Patents

Literature

34results about How to "High chlorine removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing chloride ion treating medicament

InactiveCN102351225AWide variety of sourcesLow priceWater contaminantsWater/sewage treatmentHigh concentrationMagnesium salt

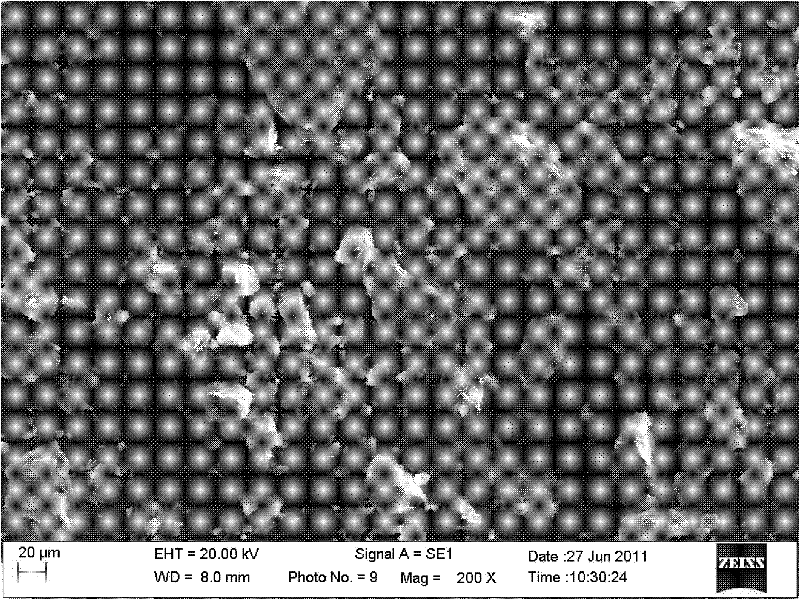

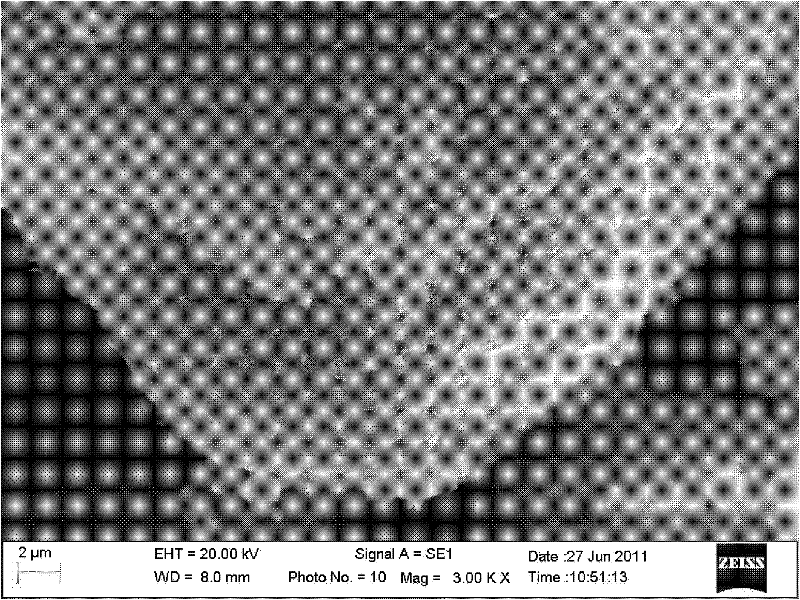

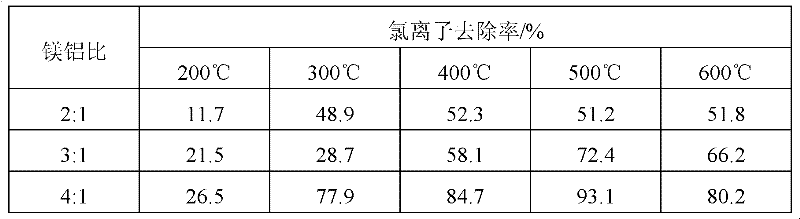

The invention relates to a method for preparing chloride ion treating medicament, which belongs to the technical field of materials and environment. In the method, solid magnesium salt raw materials and aluminum salt are prepared into metal salt solution, the metal salt solution is prepared into mixed solution with strong base, filter cake is obtained through suction filtering and washing after hydrothermal crystallization precipitation and cooling, a laminated structure is prepared through grinding and roasting, interlaminar ions have the exchangeability, the material loses interlaminar water and anions after being roasted, and roasting products with higher specific surface area can be obtained. In water environment, the roasting products can be recovered and rebuilt into the original laminated structure through absorbing the anions again. The medicament is prepared by soluble magnesium salt, aluminum salt and inorganic sodium salt. High-concentration chloride ions in waste water can be effectively removed, and in addition, the medicament can be repeatedly used after regeneration. The method has the advantages that the medicament preparation method is simple, the raw material source is wide, the price is low, the process flow is simple, the equipment investment is little, no environment pollution is caused, and the chlorine removal efficiency is high.

Owner:UNIV OF SCI & TECH BEIJING

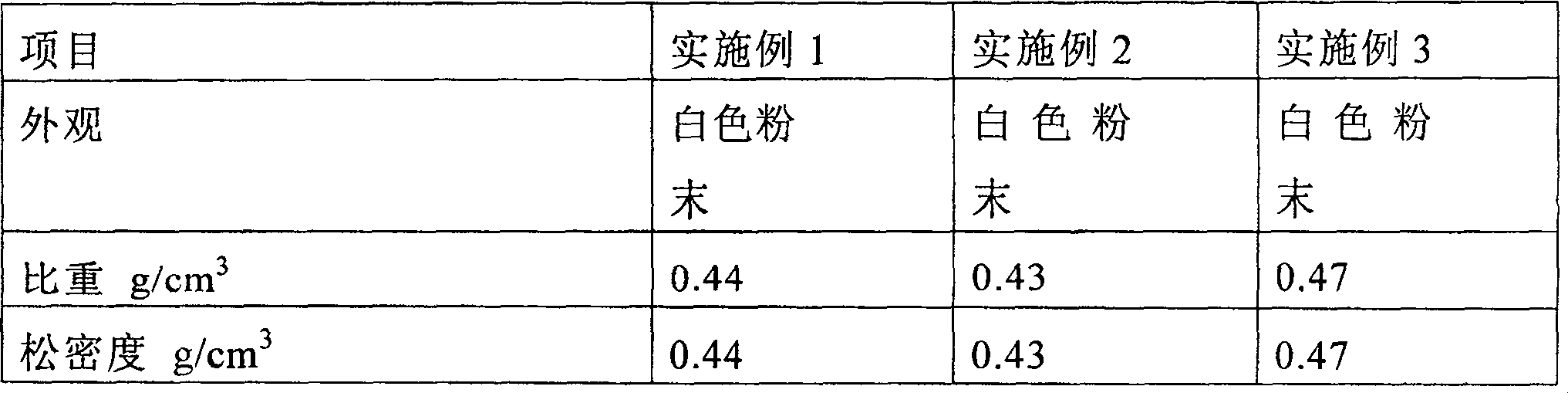

Chlorine collecting agent and its prepn and application

ActiveCN1973965AImprove hydrophobicityGood water repellencyDispersed particle separationCalcium hydroxideTextile mill

The present invention discloses one kind of chlorine collecting agent and its preparation process. The chlorine collecting agent is prepared with calcium hydroxide, surfactant, filming drier, diluent and sodium silicate. It has high chlorine eliminating efficiency, waterproof and moistureproof property, no caking, high air permeability and other advantages. It is used in absorbing and eliminating chlorine in various kinds of production fields, such as chloralkali plant, papermaking mill, textile mill, sewage treating yard, etc.

Owner:夏元超 +1

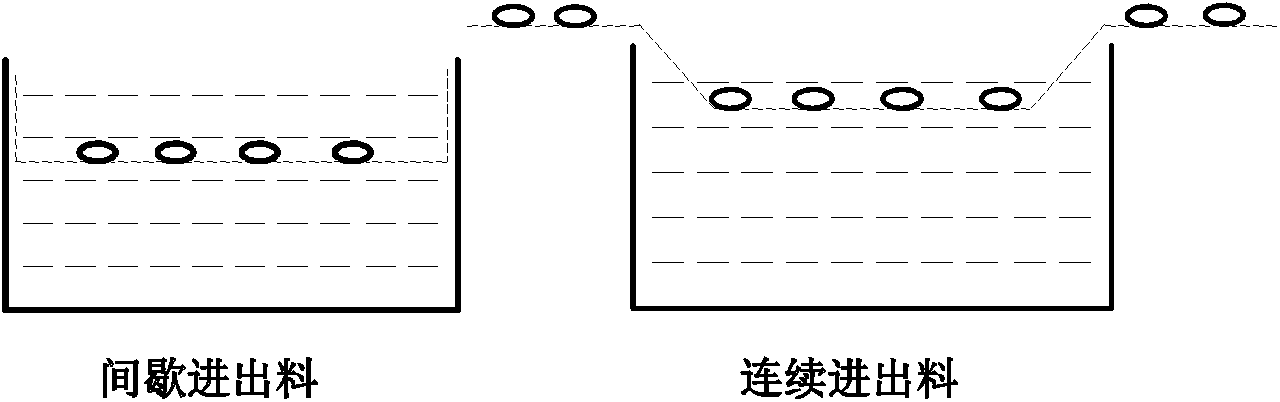

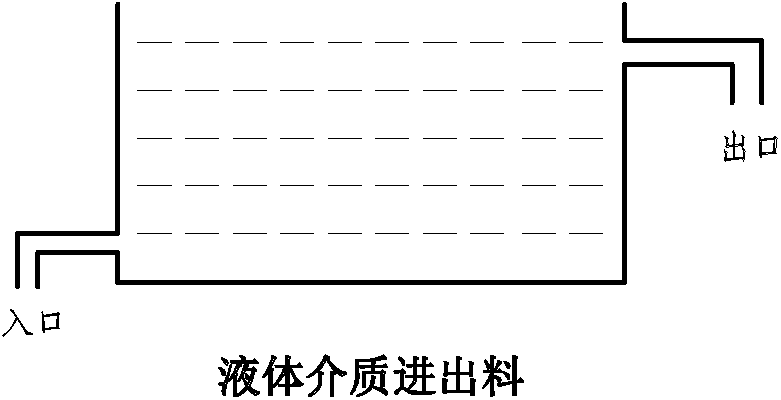

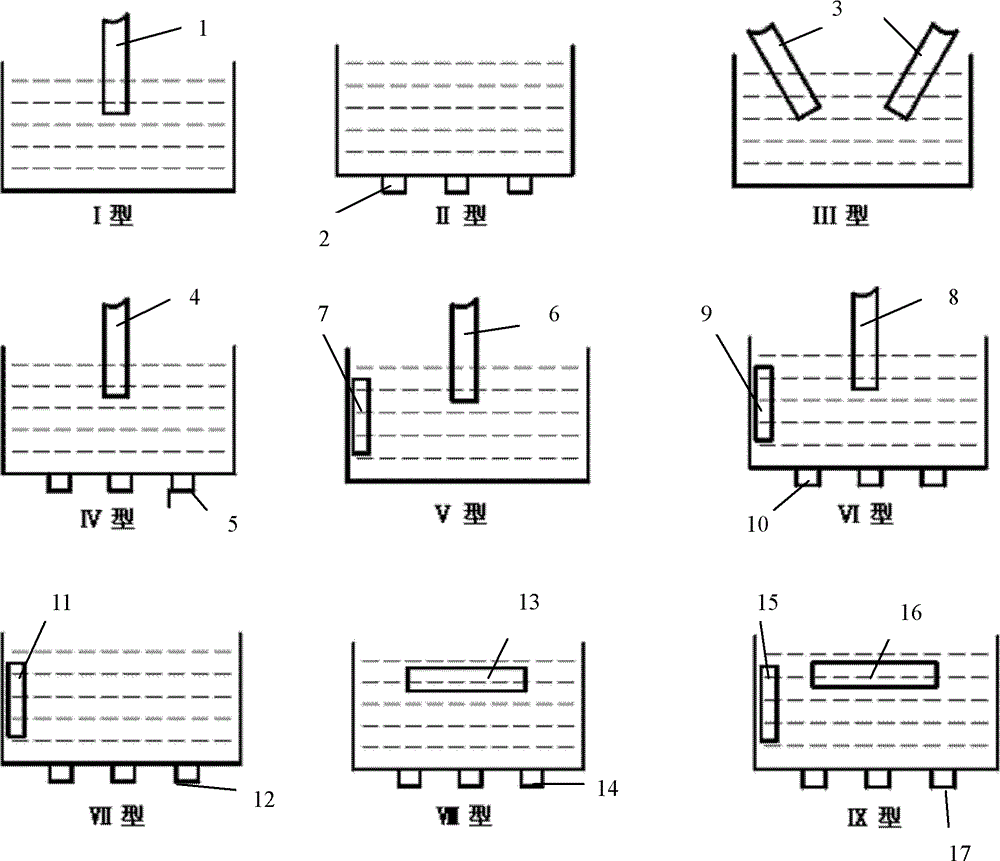

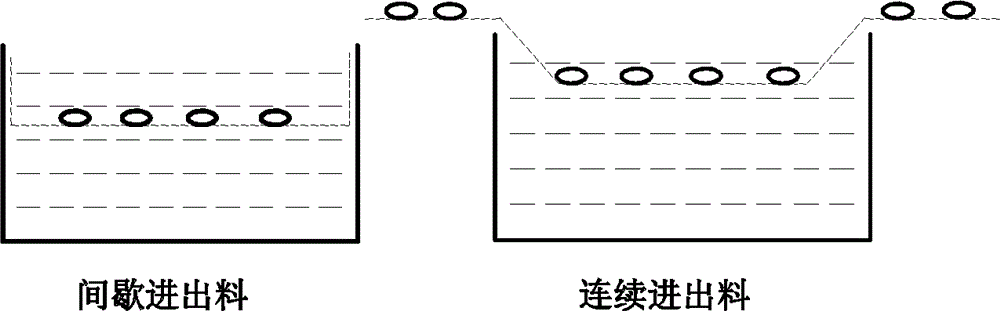

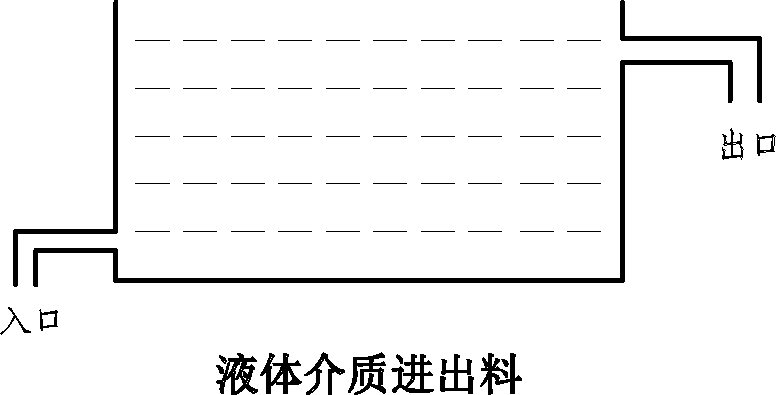

Ultrasonic defluorination method for whole euphausia superba

InactiveCN103583931ATo achieve the purpose of defluorinationNo brokenFood ultrasonic treatmentFood preparationNutritive valuesLiquid medium

The invention discloses an ultrasonic defluorination method for whole euphausia superba. After being pretreated, the euphausia superba is soaked in a liquid medium in a working container for ultrasonic defluorination, wherein the euphausia superba is fresh whole euphausia superba, refrigerated whole euphausia superba or dried euphausia superba; the pretreatment is shell softening treatment or unfreezing; the combination type of an ultrasonic treatment device is a single-unit ultrasonic device, a two-unit ultrasonic device or a three-unit ultrasonic device; the liquid medium is a first component, a second component or a third component, the first component is water distilled for three times, deionized water, tap water or seawater, the second component is ethanol, acetone, diethyl ether or No.6 extraction solvent oil, and the third component is an acid solution, alkali solution or salt solution. The technology achieves the purpose of defluorination of the euphausia superba; the defluorinated euphausia superba is kept whole and prevented from breaking, and the sensory quality and the nutritive value are not influenced.

