Patents

Literature

78results about How to "Stop breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

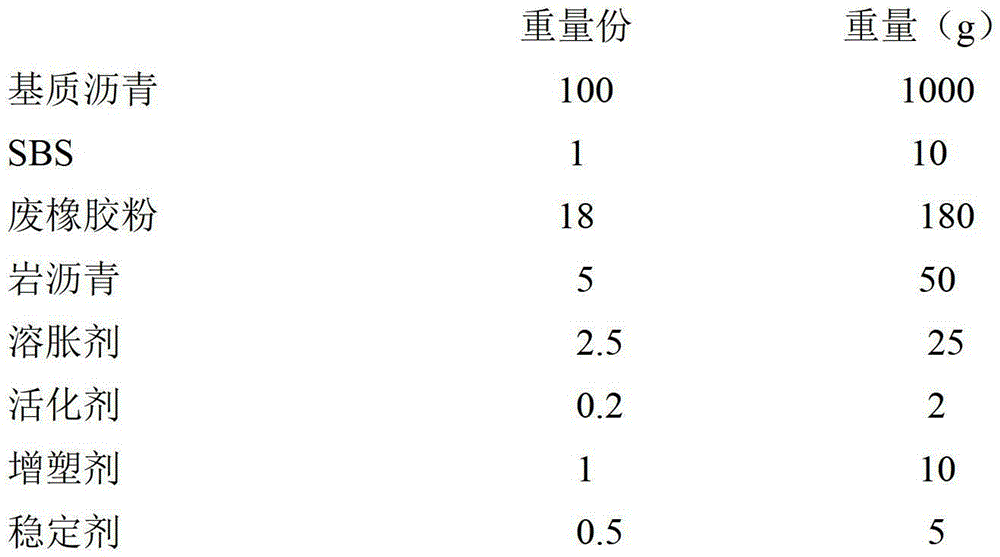

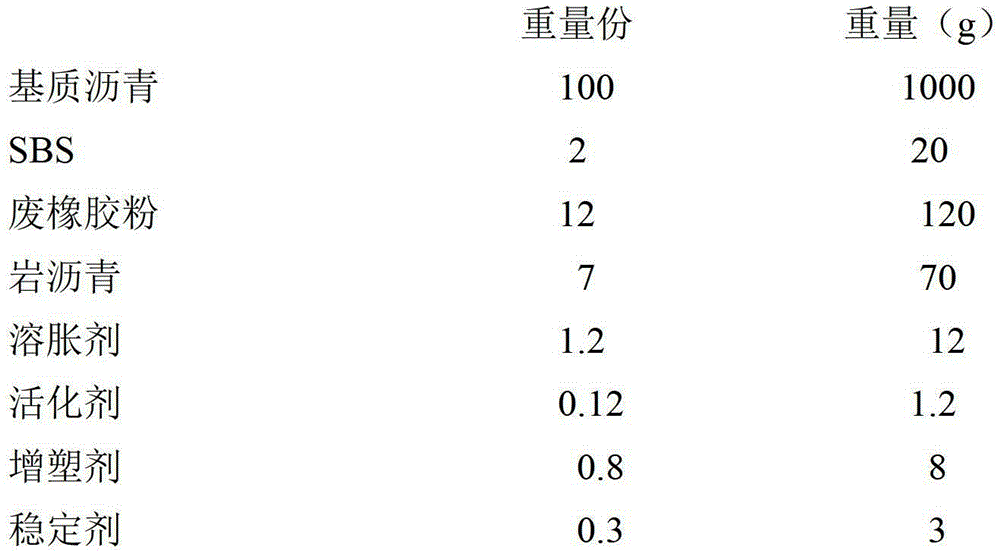

