Multifunctional peanut cleaner

A cleaning machine and multi-functional technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of large workload, high labor intensity, low efficiency, etc., and achieve reliable machine performance, low labor intensity, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

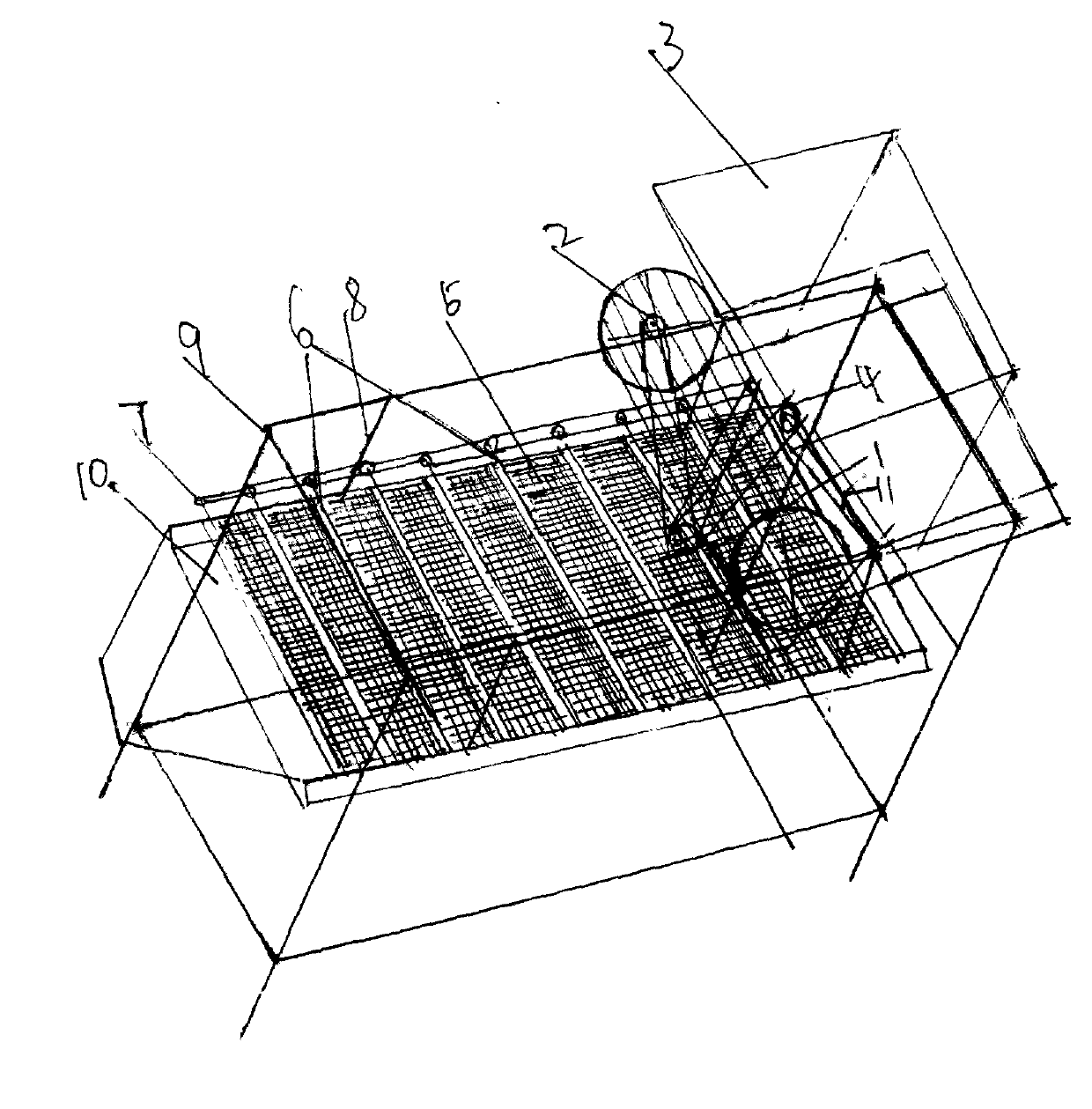

[0009] In the figure, 1 motor, 2 air duct, 3 feed hopper, 4 eccentric shaft, 8 suspenders are all fixed on the 9 frame, the other end of the 8 suspenders is connected to 5 screens, 6 shaft-picking roller groups, 10 sieve pools are integrated, and 1 motor Transmission 2 air ducts 4 eccentric shafts 7 shaft-picking roller drive wheels, one of the shaft-picking roller groups is a driving shaft, and the other is a driven shaft, and each of 6 shaft-picking roller groups is driven by one phase. Peanuts fall from the feeding hopper, and at the same time, 2 air ducts blow off the leaves and light debris, and fall on the 5 screens and 6 shaft picking rollers, and the 10 screens on the 5 screens and 6 shaft picking rollers are integrated. , connected with 11 connecting rods, 4 eccentric shafts, 4 eccentric shafts, 5 screens, 6 shaft picking rollers, 10 sieve pools, swinging back and forth together, so that the peanuts move gradually towards the exit. During the movement, small peanuts an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com