Patents

Literature

70results about How to "No broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of whole highland barley grain cereals and complex cereals

InactiveCN104187401ANo brokenOutstanding roasted aromaFood preparationBiotechnologyQinghai tibet plateau

The invention provides a preparation method of whole highland barley grain cereals and complex cereals. According to the preparation method, selected highland barley in Qinghai-Tibet plateau is taken as a raw material, and the whole highland barley grain cereals are prepared by the steps of removing impurities in the raw material, peeling, screening, washing, soaking, curing, tabletting, drying and the like, wherein the curing is performed by stir-frying at the temperature of 200-300 DEG C for 3-10min or by cooking at the temperature of 80-150 DEG C and under the high pressure of 20-50KPa for 2-8min. The preparation method provided by the invention has the advantages of simple processing steps and easiness in operation, and the situation that the taste of a product becomes poor after aging of highland barley starch is overcome. Complete highland barley grains are adopted, are not broken in the processing process and contain an appropriate amount of bran, so that nutritional ingredients in the highland barley can be retained to the greatest extent; the whole highland barley grain cereals are convenient to eat in a dry state, be brewed or cooked for eating and are suitable for all ages.

Owner:QINGHAI HUASHI TECH INVESTMENT MANAGEMENT CO LTD

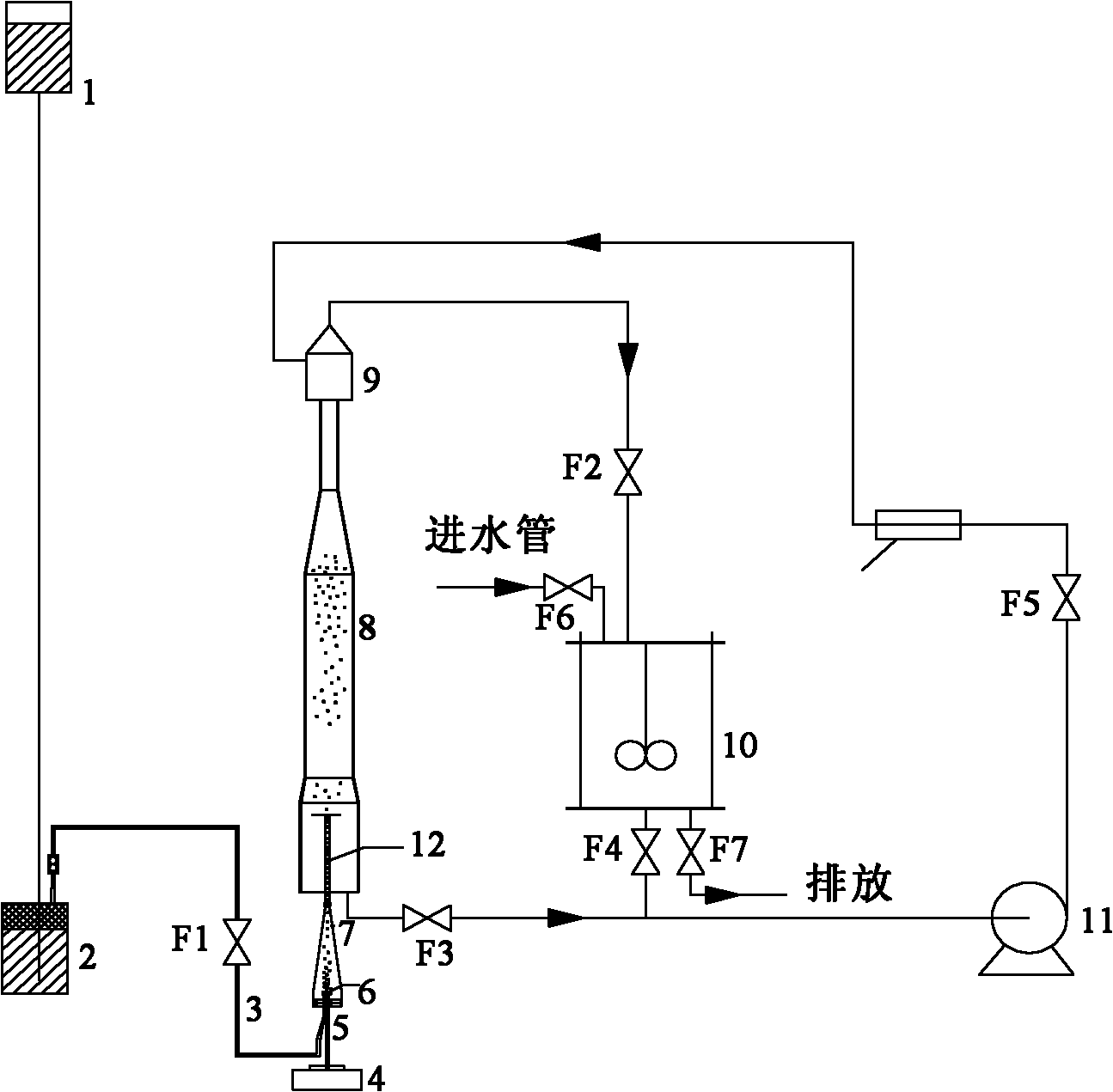

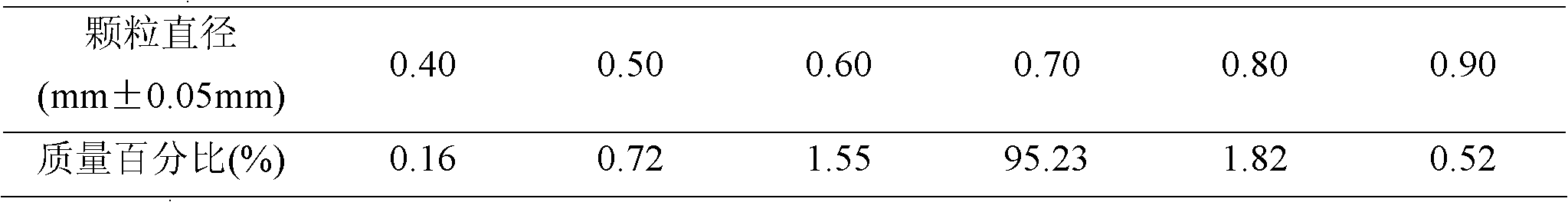