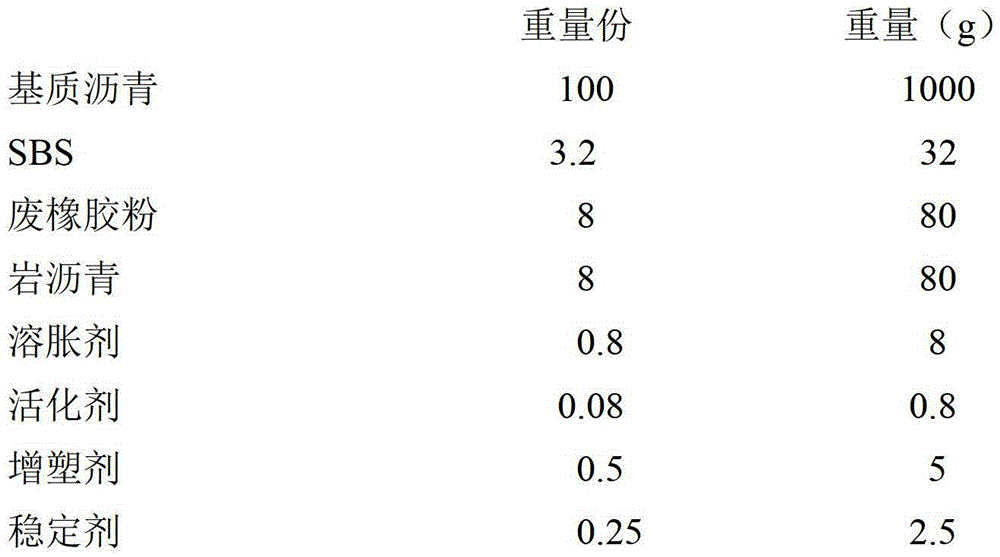

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

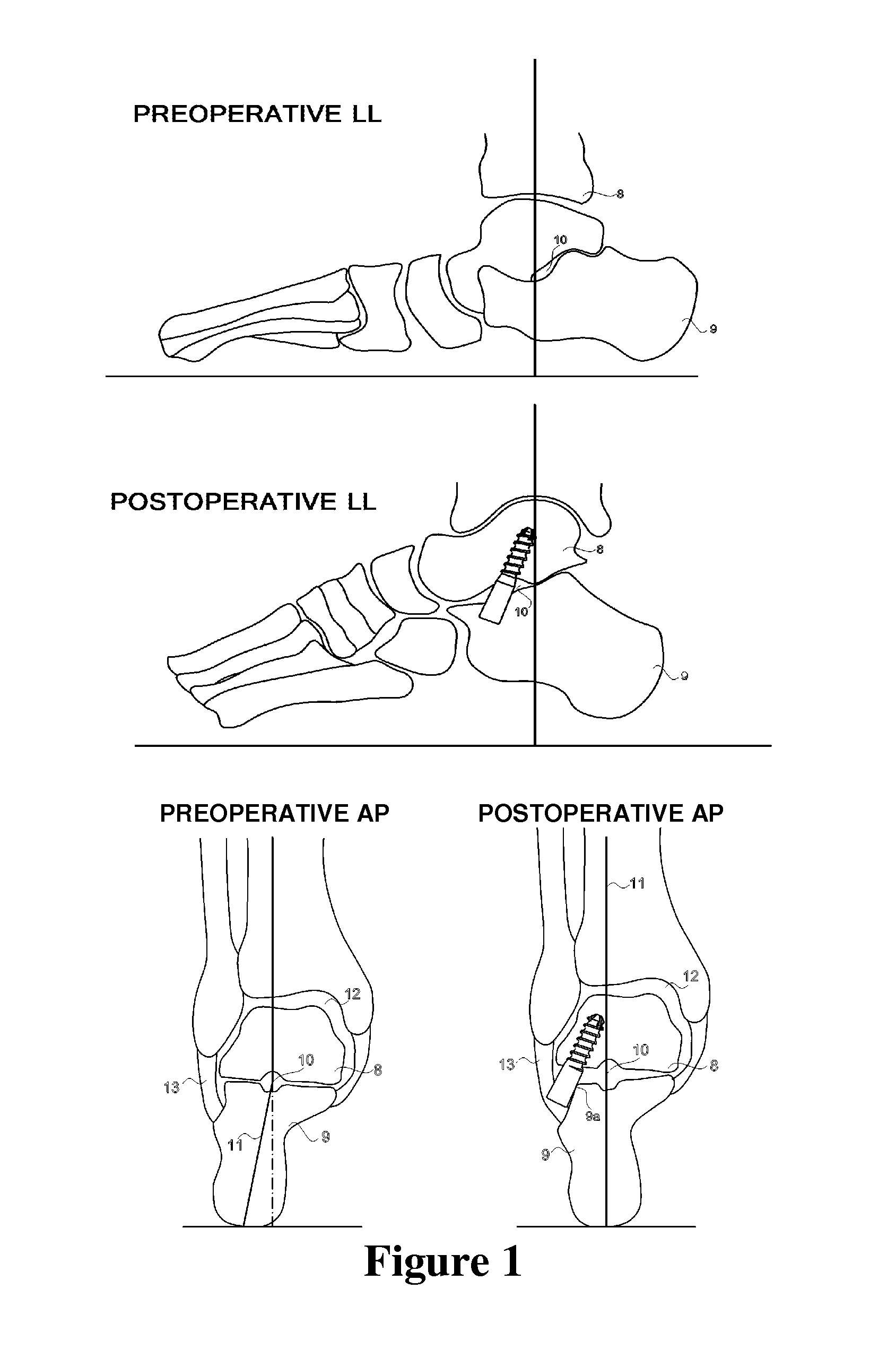

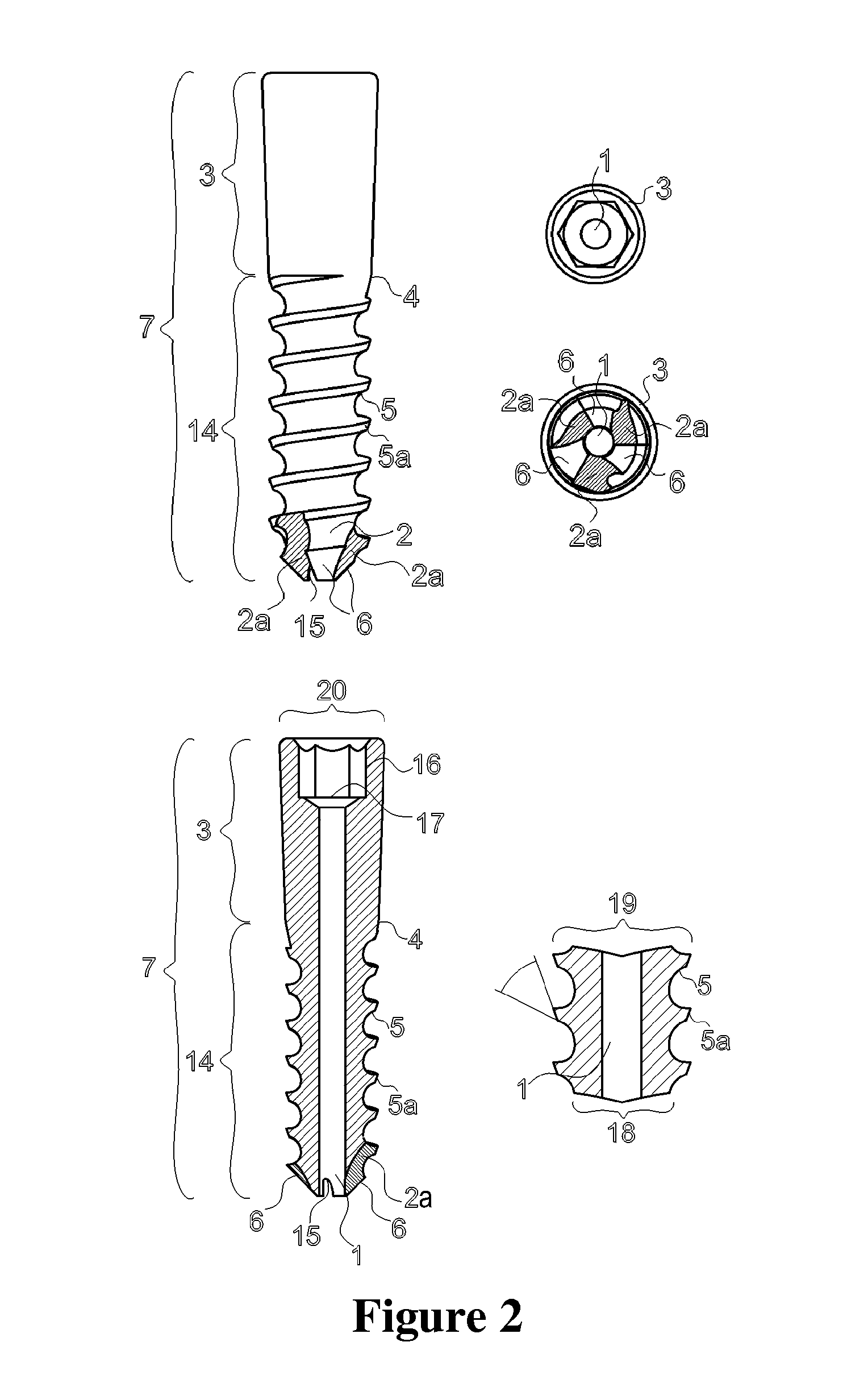

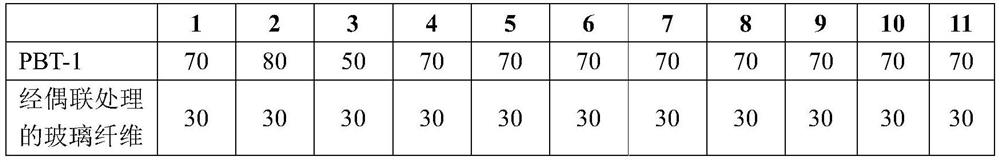

Canulated titanium implant for correcting flat feet in children

InactiveUS8267977B2Easier correctly placedHarming the surrounding tissueSuture equipmentsAnkle jointsMedicineTitanium

