscillating container; a cooling collector arranged on the right bottom of the oscillating container, and a plurality of blowers to cool and collect the generated crystallized bones passing the spindle plate and the oscillating container.

Owner:裴在烈

Method for preparing high-purity tetracycline hydrochloride

ActiveCN102993043BUniform particle size distributionSimple filterOrganic compound preparationCarboxylic acid amides preparationAlcoholTetracycline Hydrochloride

The invention relates to a method for preparing high-purity tetracycline hydrochloride. Tetracycline urea double salt and hydrochloric acid serve as raw materials, and reaction of the tetracycline urea double salt and hydrochloric acid and crystallization of tetracycline hydrochloride are simultaneously performed. The method comprises the following steps of: mixing the double salt with an organic alcohol mixed solvent according to a ratio, adding hydrochloric acid at the temperature of 5-20 DEG C, continuously stirring and filtering; transferring the filtrate into a crystallizer, raising the temperature, adding a seed crystal when the system temperature reaches 27-32 DEG C, further raising the temperature to 40-50 DEG C, and growing the grain at constant temperature; reducing the temperature of the suspension to 5-20 DEG C; and filtering, washing and drying the obtained crystal mush, thereby obtaining a tetracycline hydrochloride crystal product. The reaction and crystallization processes in the solvent system are screened and optimized, the tetracycline hydrochloride crystal which is uniform in particle size distribution, zero in coalescence and complete in crystalline form and has the purity of more than 98.0 percent is obtained, and the process yield is more than 88.0 percent. The problems that the product is non-uniform in particle size distribution and severe in coalescence so that the purity of the product is reduced are solved, and the product quality is obviously improved.

Owner:TIANJIN UNIV

High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

ActiveCN102443098BHigh molecular weightOvercome the disadvantage that the molecular weight is not easy to increaseCoatings(Hydroxyethyl)methacrylateAcrylic resin

The invention relates to a high molecular weight acrylic resin for a polyvinylidene fluoride coiled material finish paint. The acrylic resin is combined with polyvinylidene fluoride resin as a coiled material finish paint base-material, is a bead-shape transparent particle and has a number-average molecular weight Mn higher than 90 thousand and molecular weight distribution Mw / Mn less than 2.0. The resin of the invention is prepared by a suspension polymerization method from material monomers of 50-80 wt% of methyl methacrylate and / or methyl acrylate, 10-40 wt% of ethyl acrylate and / or methyl methacrylate and 0-40 wt% of one or more selected from acrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, methacrylic acid, hydroxyethyl methacrylate, hydroxypropyl methacrylate, butyl acrylate and butyl methacrylate. The high molecular weight acrylic resin of the invention can be combined with a PVDF resin, and a prepared finish paint film has comprehensive properties the same as an imported one and better performances on MEK-resistant wiping frequency and artificial ageing resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

A kind of zinc sulfate heptahydrate crystal and preparation method

The invention provides a heptahydrate crystal and a preparation method. The preparation method includes the following steps that 1, sulfuric acid is dissolved in reaction liquid, and the reaction liquid is binary solvent and / or crystallization mother liquor of alcohol and water; 2, a zinc source is added, the molar ratio of the zinc source to sulfuric acid is controlled to be 1:1+ / -0.1), and a reaction is conducted for a certain time; 3, sulfuric acid is supplemented, the molar ratio of the supplemented sulfuric acid and the zinc source added in step 2 is controlled to be (0.05-0.25):1, and the reaction is continued for a certain time; 4, after the reaction is ended, a solution is cooled and separated, the separated solid is subjected to postprocessing, and a product of the heptahydrate crystal is obtained. The product of the heptahydrate crystal has obvious prism-shaped crystallization habit, and dewatering endothermic peaks exist at the temperature of 75+ / -1 DGE C, the temperature of 103 + / -1DEG C, the temperature of 124+ / -1 DEG C and the temperature of 276+ / -1 DEG C of a differential scanning calorimetric curve.

