Preparation method of spherical alpha-aluminum oxide powder

A technology of alumina powder and aluminum hydroxide, which is applied in the preparation of alumina/hydroxide, chemical instruments and methods, inorganic chemistry, etc. And thermal conductivity and other issues, to achieve the effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] S1, take 2040g of aluminum isopropoxide, add 2040g of deionized water, use nitric acid to adjust the pH of the mixture to 4, pour it into a flask and stir in a water bath to heat, control the temperature at 80°C for 2 hours, vacuumize to remove isopropanol to obtain hydrogen oxidation Aluminum aluminum sol;

[0024] S2, pour the obtained aluminum sol into 2040g of cyclohexane, stir at a high speed of 500rpm, add 40g of Span 80 and continue stirring for 30min, then add 204g of ammonia water with a concentration of 14%, to obtain spherical aluminum hydroxide sol particles ; The aluminum hydroxide sol particles are centrifuged and dried in vacuum to obtain spherical aluminum hydroxide sol powder;

[0025] S4, input the dried powder into a vertical high-temperature furnace, and keep it at 1200° C. for 180 minutes, so as to obtain high-purity spherical α-alumina powder.

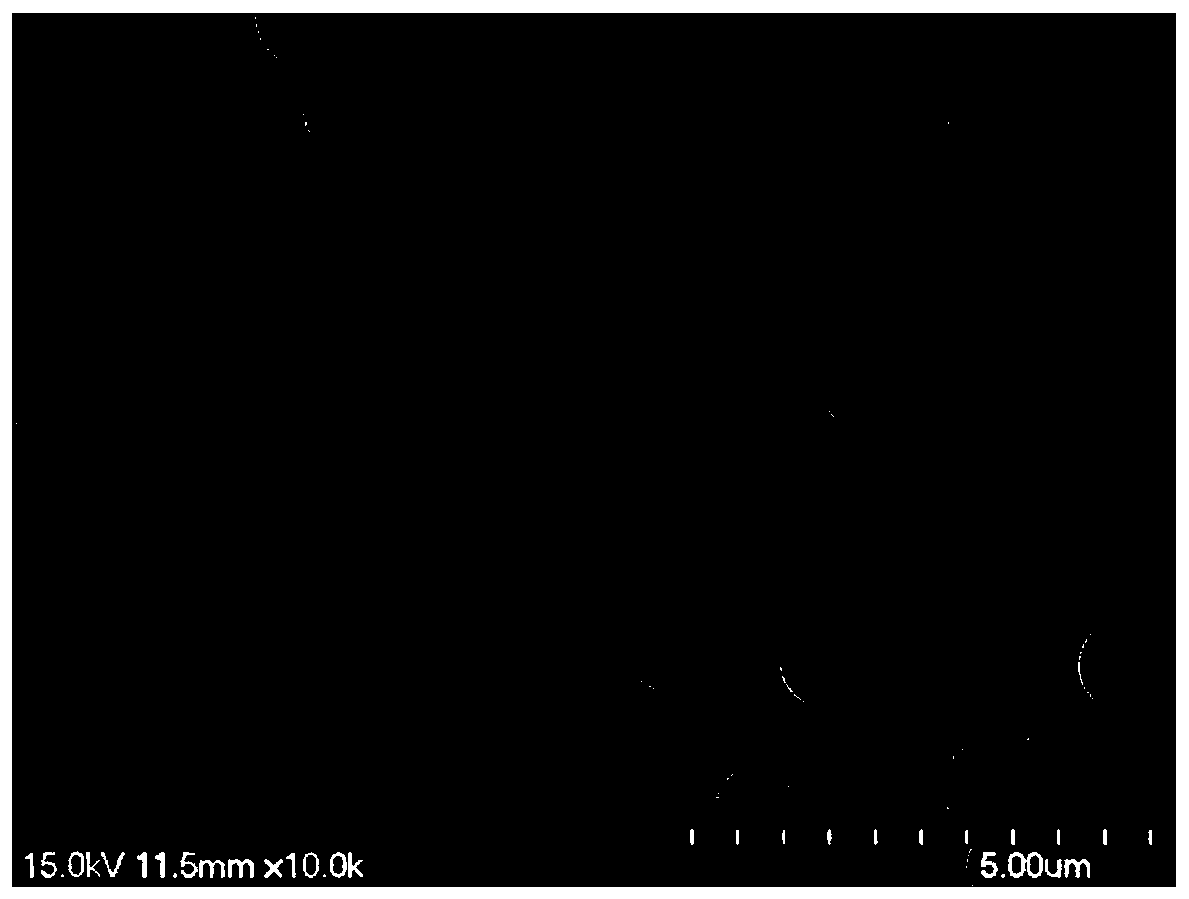

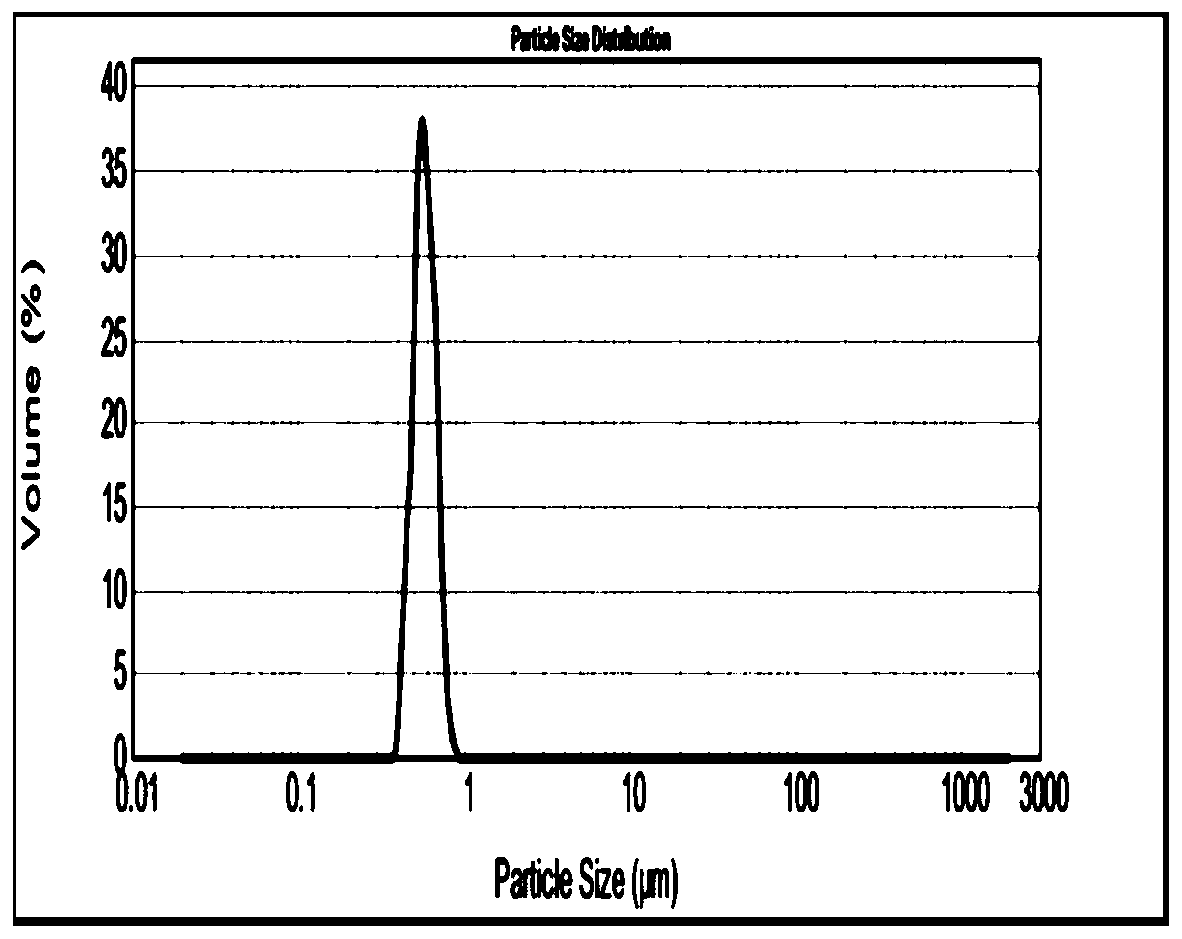

[0026] Such as figure 1 with figure 2 As shown, the obtained spherical α-alumina powder has a partic...

Embodiment 2

[0028] S1, take 2040g of aluminum isopropoxide, add 2040g of deionized water, use nitric acid to adjust the pH of the mixture to 4, pour it into a flask and stir in a water bath to heat, control the temperature at 80°C for 2 hours, vacuumize to remove isopropanol to obtain hydrogen oxidation Aluminum aluminum sol;