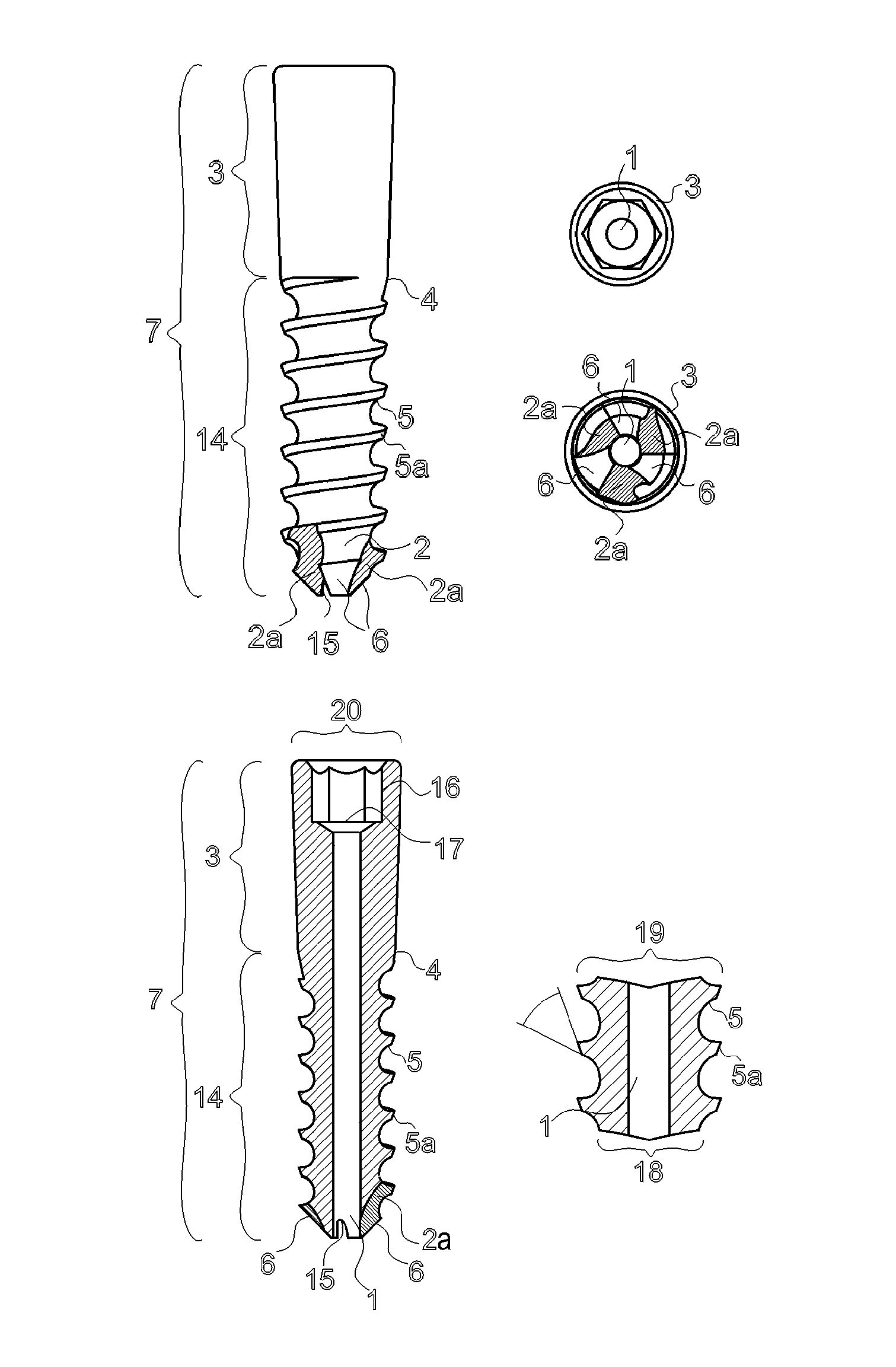

The cannulated titanium implant (screw) for correction of flat feet in children characterized by that: a) the diameter of the stem is D=4.8 mm±25%, recommended 4.8 mm±10%, and especially recommended 4.8 mm, b) it is cannulated, whose diameter is C=2 mm+25%, recommended 2 mm±10%, and especially recommended 2 mm, c) the screw-thread height is 1.15 mm±25%, recommended 1 / 15 mm±10%, and especially recommended 1.15 mm, d) on the point of the screw, which ends at the angle of 90°, on the apex thread are trisect cuts at the angle of 120°. The edges of the apex thread are cut at the angle of 55°. At the very top of the point of the screw, the trisect cuts of the apex thread go inward the tunnel in the length of the screw by 1.5 mm, e) this type of the point replaces the use of the drill and the tapping device.