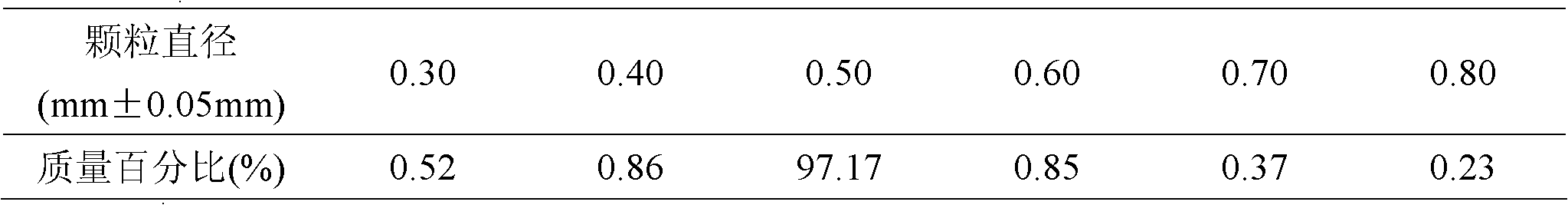

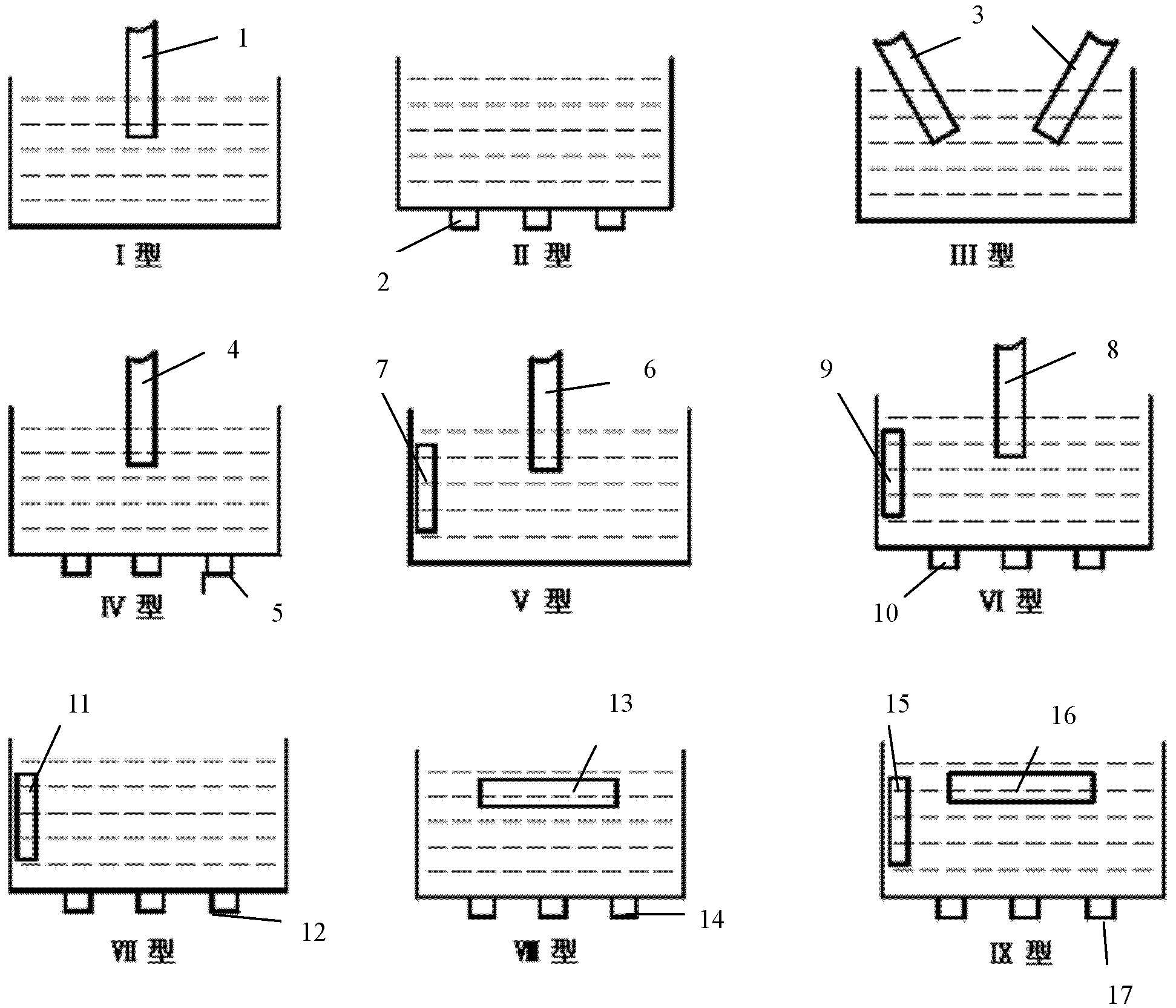

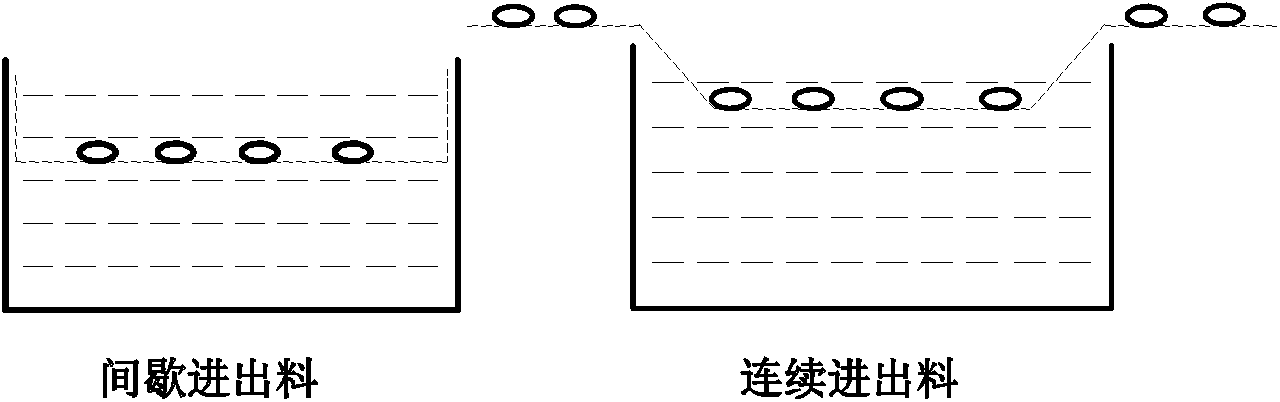

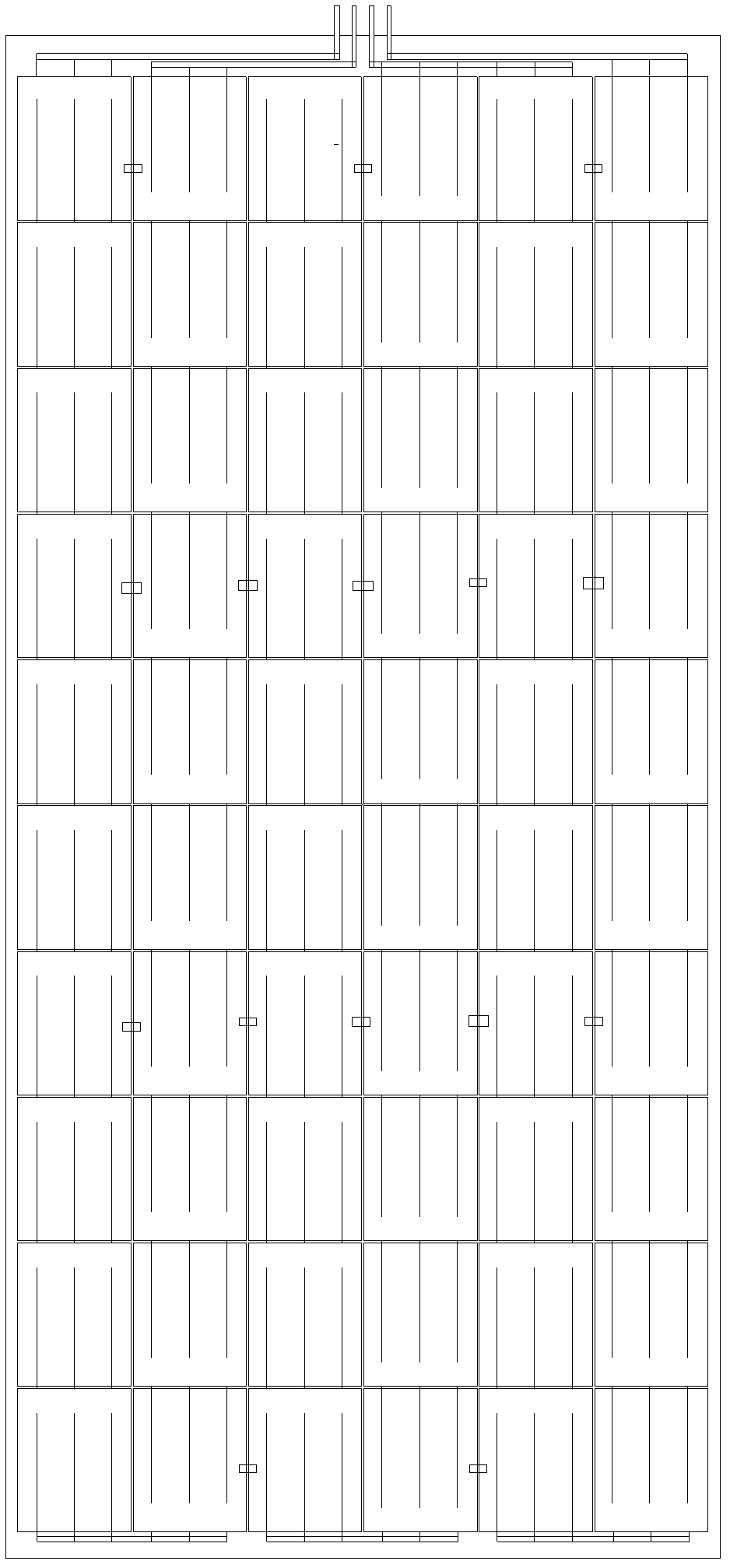

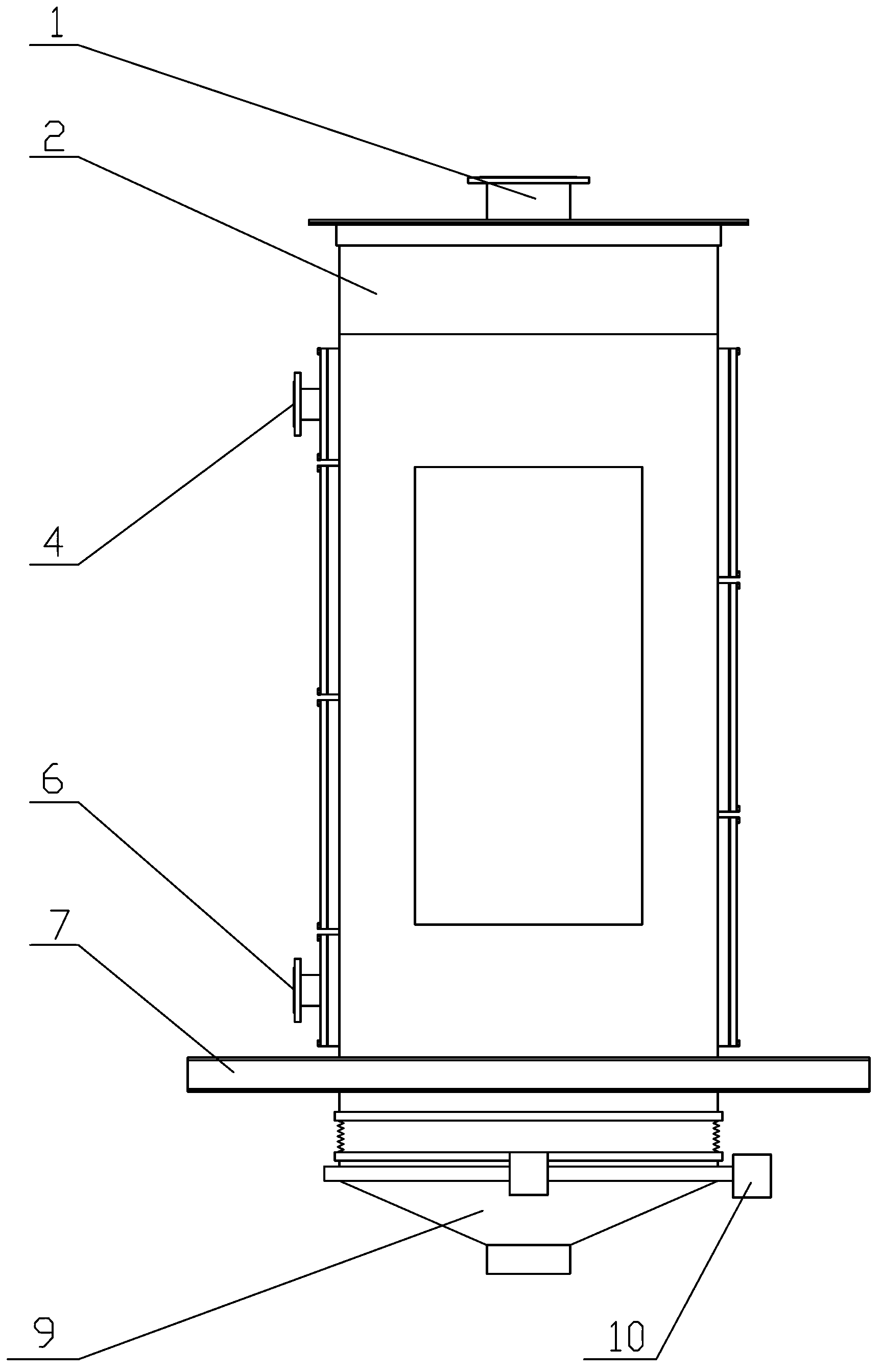

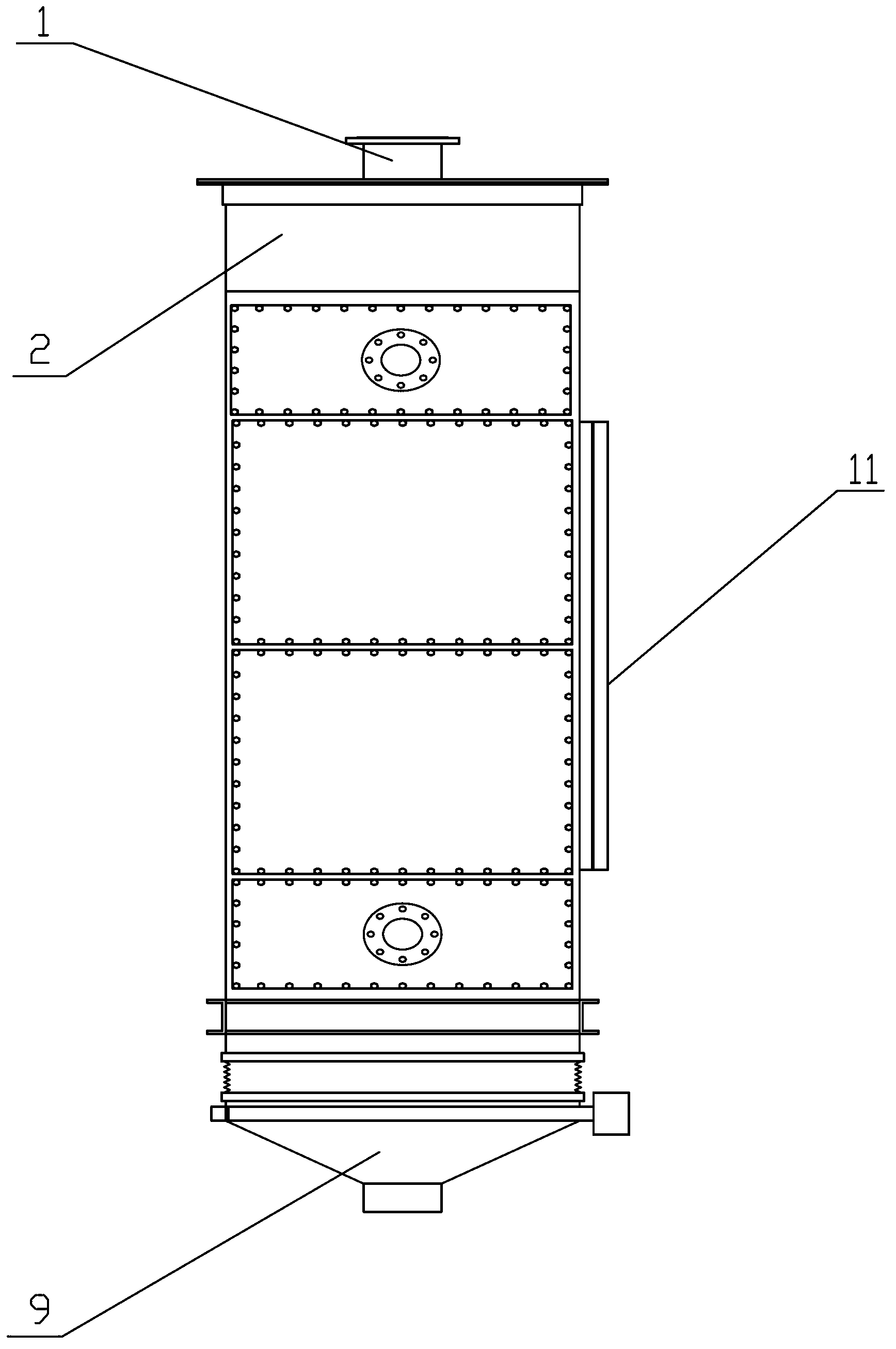

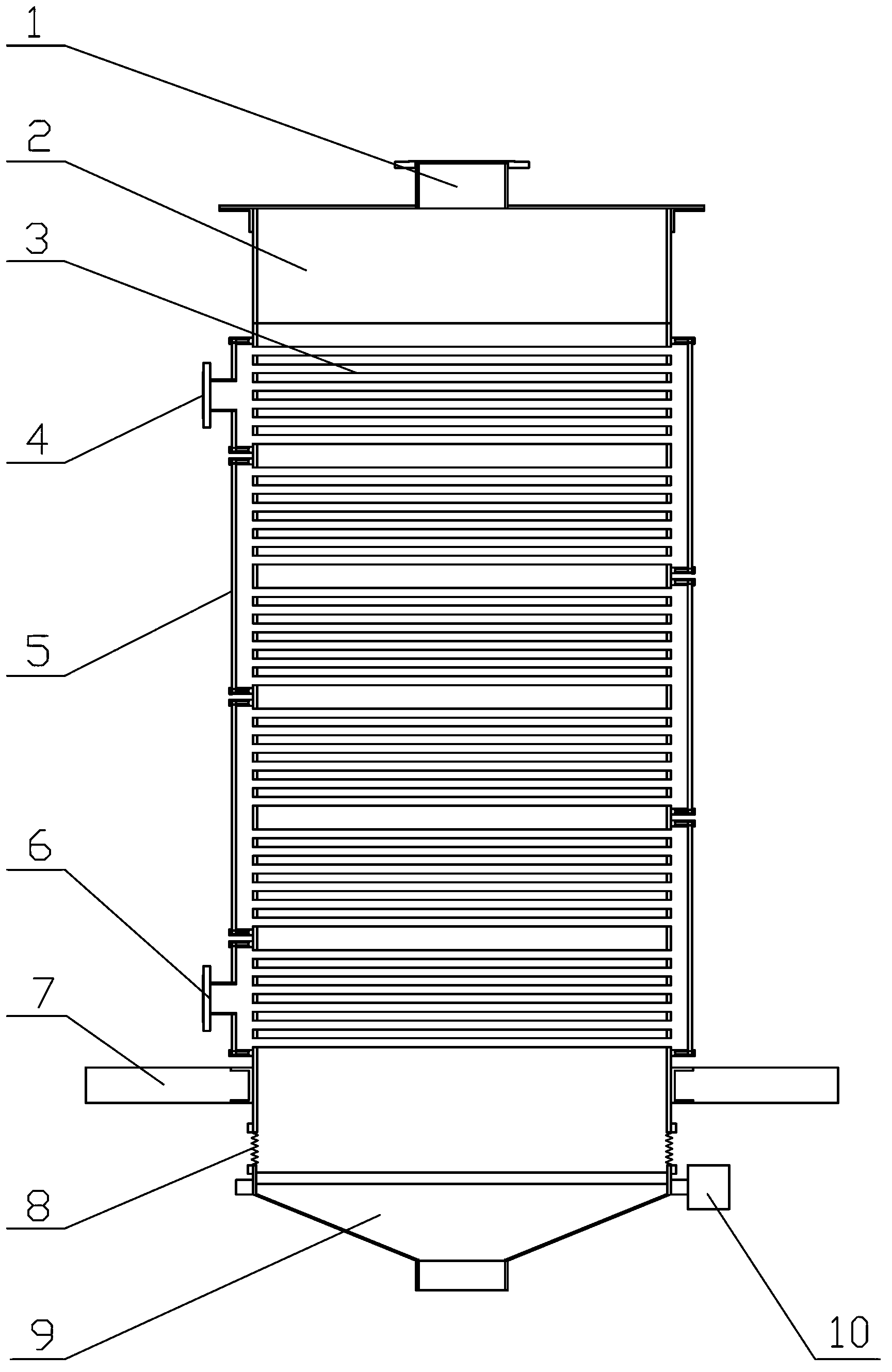

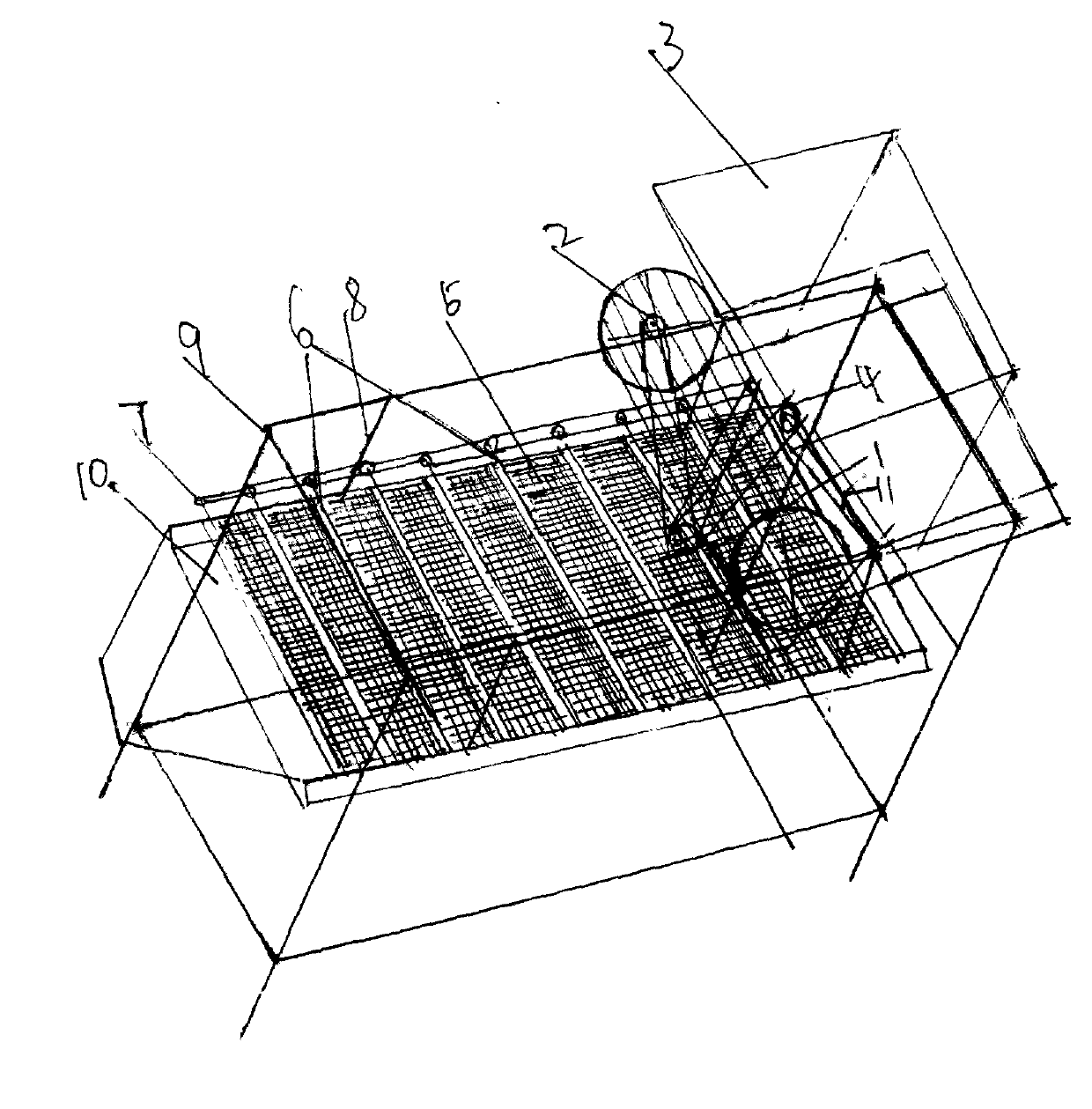

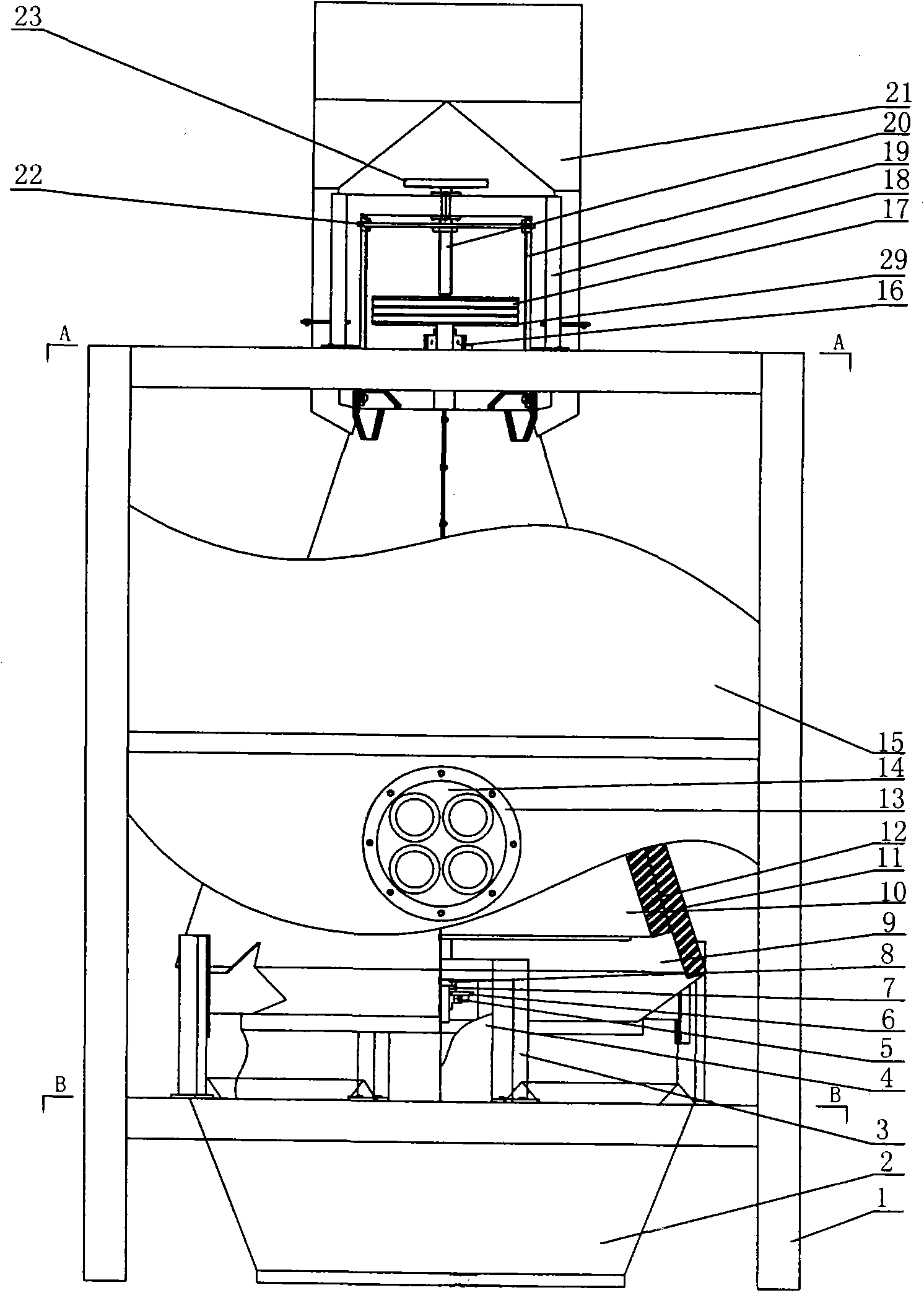

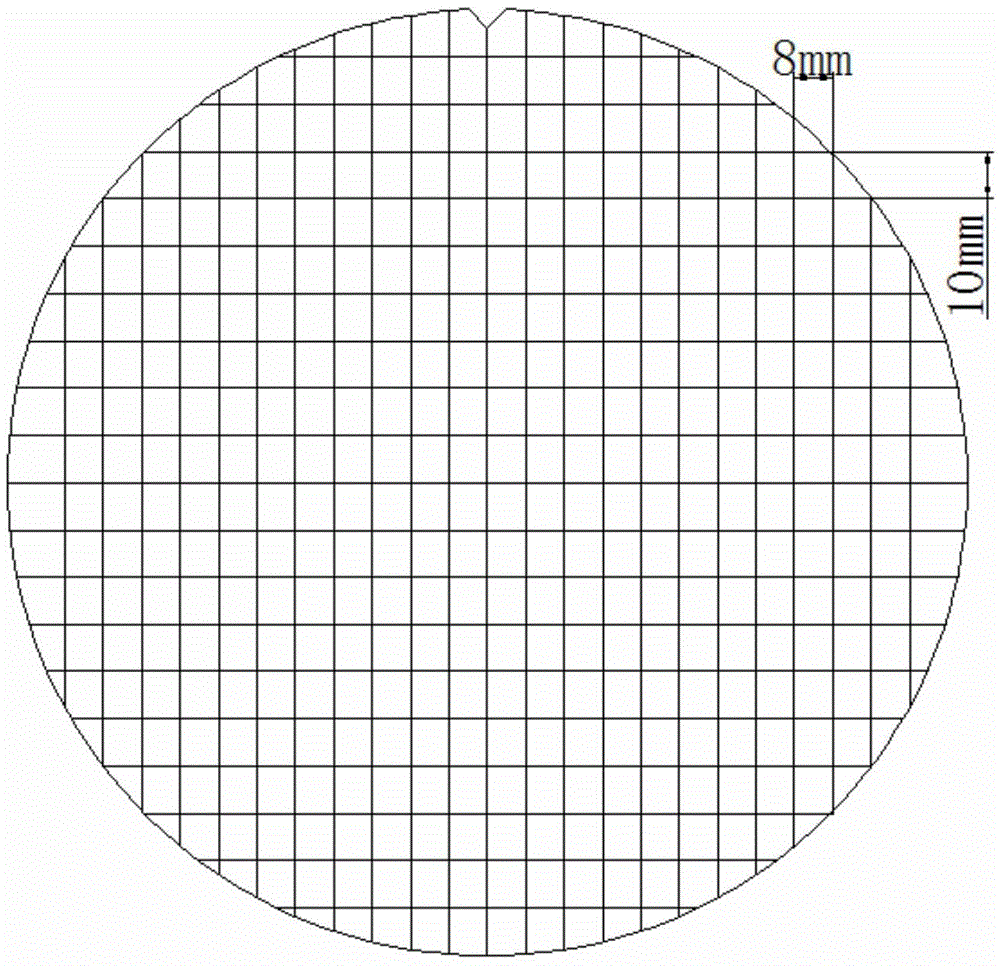

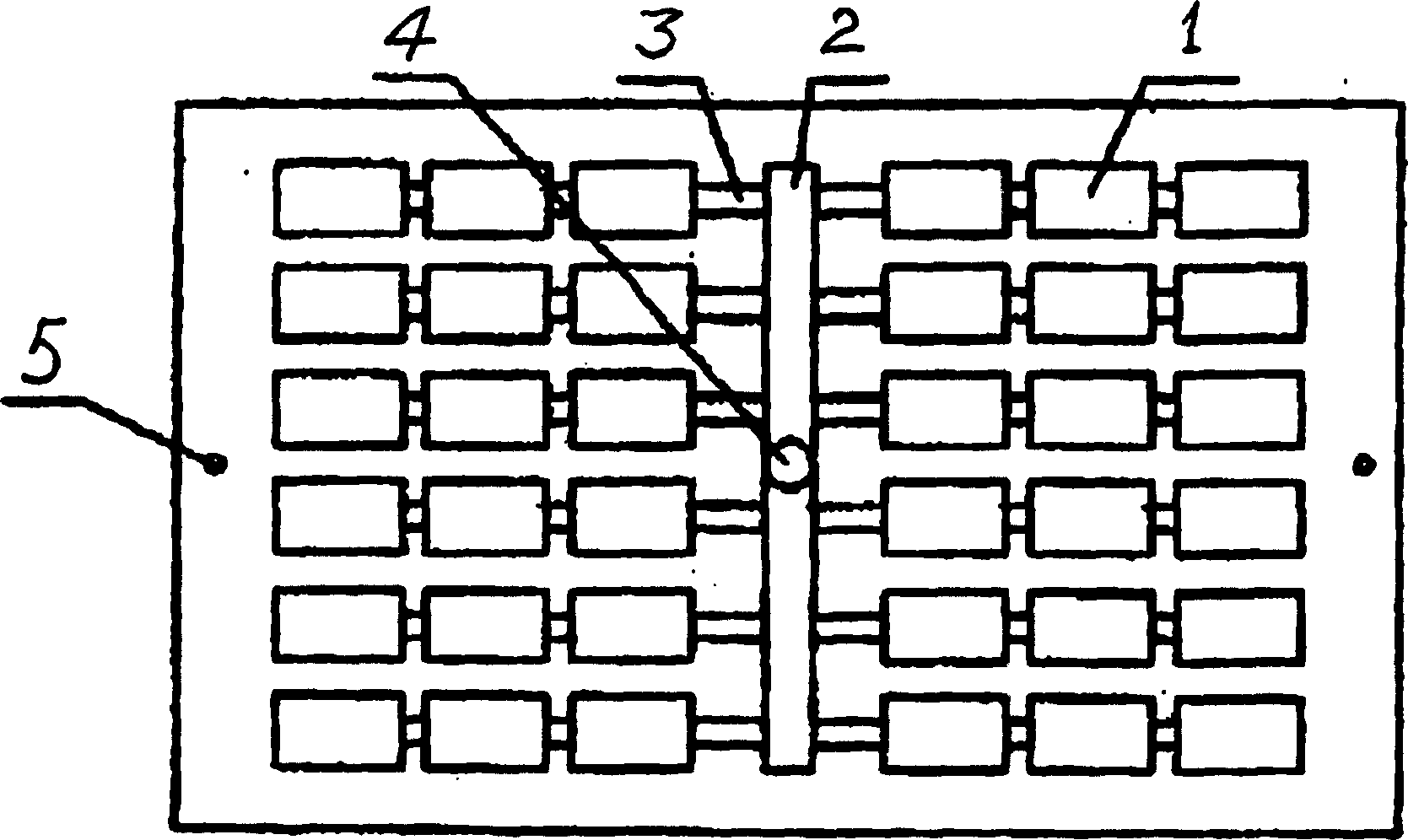

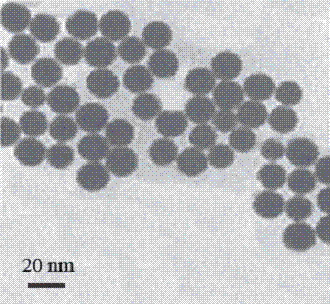

Equipment and method for producing uniform particle ion exchange resin beads

ActiveCN102086240AUniform particle sizeMaintain Particle Size UniformityMicroballoon preparationMicrocapsule preparationWastewaterOil phase

The invention discloses equipment and a method for producing uniform particle ion exchange resin beads. The equipment comprises a head tank 1, an oil phase storage tank 2, a vibration generator system 4, a nozzle 6, a fluidized polymerization reactor 8, an aqueous phase liquid distributer 9, a maturation tank 10 and an aqueous phase circulating pump 11; and the ion exchange resin beads produced by the equipment have uniform particle size. When the method is used for producing the ion exchange resin bead products, the production capacity of the equipment can be adjusted by changing the number of orifices of the nozzle and the mass fraction of the target particle size of + / -0.05mm is more than 95 percent without sieving; and in the method, the aqueous phase can be recycled, so that the wastewater discharge is reduced; therefore, sewage discharge in the reaction process is greatly reduced.

