Surface grafting modification process for waste tire rubber powder for asphalt modification

A technology of surface grafting modification and asphalt modification, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility between rubber powder and asphalt, limit the application of rubber powder modified asphalt, etc., and achieve easy operation. , Easy industrial application, simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

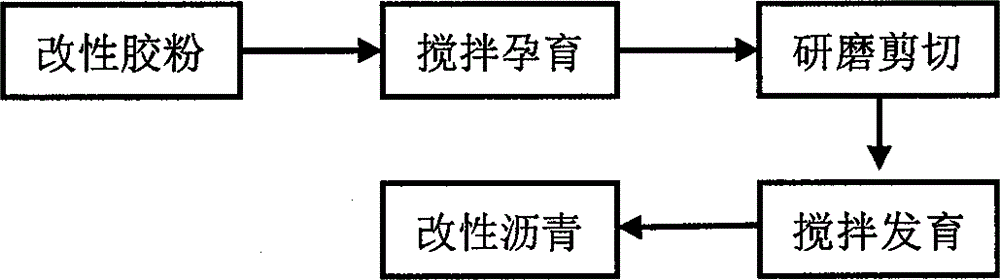

Method used

Image

Examples

Embodiment 1

[0022] Disperse 100g of waste tire rubber powder, 5g of benzoyl peroxide and 300mL of styrene in 400mL of water, and react at 120°C for 12 hours under constant stirring. The reacted waste tire rubber powder is filtered, washed, and dried at 80°C until the quality is constant to obtain the modified rubber powder. The mass grafting rate of the rubber powder was measured to be 67.2%. The modified rubber powder and Binyang No. 70 asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. degree and softening point. It is measured that the penetration at 25°C is 42 (0.1 mm), the ductility at 5°C is 7.6 (cm), and the softening point is 67.4 (°C).

Embodiment 2

[0024] Disperse 100g of waste tire rubber powder, 5g of benzoyl peroxide and 300mL of styrene in 400mL of water, and react for 2 hours under constant stirring at 120°C. The reacted waste tire rubber powder is filtered, washed, and dried at 80°C until the quality is constant to obtain the modified rubber powder. The mass grafting rate of the rubber powder was measured to be 6.4%. The modified rubber powder and Binyang No. 70 asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. degree and softening point. The measured penetration at 25°C is 43 (0.1 mm), the ductility at 5°C is 7.4 (cm), and the softening point is 65.6 (°C).

Embodiment 3

[0026] Disperse 100g of waste tire rubber powder, 5g of benzoyl peroxide and 300mL of styrene in 400mL of water, and react at 120°C for 6 hours under constant stirring. The reacted waste tire rubber powder is filtered, washed, and dried at 80°C until the quality is constant to obtain the modified rubber powder. The mass grafting rate of rubber powder was measured to be 36.1%. The modified rubber powder and Binyang No. 70 asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. degree and softening point. The measured penetration at 25°C is 49 (0.1 mm), the ductility at 5°C is 11 (cm), and the softening point is 68.5 (°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com