Owner:ROTH SANDOR UMLAUT OVER

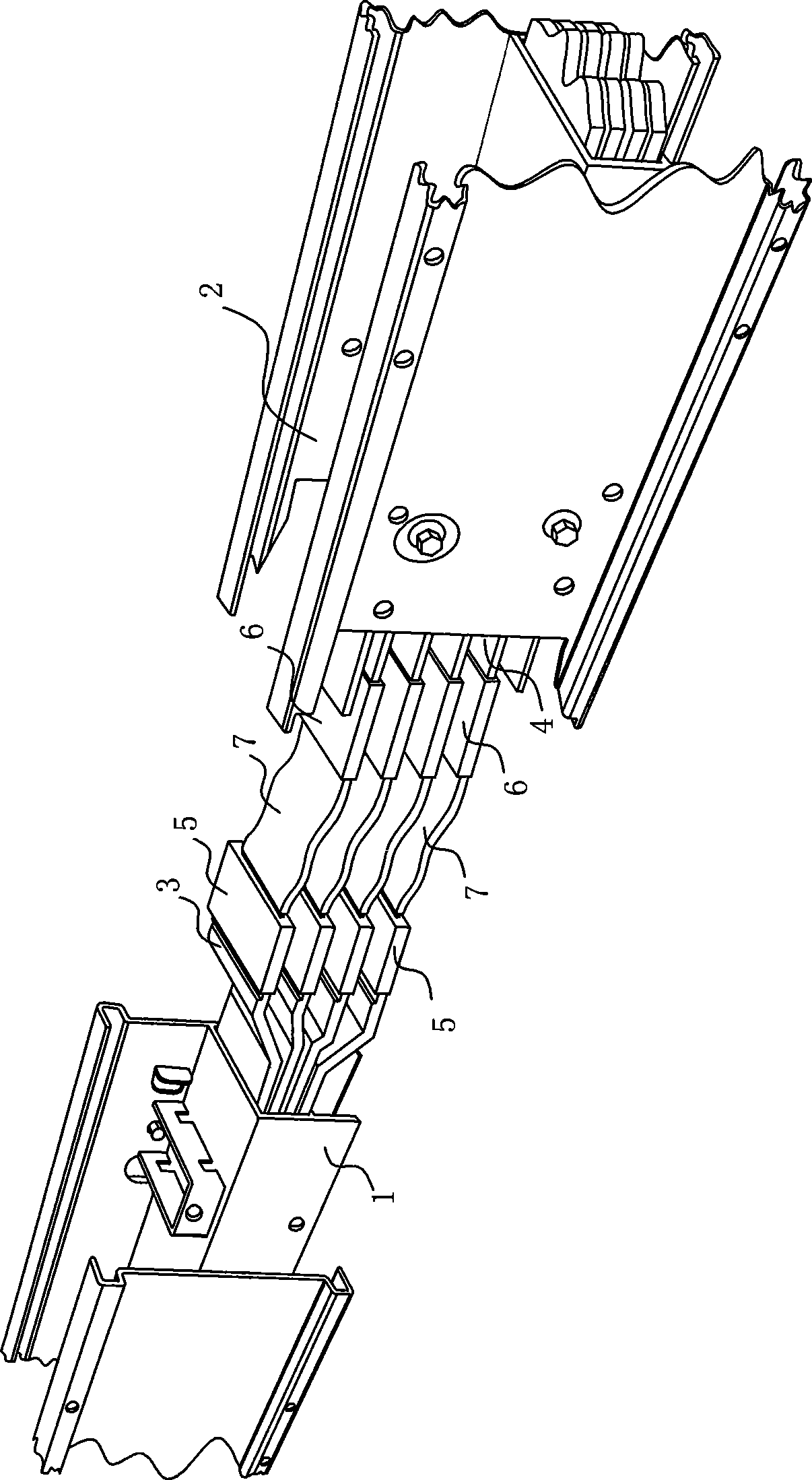