Owner:TIANJIN UNIV

Preparation method of silicon chip metallographic specimen

InactiveCN102607916ANo warpingNo brokenPreparing sample for investigationOrganic solventAcrylic resin

The invention discloses a preparation method of a silicon chip metallographic specimen. The preparation method comprises the following steps: (1) proportioning and mixing acrylic resin powder and a liquid curing agent uniformly according to instructions, adding an organic solvent with the weight of 5-25% of the total weight of the acrylic resin powder and the liquid curing agent, and mixing uniformly to prepare a cold inserted agent; (2) placing a silicon chip on the bottom of a silicon gel cold inserted mold, pouring the cold inserted agent prepared in the step (1), and curing; and (3) carrying out polishing and corrosion treatment on the cured metallographic specimen, wherein the organic solvent is ethanol, glycol or isopropanol. The preparation method of the silicon chip metallographic specimen disclosed by the invention has the advantages that the metallographic specimen of the ultra-thin and fragile silicon chip can be prepared, structure morphologies such as dislocation with clear materials are obtained, the phenomena of wrapping, crashing and the like of the ultra-thin silicon chip in specimen insertion and polishing processes are avoided, the problem that the micro scratch of the ultra-thin silicon chip is difficult to remove is solved, and the metallographic specimen of the ultra-thin silicon chip is prepared successfully.

Owner:SUZHOU XIEXIN INDAL APPL INST

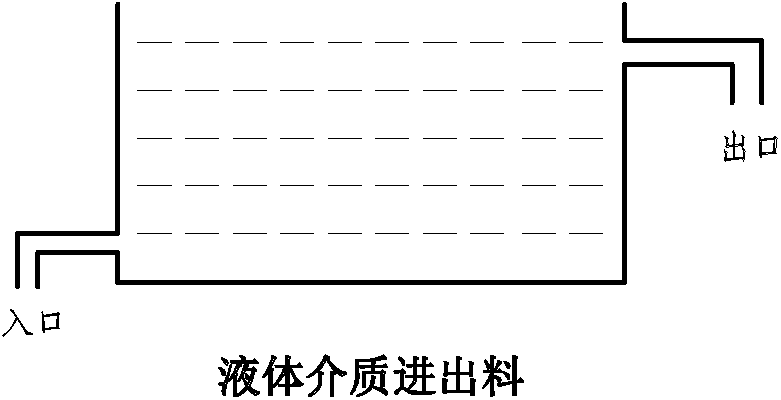

Ultrasonic defluorination method for whole euphausia superba

InactiveCN103583931ATo achieve the purpose of defluorinationNo brokenFood ultrasonic treatmentFood preparationNutritive valuesLiquid medium

The invention discloses an ultrasonic defluorination method for whole euphausia superba. After being pretreated, the euphausia superba is soaked in a liquid medium in a working container for ultrasonic defluorination, wherein the euphausia superba is fresh whole euphausia superba, refrigerated whole euphausia superba or dried euphausia superba; the pretreatment is shell softening treatment or unfreezing; the combination type of an ultrasonic treatment device is a single-unit ultrasonic device, a two-unit ultrasonic device or a three-unit ultrasonic device; the liquid medium is a first component, a second component or a third component, the first component is water distilled for three times, deionized water, tap water or seawater, the second component is ethanol, acetone, diethyl ether or No.6 extraction solvent oil, and the third component is an acid solution, alkali solution or salt solution. The technology achieves the purpose of defluorination of the euphausia superba; the defluorinated euphausia superba is kept whole and prevented from breaking, and the sensory quality and the nutritive value are not influenced.

Owner:SHANDONG NORMAL UNIV

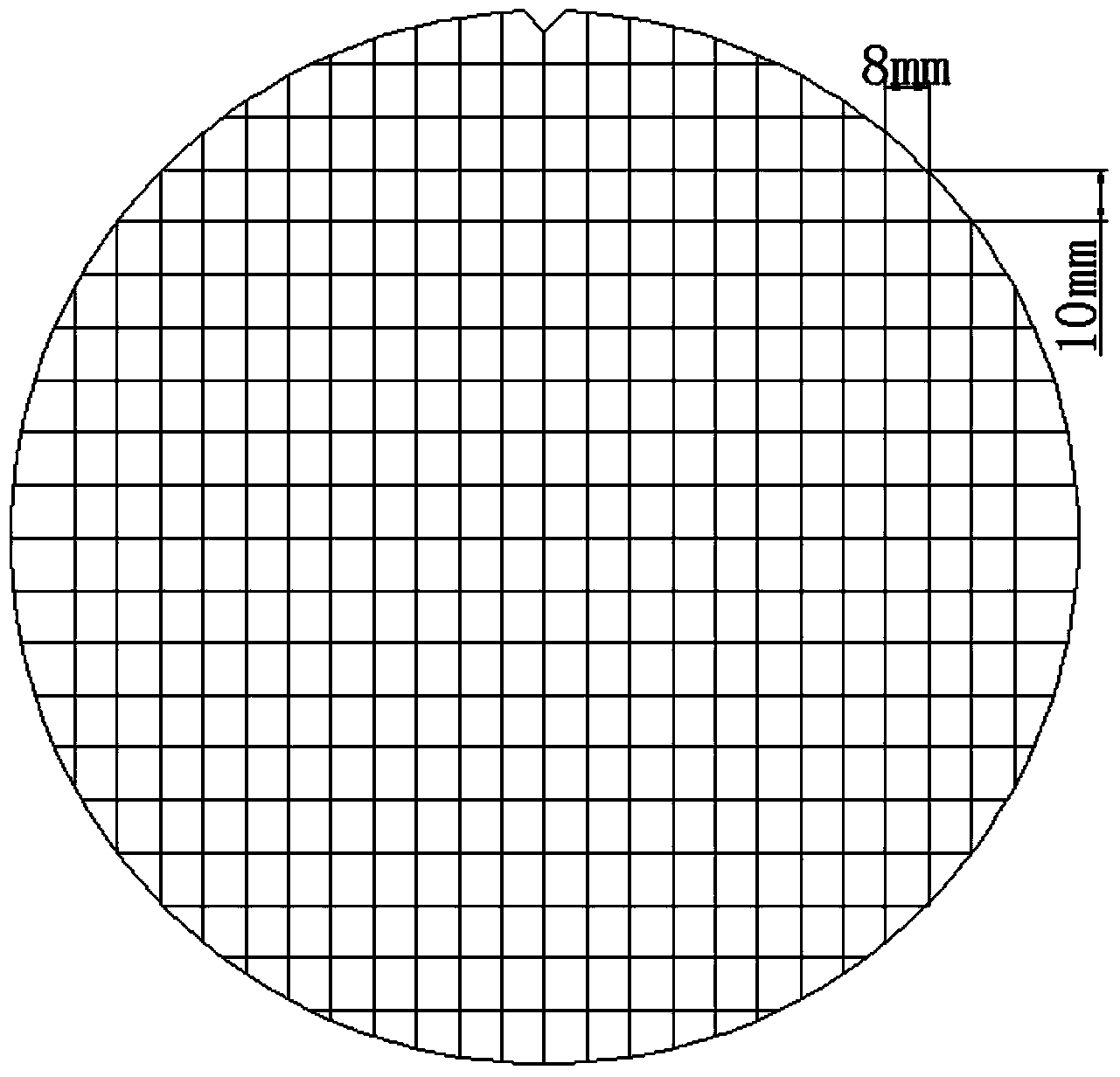

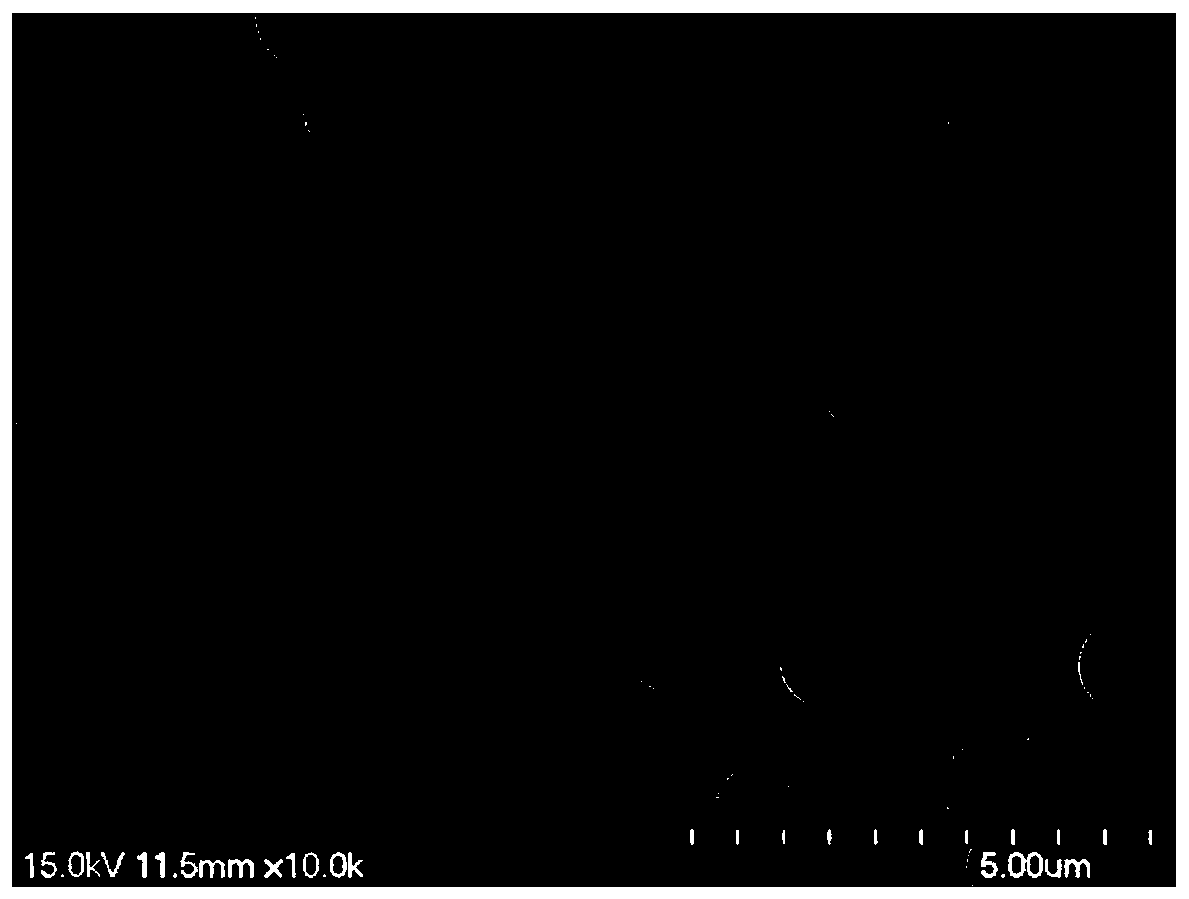

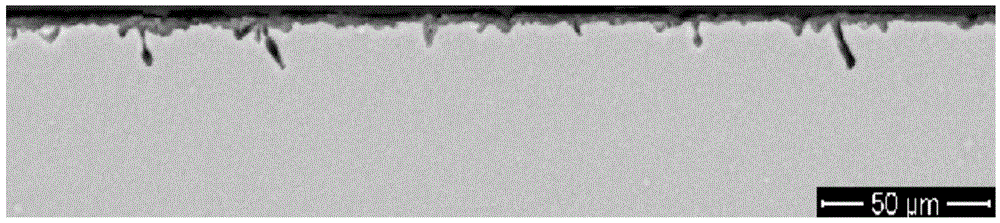

Preparation method of sample for detecting sub-surface damage depth of ultra-thin silicon wafer

ActiveCN104034568ADamage Depth ResolutionEasy to preparePreparing sample for investigationSiliconMetal

The invention discloses a preparation method of a sample for detecting the sub-surface damage depth of an ultra-thin silicon wafer. The preparation method comprises the steps of (1) cutting the whole piece of wafer into a plurality of samples; (2) taking down the sample at any position, and sticking the sample onto a metal plate; (3) grinding, polishing and corroding the stuck sample. The preparation method has the advantages that the sample which is ultra-thin (with the thickness of less than or equal to 300mu m) and can be used for detecting a sub-surface damage layer of the fragile silicon wafer can be prepared by the method; the sample preparation method is simple, the clear sub-surface microcrack can be obtained, and the problem that the sub-surface damage depth of the ultra-thin silicon wafer is hard to obtain can be solved.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

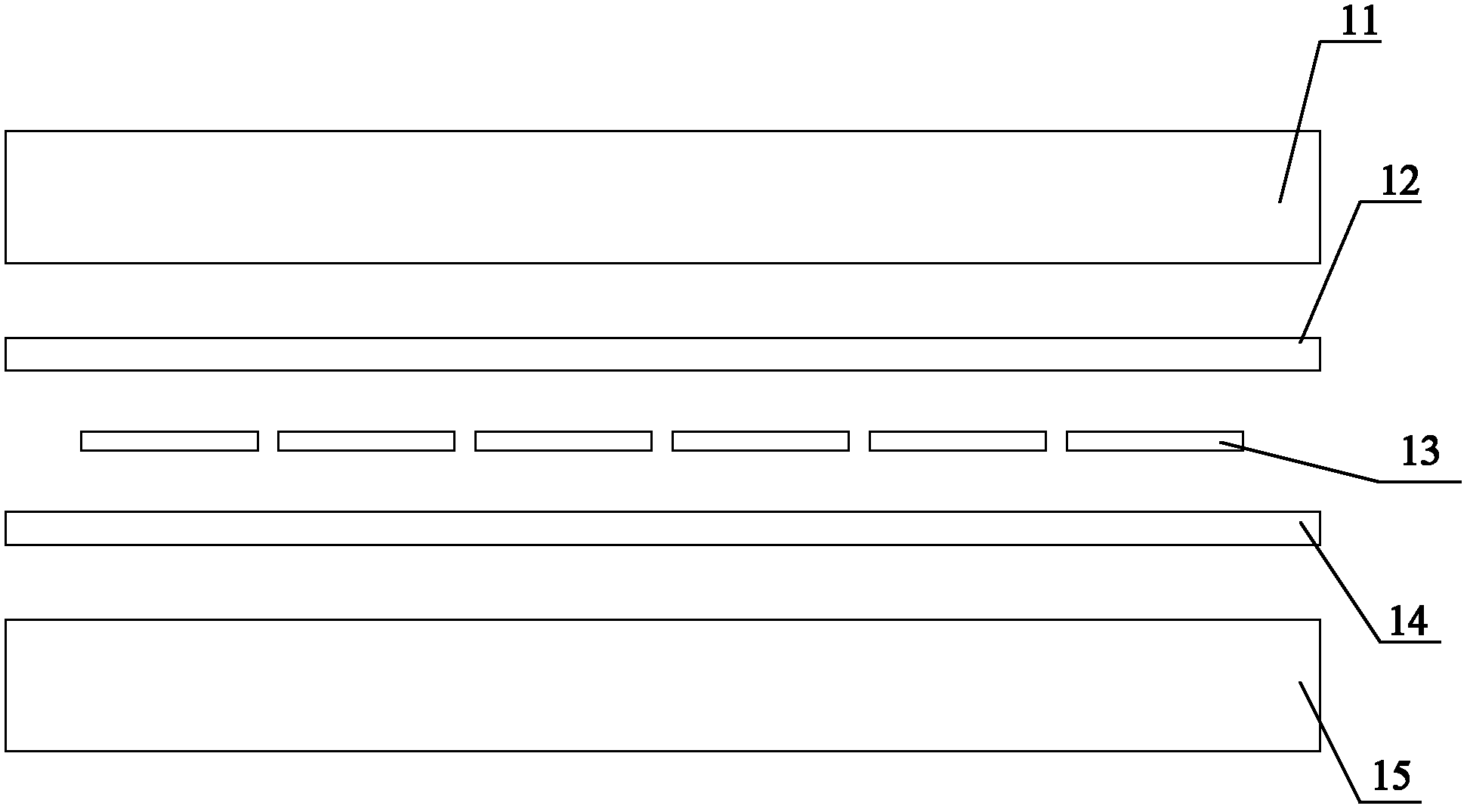

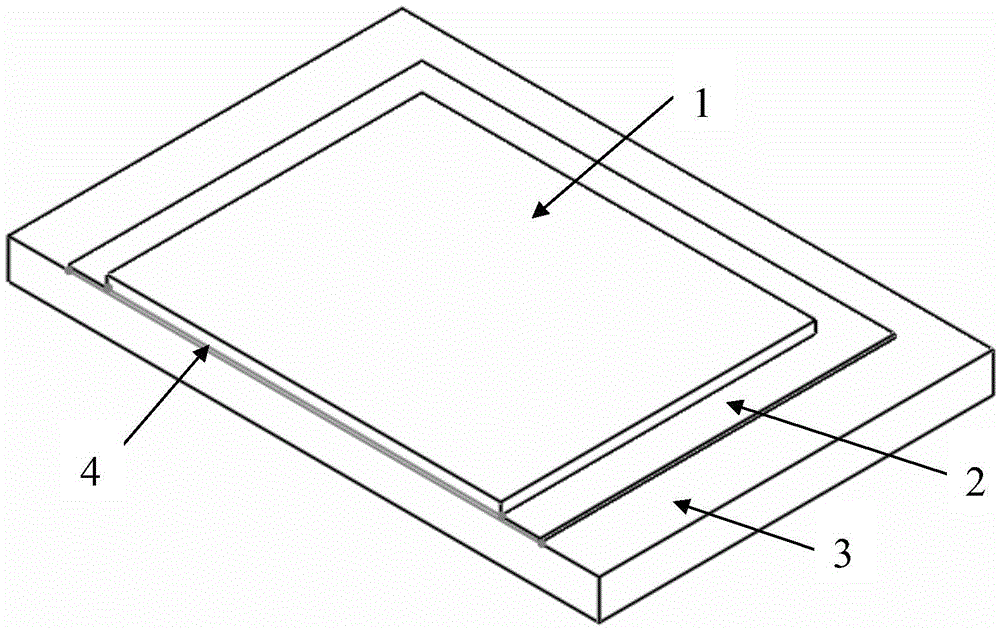

Photovoltaic module and manufacturing method thereof

InactiveCN102214716AEasy to bendAchieve bendingPhotovoltaic energy generationSemiconductor devicesShock resistanceEngineering

The invention provides a photovoltaic module and a manufacturing method thereof. The photovoltaic module comprises a substrate and a sealing part which is sealed at one side edge of the substrate, wherein the substrate comprises an armoured glass faceplate, a surface adhesive film, a cell slice, a back adhesive film and an armoured glass back plate, wherein the thicknesses of the armoured glass faceplate and the armoured glass back plate are both 2mm; and the sealing part comprises butyl rubbers, silica gels or tapes. The photovoltaic module has preferable shock resistance and flexibility, is in no need of being coated with aluminum frames and can be bent at normal temperature.

