Circulating dechlorination process and system

A process and technology of dechlorination agent, applied in the field of wastewater treatment, can solve the problems of difficulty in recycling, high price, and poor dechlorination effect of dechlorination agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1 Preparation of Chlorine Removal Agent

[0087] The diameter and height of the medicine preparation box are both 1.3m, and the bottom area is 1.32665m 2 . The liquid level height that 100L solution needs to reach is 0.07538m, namely the height of about 7.5cm. The mixer is about 20cm from the bottom.

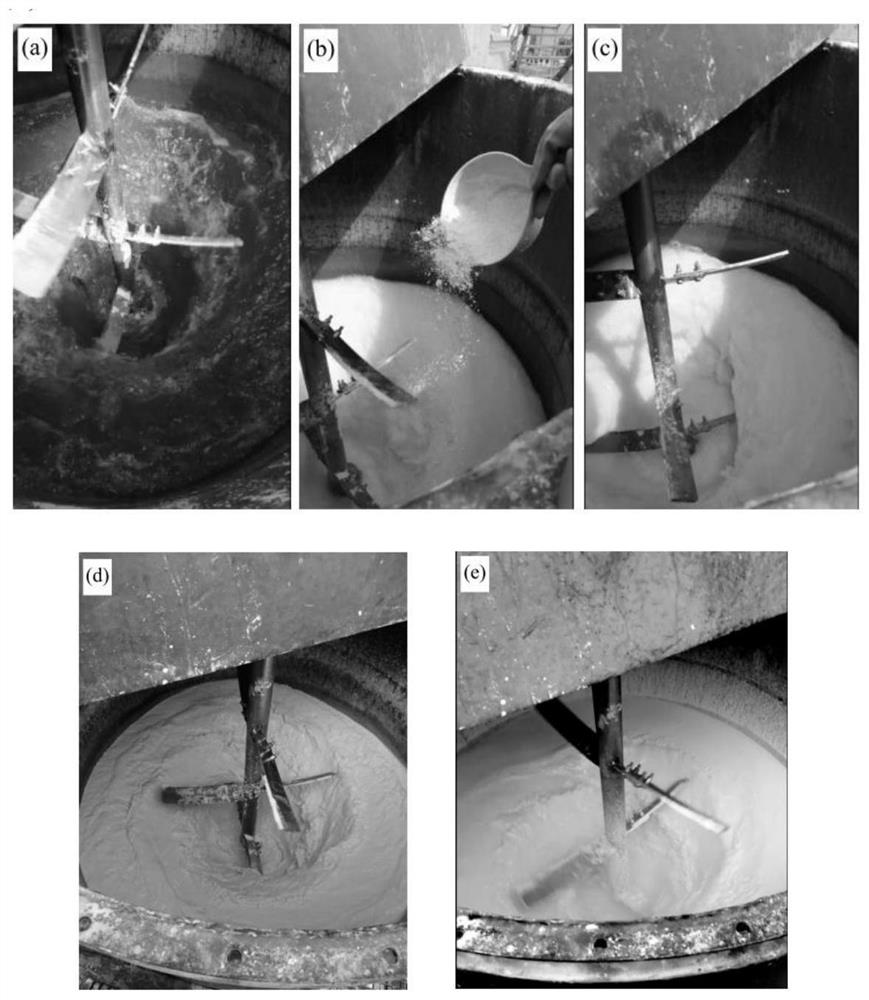

[0088] Open the desalinated water valve of the reactor, add 600L desalinated water (the amount of water is determined by measuring the liquid level of the preparation tank), open the agitator, see figure 1 a. Add 100kg (four barrels) of Bi 2 o 3 -L raw material ( figure 1 b-c), open the lift pump of the sulfuric acid tank and related valves, slowly add 100L sulfuric acid while stirring ( figure 1 e). Cover the lid of the reaction box and stir for 2 hours. After the reaction finishes, open the valve connected to the centrifuge, transfer the slurry to the centrifuge in batches and carry out dehydration, and the supernatant is directly discharged after the...

Embodiment 2

[0105] Add 500L of high-purity desalted water into the medicine preparation box ( Figure 8 a), turn on the agitator, and slowly add 67L of concentrated sulfuric acid using the concentrated sulfuric acid metering pump (the sulfuric acid metering pump has been working at 100% for half an hour; theoretically, 106L should be added, but this time it was added less, because there was a mistake when observing the liquid level ),See Figure 8 b, after stirring for 10min, add 100kg bismuth oxide ( Figure 8 c and 8d), continued to stir for 1.5 hours, and the medicament turned white ( Figure 8 e), indicating that the preparation of the medicament is substantially complete. In fact, within the visible range of the meat, the white color when the bismuth oxide has just been added is not much different from that after stirring for 1.5 hours.

[0106] After stirring for 1.5 hours, the prepared slurry was introduced into a centrifugal dehydrator for centrifugal dehydration, and the separ...

Embodiment 3

[0108] Aiming at the problem that sulfuric acid dosage is too little and filter cloth mesh number is not enough in embodiment 2, this embodiment adds sufficient sulfuric acid and adopts 8000 mesh filter cloths. The experimental steps are as follows:

[0109] Open the desalted water valve of the reactor, add 600L desalted water (the amount of water is determined by measuring the liquid level height of the preparation tank and the internal diameter of the reactor). Turn on the agitator, open the lifting pump of the sulfuric acid tank and related valves, and add 100L of sulfuric acid while stirring. Add 100kg Bi slowly (the actual feeding speed is faster than the first pilot test) 2 o 3 -L raw material (four barrels), see Figure 10a-c. Cover the reaction box lid, after stirring for 2 hours, there is also unreacted yellow block powder in the preparation box ( Figure 10 d). After the reaction, the valve connected to the centrifuge was opened, and the slurry was transferred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com