Photovoltaic module and manufacturing method thereof

A photovoltaic module and tempered glass technology, applied in the field of solar photovoltaic power generation, can solve the problems of restricting the application of photovoltaic modules, increasing the scrap rate, cumbersome operation, etc., and achieve the effects of saving transportation costs, increasing yield, and close electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a photovoltaic module, comprising:

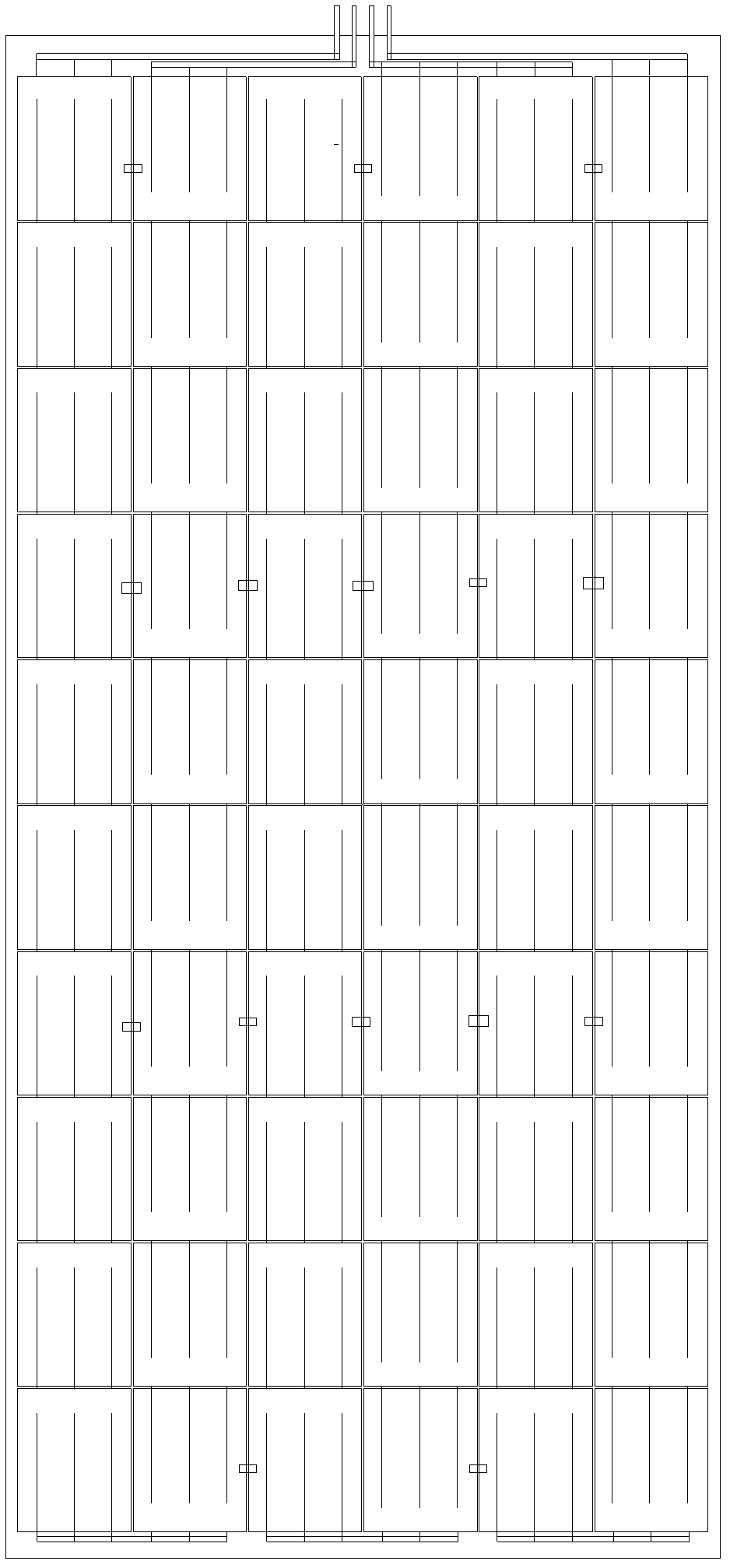

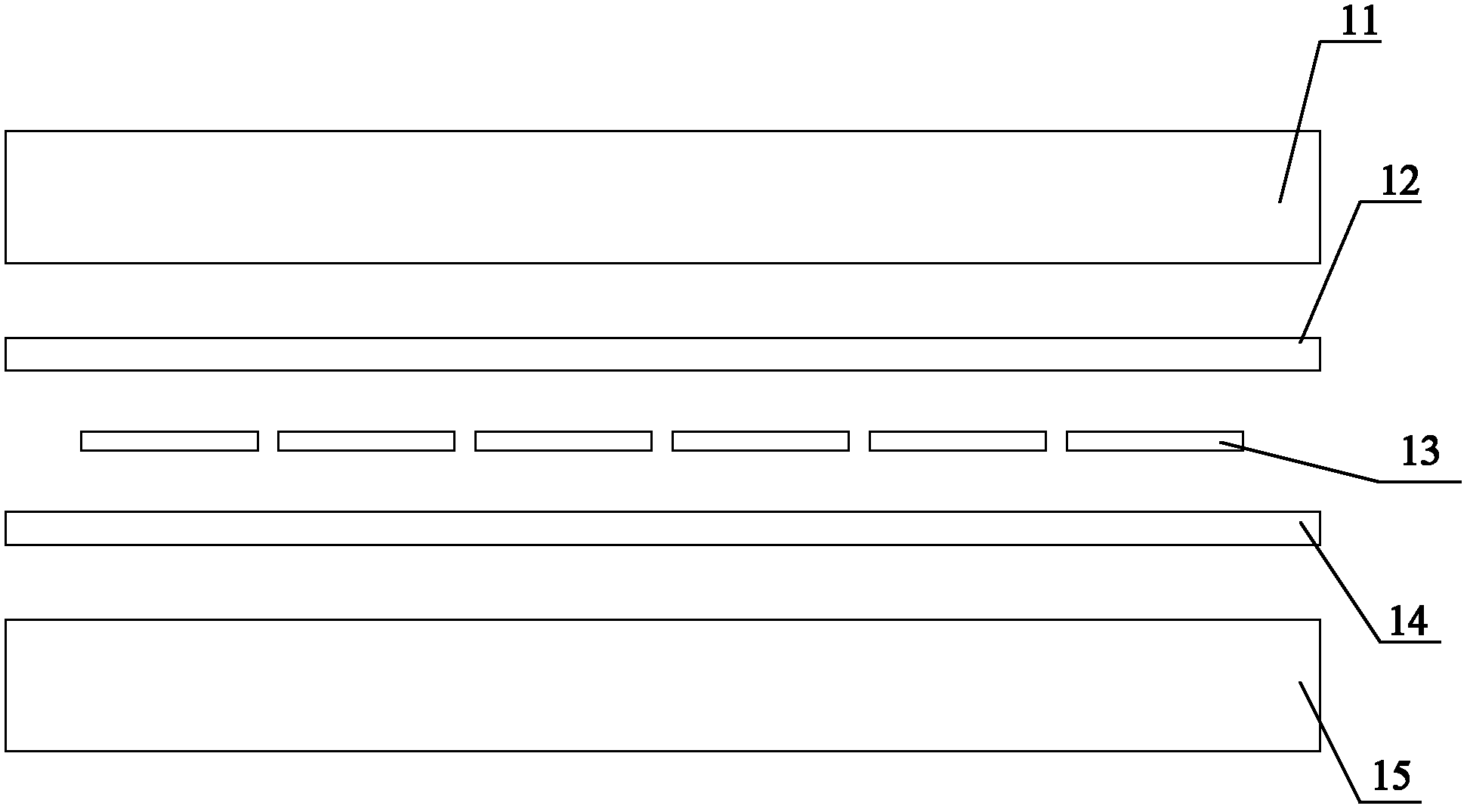

[0036] a) Laminate the toughened glass backplane, adhesive film, battery sheet, surface adhesive film, and tempered glass panel in sequence at 140°C to 160°C to obtain a substrate; the tempered glass panel and tempered glass backplane The thickness is 2mm;

[0037] b) Coating butyl glue or silica gel on the side of the substrate, or adhering adhesive tape on the side of the substrate to obtain a photovoltaic module.

[0038]Step a is the process of preparing the substrate. Since the back and the panel of the photovoltaic module are made of 2mm thick tempered glass, the 2mm thick glass is lighter in weight, and the air between the glass and the adhesive film is easy to With complete extraction, there is no need for an autoclave anymore. This step can specifically be as follows: sequentially stack the tempered glass backplane, adhesive film, battery sheet, surface adhesive fi...