Owner:HAINAN YINGLI NEW ENERGY

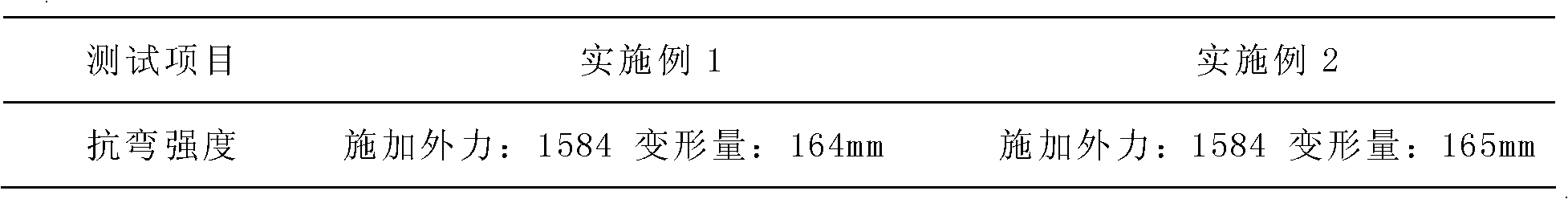

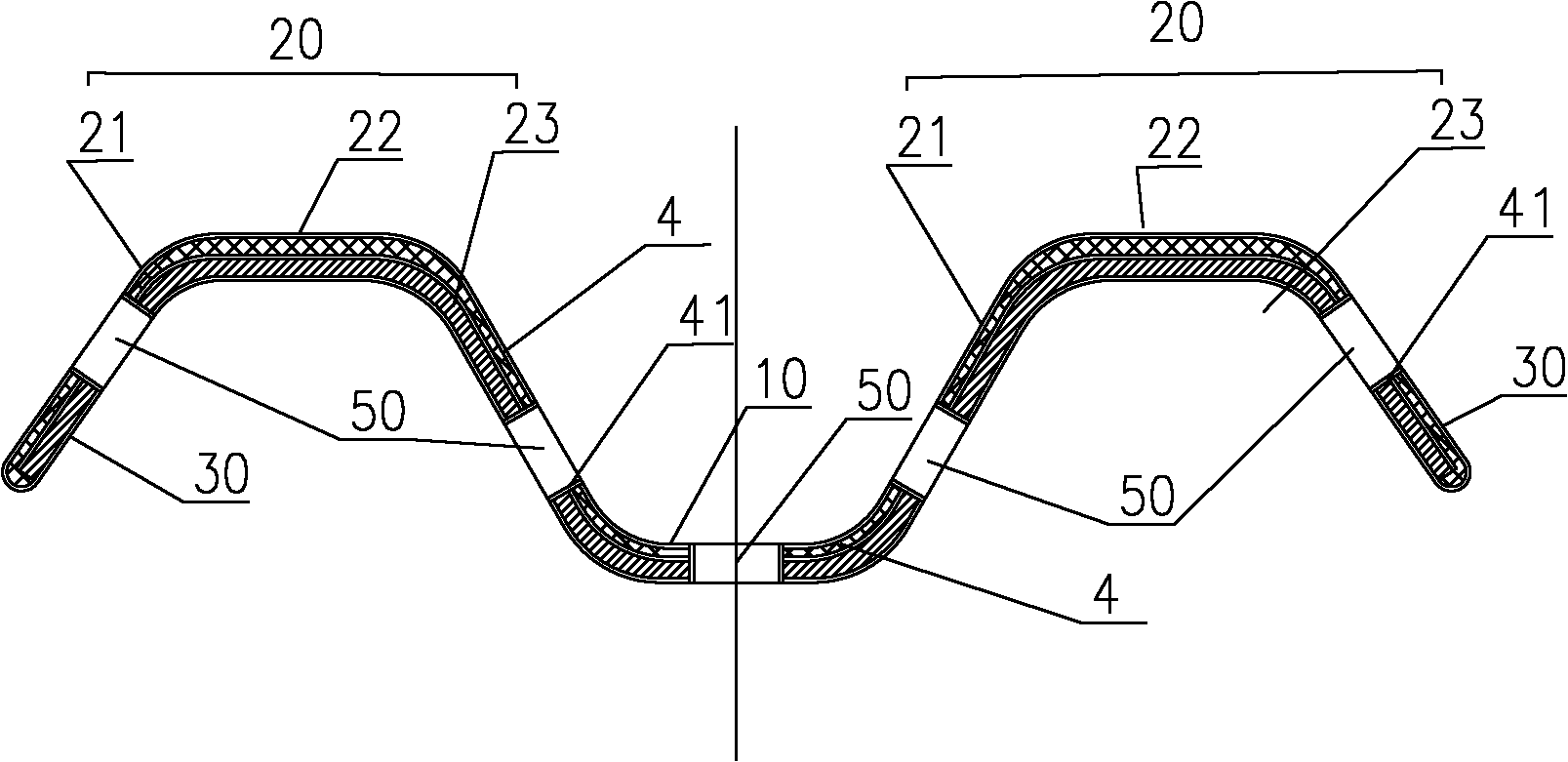

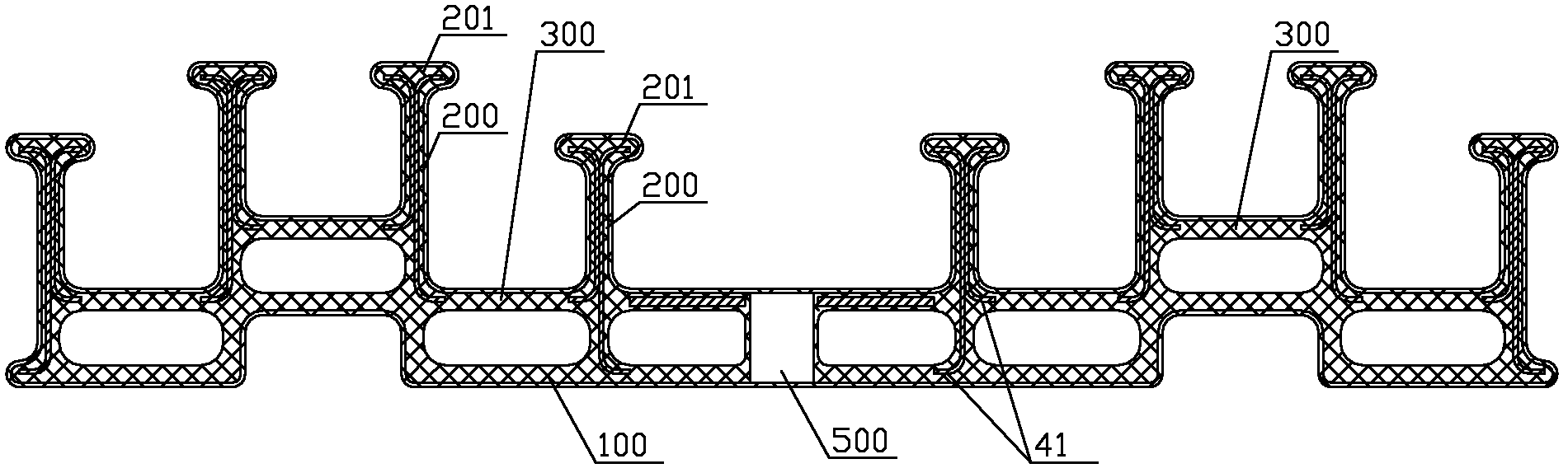

Corrugated guardrail plate

InactiveCN102535334AImprove impact resistanceImprove buffering effectFencingBridge structural detailsManufacturing technologyHigh probability

The invention discloses a corrugated guardrail plate comprising a baseplate fixedly connected with an obstruction block or a standing column, wherein corrugated plates respectively extend out of two sides of the baseplate; the baseplate is integrated with the corrugated plates; the corrugated plates protrude to the same side of the plate face of the baseplate and exceed the plate face of the baseplate; a smooth transition is adopted between the baseplate and each corrugated plate; both the baseplate and the corrugated plates extend in the length direction of the guardrail plate and are thermoplastic composite plates; and each thermoplastic composite plate comprises a reinforcing frame wrapped in a thermoplastic material layer. Aiming to overcome the defects of high probability of corrosion, high rigidity and poor collision energy absorption of a steel guardrail plate, small elastic modulus, large size and high cost of an all-plastic guardrail plate, and complex manufacturing technology and worse collision energy absorption of a plastic-steel guardrail plate, the invention provides the corrugated guardrail plate, which has the advantages of corrosion resistance and appropriately matched rigidity and flexibility and can reduce harm to a vehicle and personnel to the greatest extent.

Owner:HUNAN JINHONG TECH CO LTD

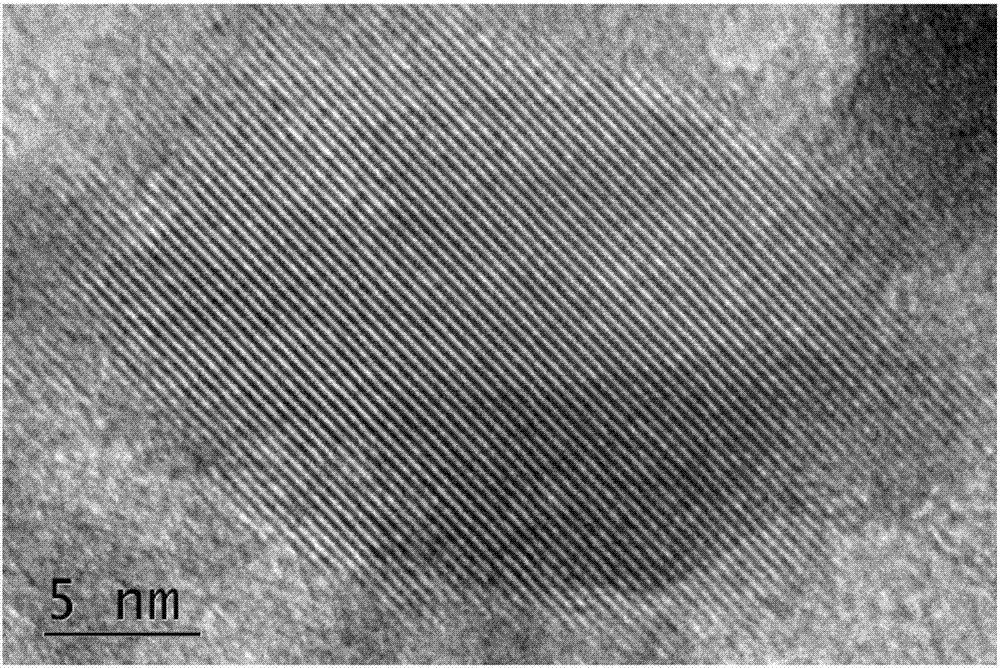

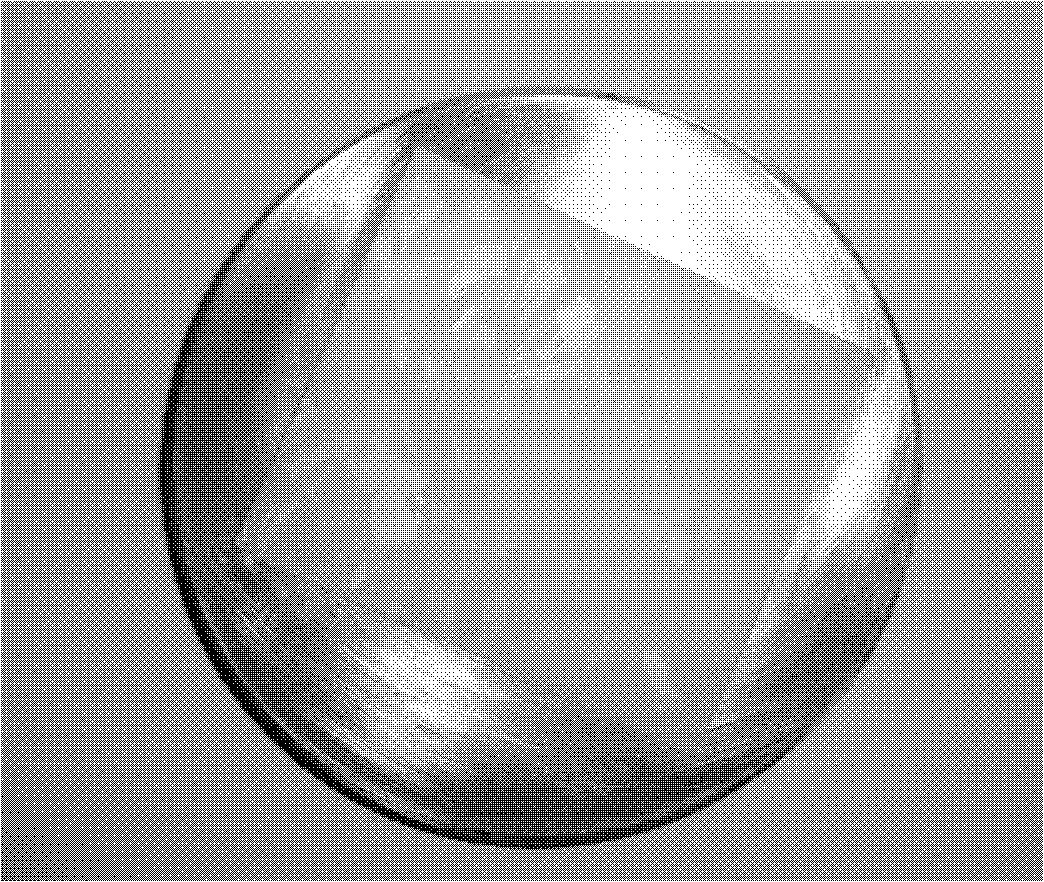

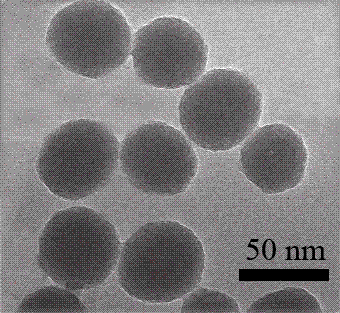

Millimeter level mesoporous ozone oxidation catalyst and preparation and application method thereof

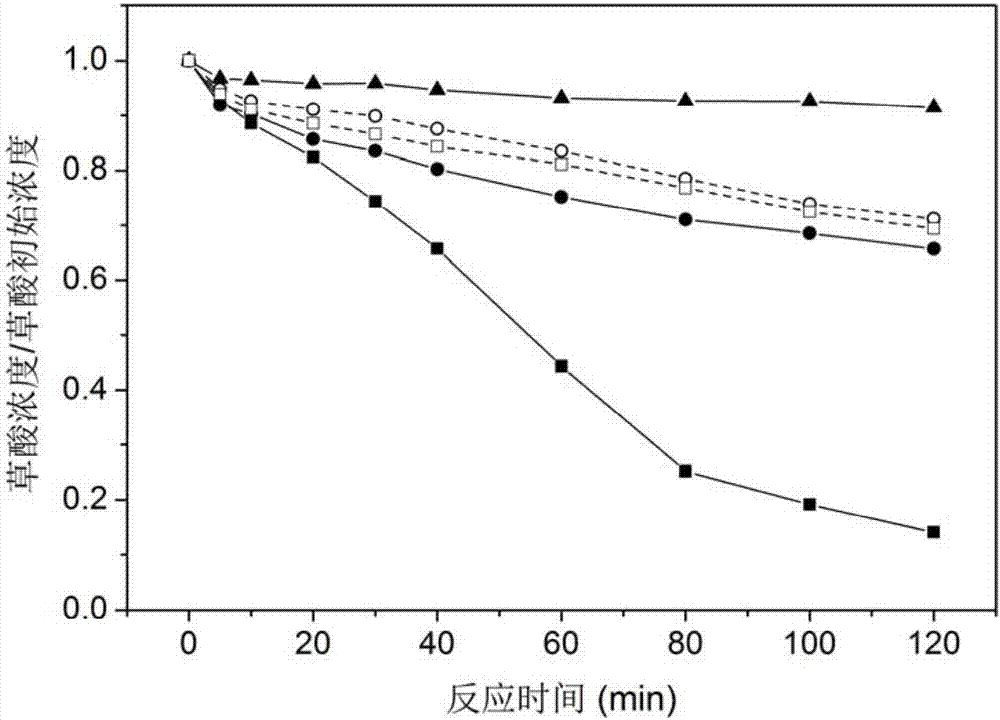

ActiveCN106944027AHigh catalytic activityGood long-lasting activitySpecific water treatment objectivesWater contaminantsMicrosphereTitanium zirconium

The invention discloses a millimeter level mesoporous ozone oxidation catalyst and preparation and an application method thereof, belongs to the technical field of water processing, and aims to solve the problems that the hydrodynamic performance of a conventional ozone oxidation catalyst is bad, the catalytic efficiency is low, and the stability is insufficient. The millimeter level mesoporous ozone oxidation catalyst comprises cerium, titanium, zirconium, and oxygen, is a millimeter level mesoporous spherical particle, has a unique crystal structure, at the same time, has the advantages of durable and stable catalytic activity, excellent hydrodynamic characteristics and pore structure, high compression strength, acid / alkali resistance, ligand stability, oxidation resistance, and thermal stability, and can prominently improve the mineralization degree of ozone oxidation. The valence composition of active components is not changed after repeated use. The preparation method comprises the following steps: preparing millimeter level mesoporous titanium-zirconium composite microspheres by a calcium alginate template method, and then combining cerium and the titanium-zirconium compound by an impregnation method. The provided catalyst can be applied to fixed bed reactor / fluidized bed reactor wastewater treatment, and can be thermally regenerated when pollutants are accumulated on the catalyst.

Owner:NANJING UNIV

Preparation method of toughened silicon dioxide aerogel, toughened silicon dioxide aerogel and application of toughened silicon dioxide aerogel

The invention relates to the technical field of aerogel, in particular to a preparation method of toughened silicon dioxide aerogel, the toughened silicon dioxide aerogel and application of the toughened silicon dioxide aerogel. The preparation method comprises the following steps: uniformly mixing a silicon source, an organic solvent and water, preparing wet gel through a sol-gel step, aging, replacing the solvent, modifying with a surface modifier, crosslinking and drying to obtain toughened silicon dioxide aerogel; wherein the surface modifier is selected from one or more of 3-methacryloyloxy propyl dimethyl chlorosilane, acryloyloxy propyl dimethyl chlorosilane, 3-methacryloyloxy propyl dimethyl methoxy silane and acryloyloxy propyl dimethyl methoxy silane. The silicon dioxide aerogelhas good toughness, the wet gel can be dried under normal pressure without damage, the device investment is saved, the production efficiency is improved, the production cost is reduced, and the silicon dioxide aerogel can be applied to the fields of thermal insulation materials, thermal insulation materials, waste gas treatment materials, wastewater treatment materials, catalysts and the like.

Owner:上海中南建筑材料有限公司

High-fiber additive-free pure-corn noodle and environment-friendly production method thereof

ActiveCN103549282AImprove sensory qualityImprove bindingMulti-step food processesFood ingredient functionsFiberExtensibility

The invention relates to high-fiber additive-free pure-corn noodle and an environment-friendly production method thereof, belonging to a food processing technology. The preparation method of the high-fiber additive-pure pure-corn noodle comprises the steps of after impurities are removed through screening ripen corn kernels, melting and expanding through high-pressure steam, crushing, improving textures, carrying out fine-crushing, blending, forming and the like to produce the high-fiber additive-free pure-corn noodle. The high-fiber additive-free pure-corn noodle produced by adopting the invention has the advantages of being good in binding force, proper in extensibility and flexibility, good in boiling fastness, and pure in corn flavor, improving the digestibility of the corn foods, and developing the main food function and the nutrition health care function of the corn. The production method is mild in conditions in a production process, does not adopt any chemical and biological synthesis technologies, is free of pollution, waste residue, waste steam and harmful substances, and realizes the environment-friendly production; no non-corn grain raw materials and products are added, thus the pure flavor of the corn is ensured; no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, no chemical reagents are used, thus the eating safety is ensured.

Owner:吉林省正源食品有限责任公司

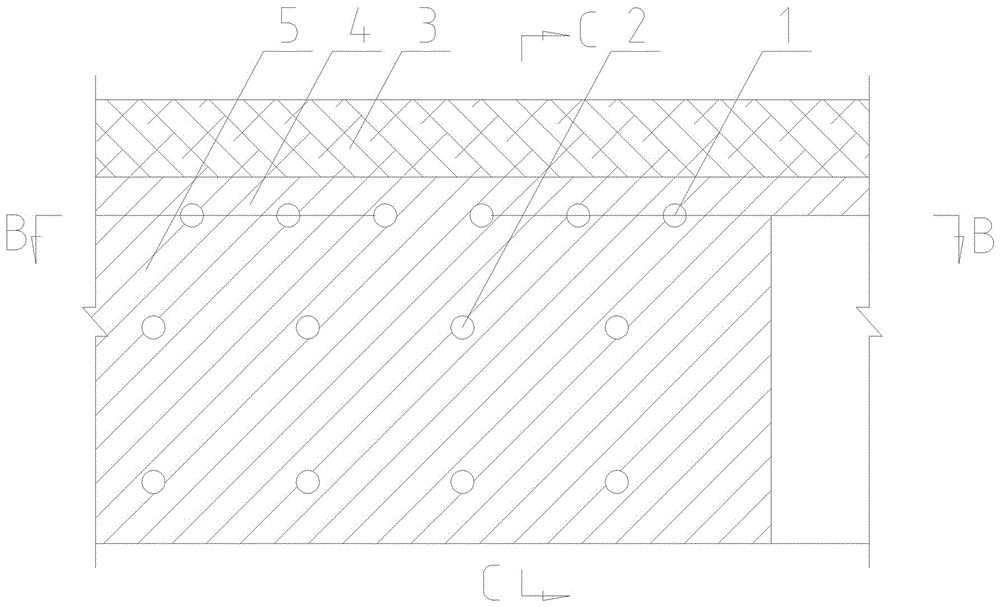

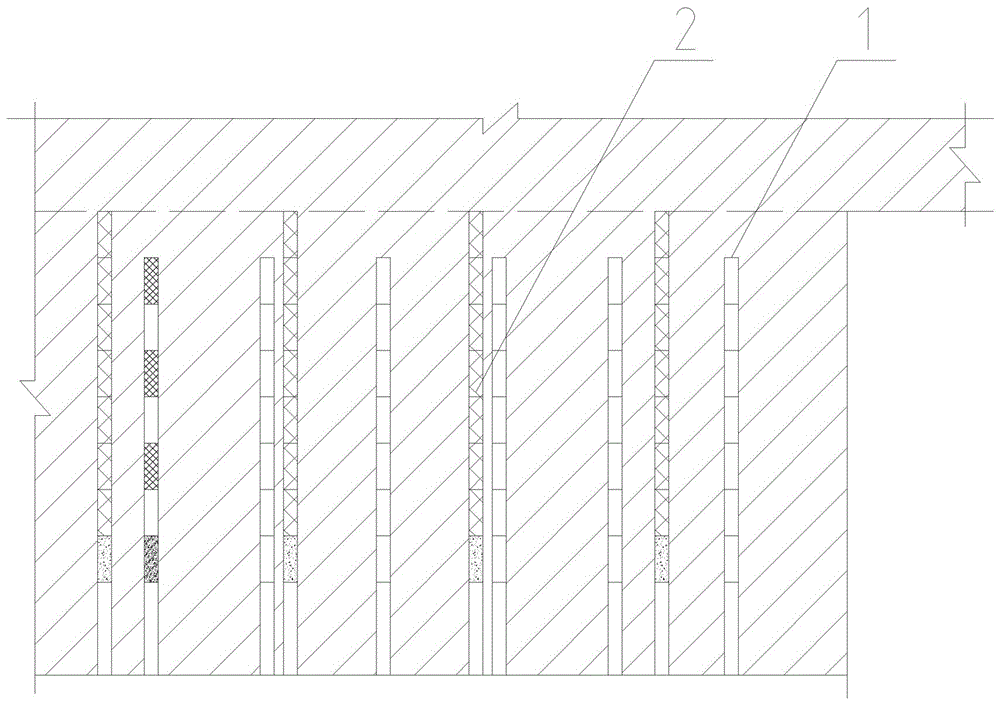

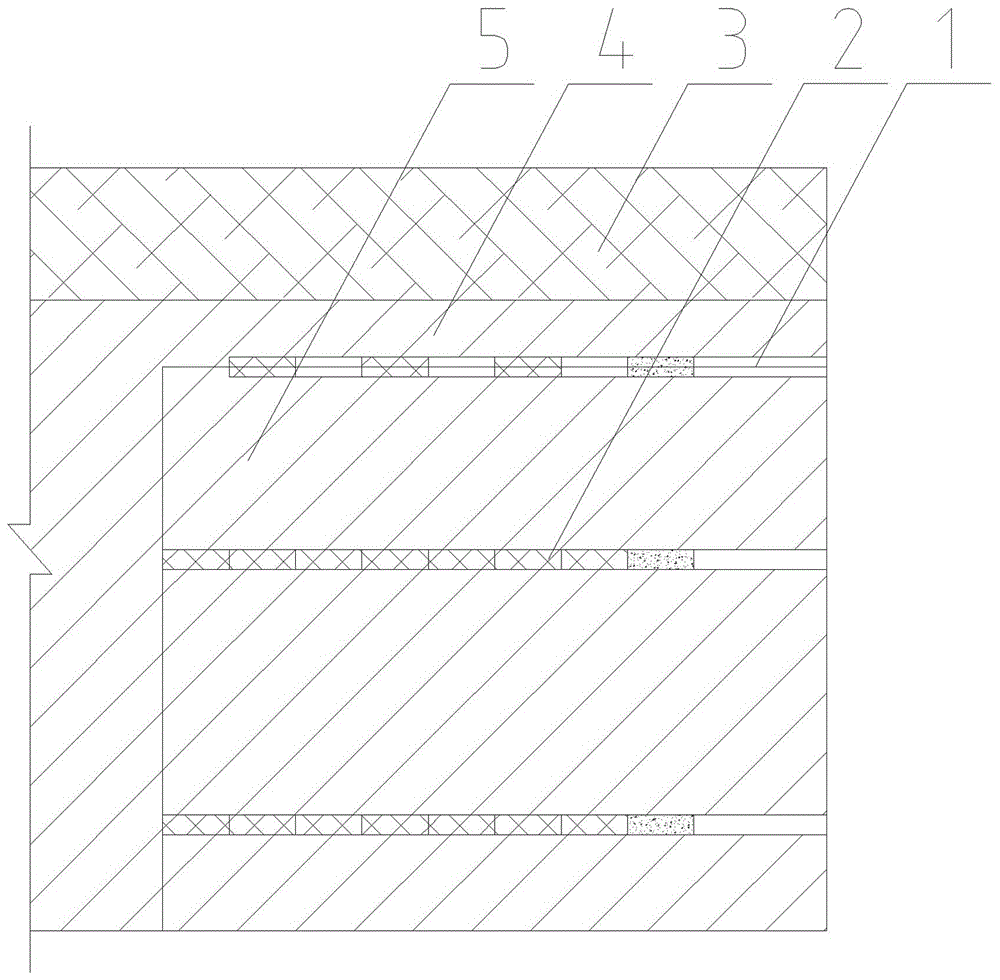

Roof-control blasting method for soft and fractured roof ore body recovery

ActiveCN106767213AReduce depletion ratePrevent collapseUnderground miningBlastingDetonatorEngineering

