Specimen preparation method for detecting subsurface damage depth of ultra-thin silicon wafer

A technology for subsurface damage and sample preparation, which is applied in the preparation of test samples, etc., can solve the problems of difficulty in obtaining the subsurface damage depth of ultra-thin silicon wafers, and achieve the effect of solving the problem of difficulty in obtaining and simple sample preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be better understood from the following examples.

[0030] The silicon wafer used in this example has a diameter of 200 mm and a thickness of 200 μm; the steel plate used is cut by a hacksaw blade; the polishing liquid used is a diamond spray polishing liquid purchased from Naibo Testing Technology (Shanghai) Co., Ltd.; the polishing machine is a double-disk desktop metallographic Grinding and polishing machine; ultrasonic cleaner KQ3200DE CNC ultrasonic cleaner.

[0031] The steps are:

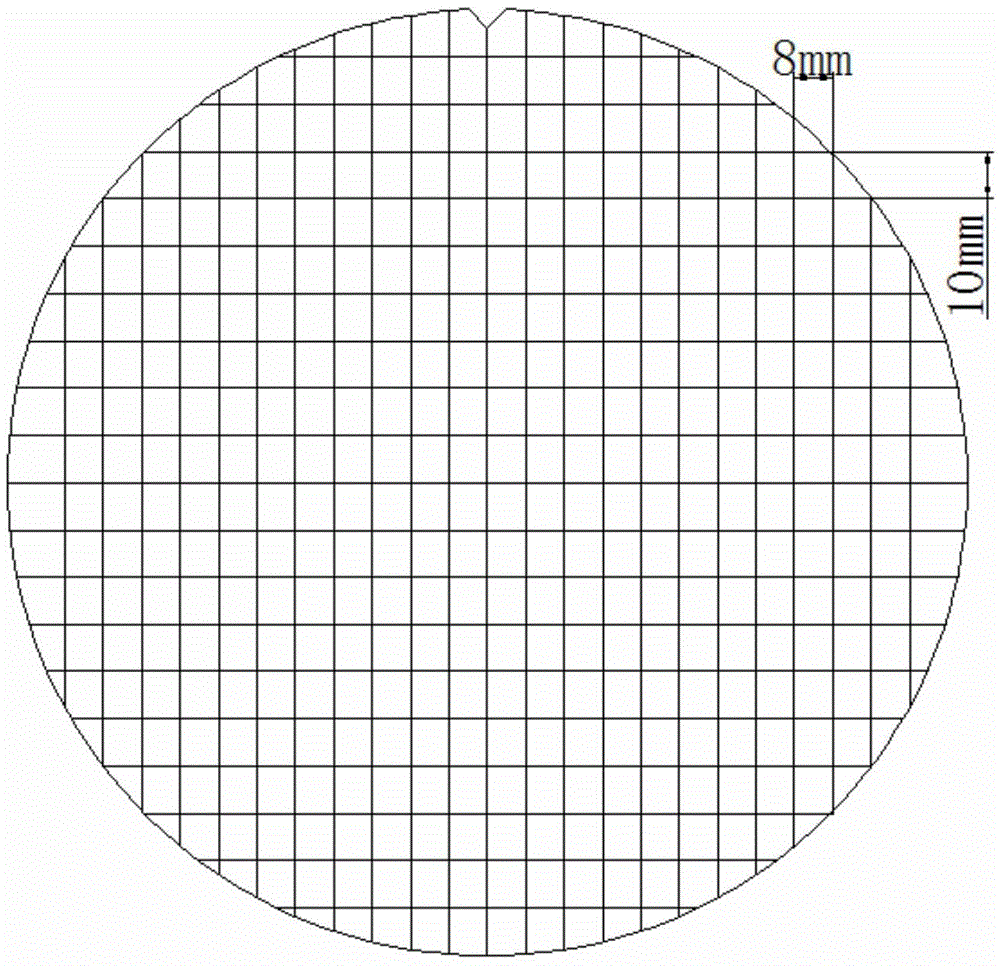

[0032] (1) Cut the entire wafer into multiple 10*8mm samples, such as figure 1 shown.

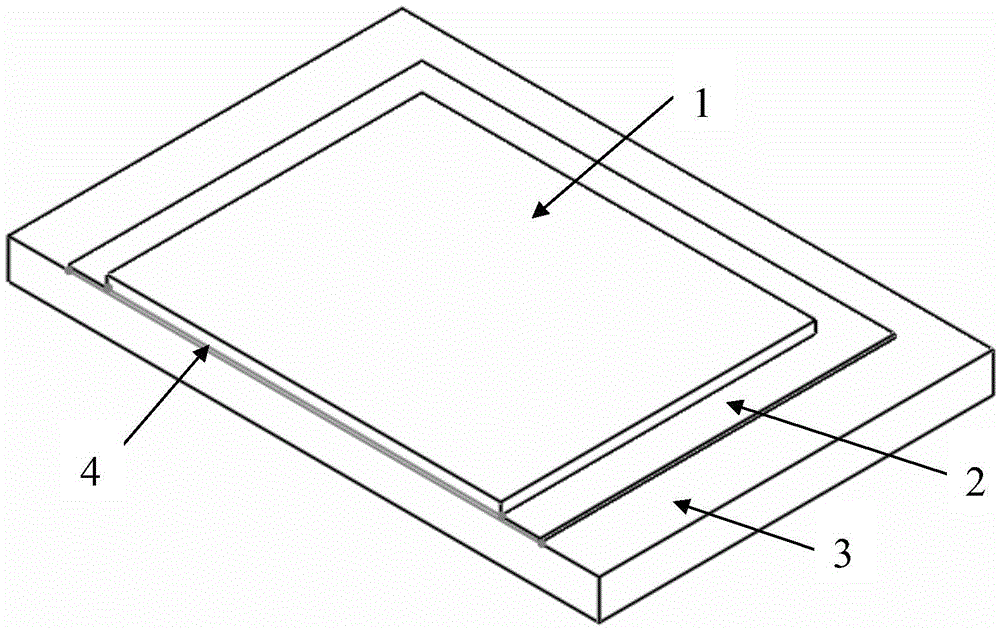

[0033] (2) Remove the sample at any position and paste it on the cut-off of the hacksaw blade. The edge of the wafer sample exceeds the edge of the steel plate, and the grinding surface of the wafer should be close to the position of the steel plate;

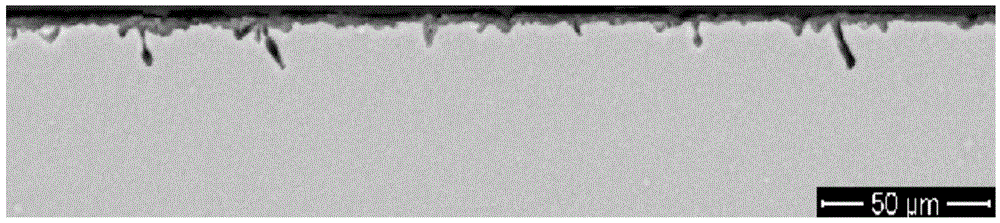

[0034] (3) Grind the pasted sample on a polishing machine with P800 sandpaper until the section to be observed is expos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com