[0029] S2, pour the obtained aluminum sol into 2040g of cyclohexane, stir at a high speed of 200rpm, add 40g of Tween and continue to stir for 30min, then add 204g of ammonia water with a concentration of 14%, to obtain spheroidized aluminum hydroxide sol particles; The aluminum hydroxide sol particles are centrifuged and dried in vacuum to obtain spherical aluminum hydroxide sol powder;

[0030] S4, input the dried powder into a vertical high-temperature furnace, and keep it at 1300° C. for 120 minutes, so as to obtain high-purity spherical α-alumina powder.

[0031] The prepared spherical α-alumina powder has a particle size of D50=2.5 μm, uniform distribution...

Embodiment 3

[0033] S1, take 2040g of aluminum isopropoxide, add 2040g of deionized water, use nitric acid to adjust the pH of the mixture to 4, pour it into a flask and stir in a water bath to heat, control the temperature at 80°C for 2 hours, vacuumize to remove isopropanol to obtain hydrogen oxidation Aluminum aluminum sol;

[0034] S2, pour the obtained aluminum sol into 2040g of cyclohexane, stir at a high speed of 150rpm, add 40g of Span 80 and continue stirring for 30min, then add 204g of ammonia water with a concentration of 14%, to obtain spherical aluminum hydroxide sol particles ; The aluminum hydroxide sol particles are centrifuged and dried in vacuum to obtain spherical aluminum hydroxide sol powder;

[0035] S4, input the dried powder into a vertical high-temperature furnace, and keep it at 1300° C. for 60 minutes, so as to obtain high-purity spherical α-alumina powder.

[0036] The prepared spherical α-alumina powder has a particle size of D50=5 μm, uniform distribution, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com