The invention discloses a roof-control blasting method for soft and fractured roof ore body recovery. A control blasting technology is adopted to break ores under a blasting layer through millisecond blasting; and an ore roof supporting layer is reserved, so that safety of a stope roof is maintained. The method adopts a short-hole drilling mode to form control blast holes and main blast holes, the control blast holes are formed in a control blast line, and the main blast holes are vertically arranged perpendicular to a rock drilling working surface; and millisecond detonators are adopted, the main blast holes are blast row by row along a free surface, and the control blast holes are finally blast once to downwards press ores. The roof-control blasting method is suitable for ore body recovery which has an obvious ore body boundary, an unstable roof, firm and stable ores, and needs keeping ores to support the roof, effectively keeps ores to support the roof, and prevents stope ore loss caused by roof collapse, so that a recovery ratio is increased; and meanwhile, roof waste rocks are effectively prevented from mixing, so that an ore dilution rate is reduced.

Owner:CINF ENG CO LTD

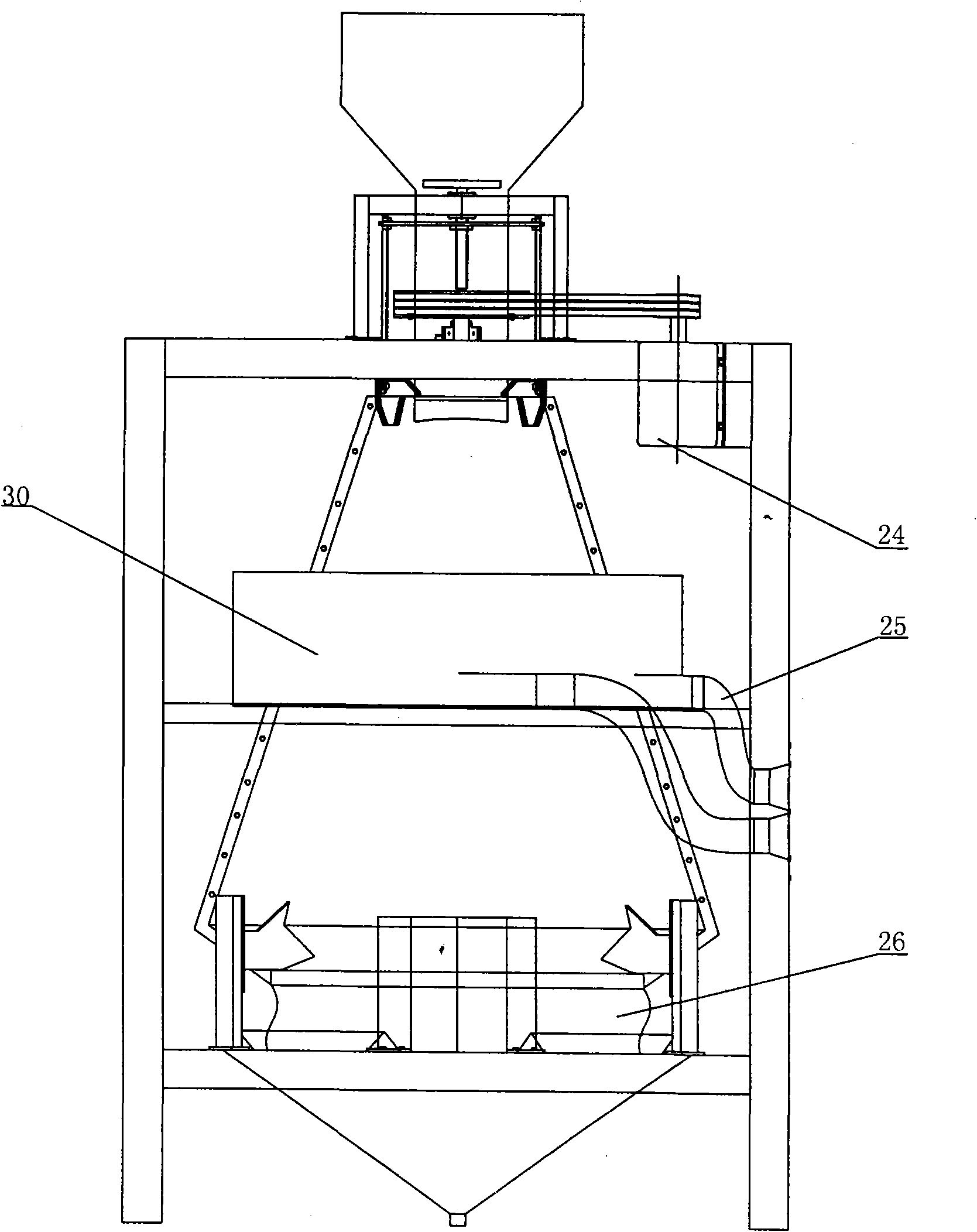

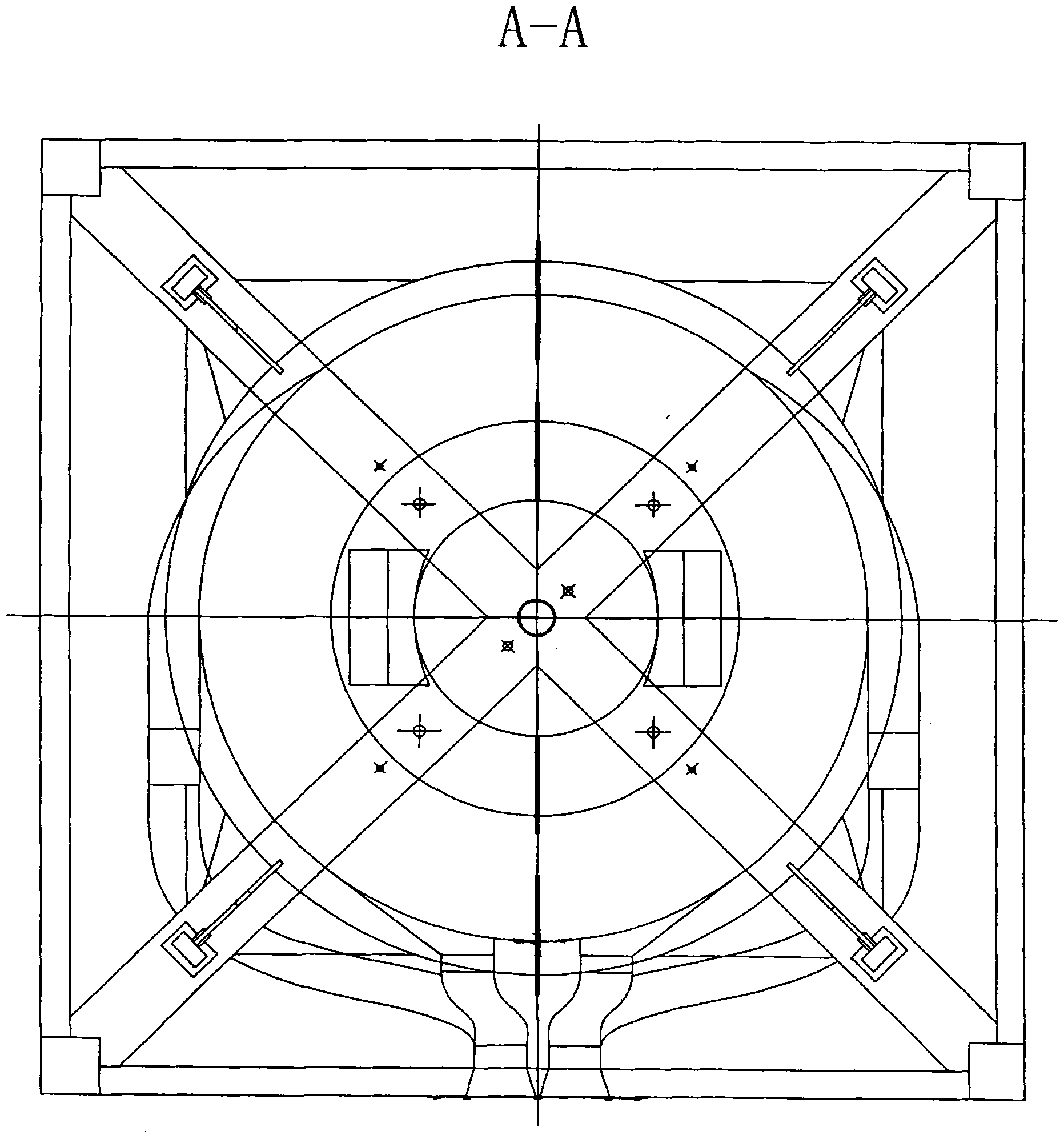

Tube nest type micro-powder heat exchanger

ActiveCN103292622ASimple structureEasy to manufactureStationary tubular conduit assembliesHeat exchange apparatusProcess engineeringSmall footprint

The invention discloses a tube nest type micro-powder heat exchanger comprising a feed box and a heat exchange box. The feed box is arranged at the upper end of the heat exchange box, a discharge hopper is arranged at the lower end of the heat exchange box, and a vibrating motor is arranged outside the discharge hopper. Heat exchange tubes are arrayed in the heat exchange box, a water inlet box cover communicated with the heat exchange tubes is arranged outside the heat exchange box, and a water outlet box cover communicated with the heat exchange tubes is arranged outside the heat exchange box. The tube nest type micro-powder heat exchanger has the advantages of simple structure, convenience in manufacturing, no accessory devices, low device cost, non-breakable grain crystals, low energy consumption, small occupation space and the like. Materials generally go down among the heat exchange tubes in the heat exchange box, the grain crystals are less breakable, and product quality is effectively improved. Only the vibrating motor in the heat exchanger consumes energy, water for heat exchange is recycled, no dust and waste gas is discharged, energy saving and emission reduction effects are remarkable. Besides, the heat exchanger practically without motion parts during operation is good in stability and low in maintenance and can produce great economic and social benefits for users.

Owner:CHENGDU TIANBAO HEAVY IND

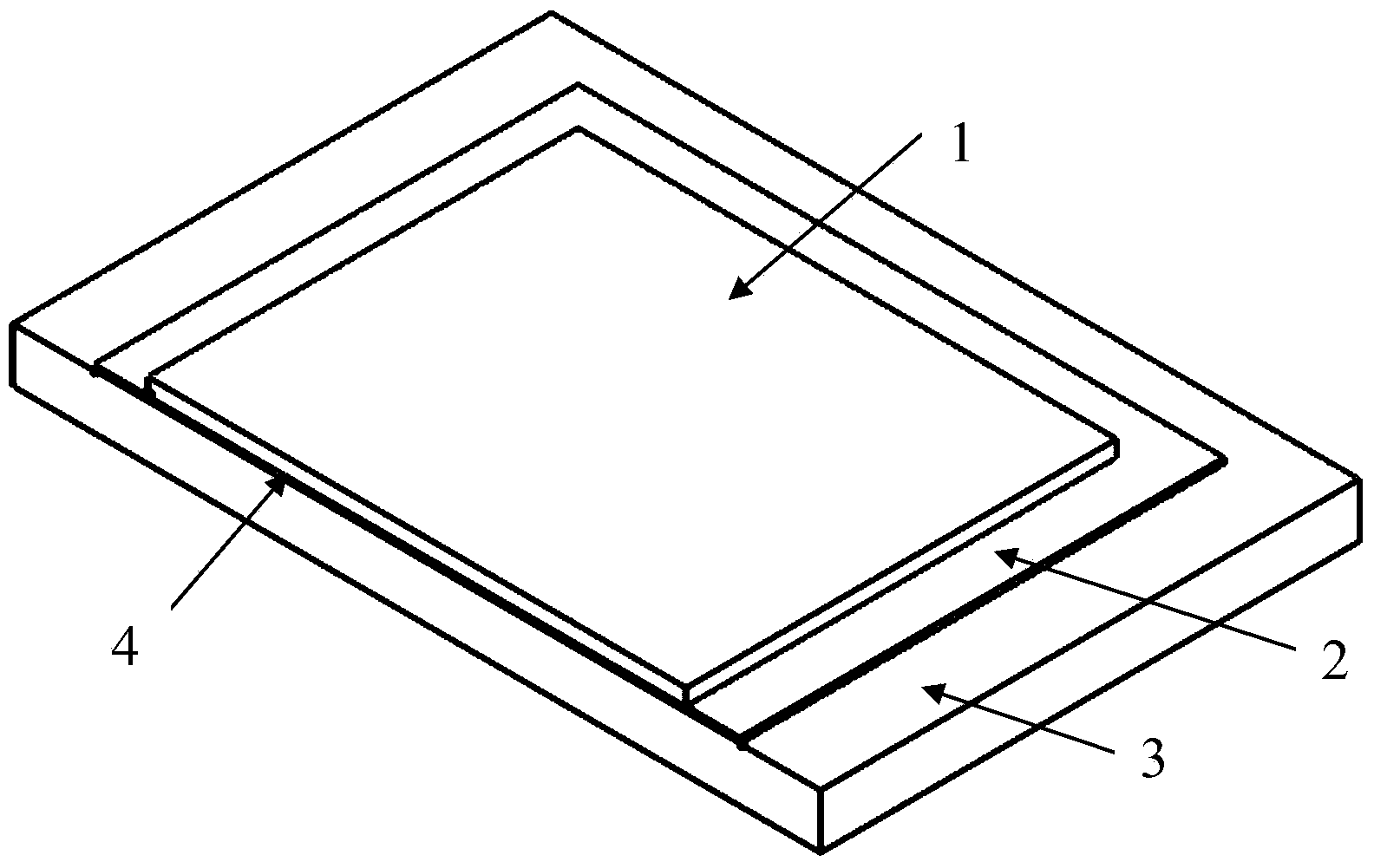

Simple preparation method for metallographic phase sample of silicon wafer

InactiveCN102589951ASimple processEasy to operatePreparing sample for investigationMicrostructureHot-melt adhesive

The invention disclosers a simple preparation method for a metallographic phase sample of a silicon wafer. A flat cylinder is used as a carrier plate of the silicon wafer, and the method comprises the following steps of: placing a hot melt adhesive on the carrier plate, and heating the carrier plate until the hot melt adhesive is molten; flatly placing the silicon wafer in the middle of the carrier plate and covering on the hot melt adhesive, and applying force to the silicon wafer by using the other flat pressing block; cooling the carrier plate to room temperature to ensure that the hot melt adhesive is cured; polishing the prepared sample; after polishing, heating the carrier plate again to ensure that the cured hot melt adhesive is molten, allowing the silicon wafer to fall off and taking down the silicon wafer; and washing the silicon wafer to finish the metallographic phase sampling of an ultra thin silicon wafer. The process is simple, and is convenient to operate, and low in implement cost; and the prepared thin silicon wafer sample is not warped or crushed, and is stable during polishing; the key point is that after processing, the silicon wafer can be conveniently taken out, the omnibearing observation of the microstructure of the ultra thin silicon wafer can be realized, the specific area can be selected conveniently for component or structure analysis, and in-situ multi-angle and multi-means representation and detection of the specific area of the silicon wafer can be performed.

Owner:SUZHOU XIEXIN INDAL APPL INST

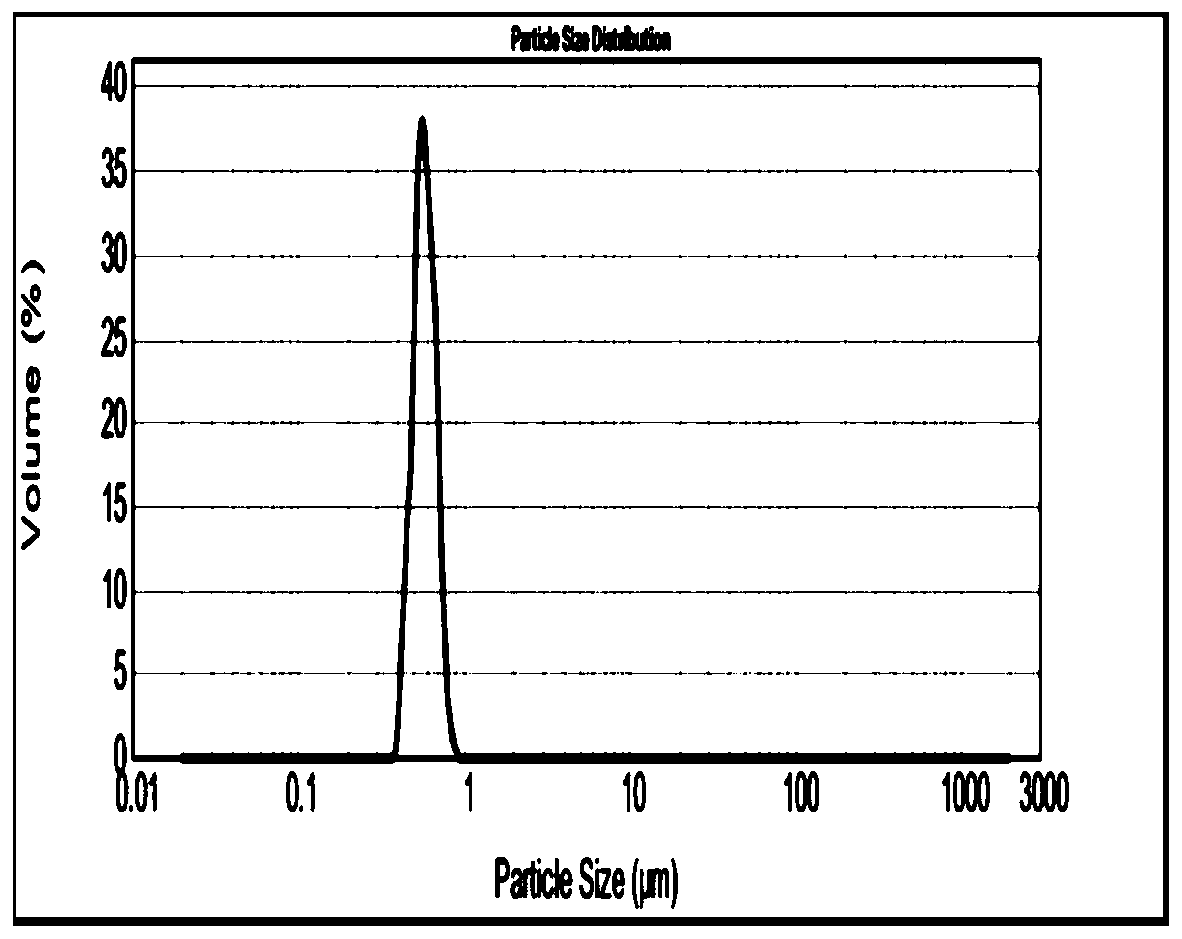

Preparation method of spherical alpha-aluminum oxide powder

InactiveCN110963516AParticle size controllableNo reunionAluminium oxide/hydroxide preparationOrganic solventEmulsion

The invention discloses a preparation method of spherical alpha-aluminum oxide powder, and belongs to the technical field of inorganic non-metallic materials. The preparation method of the spherical alpha-aluminum oxide powder comprises the following steps: S1, hydrolyzing a rectified and purified organic aluminum salt under the pH value of less than 8 to obtain an aluminum sol; evaporating to remove the organic solvent in the aluminum sol under a vacuum heating condition; S2, mixing the aluminum sol into a non-polar organic solvent, stirring at a high speed to form an emulsion, adding a certain amount of a stabilizer into the emulsion to form spheroidized aluminum hydroxide sol particles, carrying out centrifugal separation on the spheroidized aluminum hydroxide sol particles, and carrying out vacuum drying to obtain spherical aluminum hydroxide sol powder; and S3, inputting the dried powder prepared in the step S2 into a vertical high-temperature furnace, and enabling the dried powder to pass through a high-temperature region of 1100-1300 DEG C for 60-180 minutes so as to obtain the spherical alpha-aluminum oxide powder. According to the method, the alpha-phase conversion rate can be increased, the particle size of the prepared aluminum oxide powder is controllable, and the powder is free of agglomeration and breakage.

