Low-cost NH3-SCR denitration catalyst and preparing method thereof

A technology of NH3-SCR and denitrification catalyst, applied in the field of catalysis, can solve the problems of high production cost, achieve low cost, suppress sublimation, and enhance the effect of sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

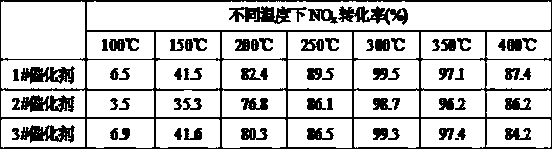

Examples

Embodiment 1

[0028] 1) Pretreatment of honeycomb stone: After crushing the honeycomb stone, sieve the 100~120 mesh sample, disperse it in the nitric acid solution with a pH value of 4, treat it under the stirring condition of 500r / min at room temperature for 30min, and then wash it Until the pH value of the filtrate is close to neutral, dry the product at 105°C for 12 hours; wherein the mass volume ratio of honeycomb to nitric acid solution is 10g / 100mL;

[0029] 2) Surface modification of honeycomb: Dissolve CTAB and PVA in deionized water, stir at room temperature for 30 minutes, then add NaOH and continue stirring for 10 minutes, then add tetraethyl orthosilicate (TEOS) and titanium dropwise tetrabutyl ester (TBT), and the pretreated honeycomb obtained in step 1) was added to it, and then the stirring was continued for 3 hours, and the resulting mixture was transferred to a hydrothermal reaction kettle for crystallization treatment at 120°C for 18 hours, and the obtained The precipitate...

Embodiment 2

[0032] 1) Pretreatment of honeycomb stone: crush the honeycomb stone and sieve the 100~120 mesh sample, disperse it in the nitric acid solution with a pH value of 4, treat it under the stirring condition of 300r / min at room temperature for 40min, and then wash it Until the pH value of the filtrate is close to neutral, dry the product at 100°C for 15 hours; wherein the mass volume ratio of honeycomb to nitric acid solution is 20g / 100mL;

[0033] 2) Surface modification of honeycomb: Dissolve CTAB and PVA in deionized water, stir at room temperature for 25 minutes, then add NaOH and continue stirring for 10 minutes, then add tetraethyl orthosilicate (TEOS) and titanium dropwise Add tetrabutyl ester (TBT) to it, and add the pretreated honeycomb obtained in step (1), then continue to stir for 3 hours, and transfer the resulting mixture to a hydrothermal reaction kettle for crystallization treatment at 115°C for 20 hours; Wash the obtained precipitate with deionized water to neutra...

Embodiment 3

[0036] 1) Pretreatment of honeycomb stone: After crushing the honeycomb stone, sieve the 100~120 mesh sample, disperse it in the nitric acid solution with a pH value of 4, treat it under the stirring condition of 400r / min at room temperature for 20min, and then wash it Until the pH value of the filtrate is close to neutral, dry the product at 110°C for 10 hours; wherein the mass volume ratio of honeycomb stone to nitric acid solution is 15g / 100mL;

[0037] 2) Surface modification of honeycomb: Dissolve CTAB and PVA in deionized water, stir at room temperature for 35 minutes, then add NaOH and continue stirring for 10 minutes, then add tetraethyl orthosilicate (TEOS) and titanium dropwise tetrabutyl ester (TBT), and the pretreated honeycomb obtained in step (1) was added to it, and then the stirring was continued for 4 hours, and the resulting mixture was transferred to a hydrothermal reaction kettle for crystallization treatment at 125°C for 15 hours; The precipitate was washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com