Owner:CHINA TIANCHEN ENG +1

Alkane dehydrogenation reaction strengthening system and method

InactiveCN112169722AIncreased phase boundary areaReduce thicknessChemical/physical/physico-chemical microreactorsCatalystsAlkaneFluid phase

The invention relates to an alkane dehydrogenation reaction strengthening system and method. The alkane dehydrogenation reaction strengthening system comprises a liquid-phase feeding unit, a gas-phasefeeding unit, a micro-interface generator, a reactor and a separation tank, wherein the liquid-phase feeding unit is used for storing and conveying C5 or above C5 alkane. According to the invention,gas is crushed to form micron-scale micro-bubbles, and the micro-bubbles are mixed with alkane to form a gas-liquid emulsion, so that the phase contact area of a gas phase and a liquid phase is increased, the effect of enhancing mass transfer within a lower preset operation condition range is achieved, and the energy consumption can be greatly reduced while the reaction efficiency is ensured; andmeanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, and the energy consumption of subsequent gas circulation compression is reduced while the gas material consumption is reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Azoxystrobin acetic acid solvate and preparation method thereof

ActiveCN108947914BHigh crystallinityReduce energy consumptionBiocideOrganic chemistry methodsAcetic acidAzoxystrobin

The invention relates to azoxystrobin acetic acid solvate and a preparation method thereof. Its X-ray powder diffraction pattern is at diffraction angle 2θ=7.40±0.20°, 8.28±0.20°, 13.26±0.20°, 14.07±0.20°, 14.52±0.20°, 18.08±0.20°, 18.42±0.20°, 18.86±0.20 °, 20.46±0.20°, 21.18±0.20°, 22.14±0.20°, 22.68±0.20°, 24.46±0.20°, 26.88±0.20°, 28.60±0.20°, etc. have characteristic peaks, of which 7.40±0.20° is the starting point peak, the relative intensity of the characteristic peak at 21.18±0.20° is 100%. The preparation method is a constant-temperature suspension crystallization method, and the operation is simple, the reproducibility is good, the product has good fluidity, is not easy to coalesce, and is easy to be industrialized.

Owner:TIANJIN UNIV

Azoxystrobin 1,4-dioxane solvate and preparation method thereof

ActiveCN108675963BMild conditionsThe dissolution process is simpleOrganic chemistry methodsAzoxystrobinPhysical chemistry

The invention relates to azoxystrobin 1,4-dioxane solvate and a preparation method. Its X-ray powder diffraction diffraction angle expressed in 2θ angle is 8.40±0.20°, 12.96±0.20°, 14.32±0.20°, 15.20±0.20°, 16.06±0.20°, 17.80±0.20°, 18.62±0.20°, 20.16 There are characteristic peaks at ±0.20°, 21.18±0.20°, 21.56±0.20°, 22.44±0.20°, 23.76±0.20°, 24.22±0.20°, 25.72±0.20°, 26.32±0.20°, starting from 8.40±0.20° The initial peak, the relative intensity of the characteristic peak at 23.76±0.20° is 100%. The preparation method is simple, the product has high crystallinity, large particle size, good fluidity and is suitable for industrial production.

Owner:TIANJIN UNIV

Enhanced reaction system and method for alkane oxidation

InactiveCN112169721AReduce material consumptionIncreased phase boundary areaChemical/physical/physico-chemical microreactorsCatalystsAlkaneMass transfer resistance

The invention relates to an enhanced reaction system and method for alkane oxidation. The enhanced reaction system comprises a liquid-phase feeding unit used for storing and conveying liquid alkane ofC4 or above, a gas-phase feeding unit, a micro-interface generator, a reactor and a separation tank. Gas is crushed to form micron-sized bubbles, the micron-sized bubbles and alkane are mixed to forma gas-liquid emulsion, the phase contact area of a gas phase and a liquid phase is increased, meanwhile, the thickness of a liquid film is reduced, the mass transfer resistance is reduced, the effectof enhancing mass transfer within a low preset operation condition range is achieved, and the energy consumption can be greatly reduced while the reaction efficiency is guaranteed; and meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, and the energy consumption of subsequent gas circulation compression is reduced while the gas material consumptionis reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com