Owner:SHANDONG NORMAL UNIV

Method for removing Cl from copper sulfate solution

InactiveCN109536720AEfficient removalHigh chlorine removal efficiencyProcess efficiency improvementSlagWastewater

The invention discloses a method for removing Cl from copper sulfate solution. The method for removing Cl from the copper sulfate solution comprises the following steps that 1, the pH value of the copper sulfate solution is adjusted to 1-1.5; and 2, cuprous oxide powders are added into the copper sulfate solution, the reaction pH value is controlled to be 1-2, and the solid-liquid separation is carried out after the precipitation reaction to obtain a dechlorinated copper sulfate solution and dechlorination slags. According to the method for removing Cl from the copper sulfate solution, throughthe pH value adjustment of the copper sulfate solution and the control of a specific reaction system, the efficient removal of Cl in the copper sulfate solution is achieved, the method is suitable for removing chloride ions from copper sulfate solution with chloride ion concentration of 0.01-20g / L, and the chloride ion concentration after removing the chloride ions is controlled at 50 mg / L or below. The method for removing Cl from the copper sulfate solution has the advantages of being stable in a dechlorination effect, high in dechlorination efficiency, simple in technical operation, free ofwaste water and waste gas generation and the like, and can be widely applied to the purification of copper sulfate solutions which are recycled in the production of electrodeposited copper and cupricsulfate purified products.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

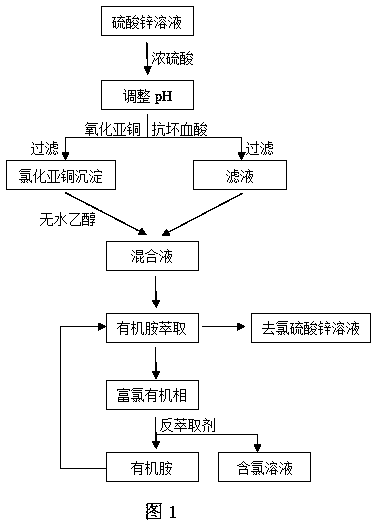

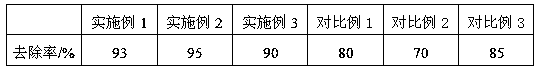

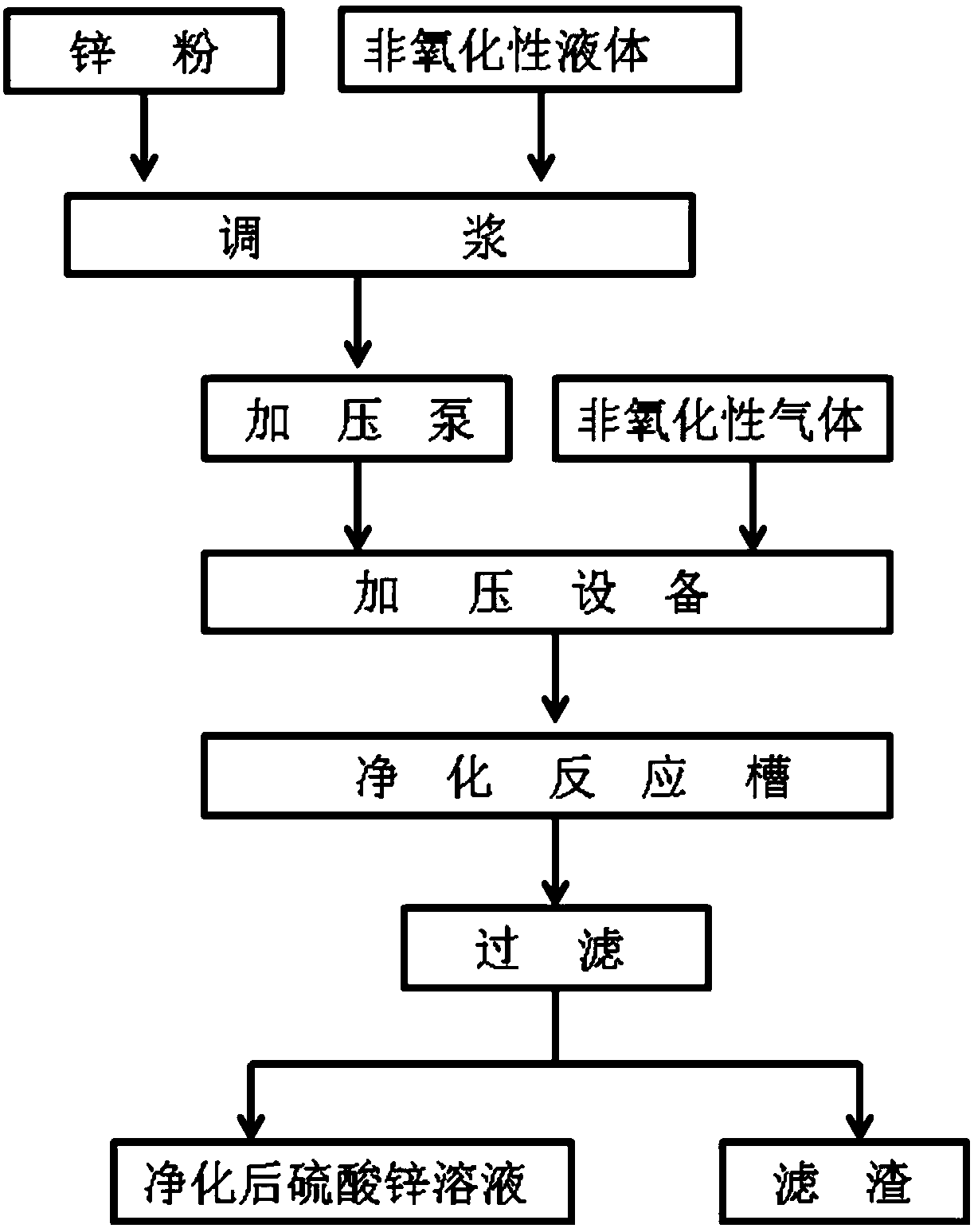

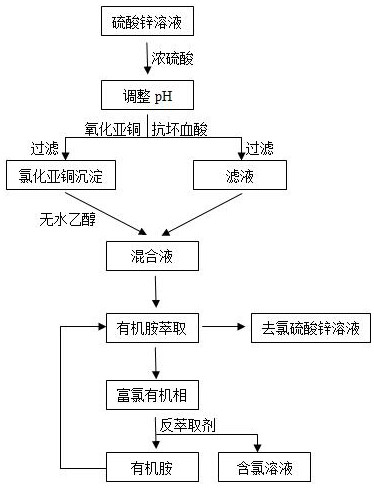

Method for removing chlorine from zinc sulfate solution

ActiveCN109371259AHigh removal rateAchieve separationPhotography auxillary processesProcess efficiency improvementAlcoholSulfate

The invention discloses a method for removing chlorine from a zinc sulfate solution. The method comprises the following steps that concentrated sulfuric acid is added into the zinc sulfate solution toadjust the pH value; ascorbic acid is added, then cuprous oxide is added for dechlorination treatment to form a cuprous chloride precipitate, filtering is carried out, and then a filtrate is taken for later use; the cuprous chloride precipitate is washed by using absolute ethyl alcohol, and the washing liquid and the filtrate are combined to obtain a mixed solution; an equal volume of organic amine is added into the mixed solution, extraction is carried out, and standing and layering are carried out so as to obtain a zinc sulfate solution with the chlorine removed and a chlorine-rich organicphase; and a reverse extraction agent is used for reversely extracting the chlorine-rich organic phase, so that the chlorine and the organic phase are separated. According to the method, chlorine ionsin the zinc sulfate solution are effectively removed, the dechlorination efficiency is high, the process is simple, and the chlorine removal cost is reduced.