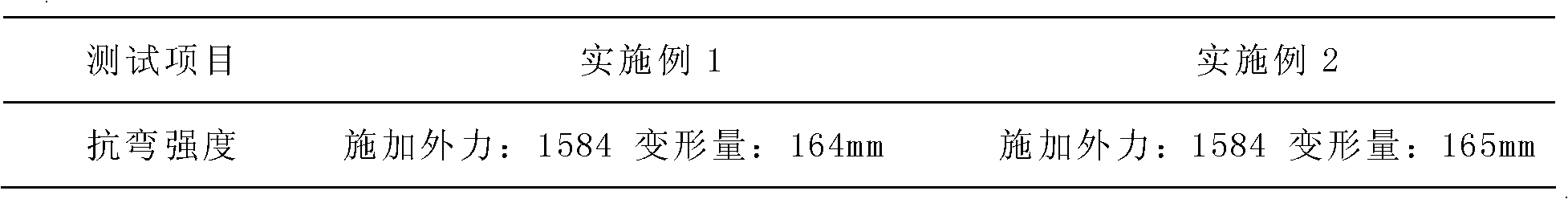

Embodiment 1

[0047] 1. Stack the 2mm thick tempered glass backplane, 0.5mm thick EVA film, battery sheet, 0.5mm EVA film, and 2mm tempered glass panel in sequence in the laminator, set the lamination temperature to 150°C, and vacuum for 6 minutes. Set the pressure of the first stage to 40Kpa, and the lamination time of the first stage is 1 minute and 30 seconds; set the pressure of the second stage to 20Kpa, and the lamination time of the second stage is 1 minute and 30 seconds; reduce the pressure to zero, and release the pressure for 7 Minutes to get the substrate.

[0048] 2. Use a gluing machine to apply butyl glue on the side of the substrate to obtain a photovoltaic module.

Embodiment 2

[0050] 1. Stack the 2mm thick tempered glass backplane, 0.38mm thick EVA film, battery sheet, 0.38mm EVA film, and 2mm tempered glass panel in sequence in the laminator, set the lamination temperature to 145°C, and vacuum for 7 minutes. Set the pressure of the first stage to 35Kpa, and the lamination time of the first stage is 2 minutes; set the pressure of the second stage to 15Kpa, and the lamination time of the second stage is 2 minutes and 30 seconds; reduce the pressure to zero, release the pressure for 8 minutes, Get the substrate.

[0051] 2. Use a gluing machine to apply silicone on the side of the substrate to obtain a photovoltaic module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com