Ultrasonic defluorination method for whole euphausia superba

An Antarctic krill, ultrasonic technology, applied in food ultrasonic treatment, food preparation, food science, etc., can solve the problems of destroying the appearance, texture, flavor of whole Antarctic krill, limiting the scope of application, small Antarctic krill, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

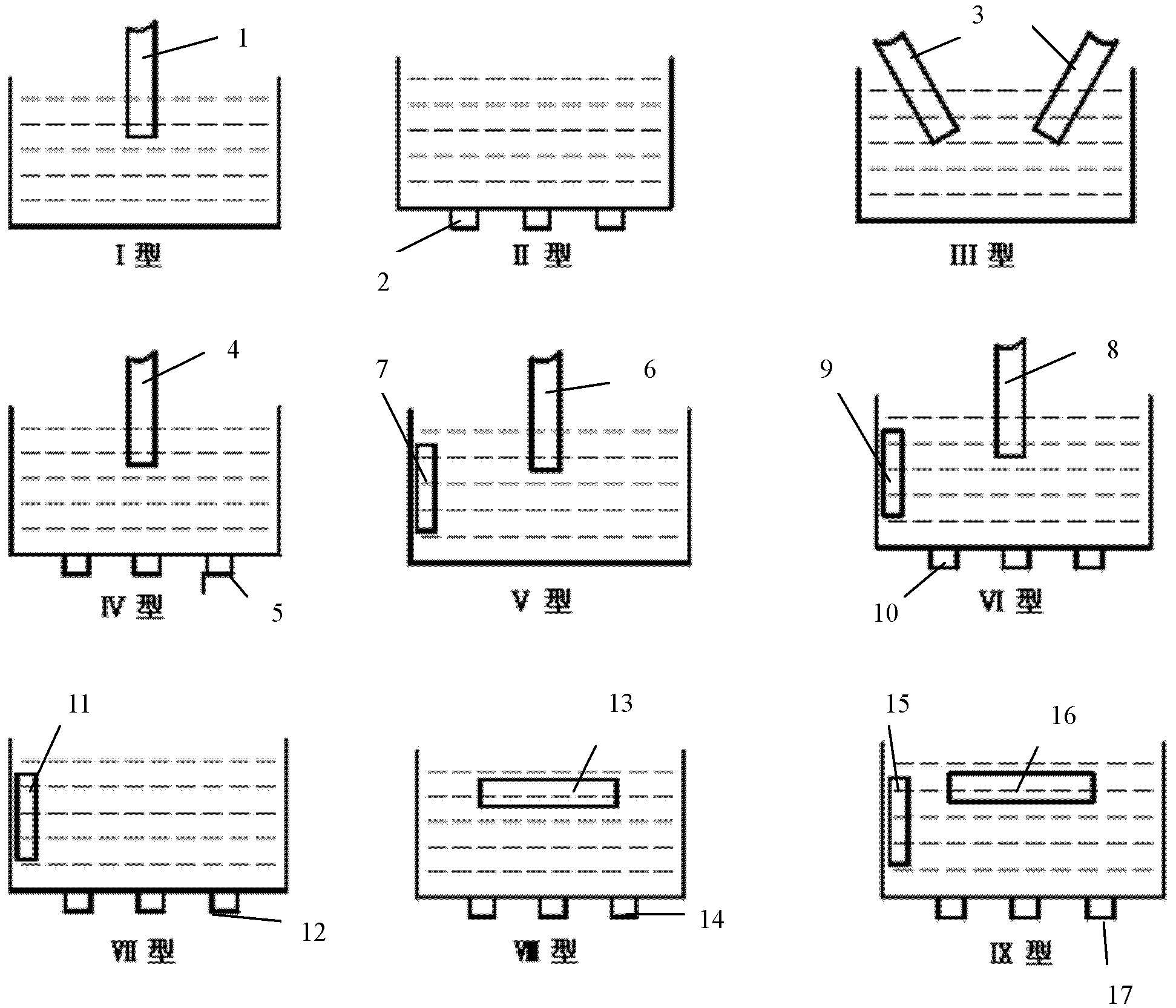

Method used

Image

Examples

Embodiment 1

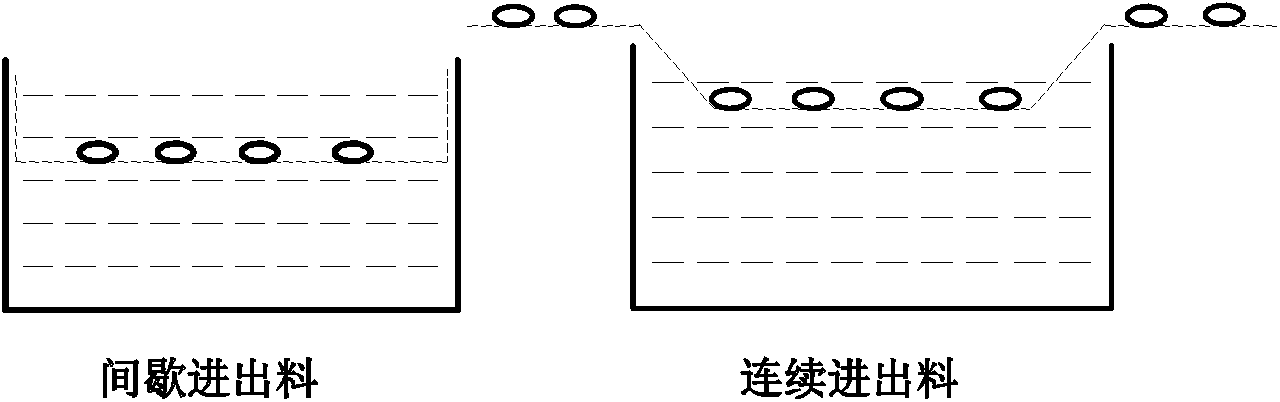

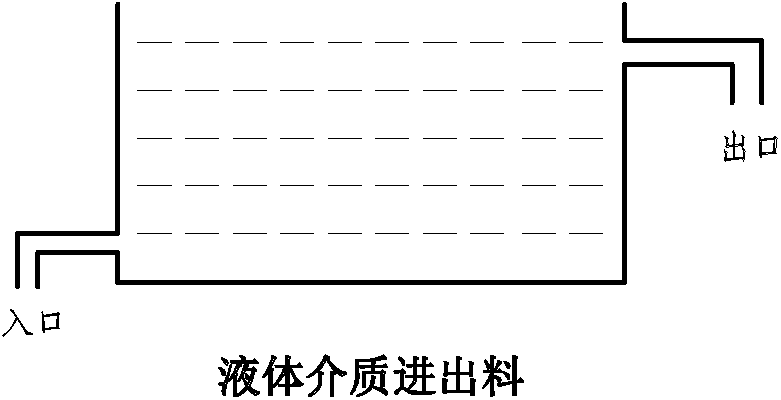

[0068] Take the frozen Antarctic krill whole shrimp, thaw naturally in the refrigerator, weigh 10g of Antarctic krill and put it in a 200ml beaker, add 150ml of deionized water according to the material-to-liquid ratio of 1:15, and use the I-type ultrasonic combination device for defluorination Sonicate and change the medium every 6 minutes. Ultrasonic treatment conditions: A is the energy-concentrating horn probe, the probe diameter is 1cm, the depth of the probe is 3cm below the liquid surface, the working frequency is 20KHz, the ultrasonic output power density is 1000W / L, the continuous power output mode, the treatment temperature is 30°C, and the treatment temperature is 30°C. The time is 24 minutes; the way of liquid medium in and out of the container is intermittent in and out, and the way of Antarctic krill in and out of material is intermittent in and out of material.

[0069] The fluorine content of whole Antarctic krill before and after treatment was determined. Wei...

Embodiment 2

[0072] The test treatment process and fluorine content determination method are the same as in Example 1, the difference being that the treatment medium is triple distilled water, and the defluorination rate of the whole shrimp is 70%.

Embodiment 3

[0074] The test treatment process and fluorine content determination method are the same as in Example 1, except that the treatment medium is tap water, and the defluorination rate of the whole shrimp is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com