Owner:衡阳市大宇锌业有限公司

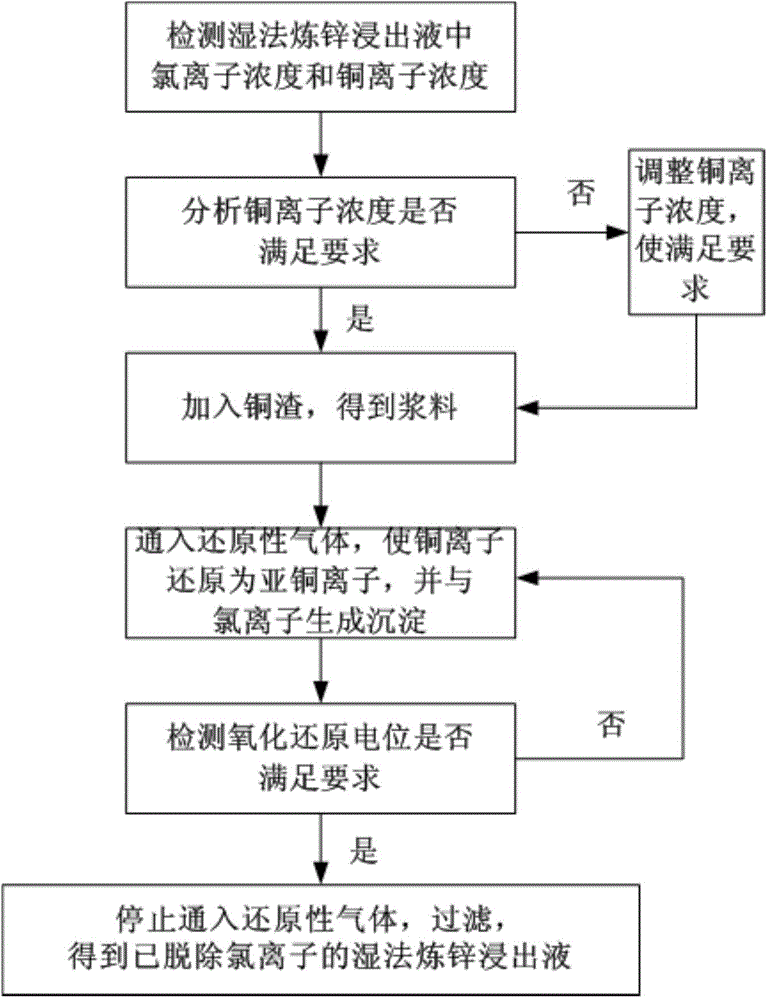

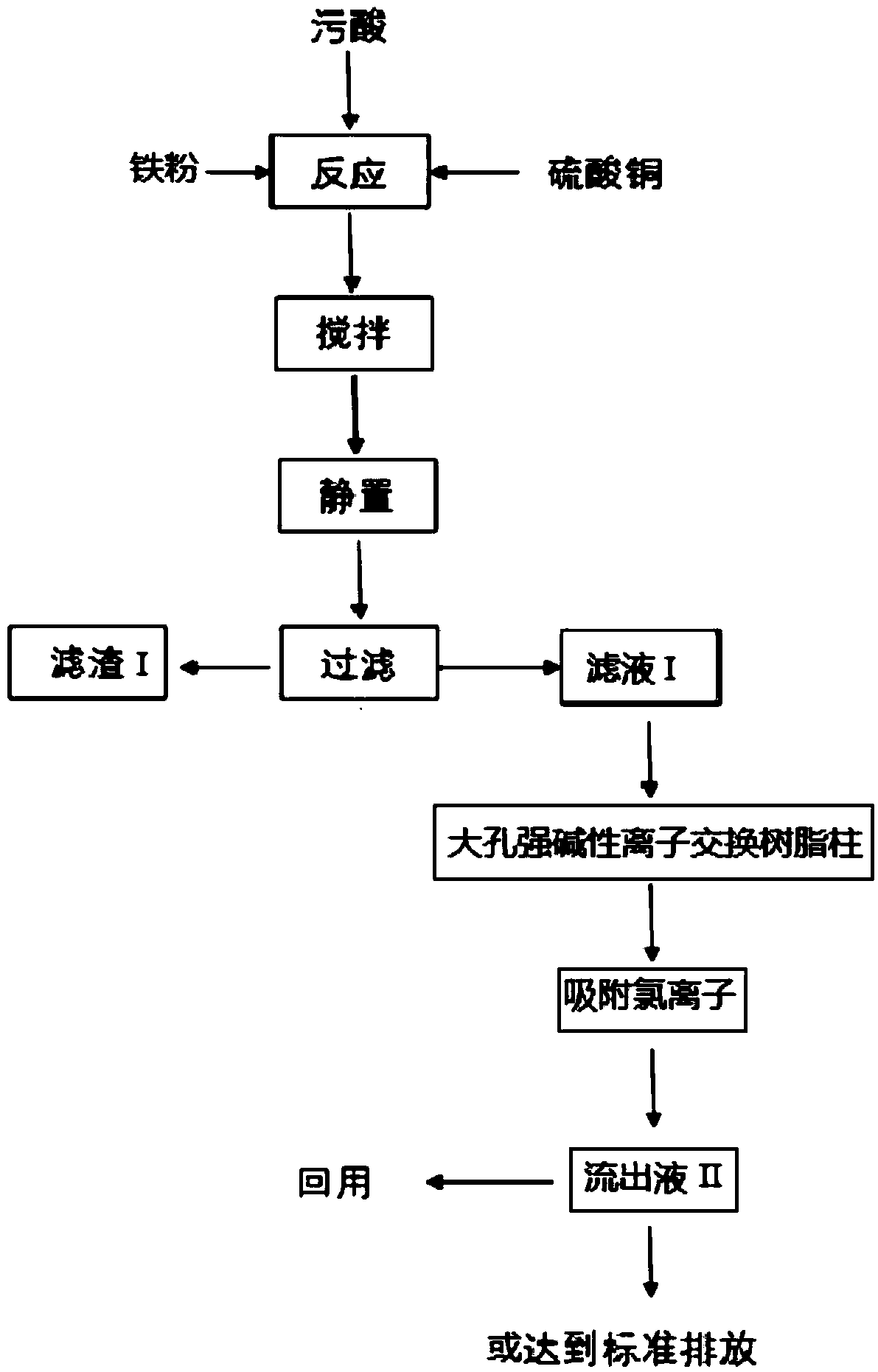

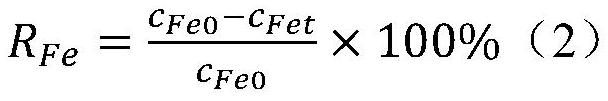

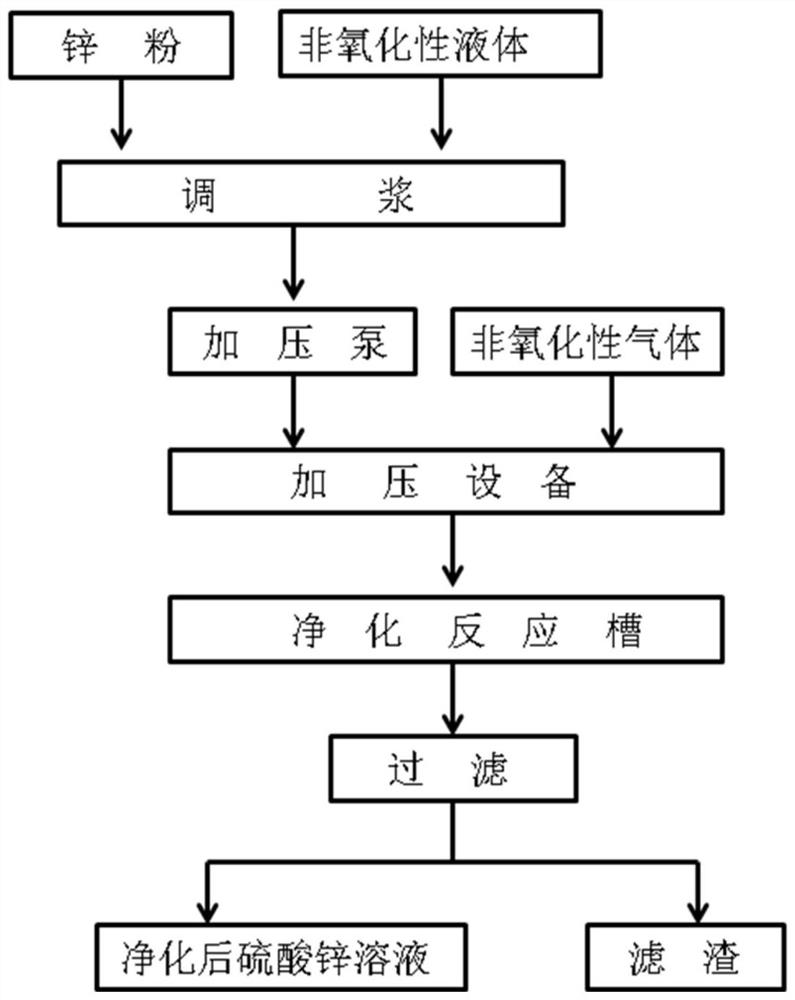

Method for removing chloride ion from lixivium of zinc hydrometallurgy

ActiveCN104694751AEnhanced reducing atmosphereReduce Chloride ContentProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention discloses a method for removing chloride ion from lixivium of zinc hydrometallurgy. The method for removing the chloride ion from the lixivium of zinc hydrometallurgy includes steps that 1, detecting the concentration of the chloride ion and concentration of copper ion in the lixivium of zinc hydrometallurgy; 2, analyzing the copper ion concentration of the step 1; 3, adding copper slag to the lixivium of zinc hydrometallurgy to obtain slurry; 4, filling reductive gas to the slurry to enable the chloride ion to form sediment; 5, detecting the oxidation reduction potential of the slurry, if the oxidation reduction potential meets the demand, stopping filling reductive gas, and filtering to obtain the lixivium of zinc hydrometallurgy without chloride ion; otherwise, returning to the step 4. The method for removing the chloride ion from the lixivium of zinc hydrometallurgy is featured with short flow, low cost and high chloride removing efficiency, other impurities are not led in, the original zinc hydrometallurgy technique is kept, and the popularization value is high.

Owner:XIAN RAREALLOYS

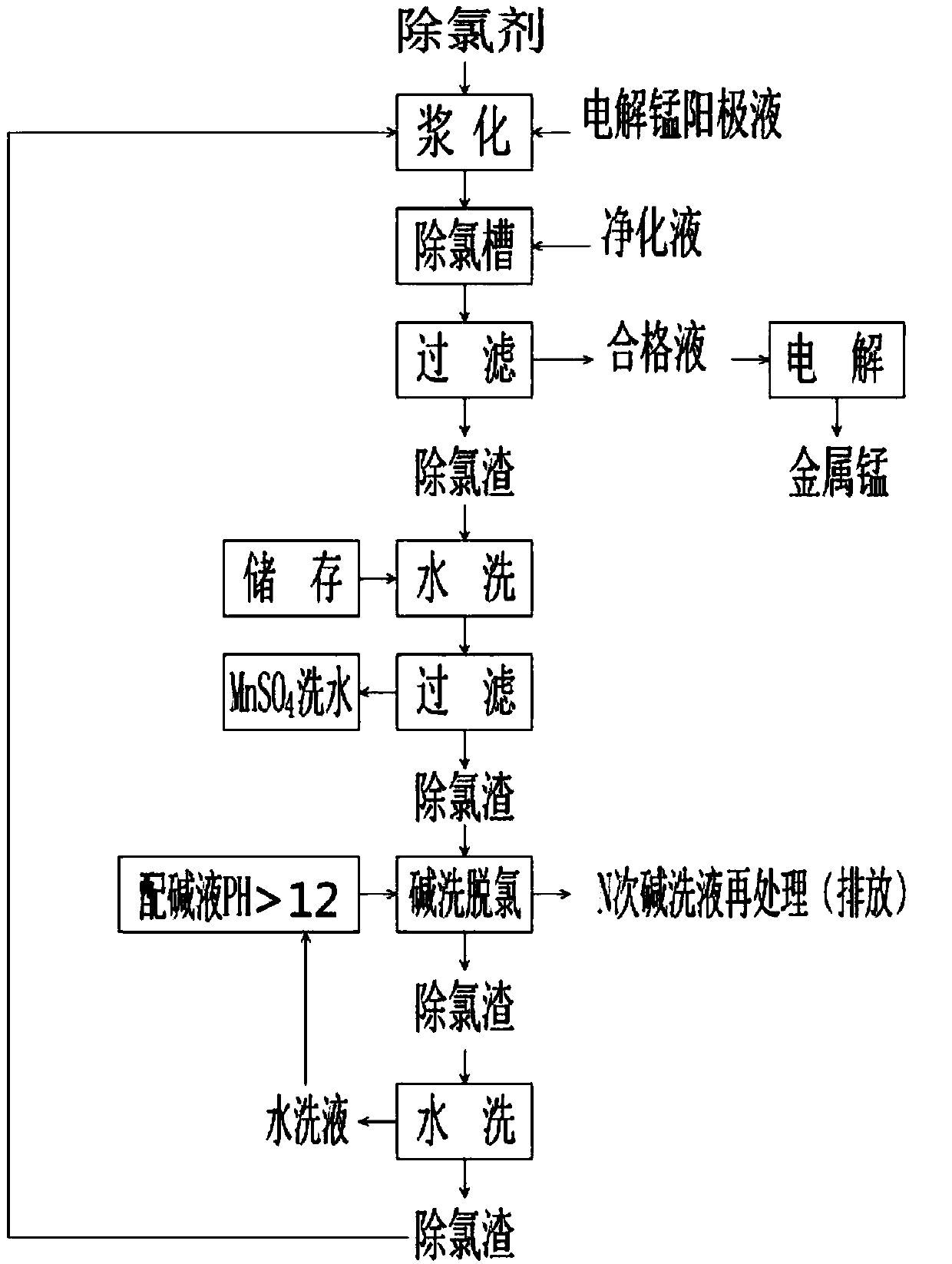

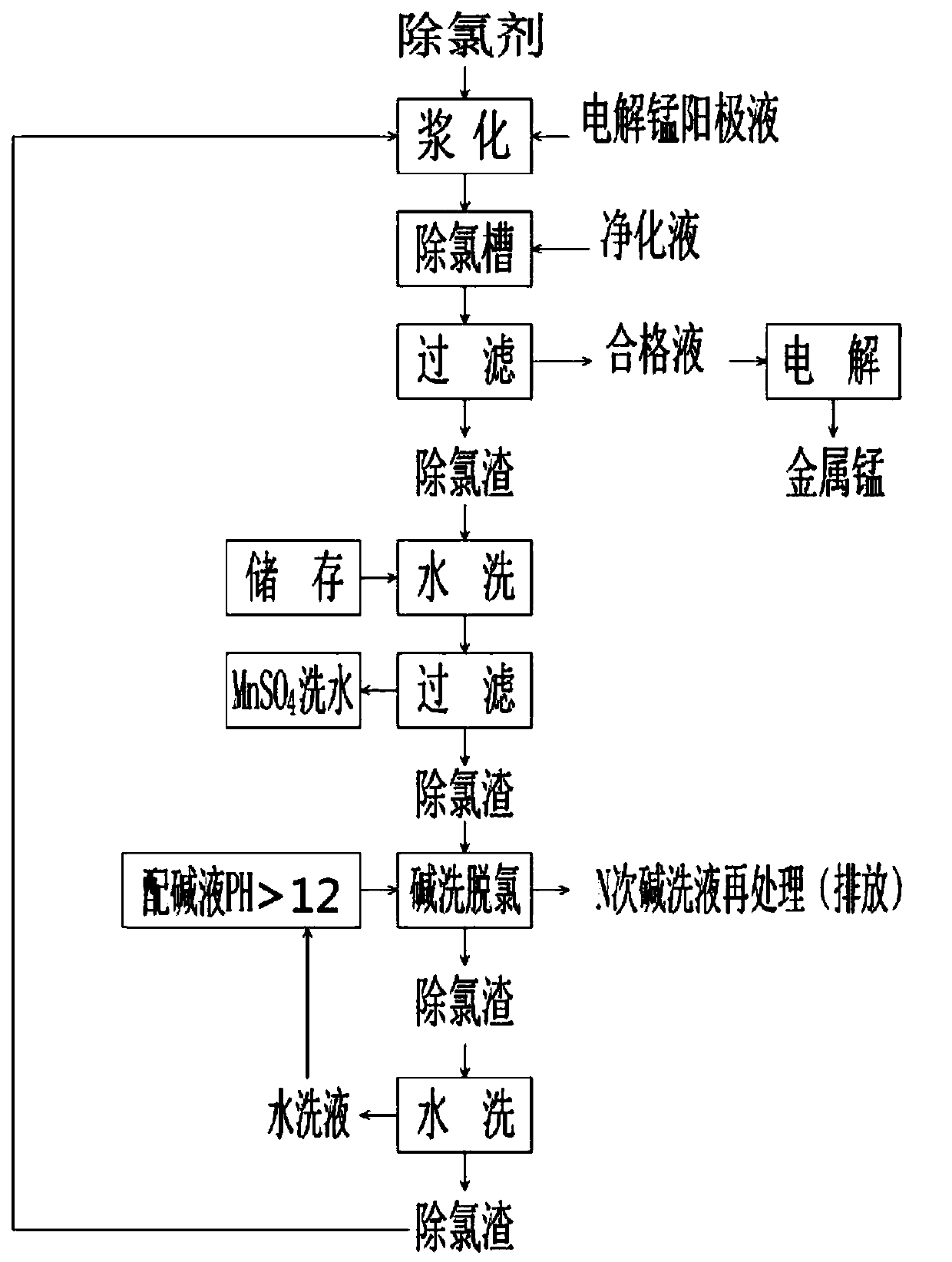

Method for removing chloride ions in electrolytic manganese solution

InactiveCN107630147AImpurities will not increaseSmall amount of chlorine slag removalProcess efficiency improvementElectrolysisSlag

The invention discloses a method for removing chloride ions in an electrolytic manganese solution. An R-Bi2O3 antichlor is added in an electrolytic manganese anode solution with the sulfur acid content being 30-40 g / l, stirring is conducted for 20-30 min, slurrying is conducted, slurry is added in a to-be-treated electrolytic manganese solution, and after sufficient stirring is conducted for 40-60min at the temperature ranging from 40 DEG C to 60 DEG C and with the stirring rate being 60 r / min, filtering is conducted; filter liquor is injected into a qualified liquid system, and metal manganese is obtained through electrolysis; R in the R-Bi2O3 antichlor is silicon dioxide and manganese oxide, and the adding mass of the R-Bi2O3 antichlor is 10-15 times of the mass of the chloride ions inthe electrolytic manganese solution; and removed filter slag is sequentially subjected to washing and filtering, the removed chloride slag is subjected to alkaline washing for dissolving and dechlorinating through alkaline liquor, filtering is conducted, the filter slag obtained after filtering is sequentially washed and filtered and then is added in a chloride slag removing acidification tank tobe recycled. By means of the method, chloride can be effectively and rapidly removed, the antichlor can be circularly reutilized, and cost is low.

