Spherical activated carbon ozone catalyst with high alkalinity on surface and application of spherical activated carbon ozone catalyst

A technology of surfactants and catalysts, applied in physical/chemical process catalysts, oxidized water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high preparation cost, long time-consuming, complicated preparation process, etc., and achieve simple preparation method , good stability and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

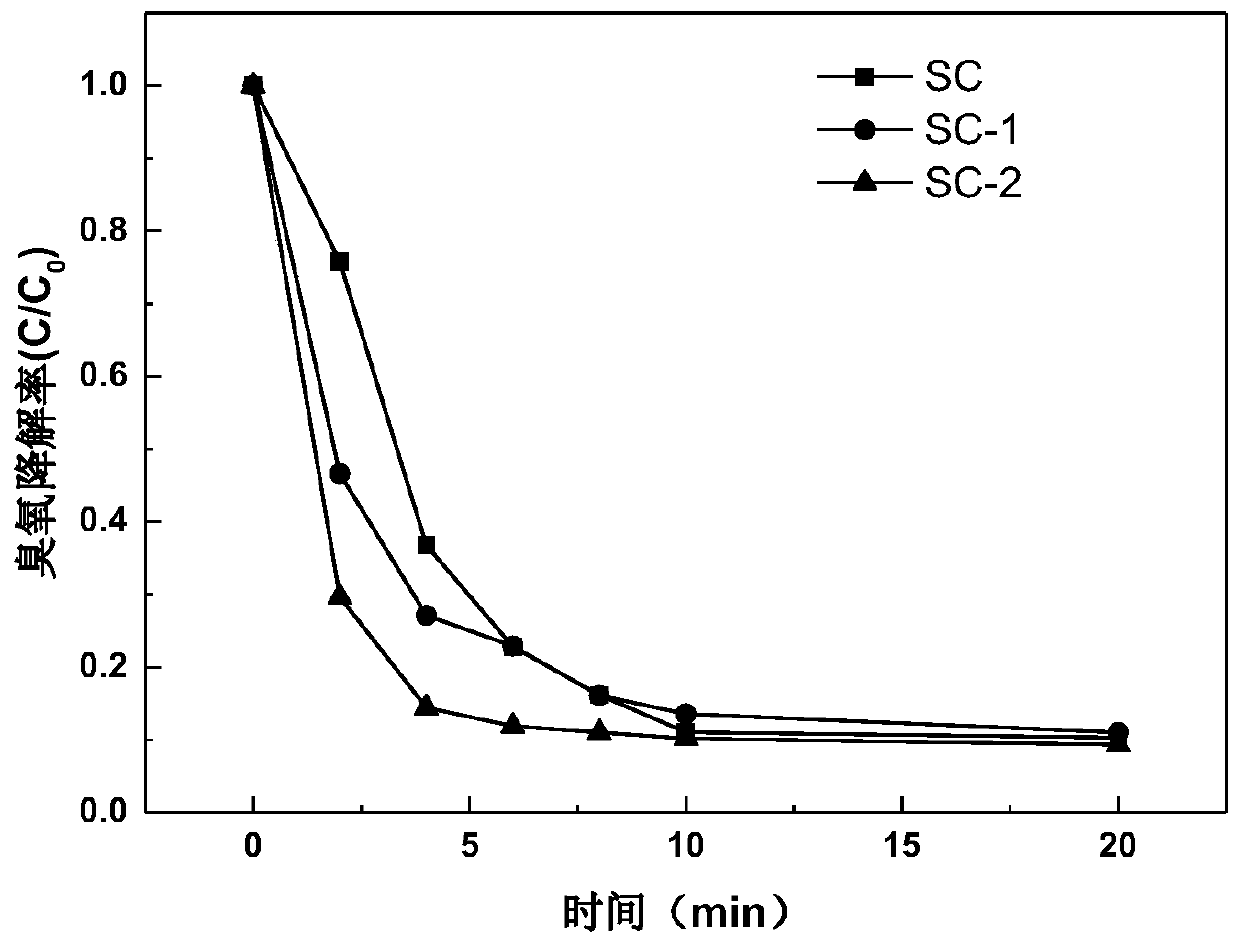

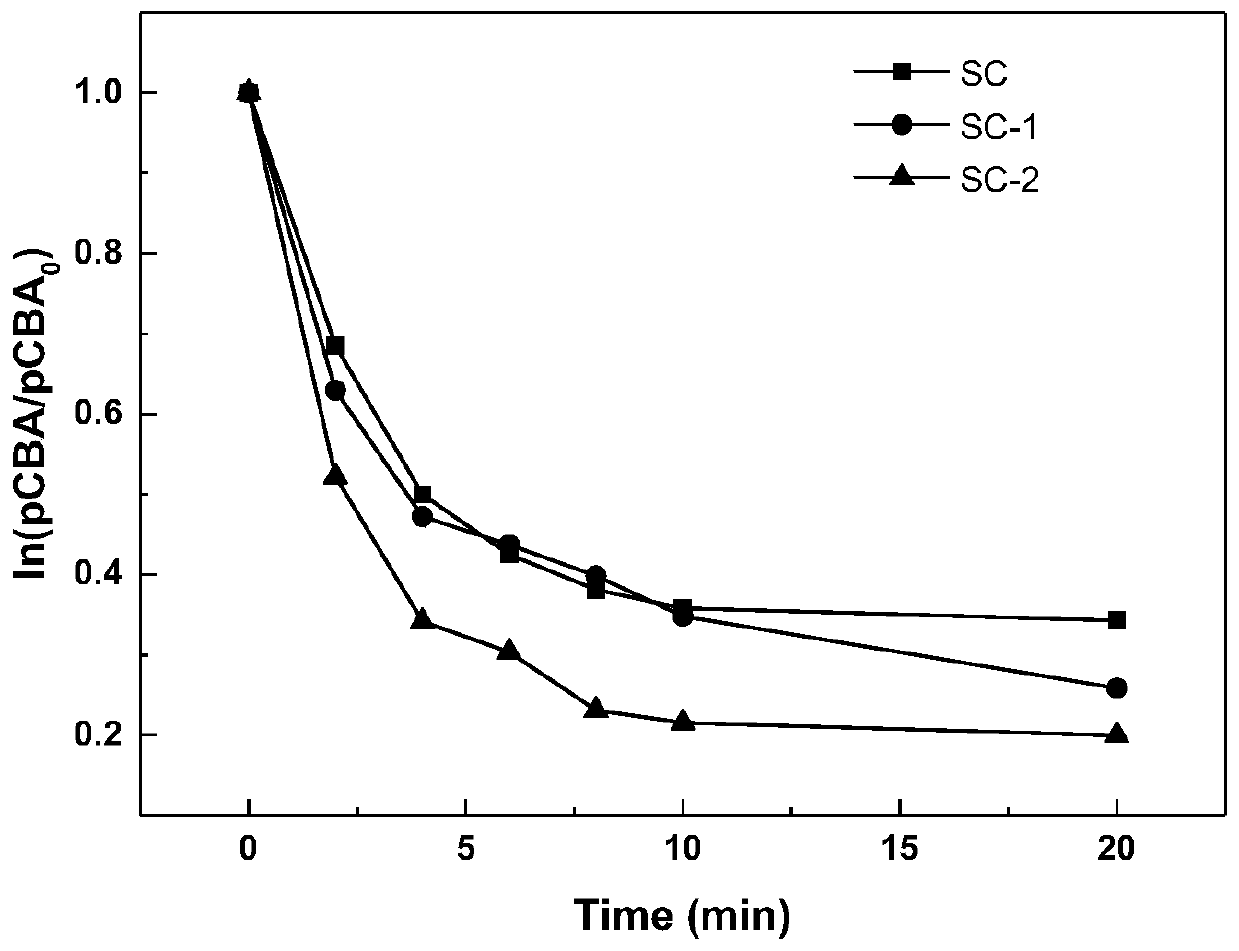

Embodiment 1

[0040] Add 1g of anhydrous aluminum chloride and 1g of sulfur to 100g of petroleum pitch with a softening point of 40°C and 0% toluene insoluble matter. Stir at 250°C for 3 hours under a nitrogen atmosphere. The intermediate pitch is obtained after cooling down. Then pour the intermediate bitumen into a reaction kettle, add 1000ml of water and 2g of sodium alginate, stir at 150°C to suspend into balls. Subsequently, the ball was rapidly heat-treated at 400° C. for 30 min in an air atmosphere to obtain non-melting balls. Then in the activation furnace, under the steam atmosphere, at 10 ~ 20 ℃ min -1 The heating rate was increased to 1000 °C and maintained for 1 h. Finally, the mesoporous spherical activated carbon catalyst SC was obtained.

Embodiment 2

[0042] Get the mesoporous spherical activated carbon catalyst 3g among the embodiment 1, add the NaOH solution of 40ml 5mol / L. Stir at a constant temperature of 70°C for 4 hours, adjust the temperature to 35°C and stir for 24 hours. The activated carbon was fished out and washed with distilled water until the pH remained constant. Dry in a vacuum oven for 12 hours to obtain a surface highly basic spherical activated carbon catalyst SC-1.

Embodiment 3

[0044] Get the mesoporous spherical activated carbon catalyst 3g among the embodiment 1, add the NaOH solution of 40ml 10mol / L. Stir at a constant temperature of 70°C for 4 hours, adjust the temperature to 35°C and stir for 24 hours. The activated carbon was fished out and washed with distilled water until the pH remained constant. Dry in a vacuum oven for 12 hours to obtain a surface highly basic spherical activated carbon catalyst SC-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com