Process for producing cross-linked polymer microsphere with even grain diameter

A cross-linked polymer and uniform technology, applied in the field of preparation of cross-linked polymer microspheres with uniform particle size, can solve difficulties and other problems, and achieve the effect of smooth surface and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] The reaction vessel uses a 250mL four-neck flask with PTFE stirring, and condensed water is passed through, and the N 2 Protection, insert the thermometer. Use a water bath to heat.

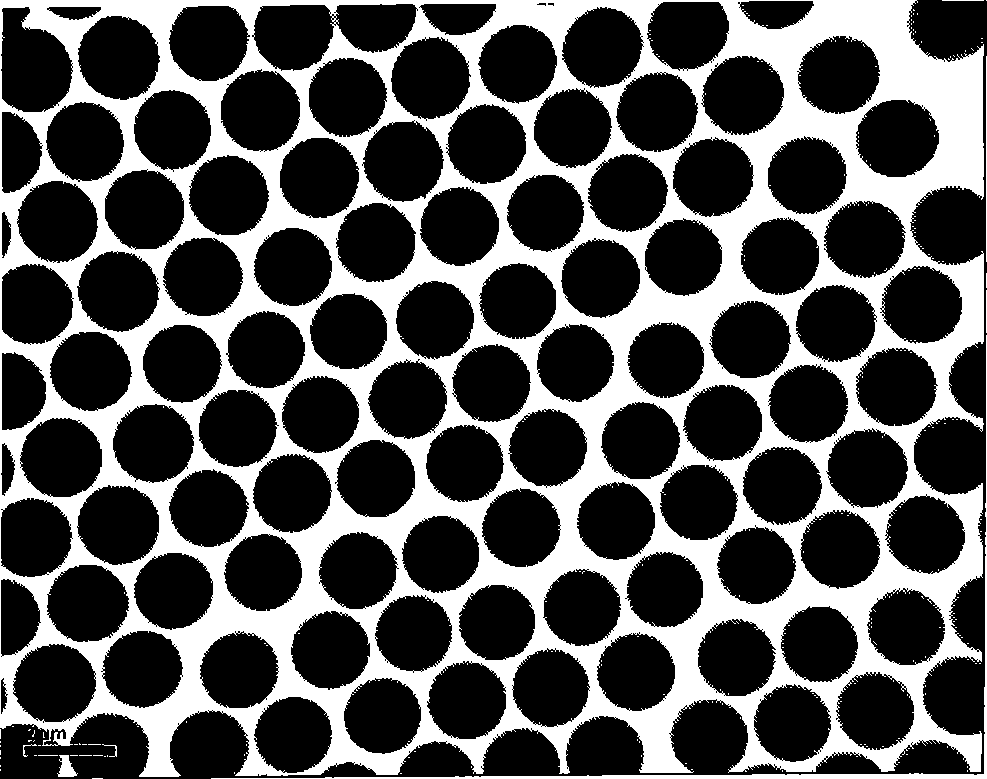

[0027] Styrene: 10 g; Trimethylolpropane triacrylate 0.6 g; PVPK30: 0.8 g; AIBN: 0.1 g; Ethanol: 120 g. Will N 2 Insert the inlet under the liquid phase, replace the air for 1h, and then continue to pass N through the gas phase 2 . The temperature was raised to 70°C, the stirring speed was 80rpm, and the polymerization was carried out for 24h. Wash three times with ethanol, filter under reduced pressure, and dry the product in vacuum. The obtained polymer microspheres had a particle size of 1.6 μm and were left at 180° C. for 5 minutes without deformation. microsphere TEM see figure 1 .