Owner:曹德忠

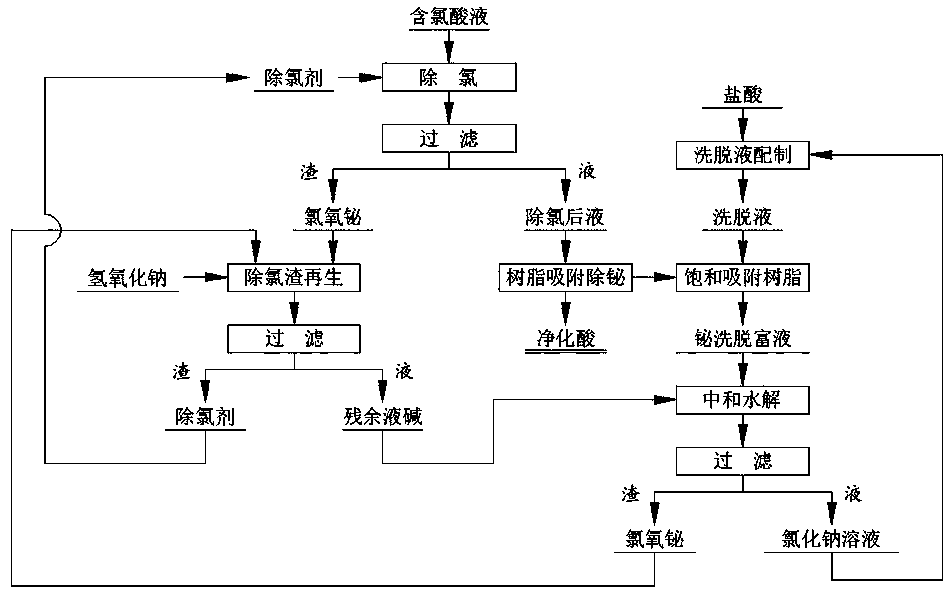

Acid solution dechlorination method

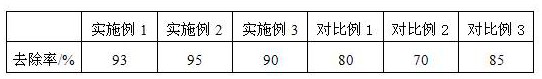

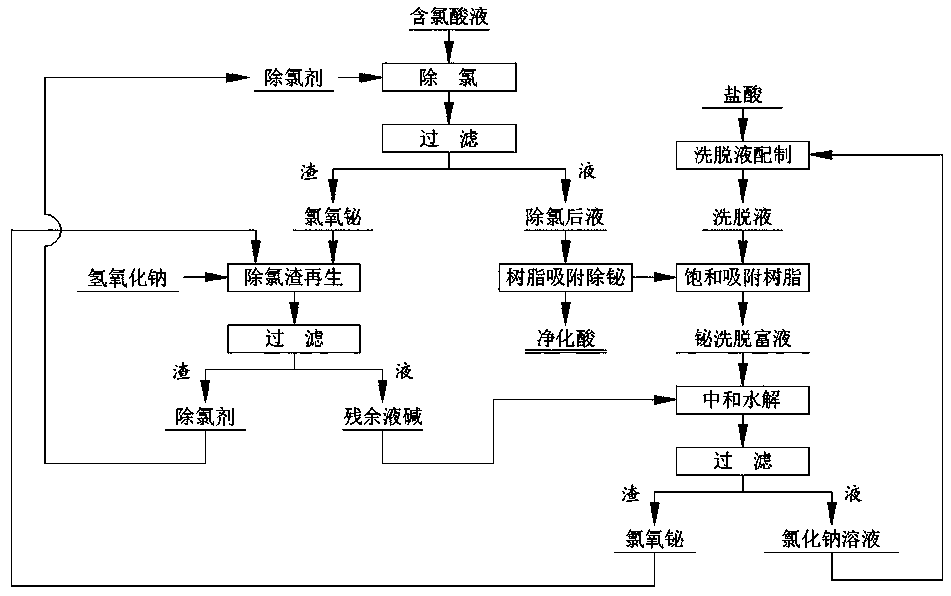

ActiveCN110734169ANothing producedHigh chlorine removal efficiencyWater treatment parameter controlSpecific water treatment objectivesDechlorinatorPhysical chemistry

The invention discloses an acid solution dechlorination method. The acid solution dechlorination method comprises the following steps: adding a dechlorinating agent into a chlorine-containing acidic solution for reacting and dechlorinating so obtain a dechlorination residue and a dechlorinated liquid; stirring and regenerating the dechlorination residue with an alkali liquor to obtain a residual alkali liquor, recovering the residual dechlorinating agent component in the dechlorinated liquor by using an adsorbing material, and regenerating with an eluent after adsorption saturation; recyclinga regenerated adsorbing material, neutralizing an obtained eluent with the residual alkali liquor, and recovering bismuth oxychloride residues and / or antimony oxychloride residues and a chlorine saltsolution. The method comprises the following advantages: in the chlorine-containing acidic solution system, dechlorination efficiency is high, antimony bismuth dissolved in the dechlorinated liquid can be recycled at low cost, so that low cost circulation of antimony bismuth elements is realized; no other component is introduced into a stock solution, only a small amount the alkali liquor and hydrochloric acid are needed; the simple process is capable of realizing whole system circulation; the whole process is simple; almost no wastewater is generated; and treatment cost is low.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

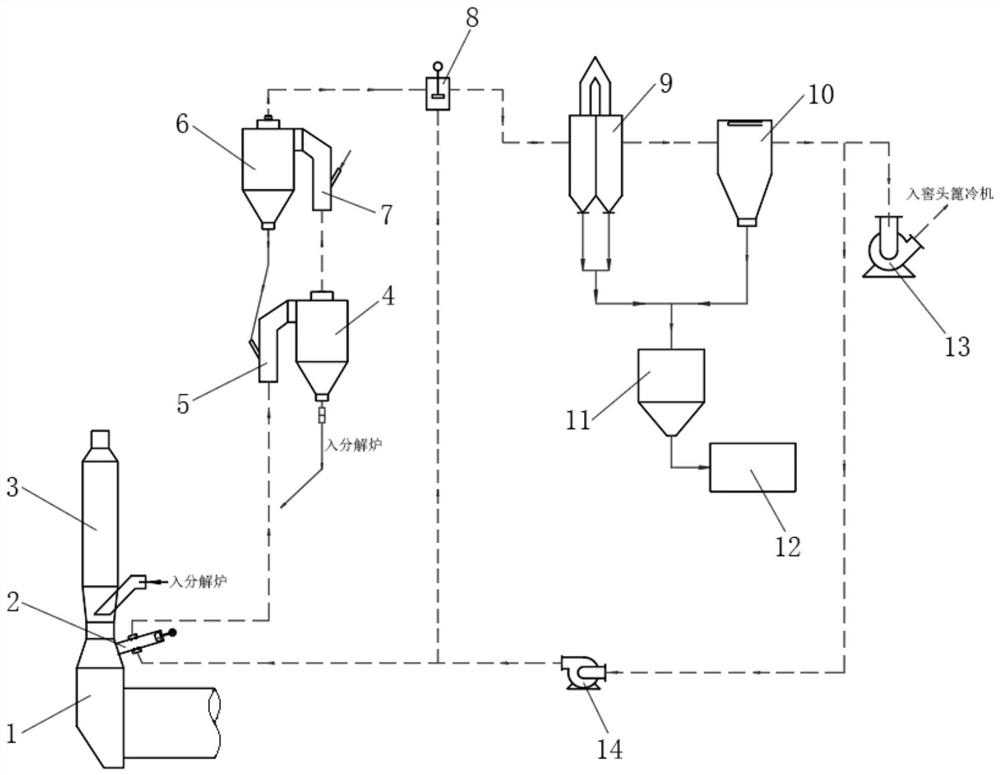

Dechlorination system for co-processing washing fly ash by cement kiln and dechlorination method

PendingCN112775158AHigh chlorine removal efficiencyZero emissionCombination devicesSolid waste disposalEnvironmental engineeringMechanical engineering

The invention discloses a dechlorination system for co-processing washing fly ash by a cement kiln and a dechlorination method. The dechlorination system is characterized in that an air taking device communicates with a feed-end chamber in a kiln system, an air outlet of a circulating fan communicates with an air outlet of the air taking device and an air inlet of a heat exchanger, and the air outlet of the air taking device further communicates with an air inlet of a lower-layer cyclone separator; an air outlet of the lower-layer cyclone separator communicates with an air inlet of an upper-layer cyclone separator, an ash falling opening of the upper-layer cyclone separator communicates with the air inlet of the lower-layer cyclone separator, and an air outlet of the upper-layer cyclone separator communicates with the air inlet of the heat exchanger; and an air outlet of the heat exchanger communicates with an air inlet of a cooler, an air outlet of the cooler communicates with an air inlet of a bag type dust collector, and an air outlet of the bag type dust collector communicates with air inlets of an induced draft fan and a circulating fan correspondingly. The dechlorination system and the dechlorination method improves the dechlorination efficiency, and achieve zero emission.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Agent for removing chloride ions in acidic wastewater, dechlorination method and application

ActiveCN111302469ATo achieve the purpose of removing chloride ions in polluted acid wastewaterMeet recycling requirementsWater contaminantsDispersed particle separationIndustrial waste waterChloride

The invention relates to an agent for removing chloride ions in waste acid wastewater and a dechlorination method and application, and belongs to the technical field of industrial wastewater treatmentand recycling. In order to solve the technical problems of limited dechlorination efficiency, large dosage and high cost of the existing dechlorination agent, the invention provides the agent for removing the chloride ions in the acidic wastewater, and the agent comprises bismuthate and / or bismuthate hydrate. The dechlorination agent provided by the invention is convenient to use and high in dechlorination efficiency, the highest dechlorination efficiency can reach 98.9%, and the dechlorination agent can be regenerated and recycled, so that the cost is relatively low, the problem of removal of chloride ions in the waste acid wastewater is solved, and resource recycling of the chloride ions in the waste acid wastewater is realized.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

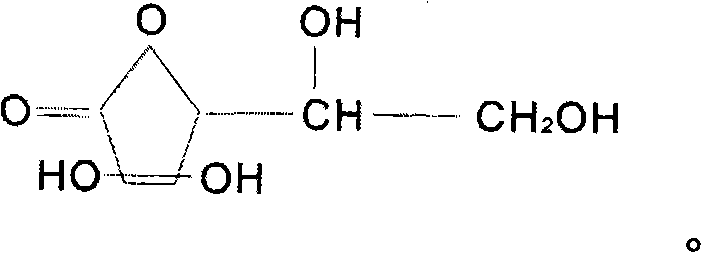

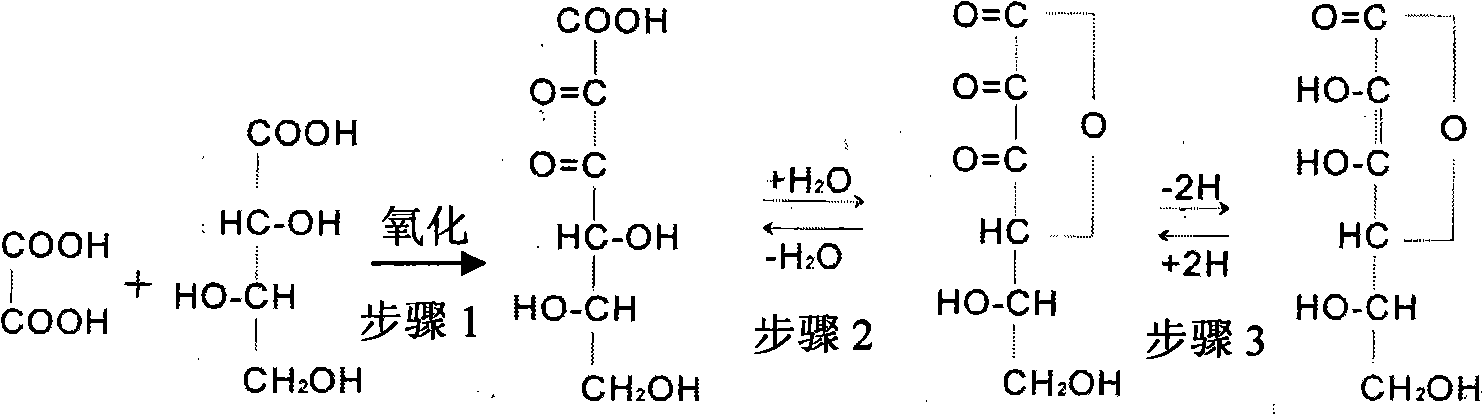

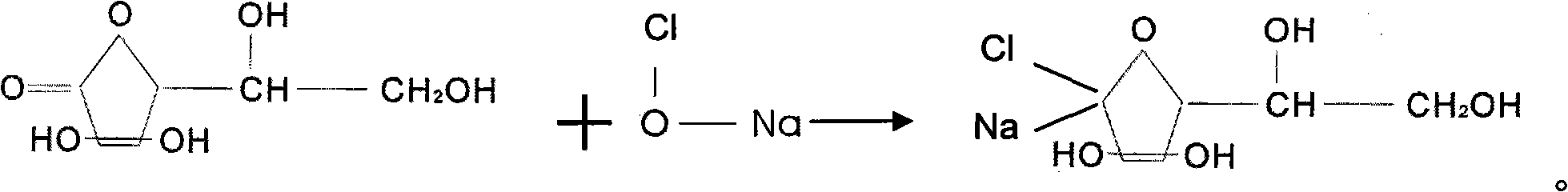

Dechlorination material in water treatment as well as preparation and use methods thereof

InactiveCN101575134AHigh porosityStrong exchange abilityAmphoteric ion-exchangersWater/sewage treatmentHalogenVoid ratio

The invention relates to a dechlorination material in water treatment as well as preparation and use methods thereof. The dechlorination material is formed by mixing a compound (I), an adhesive and vitamin H together, the compound (I) is shown as the formula above. The preparation method comprises the following steps of: dissolving the adhesive into solvent to form colloidal fluid; adding the compound and vitamin H slowly into the colloidal fluid and stirring evenly for forming floury materials; granulating with a granulator or granulating by manually rubbing with a mesh sieve to make wet particles; and placing the wet particles into an oven for drying to make the dechlorination material. The invention has the advantages that the dechlorination material is a redox system of disordered non crystalline structure, has large void ratio, strong exchanging ability and long releasing period, can be used for specially treating residual chlorine in water with residual chlorine removing efficiency above 99 percent, and can be used for removing residual chlorine, iodine in tap water as well as other halogen elements, thereby achieving the aim of purification.