Owner:SUZHOU NANODISPERSIONS

Easily-degradable anti-shrinkage polypropylene master batch and preparation method thereof

InactiveCN106674728AImprove high temperature resistanceImproves shrink resistanceFungiMicroorganism based processesPolypropyleneAntioxidant

The invention discloses an easily-degradable anti-shrinkage polypropylene master batch, wherein polypropylene serves as a base material, the types and the formula of the master batch are optimized, and a production process is improved. A complex antioxidant which contains a biologic antioxidant, modified nanocarbon which can obviously improve high temperature resistance, shrinkage resistance, relative tensile load, strength and toughness and elasticity modulus of the polypropylene master batch, calcium fruit fibers which can obviously improve shock resistance of the polypropylene master batch, are easily biodegradable and lower production cost, polyethylene / winter rye peptide complexes which can greatly improve low temperature resistance of the polypropylene master batch and bitter almond oil which can effectively improve lubricating property and oxidation resistance of the polypropylene master batch are scientifically compounded; the obtained compound has a synergistic effect with other processing aids; finally, the environment-friendly easily-degradable anti-shrinkage polypropylene master batch with good physical property is obtained.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

Method for preparing microbe carrier for immobilization of Flavobacterium through refrigerating-defrosting twice

This invention describes a process for preparing a microbe carrier prepared by two times freezing-defreezing of flavorbacteria, comprising the steps of: adding appropriate amounts of activated carbon, zeolite powders and Tween 80 into the PVA- NaíñAlg gel; uniformly mixing the gel and the flavorbacteria seed liquid, and then pouring the mixed liquid into a culture plate that is covered with two layers of non-woven fabrics at 35-48 deg.C; freezing the culture plate in a refrigerator at 10-15 deg.C for 15-18h, defreezing, and repeating the procedure once again; solidifying the mixed liquid with the solification agent, immersing in sterilized water for a time, and then cutting for enrichment culture. The carrier in this invention has good elasticity, diffusion and mechanical properties. The flavorbacteria immobilized have good activities without any leakage.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

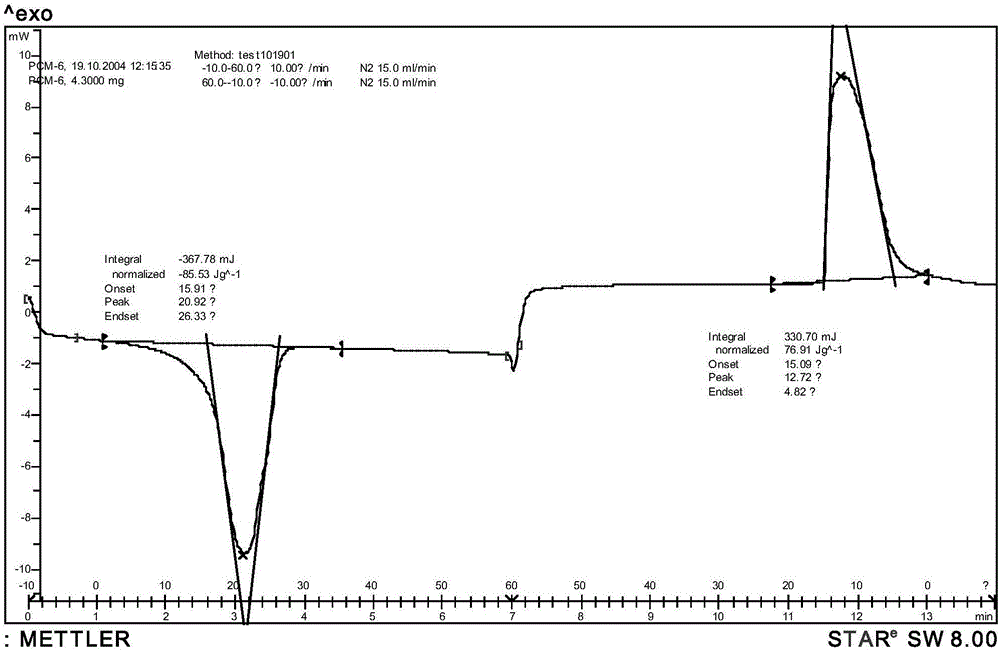

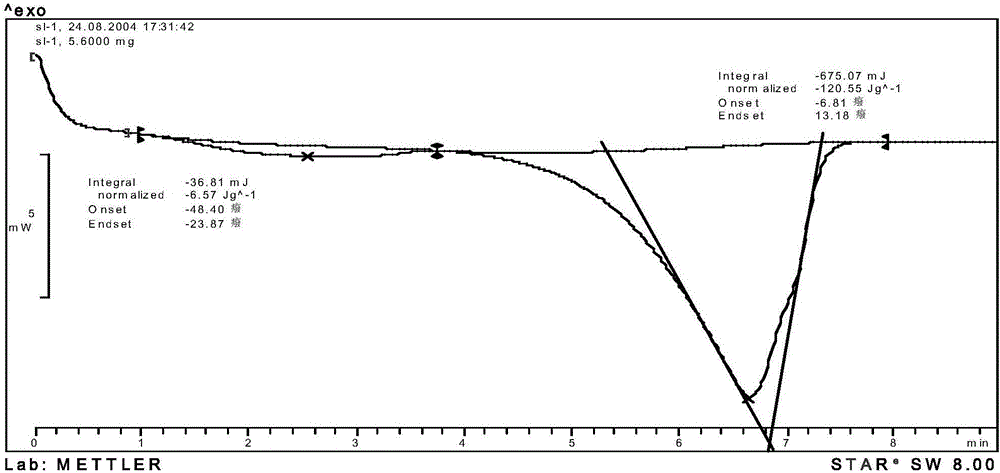

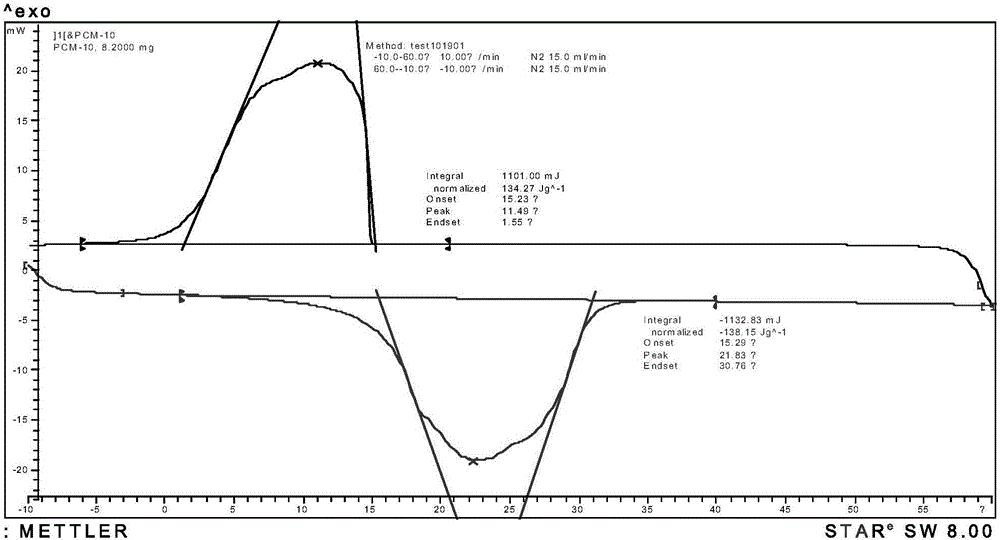

Carbon fiber-added microcapsule shape-stabilized phase-change material and preparation method thereof

InactiveCN106753262AHigh mechanical strengthNo brokenHeat-exchange elementsMicroballoon preparationFiberPolymerization

The invention discloses a carbon fiber-added microcapsule shape-stabilized phase-change material and a preparation method thereof. The carbon fiber-added microcapsule shape-stabilized phase-change material comprises the following components in parts by weight: 50 to 100 parts of a core material, 200 to 500 parts of chloroform, 0.2 to 0.6 part of an emulsifying agent, 15 to 30 parts of toluene diisocynate, 6 to 15 parts of ethidene diamine and 0 to 100 parts of distilled water, wherein the core material comprises paraffin, polyethylene and carbon fiber powder, and the weight ratio of the paraffin to the polyethylene to the carbon fiber powder is (30-70):(20-50):(5-15). The microcapsule shape-stabilized phase-change material provided by the invention adopts the polyethylene and the carbon fiber as composite supporting materials, the mechanical strength of the microcapsules is greatly enhanced, the microcapsules are not broken when 10-Kg pressure is applied, and the microcapsule shape-stabilized phase-change material can be widely applied to various aspects in the field of buildings and in the fields of military, civil use, household appliances and the like. The carbon fiber-added microcapsule shape-stabilized phase-change material is wrapped by an interface polymerization method, loss of the paraffin can be retarded or stopped, heat storage and release functions of the phase-change material are guaranteed, the service life of the phase-change material is prolonged (after heat storage and release is conducted for 50 times, attenuation is zero), and the carbon fiber-added microcapsule shape-stabilized phase-change material can adapt to more use environments.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Multifunctional peanut cleaner

Owner:王彦忠

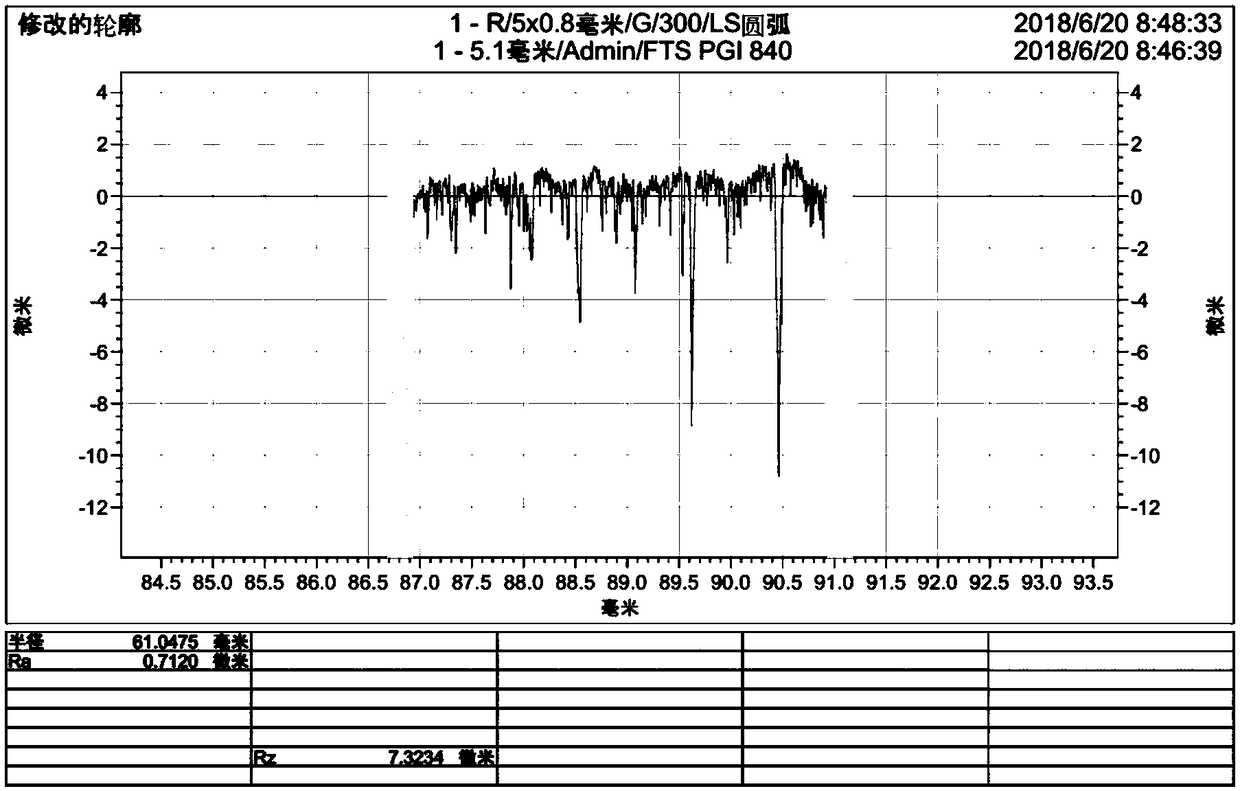

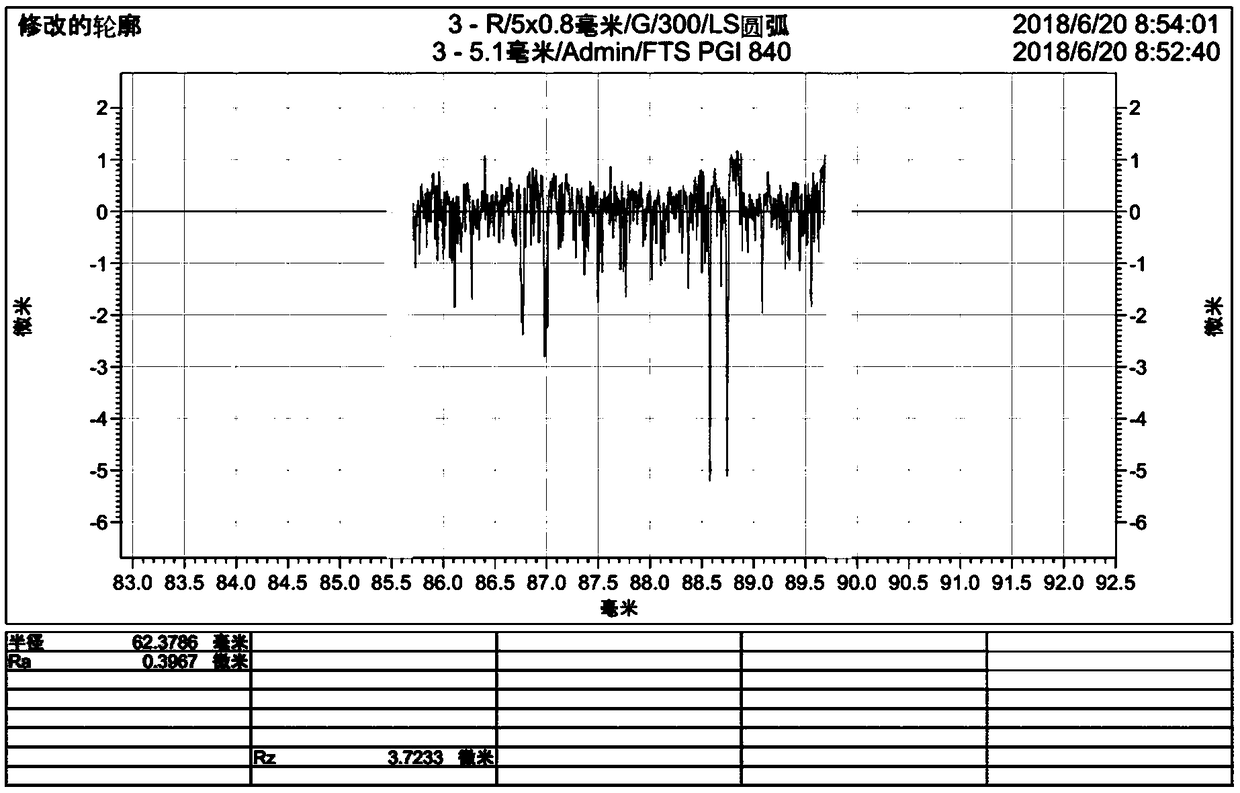

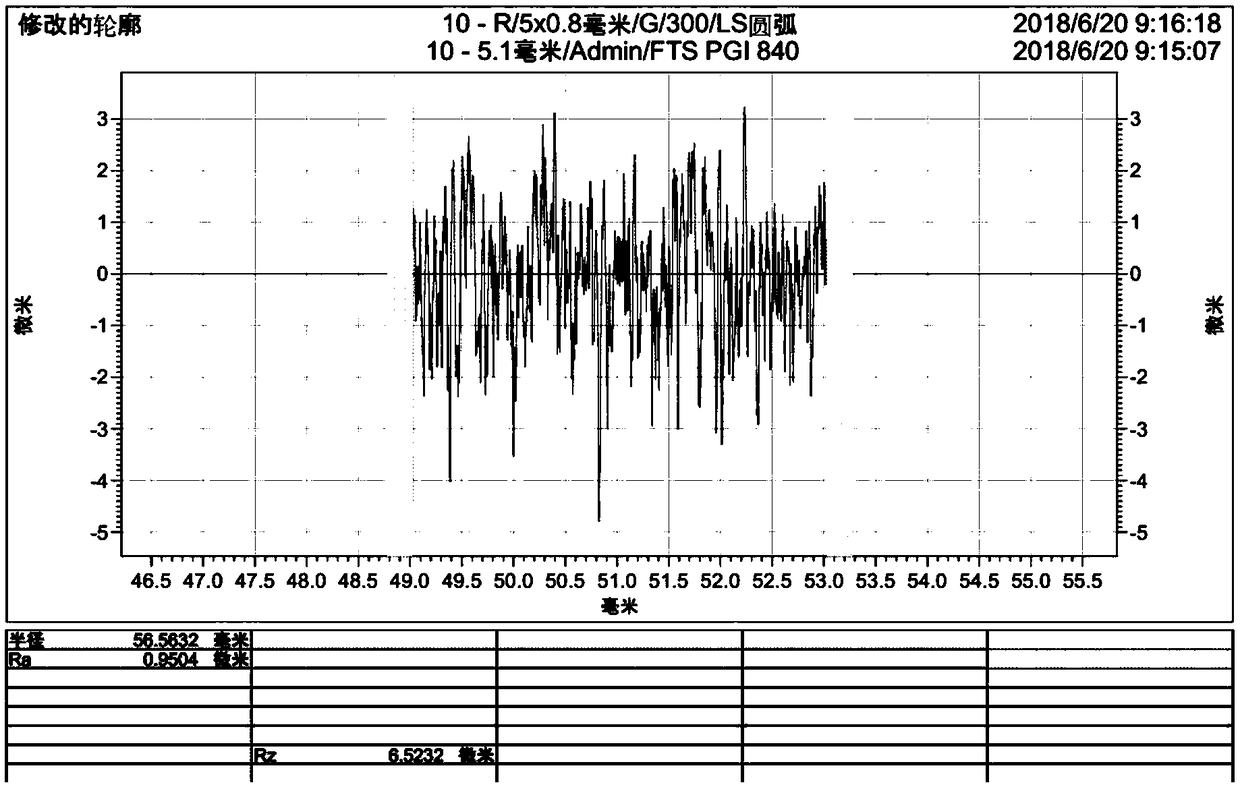

Sapphire dome grinding method

InactiveCN108818159AFlat surfaceNo fracture processing defectsGrinding machinesOptical axisSurface roughness

The invention discloses a sapphire dome grinding method. A combination of metal bond diamond grinding heads of different particle sizes and shapes are adopted for machining. The method includes adopting a cylindrical diamond grinding head to grind the end face and the outer circle of a sapphire, and adopting diamond spherical grinding heads of different particle sizes to grind the inner sphericalsurface; adopting a turning method to machine a tool with one end as the hemispherical surface concentric with the grinding inner spherical surface and the other end as an optical axis; milling 6-8 grooves in the hemispherical surface by milling; bonding the workpiece to the tool coaxially by high-strength glue, and injecting the high-strength glue from the grooves; adopting cup-shaped diamond grinding heads of different particle sizes when grinding the outer spherical surface with the coarse grinding particle size of #100-#180 and the fine grinding particle size of #240-#320. According to thesapphire dome grinding method, a ground sapphire dome is smooth in surface without chipping, crushing and fracture processing defects, and the surface roughness Ra is less than 1 Mum.

