Fluoroplast sleeve defluorination treatment device and defluorination treatment method thereof

A fluororesin and treatment device technology, which is applied in the field of fluororesin sleeve defluorination treatment devices, can solve the problems of surface damage of fluororesin products, difficulty in realizing continuous production, and poor control of treatment effects, so as to avoid damage. Product, convenient control, good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

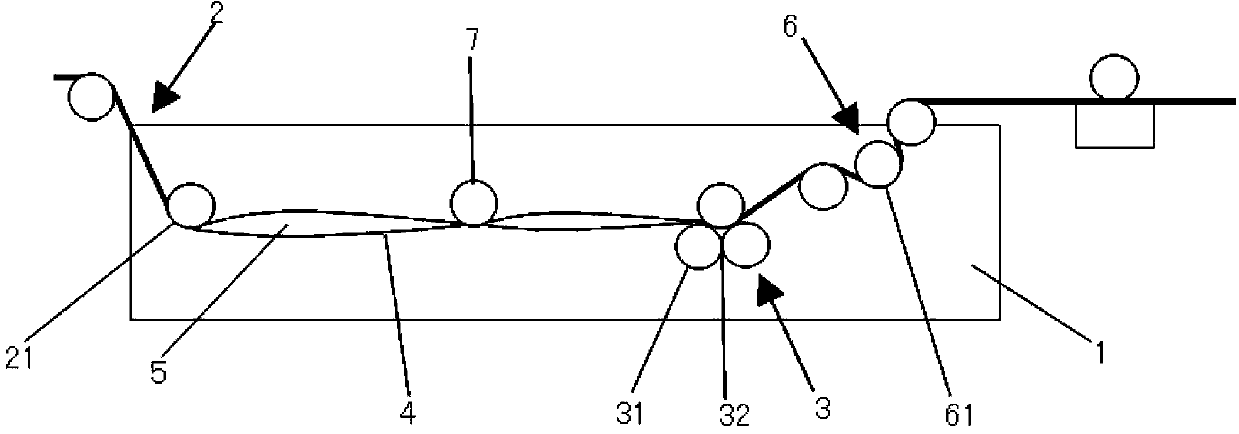

[0025] Such as figure 1 As shown, the present invention provides a fluororesin bushing defluorination treatment device, which includes a refrigerant tank 1 filled with refrigerant, a positioning mechanism 2 and a first extrusion mechanism 3 arranged in the refrigerant tank 1 at intervals; the horizontal plane is used as a reference , the positioning mechanism 2 includes two first rollers 21 arranged up and down, and the first extrusion mechanism 3 includes three second rollers 31 arranged in a triangle and tangent to each other; During fluorine treatment, the fluororesin sleeve before defluorination goes around the two first rollers 21 in a zigzag shape, and the fluororesin after defluorination goes around two of the three second roller tangent surfaces 32, positioning The mechanism 2 cooperates with the first extrusion mechanism 3 to positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com