Owner:上海鑫辰实业发展有限公司

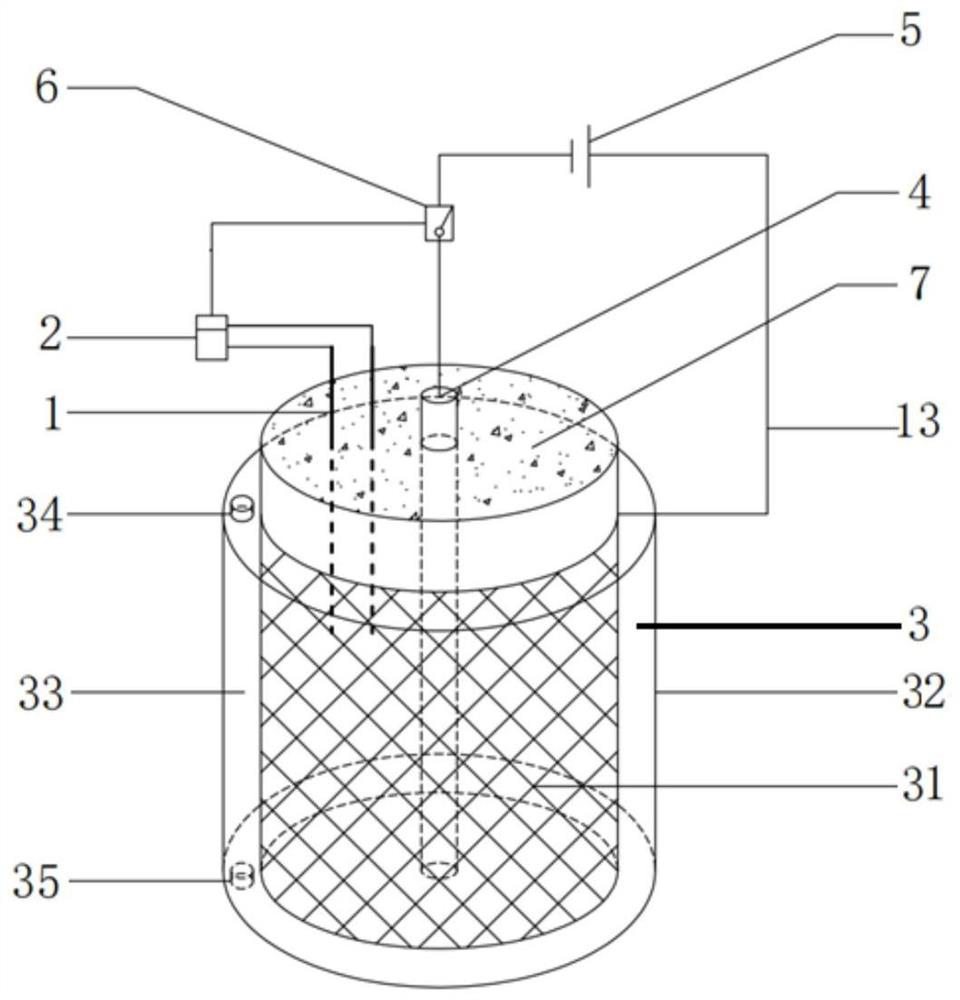

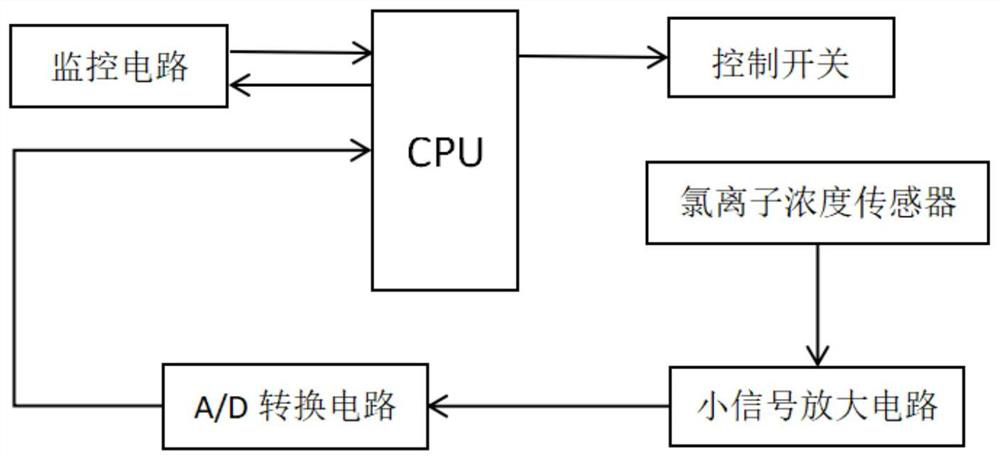

Device for monitoring concentration of chloride ions in reinforced concrete and automatically removing chlorine

InactiveCN112179961AUniform divergenceAccurate outputMaterial electrochemical variablesReinforced concretePhysical chemistry

The invention discloses a device for monitoring the concentration of chloride ions in reinforced concrete and automatically removing chlorine, which comprises a chloride ion concentration monitoring device and an electrochemical dechlorination device, and is characterized in that the chloride ion concentration monitoring device is used for monitoring the concentration of chloride ions in the concrete, and the electrochemical dechlorination device performs dechlorination according to the chloride ion concentration monitored by the chloride ion concentration monitoring device, and controls the concentration of the chloride ions in the concrete within a given concentration range. According to the invention, the concentration of the chloride ions in the concrete can be monitored in real time,and the chloride ion concentration is controlled within a given concentration range through the automatic dechlorination device. The device has the characteristics of being simple in structure, good in dechlorination performance, capable of being repeatedly used, low in cost and low in energy consumption.

Owner:HOHAI UNIV

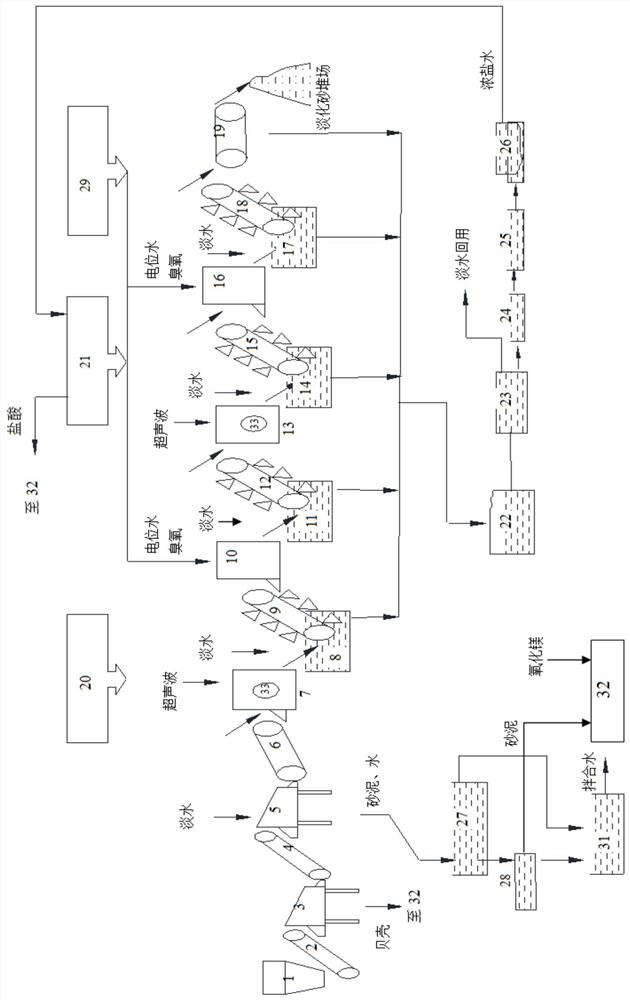

Whole-course recycling sea sand chlorine removal and impurity removal system

PendingCN113510136AMeet the requirements of construction sandIncrease productivityWaste processingSolid waste disposalSaline waterReverse osmosis

The invention discloses a whole-course recycling sea sand impurity removal and chlorine removal system which comprises a screening unit, a cleaning and showering unit, an impurity separation unit, an ultrasonic generator, an alkaline potential water generator, a low-pressure ozone generation array pile, a linear vibration conveying and water screening unit, a flocculation basin, a filter press, a water collection tank, a reverse osmosis treatment tank, a sun-drying evaporator and a strong brine collection unit, and the system further comprises a caulking brick production unit and a mixing water collection unit. The system has good chlorine removal and impurity removal effects on sea sand, the chlorine content of the treated sea sand can be reduced to 0.0015%, chloride ion slow release is permanently avoided, and the sea sand reaches and exceeds the fresh water sand standard; and waste liquid and solid waste generated in the operation process of the system can be recycled, no pollution is caused to the environment, the sea sand treatment capacity can reach 300-600 tons per hour, and the economic benefit is remarkable.

Owner:临沂远大正和海洋科技有限公司

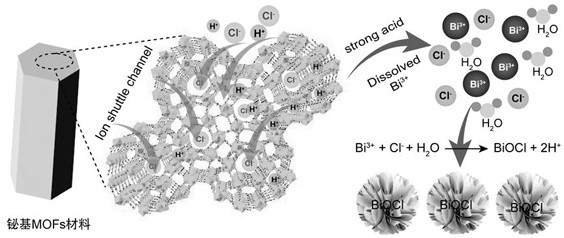

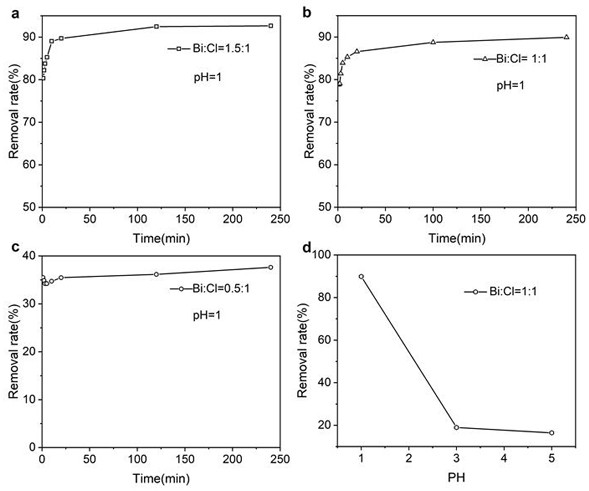

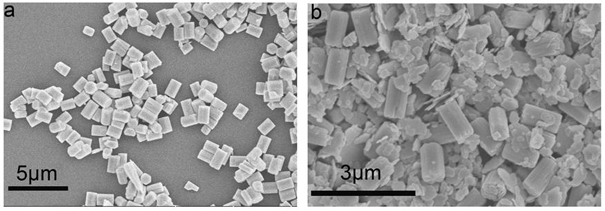

Method for rapidly removing chloride ions in wastewater by using bismuth-based metal organic framework material

ActiveCN114835233AControl molar ratioHave economic effectGeneral water supply conservationWater contaminantsOrganic acidFiltration

The invention provides a method for rapidly removing chloride ions in wastewater by using a bismuth-based metal organic framework material. According to the method, soluble bismuthate and non-toxic organic acid are utilized to form a porous bismuth-based metal organic framework material as a dechlorination reagent, the bismuth-based MOFs material is added into chlorine-containing wastewater, the pH value and stirring time of the wastewater are adjusted, the molar ratio of bismuth ions to chloride ions is controlled, and qualified filtrate with low-concentration chlorine content and a bismuth oxychloride product are obtained after filtration.

Owner:MINJIANG UNIV

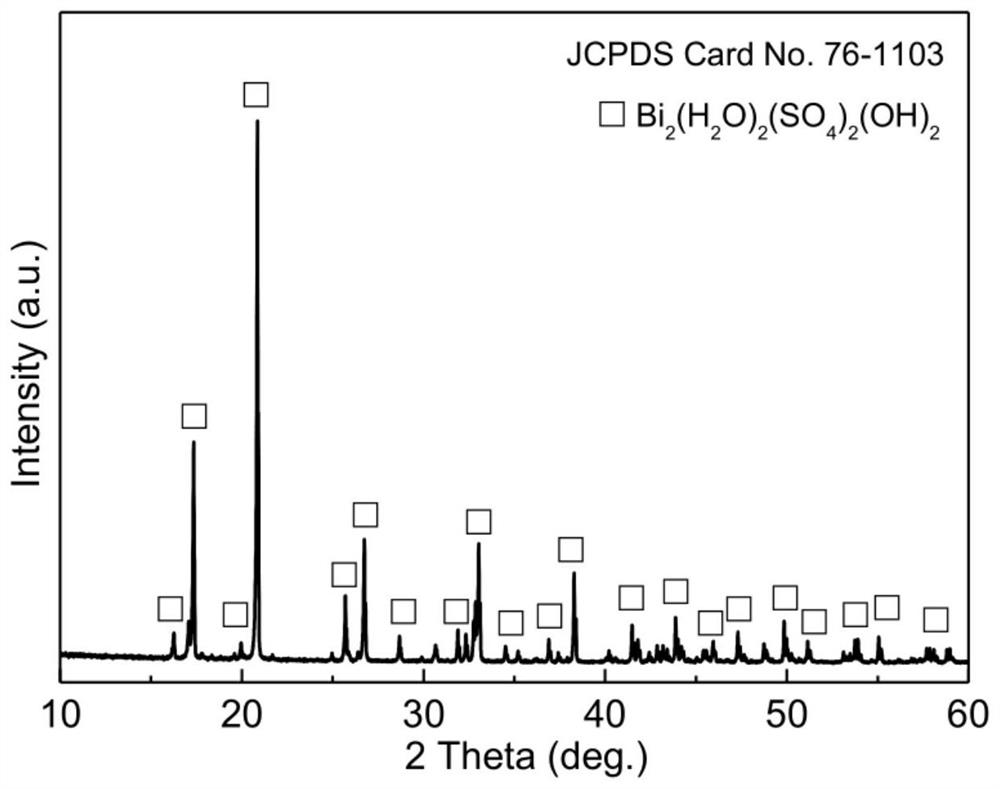

Circulating dechlorination process and system

InactiveCN113072159ARealize industrial applicationHigh chlorine removal efficiencyWater/sewage treatment by centrifugal separationWater contaminantsDechlorinatorProcess engineering