Owner:DALIAN UNIV OF TECH

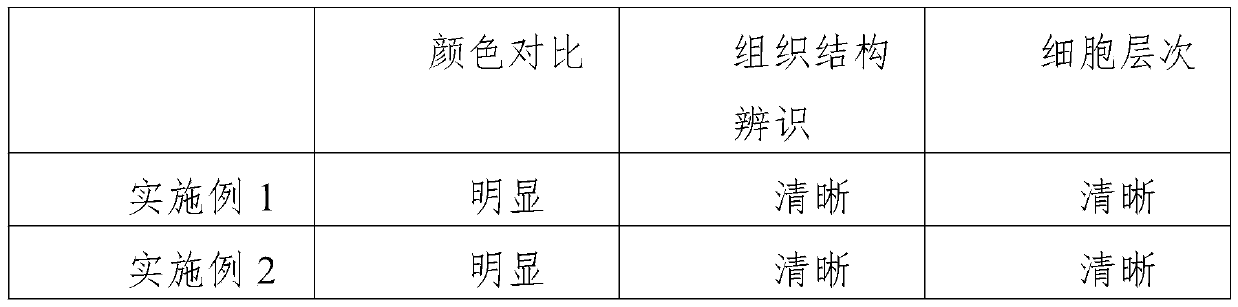

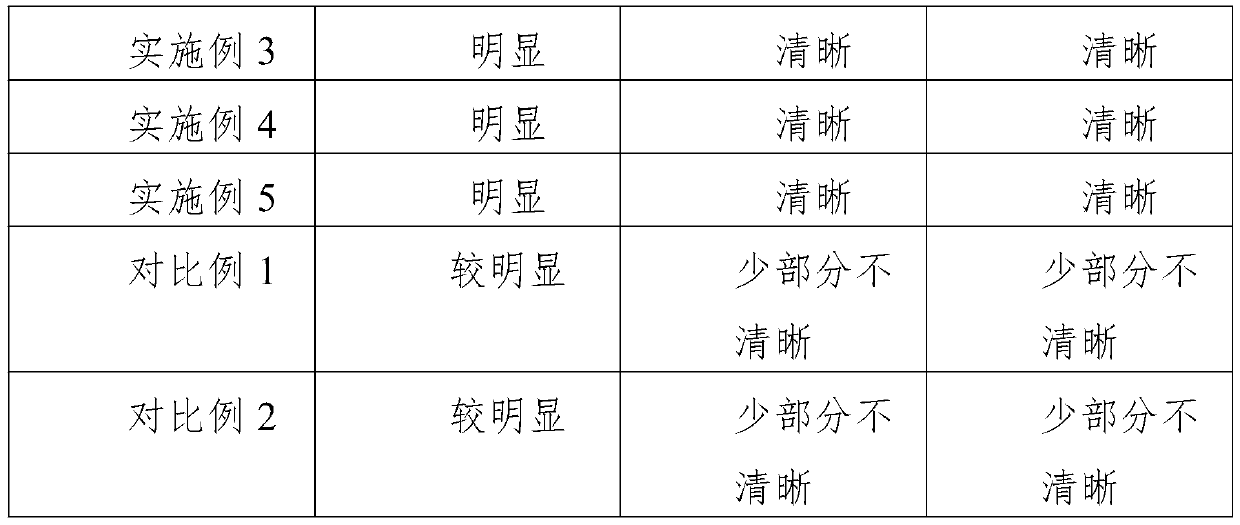

Histopathological tissue sample treatment method

PendingCN110887719AEffective preservationEasy to fixPreparing sample for investigationStainingEthylic acid

The invention provides a histopathological tissue sample treatment method, which comprises the following steps: (1) fixing: fixing an in-vitro tissue sample by adopting a fixing agent I and a fixing agent II in sequence during fixing; (2) washing; (3) dehydrating; (4) transparency treatment; (5) wax dipping and embedding; and (6) slicing and dyeing: carrying out dewaxing, treating dewaxed slices with a hematoxylin pre-dyeing solution for 2-3 minutes, and then, treating the dewaxed slices with a hematoxylin dyeing solution for 5-10 minutes, wherein the hematoxylin dyeing assistant solution comprises the following components: hematoxylin, aluminum sulfate, potassium permanganate, citric acid, nonylphenol polyoxyethylene ether and water, and the hematoxylin dyeing solution comprises the following components: hematoxylin, aluminum potassium sulfate dodecahydrate, potassium permanganate, acetic acid, nonylphenol polyoxyethylene ether, glycerol, absolute ethyl alcohol and water. The treatment method disclosed by the invention is easy to operate, high in tissue sample section integrity, good in dyeing effect, obvious in dyeing, clear in comparison and clear in cell hierarchy.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

Spherical activated carbon ozone catalyst with high alkalinity on surface and application of spherical activated carbon ozone catalyst

ActiveCN110743524AHigh degree of mineralizationHigh catalytic activityPhysical/chemical process catalystsWater contaminantsActivated carbonPtru catalyst

The invention provides a spherical activated carbon ozone catalyst with high alkalinity on the surface. The spherical activated carbon ozone catalyst is prepared by the following steps: mixing asphaltof a low softening point and an oxidation accelerator with a Lewis catalyst, adding a surfactant and a water suspension, performing sphere formation, performing carbonization and activation so as toobtain a mesoporous spherical activated carbon catalyst, further adding an alkali liquid, performing sufficient mixing and modification, uniformly mixing the components through gradient temperature change, performing washing till the pH value is stable, performing vacuum drying, so as to obtain mesoporous spherical activated carbon with high alkalinity on the surface. The material is high in catalytic activity, is capable of significantly improving the efficiency of converting ozone into hydroxyl radicals and promoting mineralization of refractory pollutants, is good in stability and can maintain high catalytic activity in long-term use. The catalyst can be applied to treatment on organic pollutants, and is beneficial to adsorption and intragranular diffusion and mass transfer of pollutants, and the degradation efficiency can be improved.

Owner:EAST CHINA UNIV OF SCI & TECH +2

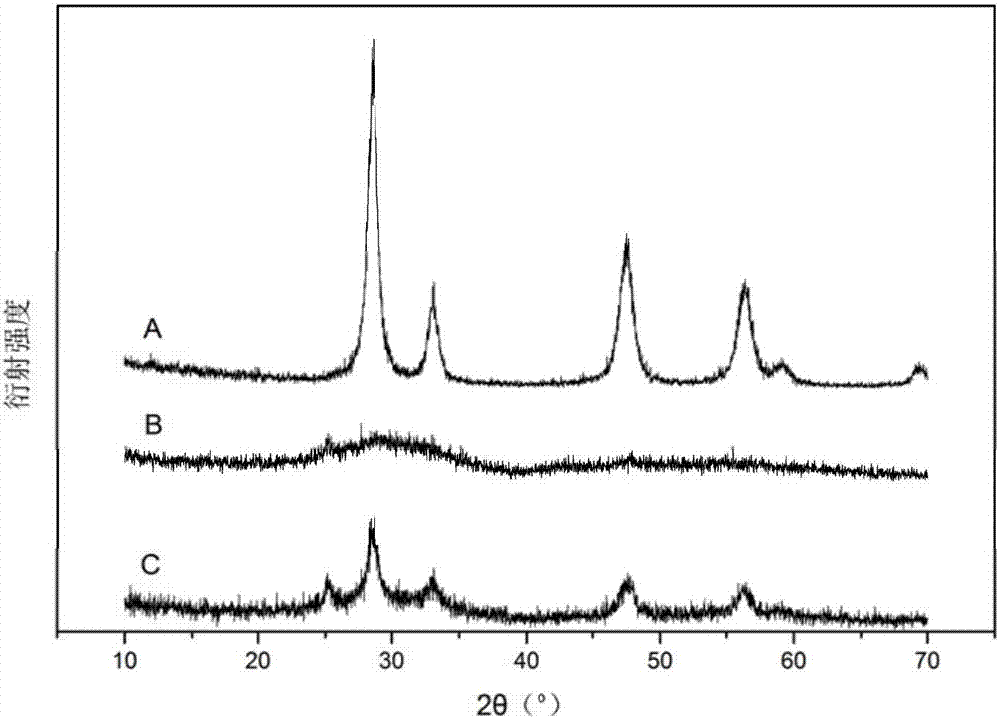

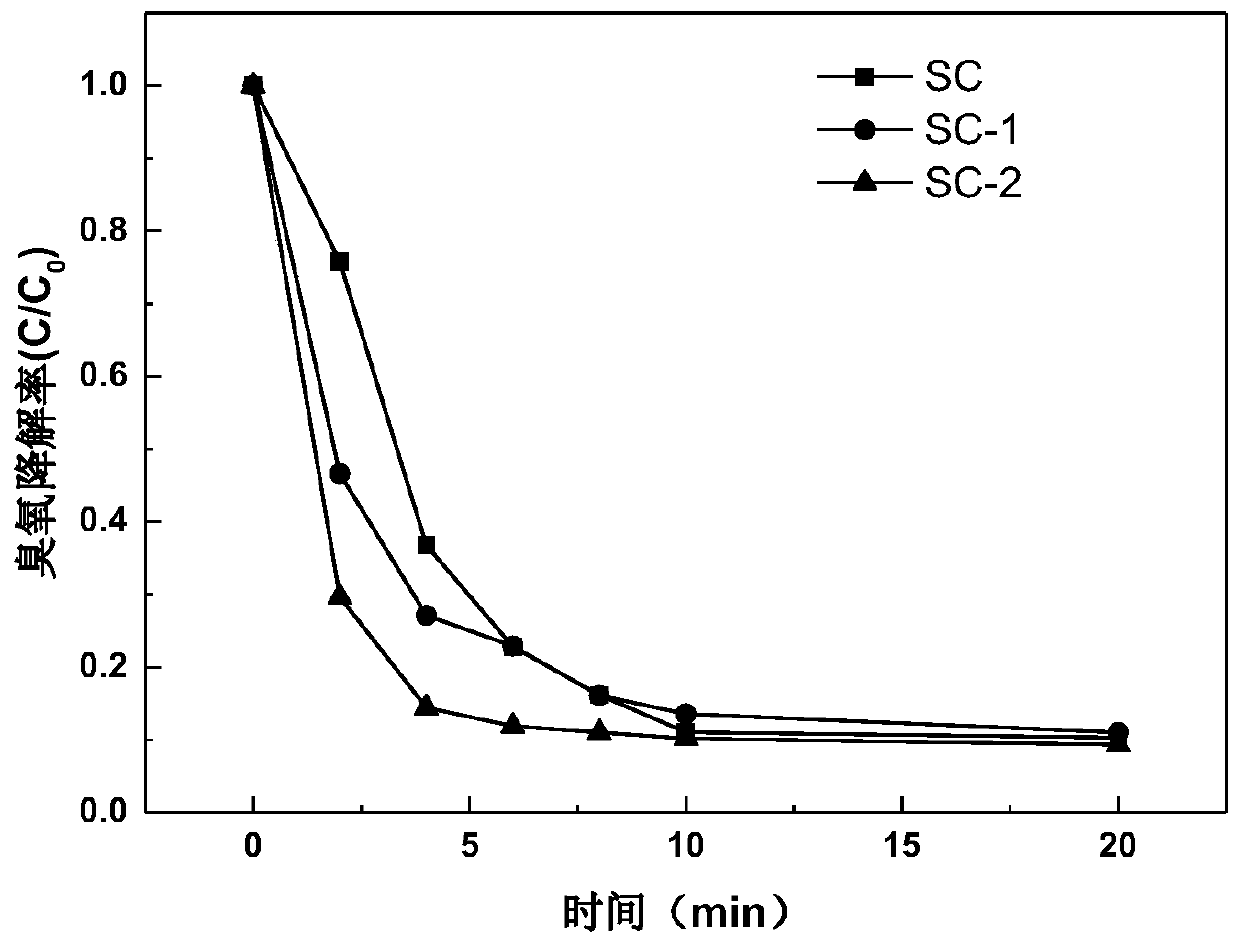

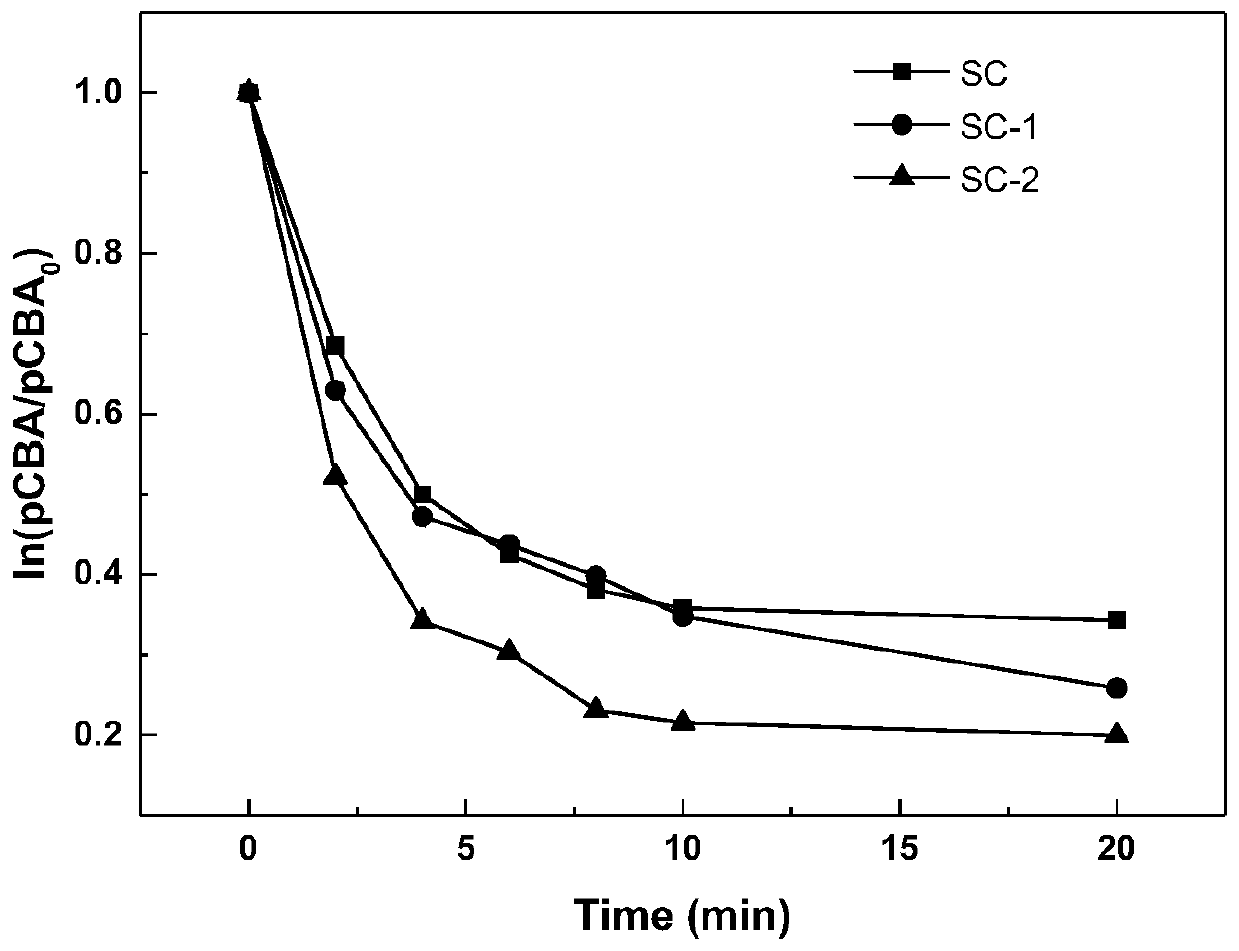

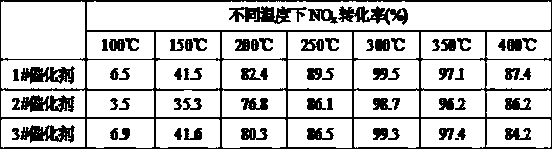

Low-cost NH3-SCR denitration catalyst and preparing method thereof

InactiveCN109395775ARich sourcesLow costMolecular sieve catalystsDispersed particle separationMolecular sieveChemistry

The invention discloses a low-cost NH3-SCR denitration catalyst and a preparing method thereof. The preparing method comprises the steps that honeycomb stones washed with acid are used as carriers andcoated with mesoporous titanium silicon molecular sieves, and ammonium vanadate and zinc nitrate are used as active ingredients; the surfaces of the modified honeycomb stones are coated with a layerof the titanium silicon molecular sieves of a mesoporous structure, then the active ingredients which include ammonium vanadate and zinc nitrate are loaded, not only can erosion caused by alkali metalNa and K which are contained in the honeycomb stone base bodies to the active ingredients be inhibited, but also the denitration performance be improved; the specific surface area of the catalyst canalso be increased, and thus loading and dispersion of the active ingredients are facilitated; the two active ingredients form a Zn2V2O7 structure, on one hand, the reaction activity of NH3-SCR can beimproved, and on the other hand, sublimation of vanadium varieties under a high temperature condition can be obviously inhibited.

