Lightening admixture

A lightening agent and high molecular polymer technology, applied in the field of oil well cement lightening agent, can solve the problems of poor stability, easy breakage, high permeability, etc., and achieve good chemical durability, good solvent resistance, and stable chemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The most typical embodiments of the present invention are given below.

[0018] A modified polypropylene (PP) oil well cement lightening agent.

[0019] 1. Processing method: raw material: polypropylene resin (PP). Production conditions: -35°C. Additive: dilauryl thiodipropionate. Equipment: cooling device, pulverizer, grinder, sorting screen, packaging machine. The production process is: PP raw material → conveying and loading → hopper storage → feeding → cooling and embrittlement → crushing → fine grinding → sorting → inspection → storage.

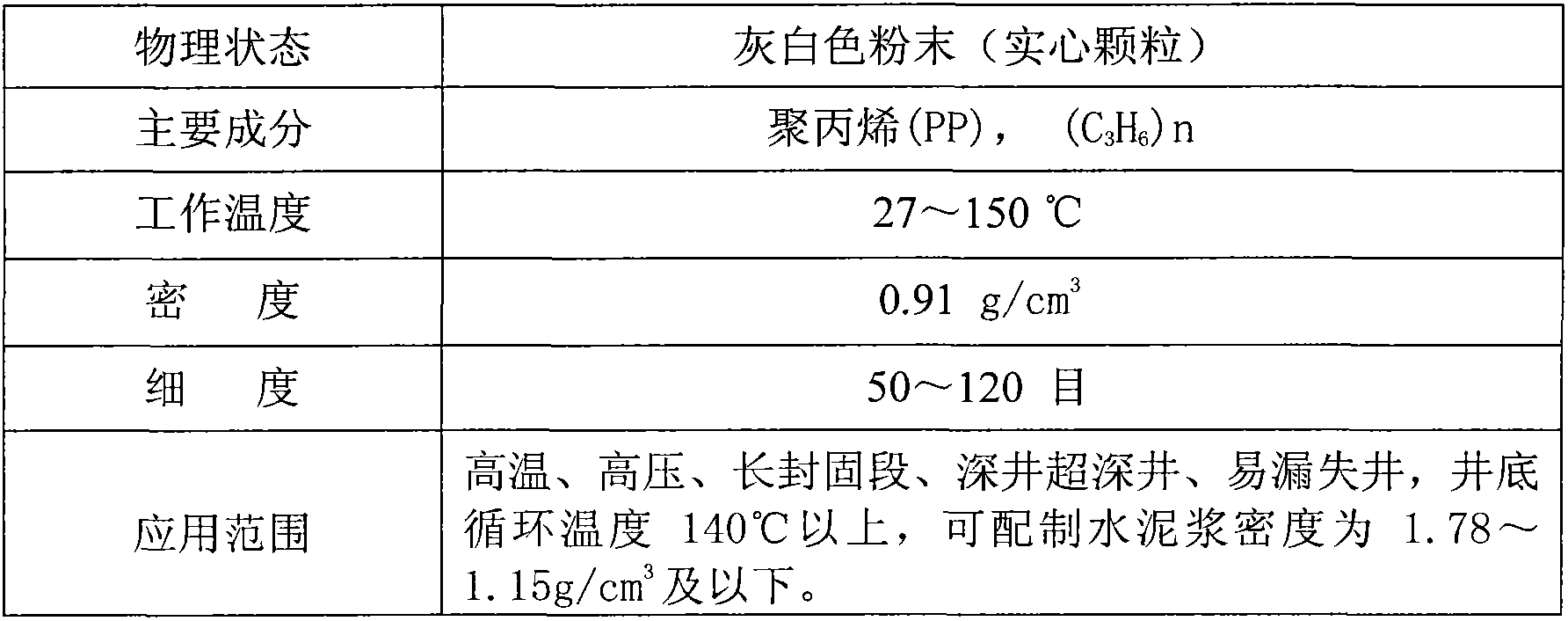

[0020] 2. Product physical and chemical properties:

[0021] Physical and chemical properties of modified PP oil well cement lightening agent

[0022] Test items

Quality Index

Exterior

No moisture compaction

Moisture %

≤0.2

Impurity %

≤0.35

Specified range

≤5

Density g / cm 3

0.91

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com