Elastic agent for well cementation, preparation method thereof and elastic isolation fluid

A technology of elastic agent and spacer fluid, which is applied in the field of petroleum drilling engineering, can solve the problems of inability to exert annular pressure, volume compensation, and easily broken particles, etc., and achieve the effects of adjustable density, wide temperature range and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

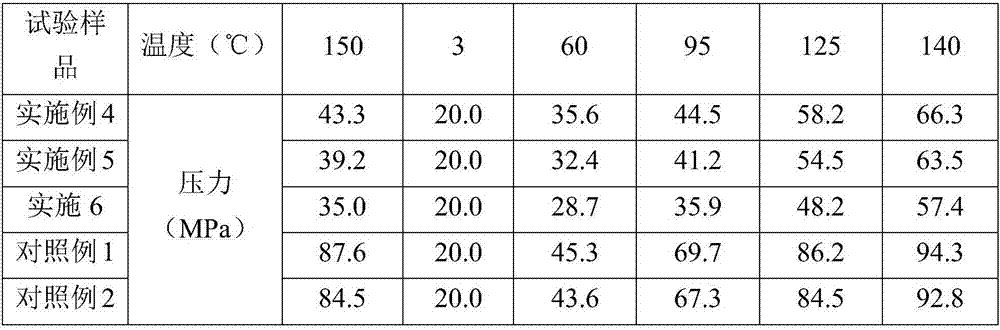

Examples

Embodiment 1

[0029] Elastomer is obtained according to the following scheme: the following are all in parts by weight,

[0030] Add 30 parts of bisphenol A, 20 parts of epichlorohydrin, 15 parts of diglycidyl ether, 2 parts of 10% sodium hydroxide solution, and 40 parts of deionized water into a closed reaction kettle in proportion. React for 4 hours, cool naturally after the reaction is complete, wash and dry with water, and obtain the shell material for preparing the hollow ball elastic agent;

[0031] Add 15 parts of diethylenetriamine, 25 parts of propylene carbonate, and 30 parts of deionized water into a closed reaction kettle in proportion, and react for 1.5 hours at 40°C, then add 20 parts of amino polyether, 15 parts of Dimethylimidazole, reacted at 70°C for 5 hours, cooled naturally after the reaction was complete, washed with water and dried to obtain a toughening agent for preparing shell materials;

[0032] Prepare 100 parts of xanthan gum solution with a viscosity of 80mPa.s...

Embodiment 2

[0034] Elastomer is obtained according to the following scheme: the following are all in parts by weight,

[0035] Add 20 parts of bisphenol A, 10 parts of epichlorohydrin, 10 parts of diglycidyl ether, 1 part of 10% sodium hydroxide solution, and 30 parts of deionized water into a closed reaction kettle in proportion. React for 5 hours, cool naturally after the reaction is complete, wash and dry with water, and obtain the shell material for preparing the hollow ball elastic agent;

[0036] Add 10 parts of diethylenetriamine, 20 parts of propylene carbonate, and 20 parts of deionized water into a closed reaction kettle in proportion, and react for 2 hours at 30°C, then add 15 parts of amino polyether, 10 parts of di Methylimidazole was reacted at 60°C for 6 hours, cooled naturally after the reaction was complete, washed with water and dried to obtain a toughening agent for preparing shell materials;

[0037] Prepare 100 parts of xanthan gum solution with a viscosity of 60mPa.s,...

Embodiment 3

[0039] Elastomer is obtained according to the following scheme: the following are all in parts by weight,

[0040] Add 35 parts of bisphenol A, 25 parts of epichlorohydrin, 20 parts of diglycidyl ether, 3 parts of 10% sodium hydroxide solution, and 50 parts of deionized water into a closed reaction kettle in proportion. React for 3 hours, cool naturally after the reaction is complete, wash and dry with water, and obtain the shell material for preparing the hollow ball elastic agent;

[0041] Add 20 parts of diethylenetriamine, 30 parts of propylene carbonate, and 40 parts of deionized water into a closed reaction kettle in proportion, and react at 50°C for 1 hour, then add 30 parts of amino polyether, 20 parts of di Methylimidazole was reacted at 80°C for 3 hours, cooled naturally after the reaction was complete, washed with water and dried to obtain a toughening agent for preparing shell materials;

[0042] Prepare 100 parts of xanthan gum solution with a viscosity of 100mPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com