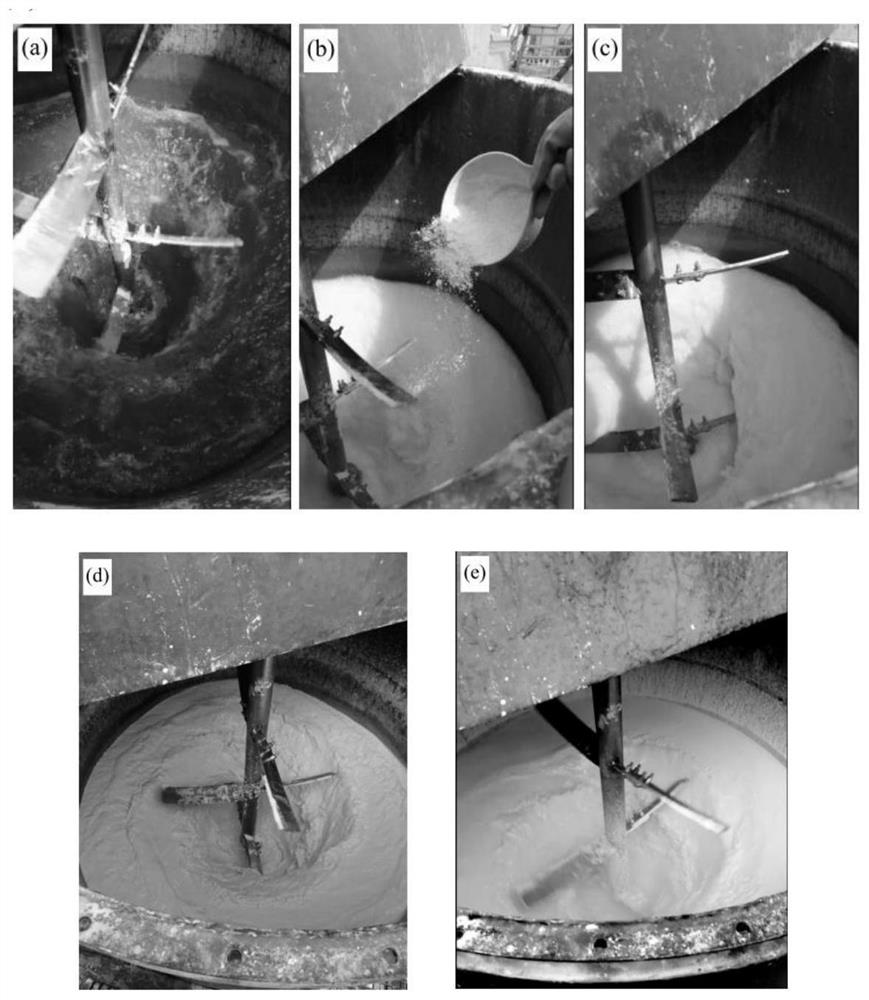

The invention provides a circulating dechlorination process which is characterized in that Bi2(H2O)2(SO4)2(OH)2 or a dechlorination agent taking Bi2(H2O)2(SO4)2(OH)2 as an active component is adopted for dechlorination, a dechlorination product after dechlorination is regenerated to obtain a regenerated product, the regenerated product continues to prepare the dechlorination agent to participate in dechlorination, or the regenerated product continues to participate in dechlorination, and circulation is carried out in this way. The process is good in dechlorination effect, the first-time dechlorination effect can reach 99%, cyclic dechlorination can be achieved, and the dechlorination efficiency is still kept at 80% after repeated cyclic use.

Owner:山东国舜节能环保科技有限公司 +1

A kind of removal method of chloride ion in desulfurization wastewater

ActiveCN113683249BInfluence formationImprove removal efficiencyWater/sewage treatment with mechanical oscillationsWater contaminantsCalcium hydroxideAluminium powder

The invention discloses a method for removing chloride ions in desulfurization wastewater. Calcium aluminate is added to the desulfurization wastewater for pretreatment, and after the primary precipitation is removed, calcium hydroxide and aluminum powder are added, and the pH is adjusted to alkali. Then, ultrasonic treatment is carried out, and then secondary precipitation is generated by heat treatment, and the secondary precipitation is removed. The invention is not only suitable for the removal of chloride ions in a large amount of waste water, but also can effectively reduce the cost of chlorine removal.

Owner:SHANDONG GUOSHUN CONSTR GRP

Chlorine collecting agent and its prepn and application

ActiveCN100482321CEliminate security concernsEasy to removeDispersed particle separationTextile millCalcium hydroxide

Owner:夏元超 +1

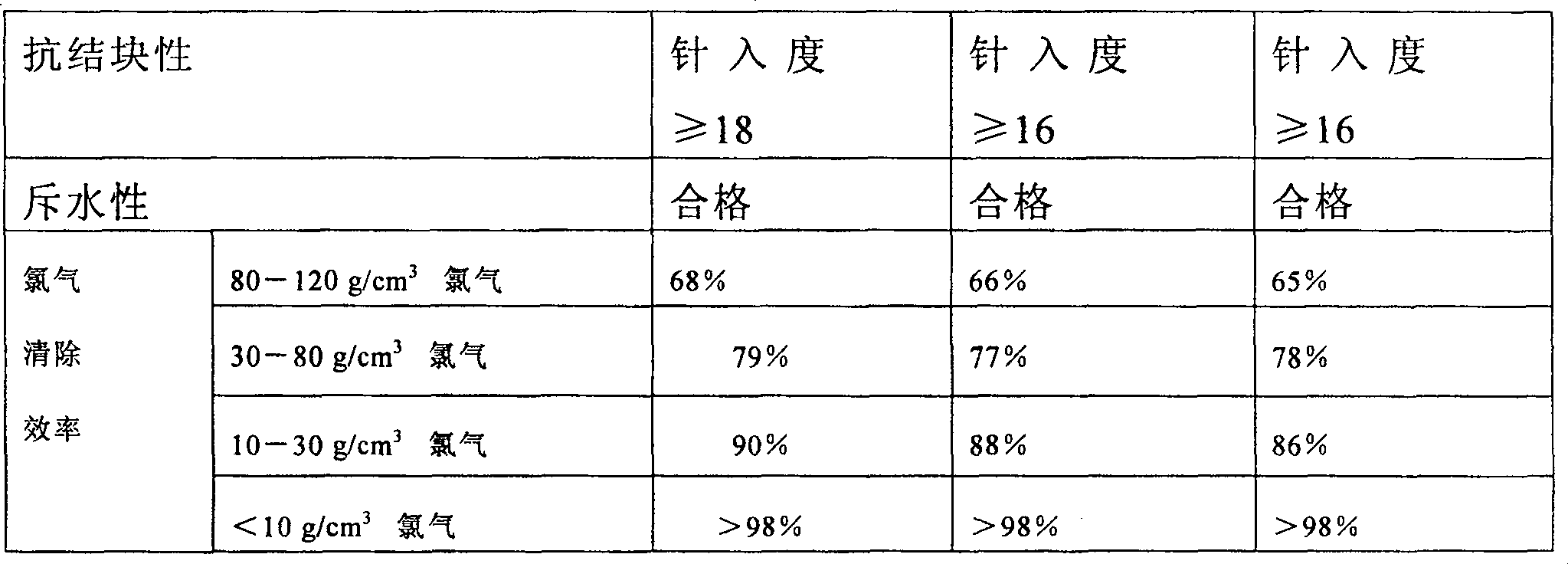

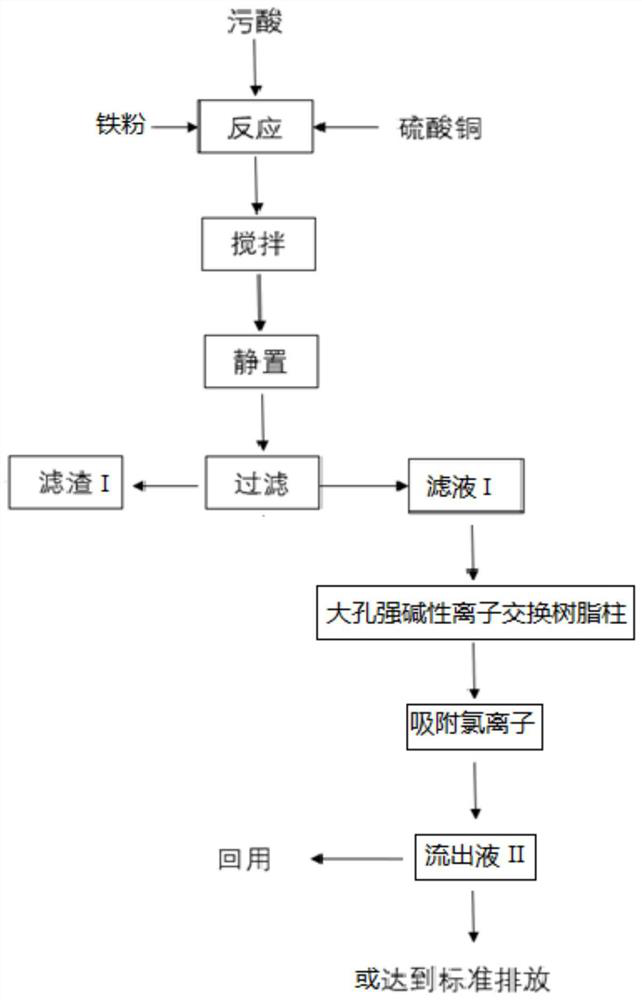

Method for removing arsenic and chlorine from acidic wastewater of metallurgical enterprises

ActiveCN111018212AReduce generationReduce pollutionWater contaminantsTreatment involving filtrationSlagIon exchange

The invention relates to a method for removing arsenic and chlorine in acidic wastewater of metallurgical enterprises so as to remove arsenic and chlorine in acidic wastewater. The method comprises the following steps: simultaneously adding a certain amount of iron powder and a copper sulfate solution into acidic wastewater, stirring, reacting for a set time, generating precipitate, and carrying out solid-liquid separation to obtain a filtered solution and precipitate impurities; and continuously carrying out adsorption exchange dechlorination on the filtrate by using an ion exchange resin. According to the arsenic removal method provided by the invention, the generation of lime slag is effectively reduced, arsenic impurity ions in waste acid are effectively removed, and the arsenic removal efficiency is high; other impurities are prevented from being introduced during chlorine removal, the treated acid and water can be reused in a workshop section, and the pollution to the environmentis reduced; the increase of the whole solution temperature of waste acid is avoided, and energy consumption in the production process is reduced; and economic benefits and environmental benefits arecomprehensively realized.

Owner:KUNMING UNIV OF SCI & TECH +1

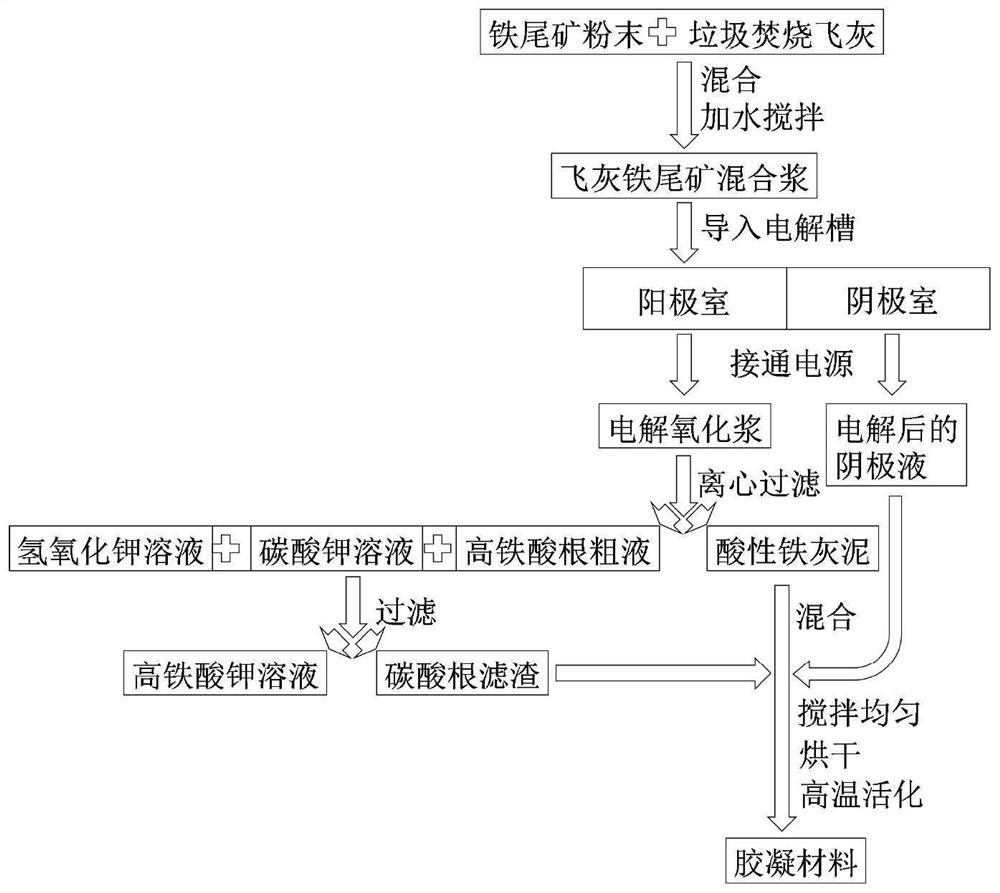

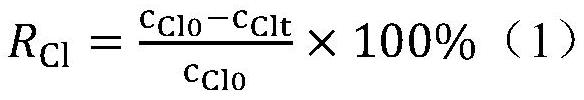

Method for preparing potassium ferrate and cementing material from waste incineration fly ash and iron tailings

PendingCN114524462AImprove gelling activityRealize resource utilizationCellsCement productionPotassium hydroxideSlurry

The invention discloses a method for preparing potassium ferrate and a cementing material by using waste incineration fly ash and iron tailings, which comprises the following steps: (1) mixing iron tailings powder and waste incineration fly ash, and adding water to obtain fly ash and iron tailings mixed slurry; (2) the fly ash iron tailing mixed slurry is placed in an anode chamber of an electrolytic cell, a power supply is switched on for electrolysis, and after electrolysis is finished, electrolytic oxidation slurry and electrolyzed catholyte are obtained in the anode chamber and the cathode chamber of the electrolytic cell respectively; (3) centrifuging and filtering the electrolytic oxidation slurry to obtain a ferrate radical crude solution and acidic iron plaster; (4) mixing and stirring a potassium hydroxide solution, a potassium carbonate solution and the crude ferrate solution, and filtering to obtain a potassium ferrate solution and carbonate filter residues; and (5) uniformly mixing the electrolyzed catholyte, the acidic iron plaster and the carbonate filter residues, drying and activating to obtain the cementing material. According to the invention, the potassium ferrate and the cementing material are prepared by synergistically utilizing the waste incineration fly ash and the iron tailings, so that resource utilization of hazardous wastes is realized.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Ammonia desulfurization system dechlorination method based on membrane treatment

InactiveCN110963624AGood removal effectReduce concentrationWater contaminantsWaste water treatment from gaseous effluentsWater productionPh regulation

The invention discloses an ammonia desulfurization system dechlorination method based on membrane treatment, which comprises the following steps: (1) introducing desulfurized wastewater into a stock solution tank, then lifting the wastewater into a pH regulation tank to regulate the pH until the wastewater is acidic, standing and settling for 20-40 minutes to form a precipitate and a supernatant,and returning the precipitate to a desulfurization system; (2) conveying the supernatant in the step (1) to a regulation tank, and adding water into the regulation tank to dilute the supernatant; and(3) filtering the diluted supernatant in the step (2) through a tubular ultrafiltration membrane to obtain suspended matters, and then conveying the suspended matters into an ultrafiltration water production tank. Chlorine in the solution is converted into ammonium chloride crystals which are brought out of the system, the chlorine ion removal effect is good, the chlorine removal efficiency is high, corrosion to equipment is reduced, the safety of the equipment in the working process is improved, and smooth production of ammonium sulfate is guaranteed.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

A method for removing chloride ions from hydrometallurgy zinc leaching solution

ActiveCN104694751BEnhanced reducing atmosphereReduce Chloride ContentProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention provides a method for removing chloride ions from the leaching solution of zinc hydrometallurgy, comprising the following steps: 1. detecting the concentration of chloride ions and the concentration of copper ions in the leaching solution of zinc hydrometallurgy; Analyze the copper ion concentration obtained; 3. Add copper slag to the zinc hydrometallurgy leaching solution to obtain a slurry; 4. Then feed reducing gas into the slurry to make chloride ions form precipitation; 5. Detect the concentration of the slurry Oxidation-reduction potential, if meet the requirements, then stop feeding the reducing gas, filter to obtain the hydro-smelting zinc leaching solution from which chloride ions have been removed; otherwise, return to step 4. The invention has the characteristics of short process, low cost, high chlorine removal efficiency, no introduction of other impurities, maintaining the original zinc hydrometallurgy process, etc., and has wide popularization value.