Owner:李俊霞

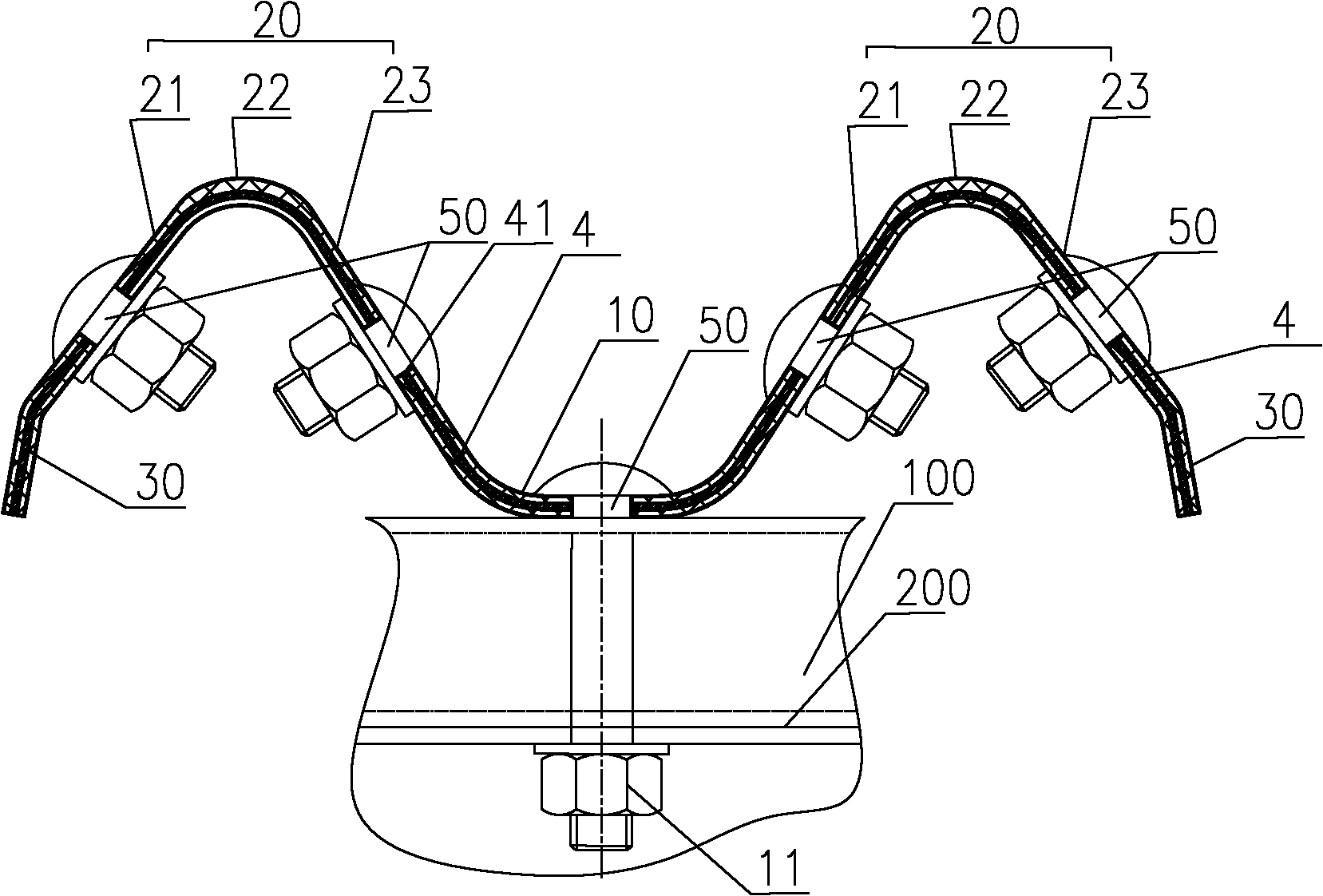

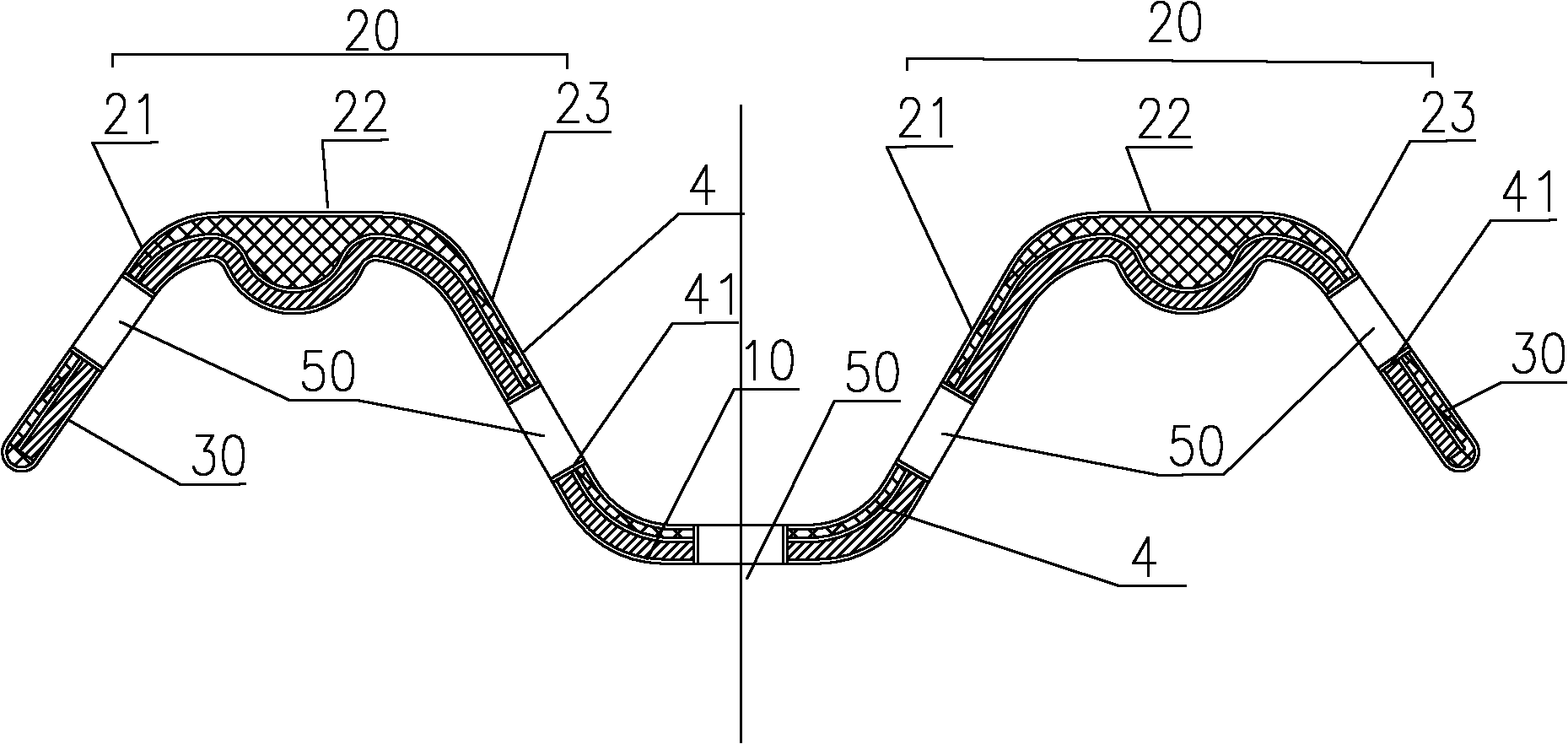

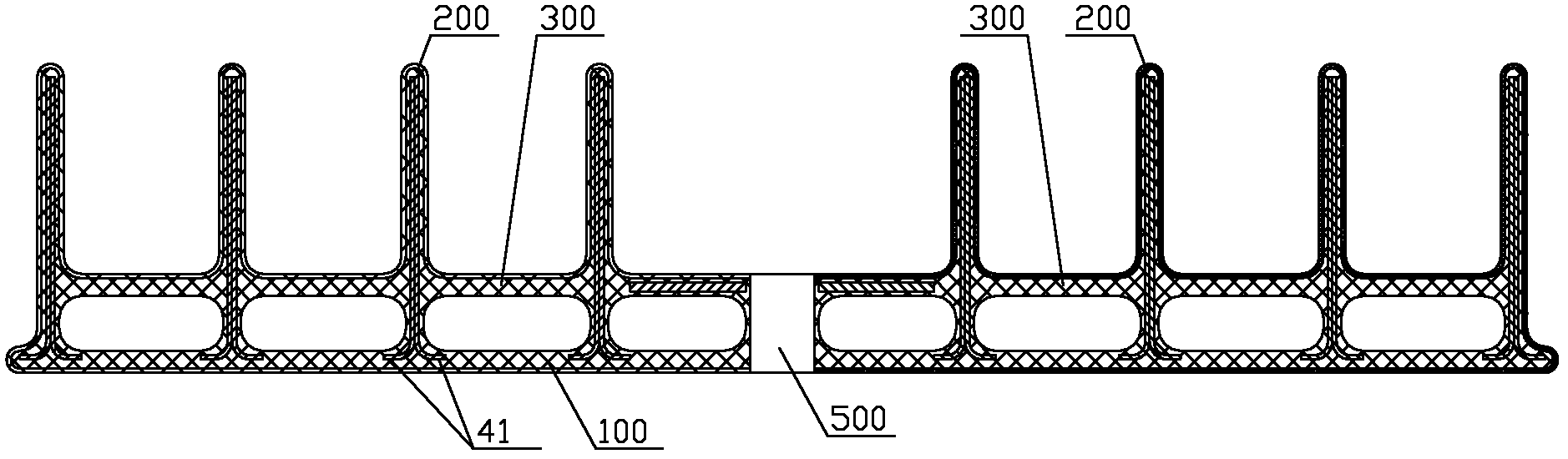

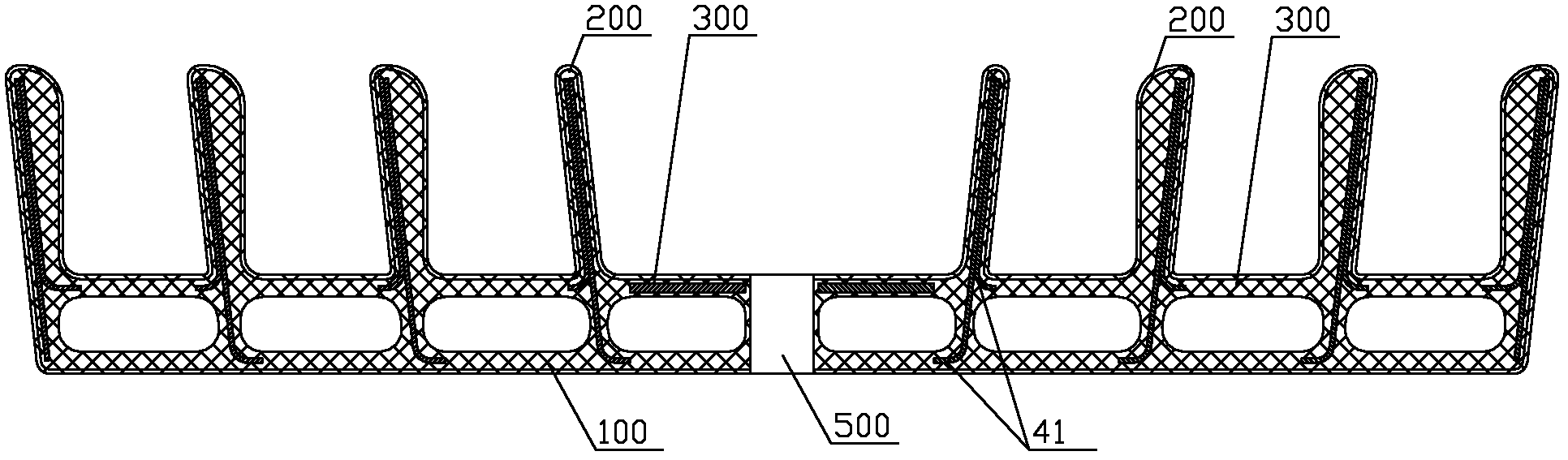

Ribbed guardrail plate

InactiveCN102535367AReduce impact forceGood flexibilitySynthetic resin layered productsMetal layered productsManufacturing technologyEnergy absorption

The invention discloses a ribbed guardrail plate comprising a beam plate, wherein a plurality of rib plates integrated with the beam plate are arranged on the plate face of the beam plate; the beam plate and the rib plates extend in the length direction of the guardrail plate; the beam plate is a thermoplastic composite plate or a thermoplastic material plate; the rib plates are thermoplastic composite plates; and each thermoplastic composite plate comprises a reinforcing frame wrapped in a thermoplastic material layer. Aiming to overcome the defects of high probability of corrosion, high rigidity and poor collision energy absorption of a steel guardrail plate, small elastic modulus, large size and high cost of the all-plastic material of an all-plastic guardrail plate, and complex manufacturing technology and worse collision energy absorption of a plastic-steel guardrail plate, the invention provides the ribbed guardrail plate, which has the advantages of corrosion resistance and lower maintenance difficulty and can excellently absorb collision energy to reduce harm to a vehicle and personnel.

Owner:HUNAN JINHONG TECH CO LTD

High-energy catalytic physical stripping preparation method of graphene

The invention relates to a high-energy catalytic physical stripping preparation method of graphene, relates to the technical field of graphene materials, and solves the problem that a conventional physical stripping method is high in cost and not easy to be mass-produced. The method specifically comprises the following steps: performing preliminary infiltration on pure water, performing first high-energy ultrasonic preliminary stripping, adding SiC for ball milling, then performing second high-energy catalysis for stripping, classifying graphene flakes by gas flow classification and spray-drying to obtain the graphene; by infiltration, ultrasonic treatment, SiC ball milling, addition of a surfactant and the secondary high-energy ultrasonic treatment, the graphene is stripped layer by layer, the process is mild, and basically no crushing and wear phenomena occur; the prepared graphene crystal lattice structure is complete and processed by a physical stripping method, the graphene flakesare present in a completely powdery form, the storage and use environments are not restricted, and the industrial production cost is relatively low, thereby facilitating the wider application of graphene in various industries.

Owner:大同墨西科技有限责任公司

Polishing machine

InactiveCN102335861ANo damageNo broken skinPortable grinding machinesDrive shaftAgricultural engineering

The invention discloses a polishing machine, which comprises a frame, a transmission shaft, a motor, an upper hopper, a lower hopper and polishing sleeves, wherein the motor and the lower hopper are arranged on the frame; the polishing sleeves comprise an outer polishing sleeve and an inner polishing sleeve; the inner polishing sleeve is welded to the transmission shaft; the outer polishing sleeve is sleeved outside the inner polishing sleeve; the inner part of the outer polishing sleeve and the outer part of the inner polishing sleeve are provided with an outer sleeve polishing cushion and an inner sleeve polishing cushion respectively; the outer polishing sleeve consists of two half sleeves; the tops of the half sleeves of the outer polishing sleeve are provided with a lifting lug; the lifting lug is connected to a screw through a bolt; the upper part of the screw is connected to an adjusting plate through a bolt; the middle part of the adjusting plate is welded with a nut which is connected with the screw; the upper part of the screw is provided with a groove which is clamped on a circular hole part in the middle of an adjusting frame; and the top of the screw is provided with a hand wheel. The polishing machine has the advantages of guaranteeing that the material is not damaged, along with good dust removal effect for the material, low single-machine working cost, long service life, convenience in replacement, small size and less space.

Owner:樊超

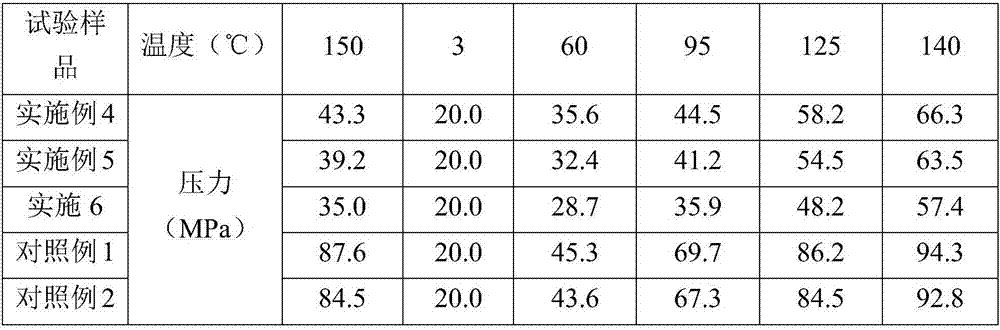

Elastic agent for well cementation, preparation method thereof and elastic isolation fluid

InactiveCN107418532AImprove ductilityAffect the final effectDrilling compositionDiethylenetriamineEngineering

The invention discloses an elastic agent for well cementation, a preparation method thereof and an elastic isolation fluid, and relates to the field of petroleum drilling engineering. The elastic agent is prepared from raw materials comprising the following components, in parts by weight: 20-35 parts of bisphenol A, 10-25 parts of epichlorohydrin, 10-12 parts of diglycidyl ether, 0.1-0.3 part of sodium hydroxide, 10-20 parts of diethylenetriamine, 20-30 parts of propylene carbonate, 15-30 parts of amino polyether, 10-20 parts of dimethylimidazole, and 5-15 parts of a foaming agent. The elastic agent is not smashed under a high temperature of 150 DEG C and a pressure of 70MPa, thus when the elastic isolation fluid is introduced to the bottom of a high-temperature and high-pressure well for displacement, final effects of the elastic isolation fluid is guaranteed to not be influenced by in-advance gas releasing caused by particle smashing. The elastic isolation fluid containing the elastic agent can be used within a temperature raising range of 0 DEG C to 150 DEG C under closed environments, the applicable temperature difference range between a mudline temperature and a bottom hole temperature is wider, the elastic isolation fluid can be used for all stages of sleeve annular space, and guarantees annular space pressure increasment to be less than largest anti-collapse strength of each stage of the sleeves.

Owner:ZHANJIANG BRANCH OF CHINA NATIONAL OFFSHORE OIL CORP +1

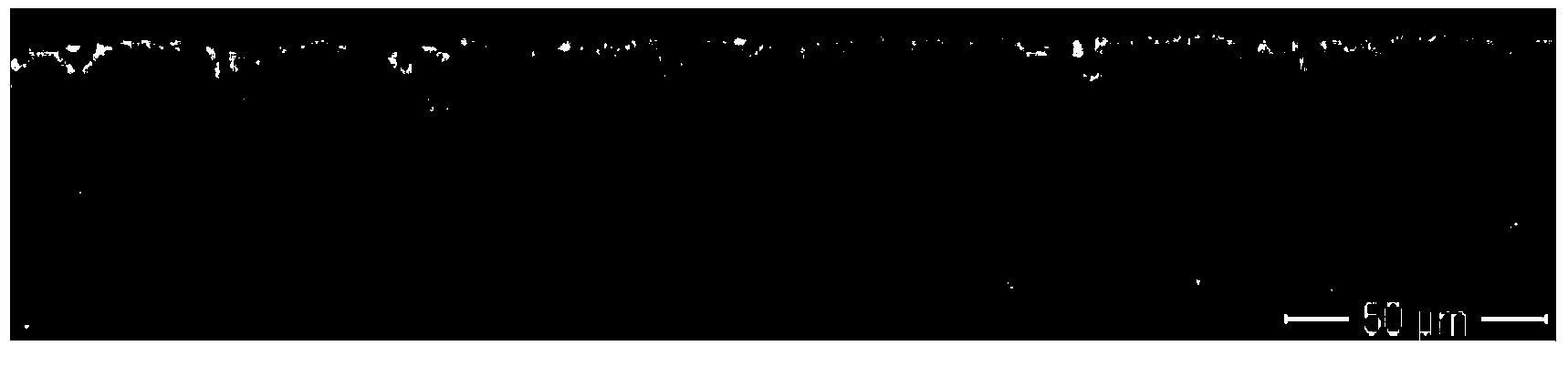

Specimen preparation method for detecting subsurface damage depth of ultra-thin silicon wafer

ActiveCN104034568BNo brokenAvoid destructionPreparing sample for investigationSpecimen preparationMetal sheet

The invention discloses a sample preparation method for detecting the subsurface damage depth of an ultra-thin silicon wafer, which comprises the following steps: (1) cutting the entire wafer into multiple samples; (2) removing a sample at any position, and paste it on the metal plate; (3) grind, polish and corrode the pasted sample; the advantage of the present invention is that it can be used to prepare ultra-thin (thickness≤300μm), fragile silicon wafer The detection sample of the surface damage layer, and the sample preparation method is simple, can obtain clear subsurface microcracks, and solves the problem that the subsurface damage depth of the ultra-thin silicon wafer is difficult to obtain.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Method for producing ball mill burnisher

InactiveCN1640547AEasy to operateImprove productivityFoundry mouldsFoundry coresProduction rateChemical composition

The present invention relates to a production method of grinding rod of ball grinding mill. Its specification is phi 300 mmX50 mm, and its chemical components are (wt%): 1.5-2.2C, 0.8-1.5 Si, 0.6-1.2 Mn, 0.1-0.3V, 0.02-0.1 Ti, 2.0-3.0 Cr, 0.1-0.5 Cu, 0.1-0.2 Ni, P is less than 0.07 and S is less than 0.07. Said invention adopts general clay green sand multiple-part moulding and stack series-injecting processes, and utilizes waste heat of casting self-body to make air quenching process, its air quenching temperature is 800-900 deg.c, after it is cooled, it is snagged so as to obtain the invented product grinding rod whose surface hardness is HRC 50-57 and core hardness is HRC 26-30.

Owner:攀枝花钢铁有限责任公司钢铁研究院

Polishing silica sol for LED sapphire substrates and preparation method thereof

ActiveCN107384220AUniform sizeImprove polishing effectPolishing compositions with abrasivesSilicon oxideSilica gel

The invention provides polishing silica sol for LED sapphire substrates. The silica sol comprises a silicon oxide source ethyl orthosilicate, a surfactant octylphenylpolyethylene glycol, a cosurfactant 4-methyl-2-amyl alcohol, an organic solvent cyclohexane, a pH regulator potassium tert-butoxide, a metal ion chelating agent ethylene diamine tetraacetic acid and the rest of deionized water, wherein size of obtained silicon oxide particle is 10-20 nm; at normal temperature, viscosity of silica sol is less than or equal to 10 mm<2> / s, pH value is 10.5-12.5, and specific weight is 1.1-1.2 g / cm<3>. According to the silica sol, usage period is long, shelf-life is greater than 1.5 years, polishing efficiency is high, and hydroxy utilization rate is high.

Owner:无锡市恒利弘实业有限公司

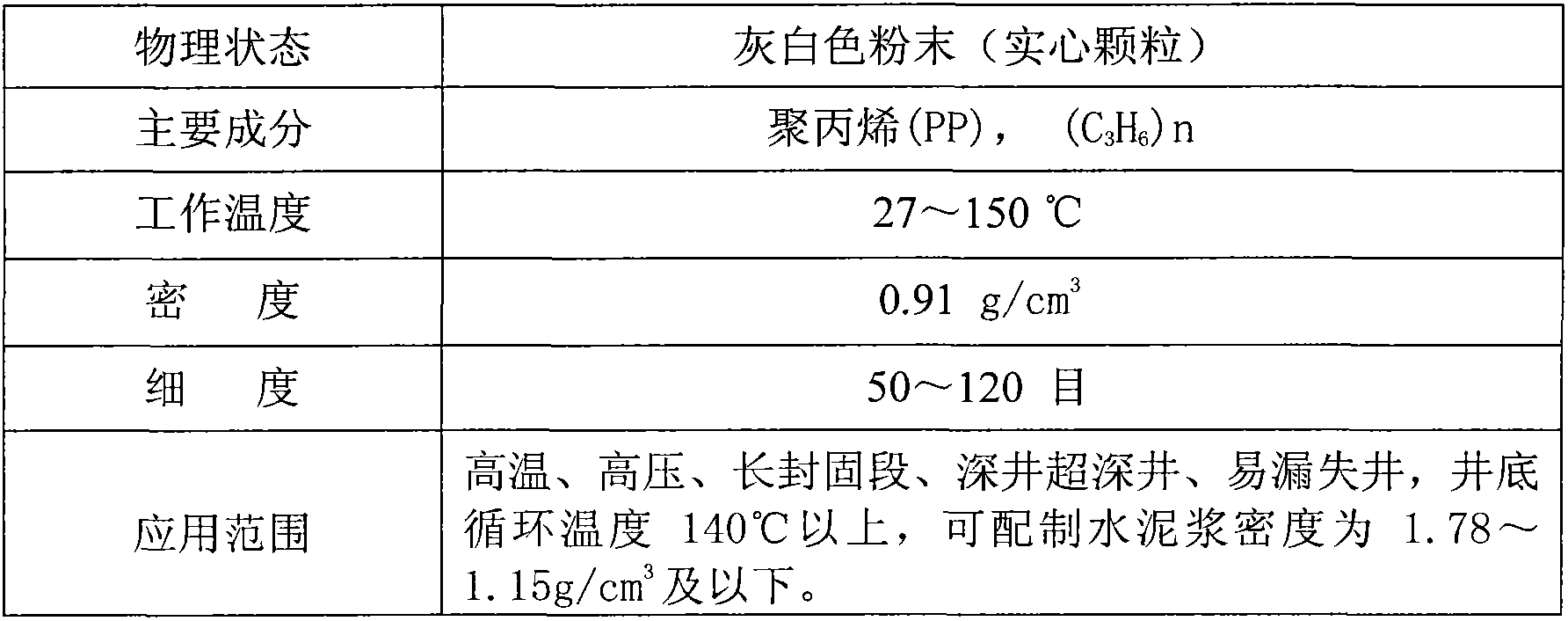

Lightening admixture

InactiveCN103509539AHigh tensile strengthGood mechanical propertiesDrilling compositionCorrosion resistantMachinability

The invention discloses a lightening admixture. The lightening admixture is characterized in that a main ingredient is a high-molecular polymer; the density of cement paste can be reduced to 1.78-1.15 g / cm<3> or less when the mixing quantity is 1-200% of the amount of cement. Compared with the prior art, the lightening admixture has the advantages that the lightening admixture is available in materials, strong in machinability, fine in obtained powder, low in density, non-absorbent, corrosion-resistant, high in withstand pressure of solid particles, free of crushing, wide in adaptive temperature range, stable in chemical properties, and free of poison and taste, can be directly blended into dry cement powder in a dry manner, and can also be compounded with additives such as a retarder, a fluid loss agent, a dispersing agent, a deformer and the like, and other lightening admixtures; low-density cement paste with excellent rheological property can be prepared in absence of additionally added construction equipment; lightweight set cement with strong compactness, good elasto-plastic property and high strength can be formed; the lightening admixture is especially suitable for implementing balance pressure on leaky stratum, so that well cementation is carried out; well leakage is prevented; the quality is ensured; the service life of oil and gas wells is prolonged.

Owner:李越

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com