Equipment and method for producing uniform particle ion exchange resin beads

An ion exchange resin and production equipment technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve problems such as harsh requirements of the material system, and achieve the effect of avoiding particle breakage, maintaining particle size uniformity and particle size uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

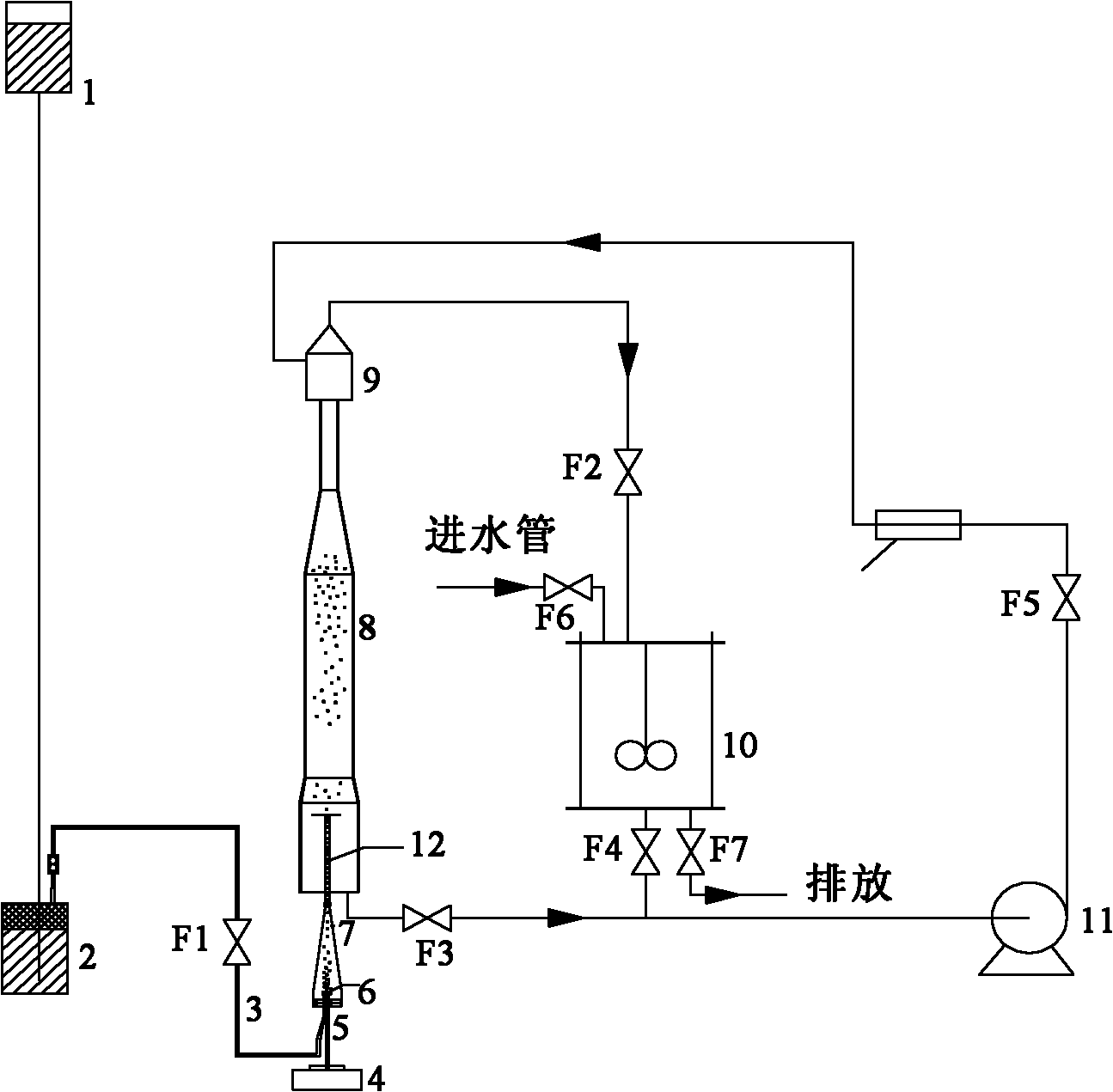

Method used

Image

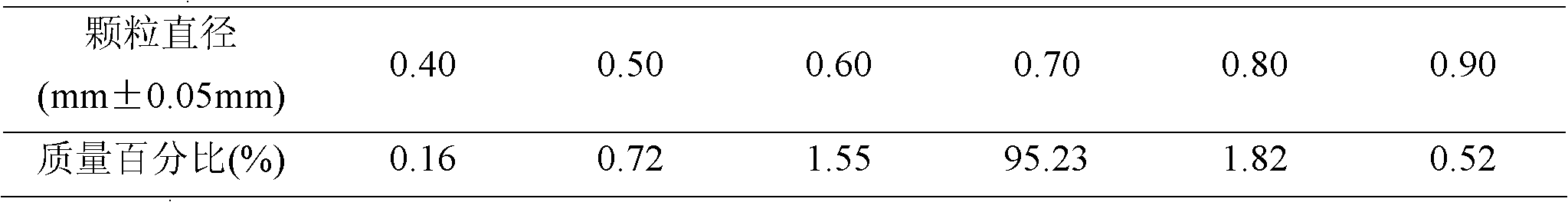

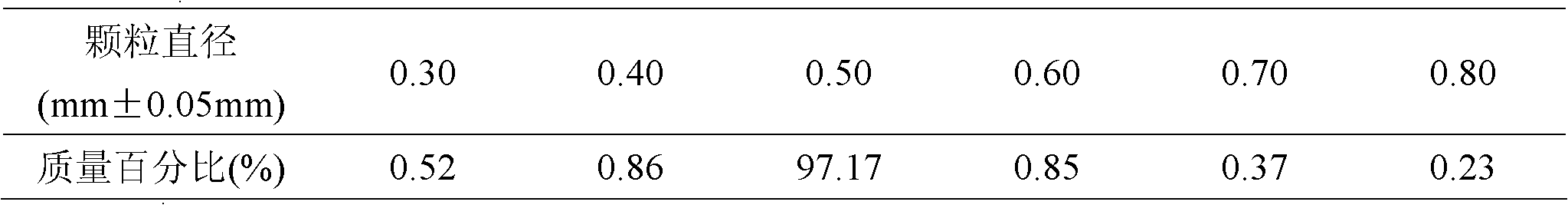

Examples

Embodiment 1

[0046] Dosing ratio (mass composition): water phase: oil phase (monomer phase) = 5: 1; where:

[0047] 1. Aqueous phase deionized water: polyvinyl alcohol (dispersant): methylene blue = 100: 0.5: 0.05

[0048] 2. Oil phase (monomer phase) styrene (polymerized monomer): divinylbenzene (crosslinking agent): paraffin (porogen): benzoyl peroxide (initiator) = 100:15:70:1

[0049] Equipment conditions: vibration frequency: 200Hz; nozzle aperture: 0.2mm; number of nozzles: 10; nozzles are located on a concentric circle with the center of the nozzle panel as the center, arranged equidistantly; the height of the fluidized polymerization reactor is 1.5m, and the inner diameter of the upper end is 40mm. The diameter of the lower end is 80mm, the flow rate of the water phase is 70L / h; the flow rate of the oil phase monomer: 20mL / min;

[0050] Ingredients: prepare styrene and divinylbenzene monomer phases according to the proportion, add porogen liquid paraffin and initiator benzoyl pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com