Owner:XIAN RAREALLOYS

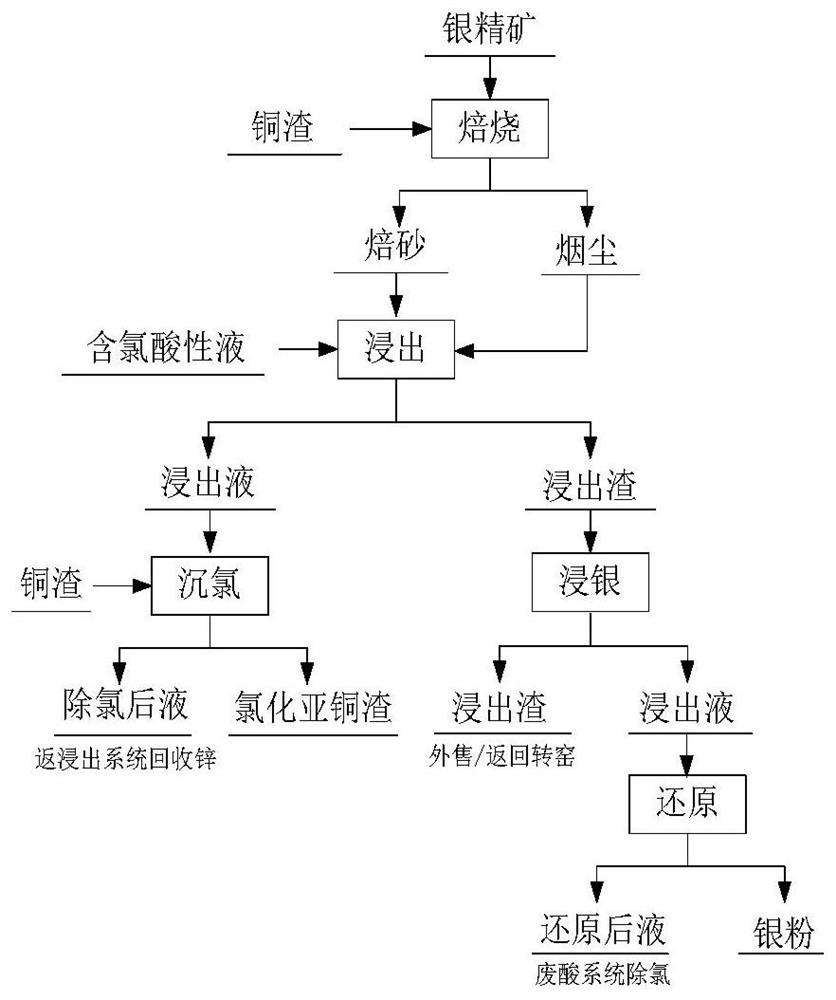

A method for high-value zinc smelting intermediate materials and collaborative chlorine removal

ActiveCN112708772BHigh activityHigh chlorine removal efficiencyProcess efficiency improvementZinc smeltingSilver chloride

The invention discloses a method for increasing the value of zinc smelting intermediate materials and synergistically removing chlorine. By adding a certain proportion of low-activity copper slag to silver concentrate for oxidation and roasting, the activity of copper slag is improved, and the chlorine removal efficiency is increased from 30 ‑60% increased substantially to over 85%. The invention solves the problems of low dechlorination efficiency of copper slag alone, high cost of dechlorination of silver chloride and difficult recovery of silver by coupling copper slag and silver concentrate dechlorination technology; meanwhile, silver, copper, The cascade recovery and high-value utilization of valuable metals such as zinc and lead solve the problems of large pollution, high cost and low metal recovery rate in the existing process.

