Tube nest type micro-powder heat exchanger

A powder-granular, tube-and-tube technology, which is applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of difficult sealing of rotary heat exchangers, complex tail gas treatment equipment, and difficult maintenance , to achieve the effect of convenient heat exchange time, no auxiliary equipment, and low maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

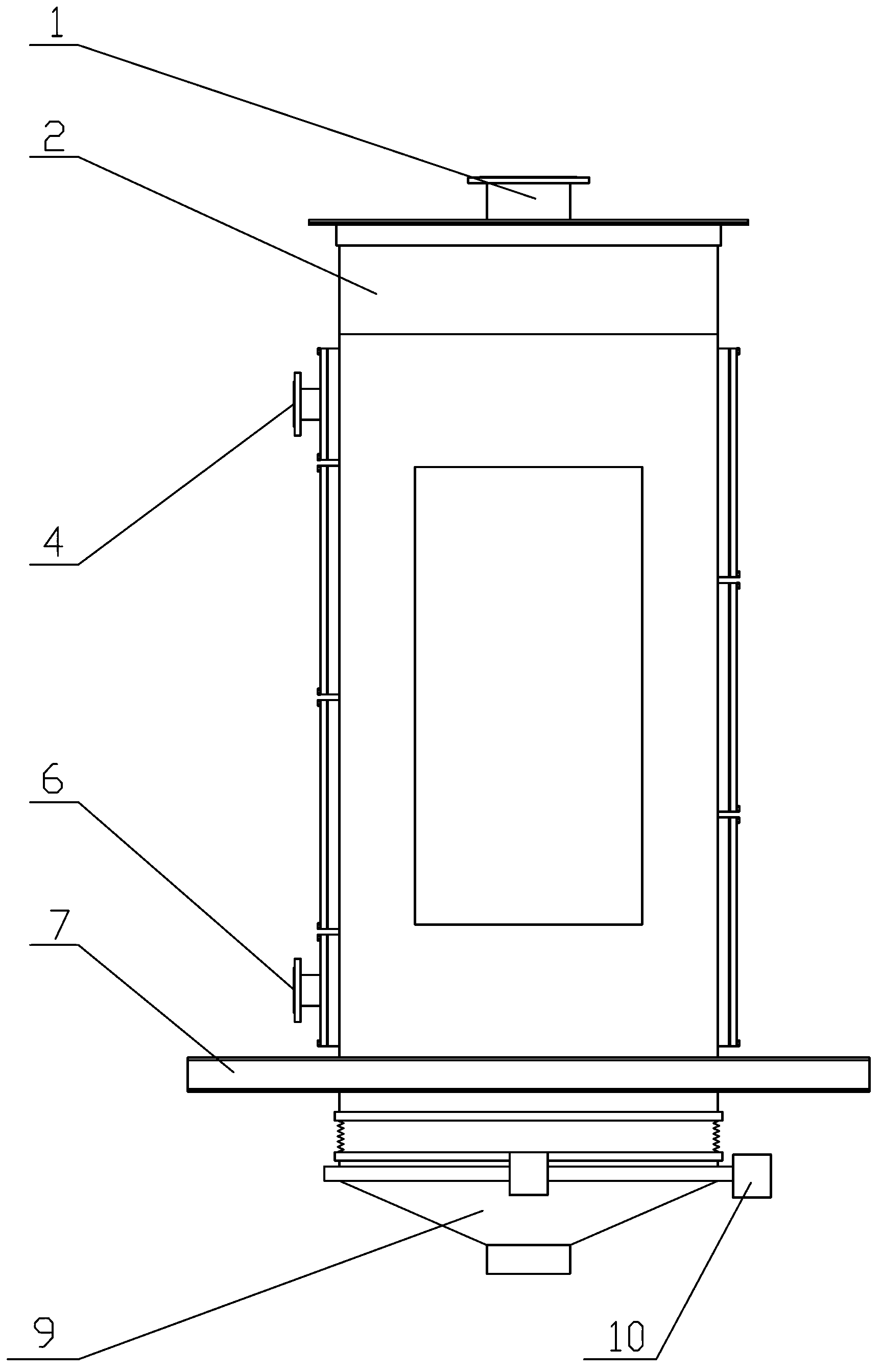

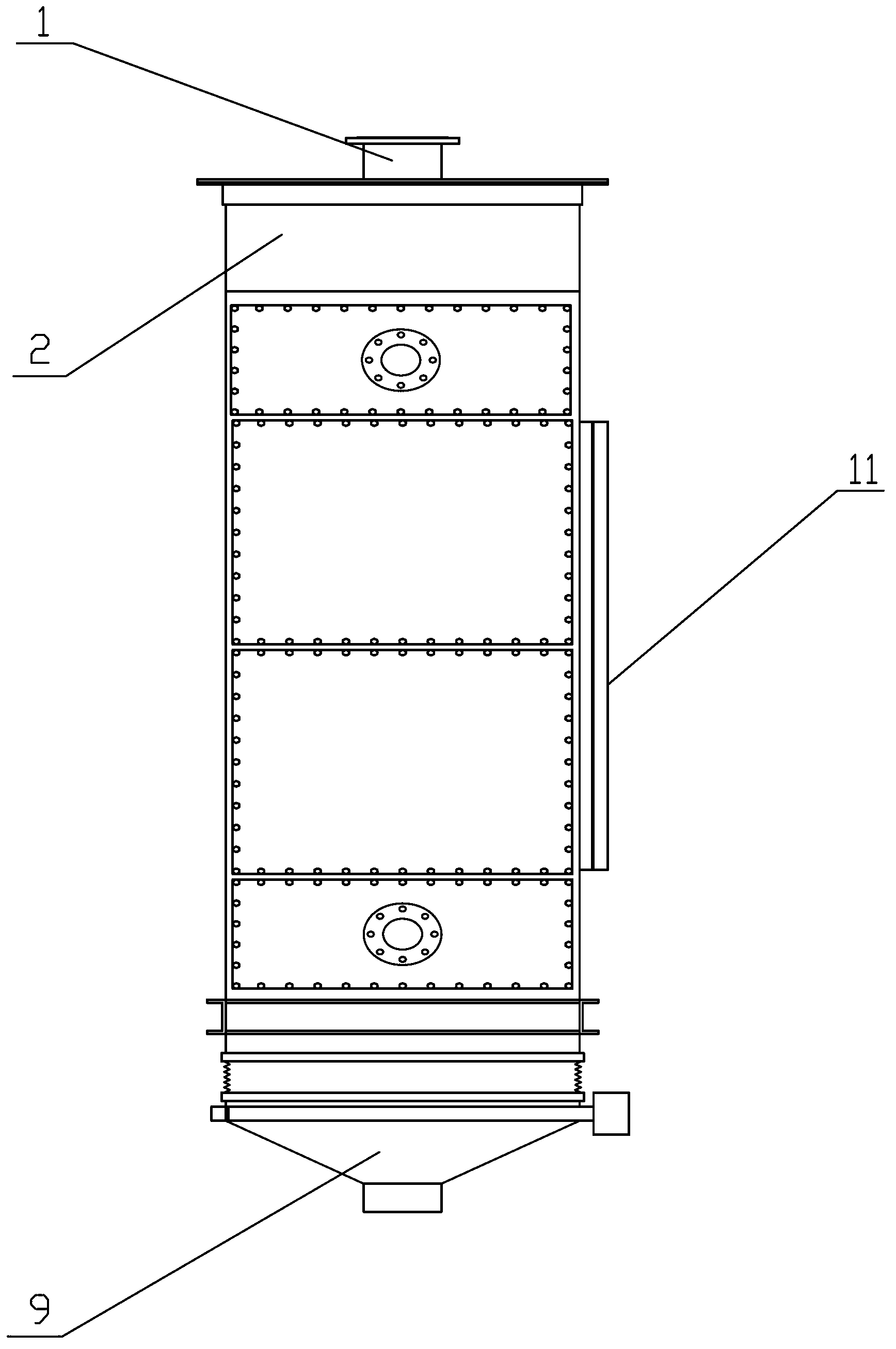

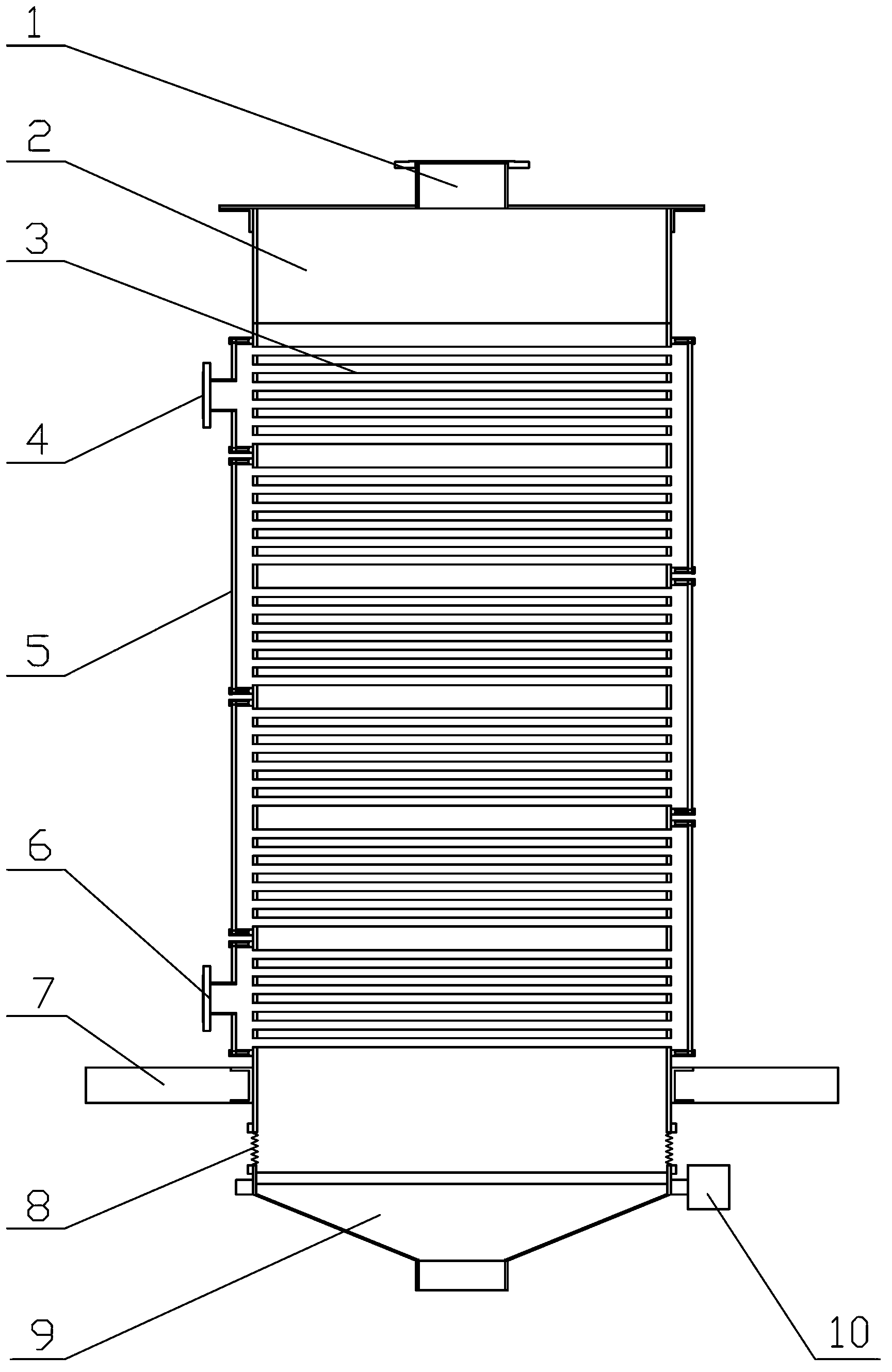

[0033] Such as Figure 1 to Figure 6 As shown, a tube-and-tube powder heat exchanger includes a feed box 2 and a heat exchange box 5, the feed box 2 is arranged at the upper end of the heat exchange box 5, and the lower end of the heat exchange box 5 is provided with a discharge hopper 9 There is a vibration motor 10 outside the discharge hopper 9. After the vibration motor 10 is started, the heat exchange box 5 can be properly vibrated to facilitate the sufficient heat exchange of materials in the heat exchange box 5 and protect the heat exchange tube 3 at the same time. Function (to prevent the heat exchange tube 3 from being in contact with high-temperature materials for too long, which will reduce the service life of the heat exchange tube 3 due to damage); the vibration motor 10 can conveniently control the heat exchange time of the material in the heat exchange box 5, and then control the discharge temperature.

[0034] Such as figure 2 , image 3 , Figure 4 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com