example 2

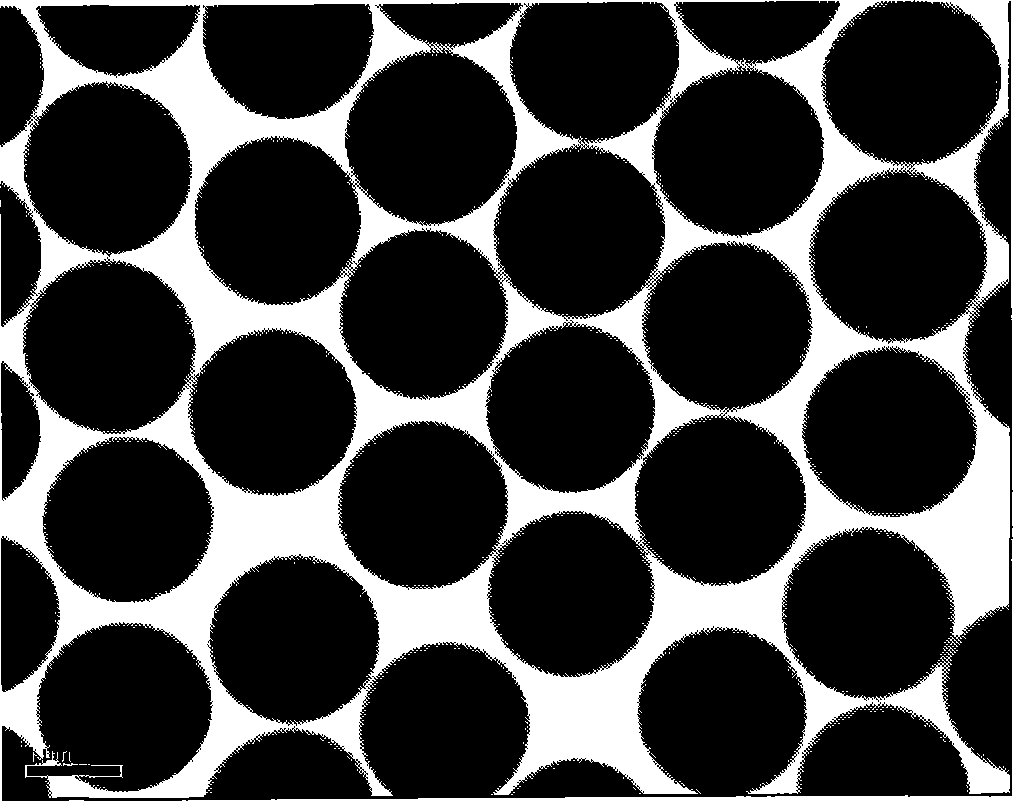

[0029] The reaction vessel uses a 250mL four-neck flask with PTFE stirring, and condensed water is passed through, and the N 2 Protection, insert the thermometer. Use a water bath to heat. Styrene: 10 g; glycidyl methacrylate: 0.5 g; PVPK30: 0.8 g; AIBN: 0.1 g; ethanol: 120 g; ethylene glycol monomethyl ether: 10 g. Will N 2 Insert the inlet under the liquid phase, replace the air for 1h, and then continue to pass N through the gas phase 2 . The temperature was raised to 65°C, the stirring speed was 60rpm, and the polymerization was carried out for 20h. Wash three times with ethanol, filter under reduced pressure, and dry the product in vacuum. The obtained polymer microspheres had a particle size of 1.7 μm and were left at 180° C. for 5 minutes without deformation. microsphere TEM see figure 2 .

example 3

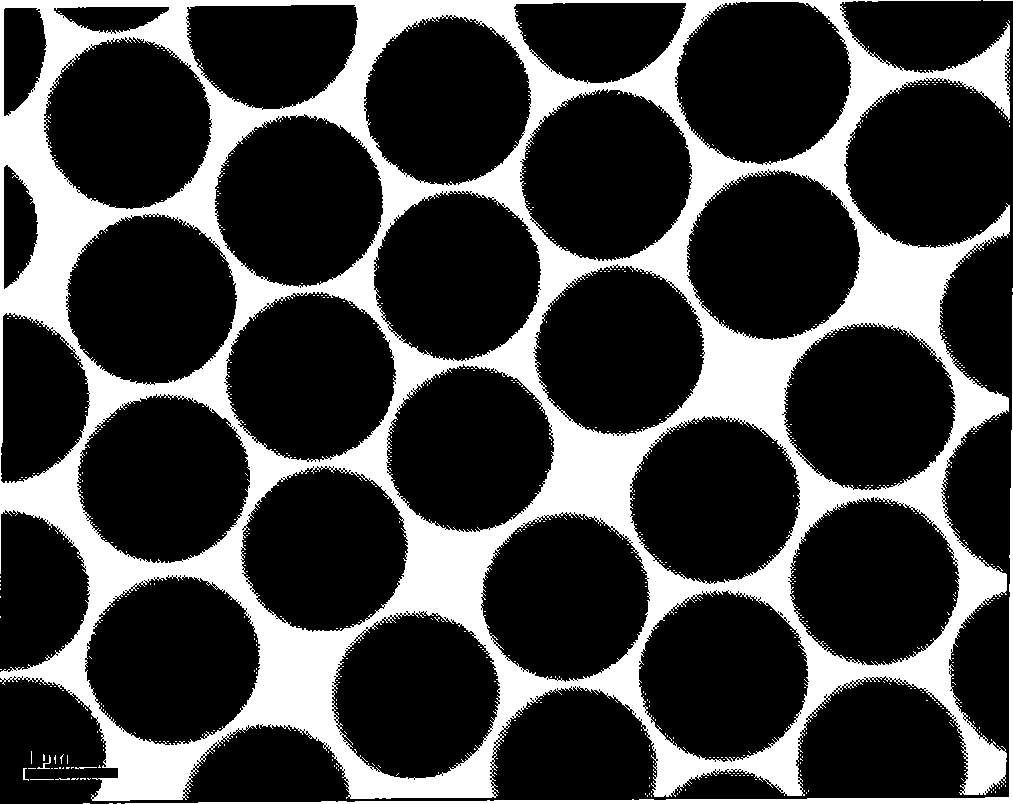

[0031] The reaction vessel uses a 250mL four-neck flask with PTFE stirring, and condensed water is passed through, and the N 2 Protection, insert the thermometer. Use a water bath to heat. Styrene: 10 g; Dipentaerythritol hexapropylene 0.6 g; PVPK30: 0.8 g; AIBN: 0.1 g; Ethanol: 120. Will N 2 Insert the inlet below the liquid level to replace the air for 1h, then lift the gas phase and continue to pass N 2 . The temperature was raised to 75°C, the stirring speed was 80rpm, and the polymerization was carried out for 22h. Wash three times with ethanol, filter under reduced pressure, and dry the product in vacuum. The obtained polymer microspheres had a particle size of 1.65 μm and were left at 180° C. for 5 minutes without deformation. microsphere TEM see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com