Owner:ZIJIN MINING GROUP +3

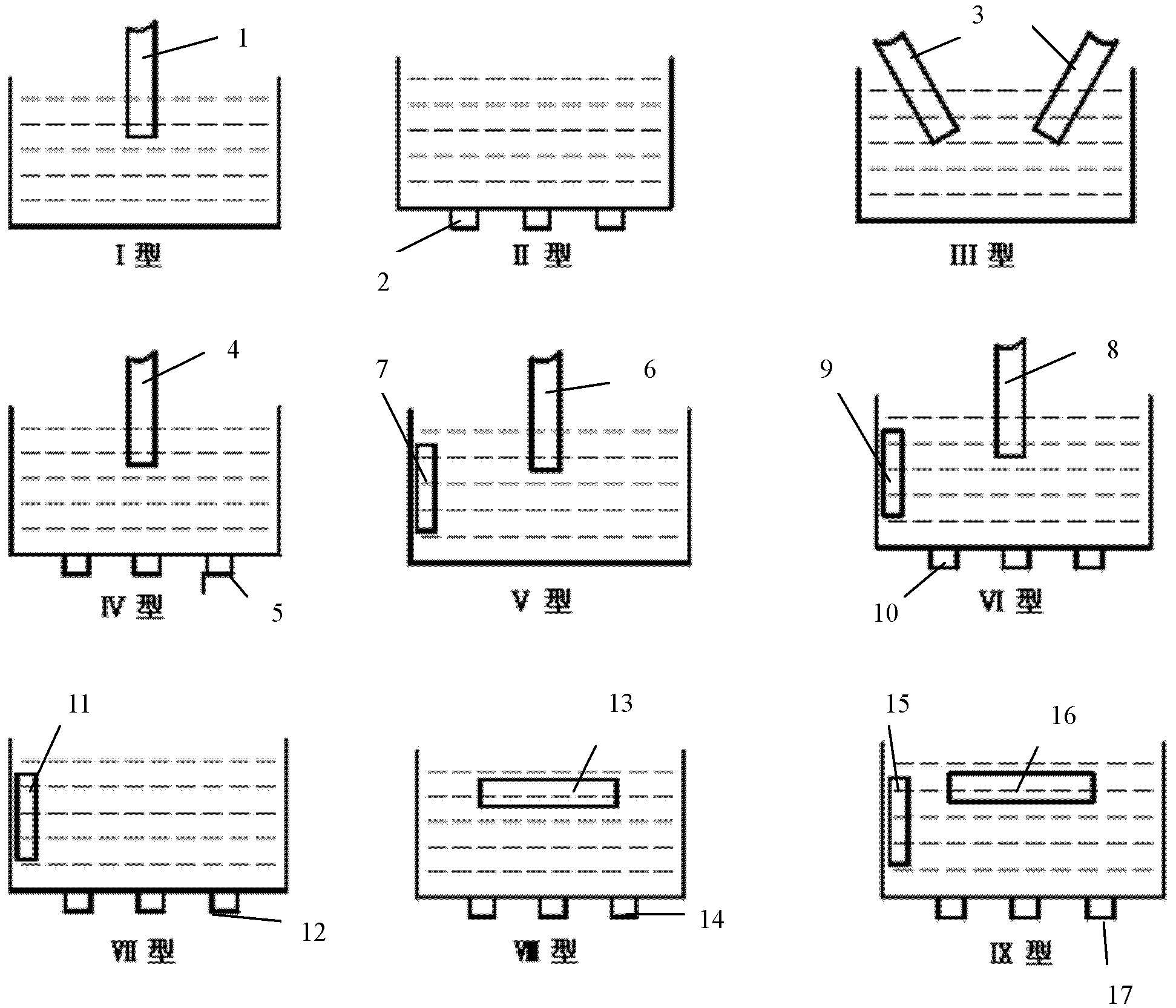

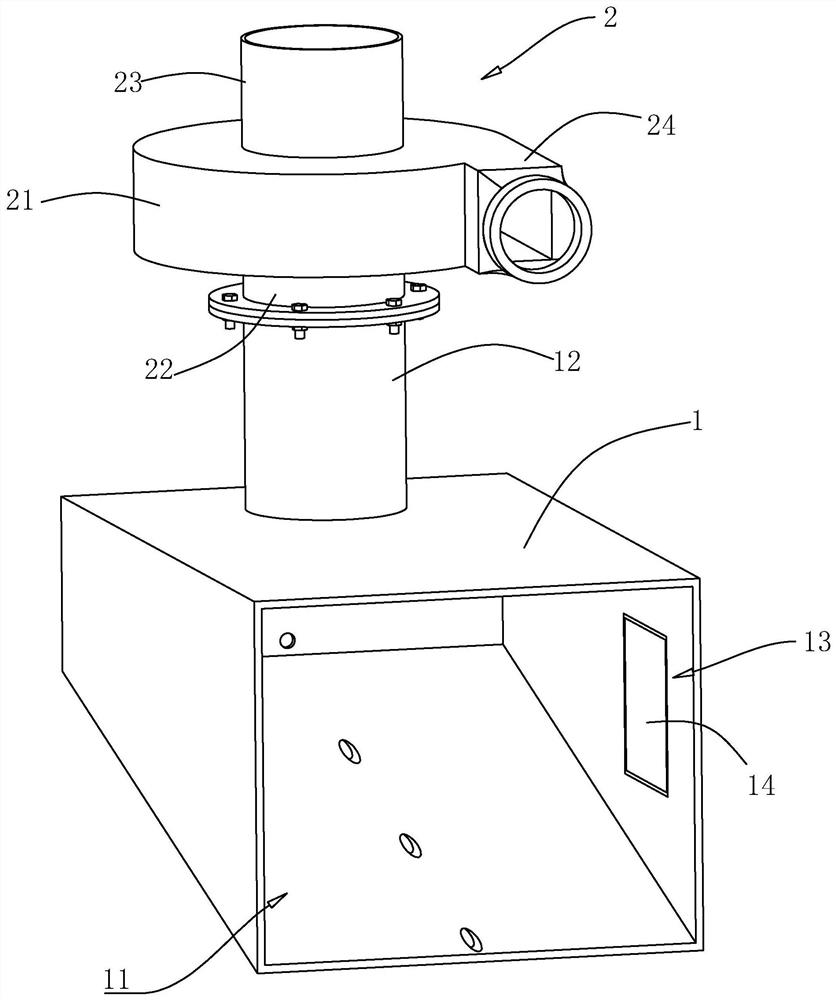

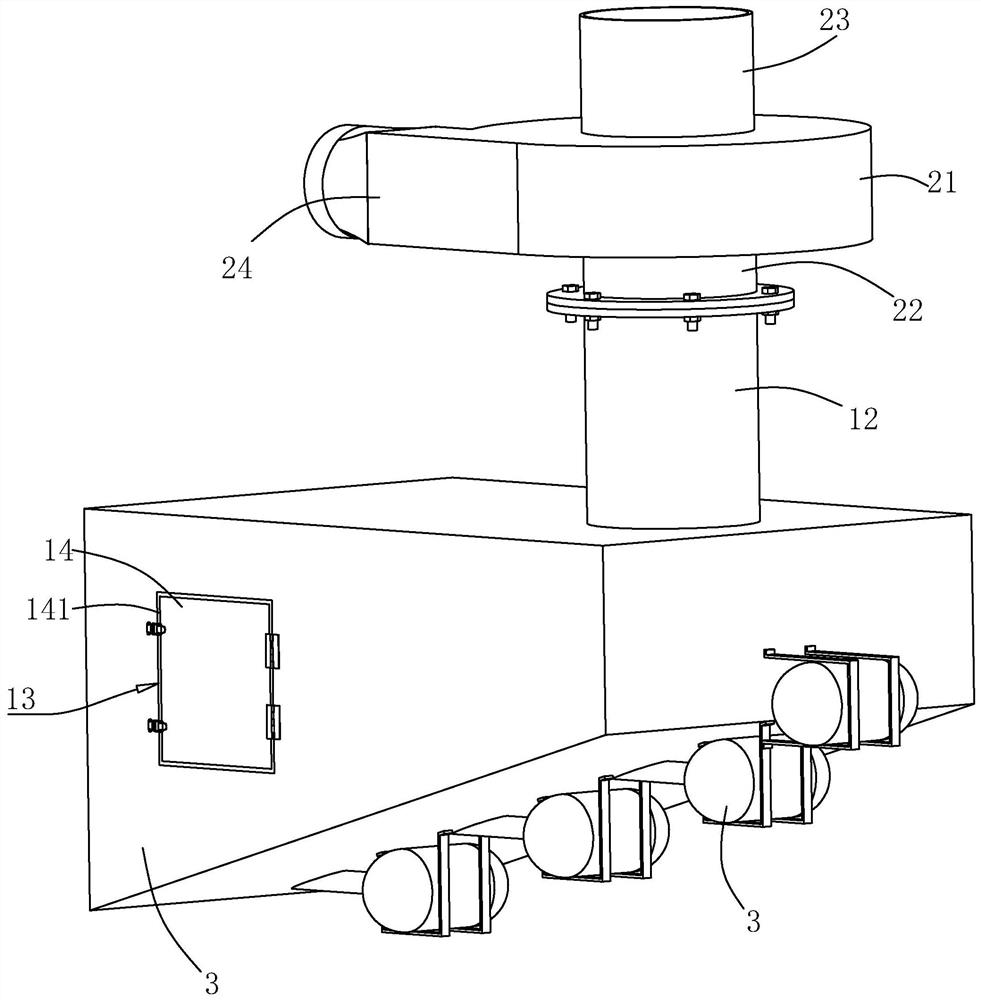

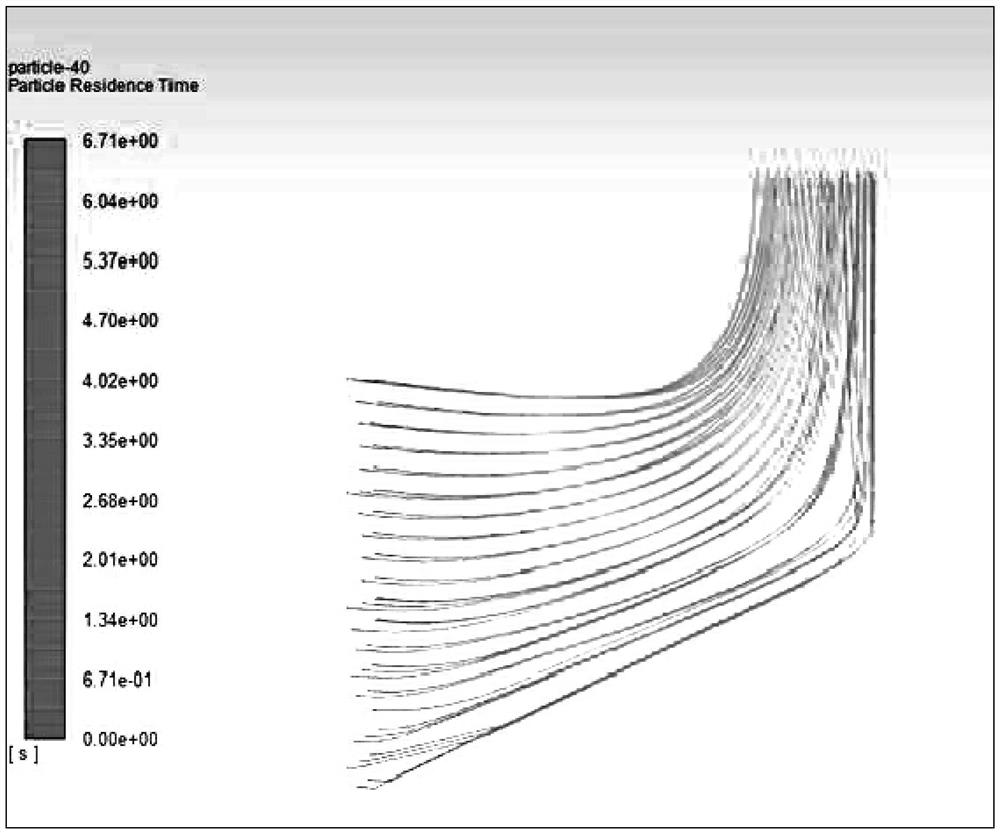

Quenching device with air taking structure and design method of air taking structure

PendingCN113237345AHigh specific surface areaHigh chlorine removal efficiencyWaste heat treatmentThermodynamicsEngineering

The invention relates to a quenching device with an air taking structure and a design method of the air taking structure. The quenching device comprises a quenching chamber and an air taking chamber; the quenching chamber comprises a volute-shaped shell, an air inlet pipe, an air outlet pipe and a blast pipe; the air inlet pipe and the air outlet pipe are located on the two sides of the circle center of the shell and fixedly connected with the shell; the blast pipe and the shell are tangent and fixedly connected; an air inlet is formed in the air taking chamber, and the end, away from the air inlet, of the air taking chamber is fixedly connected with a connecting pipe; and the air inlet of the air taking chamber is connected with a smoke chamber of a cement kiln, and the connecting pipe is connected with the air inlet pipe. The design method comprises the following steps of S1, arranging a table; S2, calculating an average particle size index; and S3, carrying out a simulation experiment. The quenching device has the effect of improving the dechlorination efficiency.

Owner:蓝天众成环保工程有限公司

Method for removing chloride ions in electrolytic manganese solution

InactiveCN107630147BImpurities will not increaseSmall amount of chlorine slag removalProcess efficiency improvementDechlorinatorAntichlor

The invention discloses a method for removing chloride ions in an electrolytic manganese solution. An R-Bi2O3 antichlor is added in an electrolytic manganese anode solution with the sulfur acid content being 30-40 g / l, stirring is conducted for 20-30 min, slurrying is conducted, slurry is added in a to-be-treated electrolytic manganese solution, and after sufficient stirring is conducted for 40-60min at the temperature ranging from 40 DEG C to 60 DEG C and with the stirring rate being 60 r / min, filtering is conducted; filter liquor is injected into a qualified liquid system, and metal manganese is obtained through electrolysis; R in the R-Bi2O3 antichlor is silicon dioxide and manganese oxide, and the adding mass of the R-Bi2O3 antichlor is 10-15 times of the mass of the chloride ions inthe electrolytic manganese solution; and removed filter slag is sequentially subjected to washing and filtering, the removed chloride slag is subjected to alkaline washing for dissolving and dechlorinating through alkaline liquor, filtering is conducted, the filter slag obtained after filtering is sequentially washed and filtered and then is added in a chloride slag removing acidification tank tobe recycled. By means of the method, chloride can be effectively and rapidly removed, the antichlor can be circularly reutilized, and cost is low.

Owner:曹德忠

A method for removing arsenic and chlorine from polluted acid wastewater of metallurgical enterprises

ActiveCN111018212BReduce generationReduce pollutionWater contaminantsTreatment involving filtrationSlagIon exchange

The invention relates to a method for removing arsenic and chlorine from polluted acid wastewater of a metallurgical enterprise, to remove arsenic and chlorine in the polluted acid. The steps include: simultaneously adding a certain amount of iron powder and copper sulfate solution to the polluted acid, stirring, and a reaction device After a certain period of time, a precipitate is formed, and solid-liquid separation is carried out to obtain a filtered solution and precipitated impurities; continue to use an ion exchange resin for adsorption and exchange of the filtrate to remove chlorine. According to the method for removing arsenic provided by the present invention, the generation of lime slag is effectively reduced, and the arsenic impurity ions in the polluted acid are effectively removed, and the arsenic removal efficiency is high; the introduction of other impurities is avoided during chlorine removal, and the treated The acid and water can be reused in the workshop, reducing the pollution to the environment; at the same time, avoiding the increase of the overall solution temperature of the polluted acid and reducing the energy consumption in the production process; comprehensively realizing the economic and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH +1

A method for removing chlorine from zinc sulfate solution

ActiveCN109371259BHigh removal rateAchieve separationPhotography auxillary processesProcess efficiency improvementSulfate zincPhysical chemistry

The invention discloses a method for removing chlorine from a zinc sulfate solution. The steps include: adding concentrated sulfuric acid to the zinc sulfate solution to adjust the pH; adding ascorbic acid, and then adding cuprous oxide for chlorine removal treatment to form cuprous chloride precipitates , after filtration, take the filtrate for later use; wash the cuprous chloride precipitate with absolute ethanol, combine the washing solution and the filtrate to obtain a mixed solution; add an equal volume of organic amine to the mixed solution, extract, and stand for stratification to obtain chlorine removal The zinc sulfate solution and the chlorine-rich organic phase; the chlorine-rich organic phase is back-extracted with a stripping agent to separate the chlorine and the organic phase. The method of the invention effectively removes chloride ions in the zinc sulfate solution, has high dechlorination efficiency, simple process, and reduces the cost of chlorine removal.

Owner:衡阳市大宇锌业有限公司

A kind of method for removing chlorine from acid solution

ActiveCN110734169BHigh chlorine removal efficiencyReduce processing costsWater treatment parameter controlSpecific water treatment objectivesDechlorinatorPhysical chemistry

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Ultrasonic defluorination method for whole euphausia superba

InactiveCN103583931BTo achieve the purpose of defluorinationNo brokenFood ultrasonic treatmentFood preparationNutritive valuesLiquid medium

The invention discloses an ultrasonic defluorination method for whole euphausia superba. After being pretreated, the euphausia superba is soaked in a liquid medium in a working container for ultrasonic defluorination, wherein the euphausia superba is fresh whole euphausia superba, refrigerated whole euphausia superba or dried euphausia superba; the pretreatment is shell softening treatment or unfreezing; the combination type of an ultrasonic treatment device is a single-unit ultrasonic device, a two-unit ultrasonic device or a three-unit ultrasonic device; the liquid medium is a first component, a second component or a third component, the first component is water distilled for three times, deionized water, tap water or seawater, the second component is ethanol, acetone, diethyl ether or No.6 extraction solvent oil, and the third component is an acid solution, alkali solution or salt solution. The technology achieves the purpose of defluorination of the euphausia superba; the defluorinated euphausia superba is kept whole and prevented from breaking, and the sensory quality and the nutritive value are not influenced.

Owner:SHANDONG NORMAL UNIV

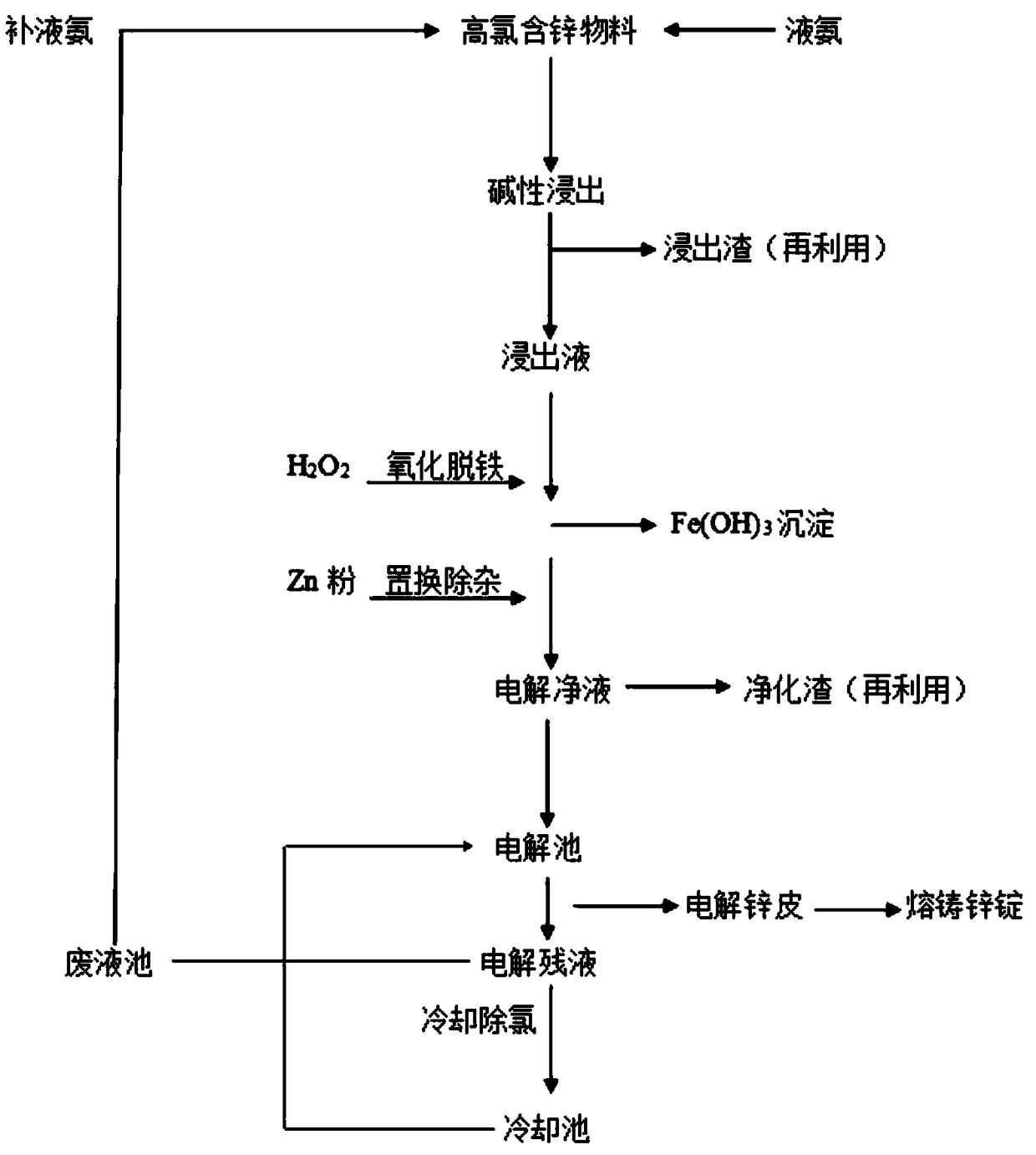

Method for removing chlorine in process of zinc electrolysis by ammonia method

InactiveCN108754548AReduce lossesReduce concentrationPhotography auxillary processesElectrolysis componentsChemical treatmentPrecipitation

The invention belongs to the technical field of chemical treatment and relates to a method for removing chlorine in the process of zinc electrolysis by an ammonia method. The method includes: firstly,leaching is performed, wherein alkaline leaching is performed on a high-chlorine zinc-containing material with liquid ammonia; secondly, solid liquid separation is performed, wherein leachate is obtained; thirdly, purification is performed, wherein the leachate is subjected to oxidization iron removing and zinc powder replacement, and electrolytic clean liquid is obtained; fourthly, electrolysisis performed, wherein electrolytic residual liquid is obtained; and fifthly, chlorine removal is performed, wherein when the concentration of chlorine ions in the electrolytic residual liquid is between 180g / L and 280g / L, the electrolytic residual liquid is used for the leaching work procedure; and when the concentration exceeds 280g / L, part of the electrolytic residual liquid is used for the leaching work procedure, and the other part is subjected to standing cooling in a cooling pond, and clean liquid flows back to an electrolysis work procedure to be used. By using the method, the concentration of chlorine ions in electrolyte is effectively reduced, the current efficiency in the electrolysis process is improved, and it is guaranteed that production is continuously performed; and meanwhile, the precipitation speed of ammonium chloride is increased through the cooling pond, and the method is safe, capable of saving energy, easy to operate, small in investment, environment-friendly andfree of emission.

Owner:宁夏鼎辉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com