Method for preparing chloride ion treating medicament

A chlorine ion and medicament technology, which is applied in the preparation field of chlorine ion medicament, can solve the problem of high chlorine ion treatment cost, and achieve the effect of high chlorine removal efficiency, low price, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

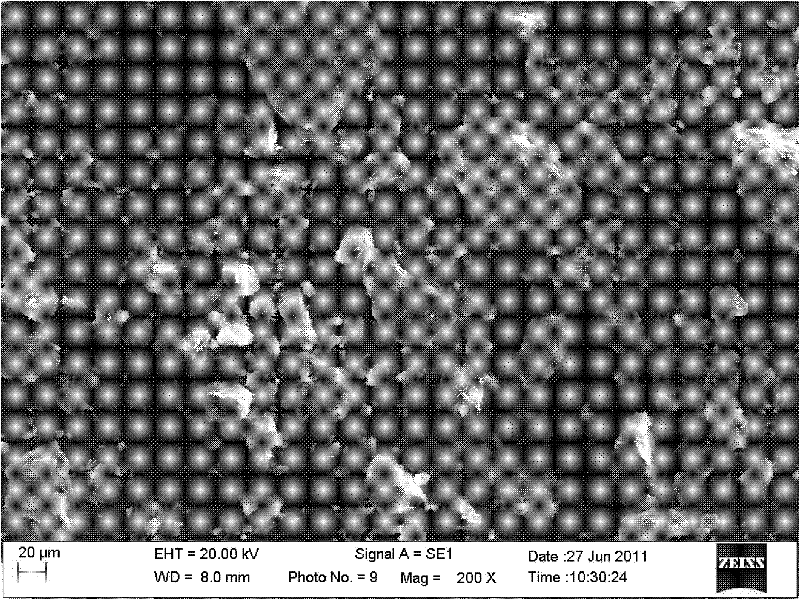

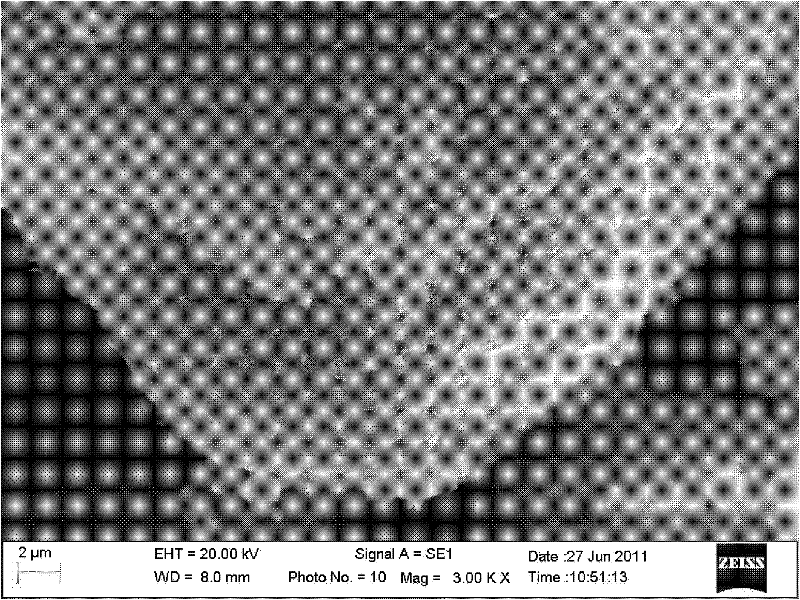

Image

Examples

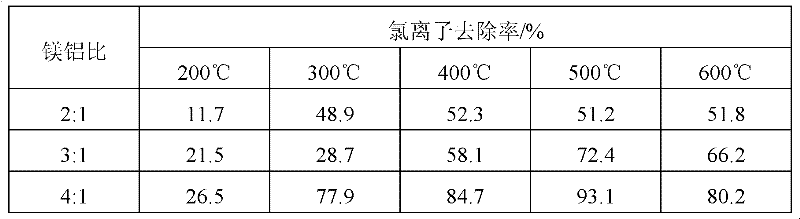

Embodiment 1

[0022] Dissolve 38.462g solid magnesium nitrate hexahydrate and 28.135g solid aluminum nitrate nonahydrate (Mg / Al=2:1) in 500ml water to configure a mixed salt solution; dissolve 30.5g sodium hydroxide and 3.975g sodium bicarbonate in 500ml Make a precipitant in water; put 1000ml of deionized water in the container, heat it to 70°C, and drop the two solutions into this container at a rate of 1 drop / s through a metering pump, and control the relative drop rate to Adjust the pH value above 13 and stir vigorously. Continue to stir for 1.5h after the titration is completed; put the mixed solution at 60°C for crystallization for 15 hours, wait for the mixed solution to precipitate and cool, and after suction filtration, wash the filter cake until neutral; put the filter cake at a temperature of 70°C After drying for 15 hours, it was ground into powder; the powder was fired in a muffle furnace at 200°C, 300°C, 400°C, 500°C, and 600°C for 200 minutes respectively to obtain a produc...

Embodiment 2

[0024] Dissolve 38.462g solid magnesium nitrate hexahydrate and 18.756g solid aluminum nitrate nonahydrate (Mg / Al=3:1) in 500ml water to configure a mixed salt solution; dissolve 28.5g sodium hydroxide and 2.651g sodium bicarbonate in 500ml Make a precipitant in water; put 1000ml of deionized water in the container, heat it to 70°C, and drop the two solutions into this container at a rate of 1 drop / s through a metering pump, and control the relative drop rate to Adjust the pH value above 13 and stir vigorously. Continue to stir for 1.5h after the titration is completed; put the mixed solution at 60°C for crystallization for 15 hours, wait for the mixed solution to precipitate and cool, and after suction filtration, wash the filter cake until neutral; put the filter cake at a temperature of 70°C After drying for 15 hours, it was ground into powder; the powder was fired in a muffle furnace at 200°C, 300°C, 400°C, 500°C, and 600°C for 200 minutes respectively to obtain a product ...

Embodiment 3

[0026] Dissolve 38.462g solid magnesium nitrate hexahydrate and 14.070g solid aluminum nitrate nonahydrate (Mg / Al=4:1) in 500ml water to configure a mixed salt solution; dissolve 27.5g sodium hydroxide and 1.990g sodium bicarbonate in 500ml Make a precipitant in water; put 1000ml of deionized water in the container, heat it to 70°C, and drop the two solutions into this container at a rate of 1 drop / s through a metering pump, and control the relative drop rate to Adjust the pH value above 13 and stir vigorously. Continue to stir for 1.5h after the titration is completed; put the mixed solution at 60°C for crystallization for 15 hours, wait for the mixed solution to precipitate and cool, and after suction filtration, wash the filter cake until neutral; put the filter cake at a temperature of 70°C After drying for 15 hours, it was ground into powder; the powder was fired in a muffle furnace at 200°C, 300°C, 400°C, 500°C, and 600°C for 200 minutes respectively to obtain a product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com