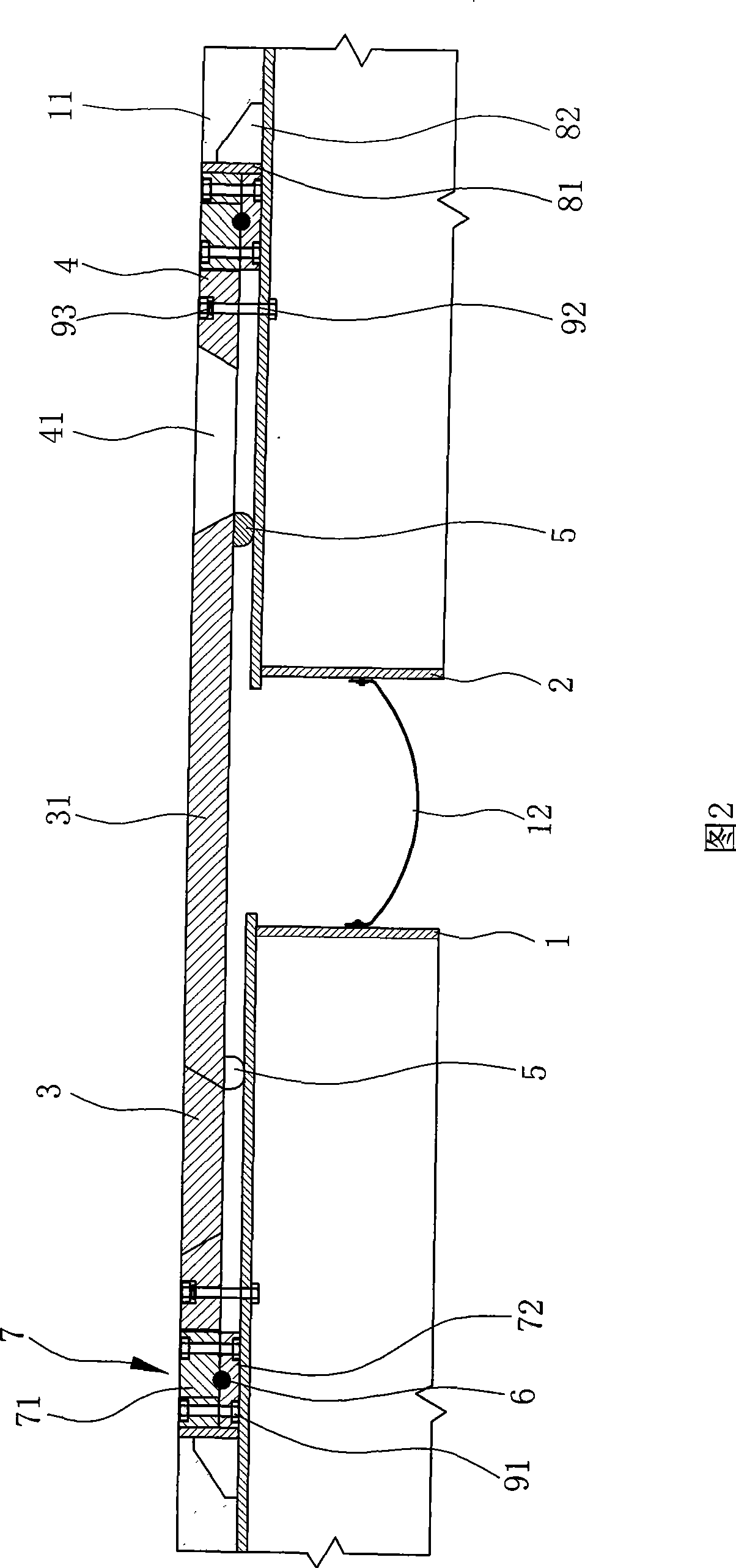

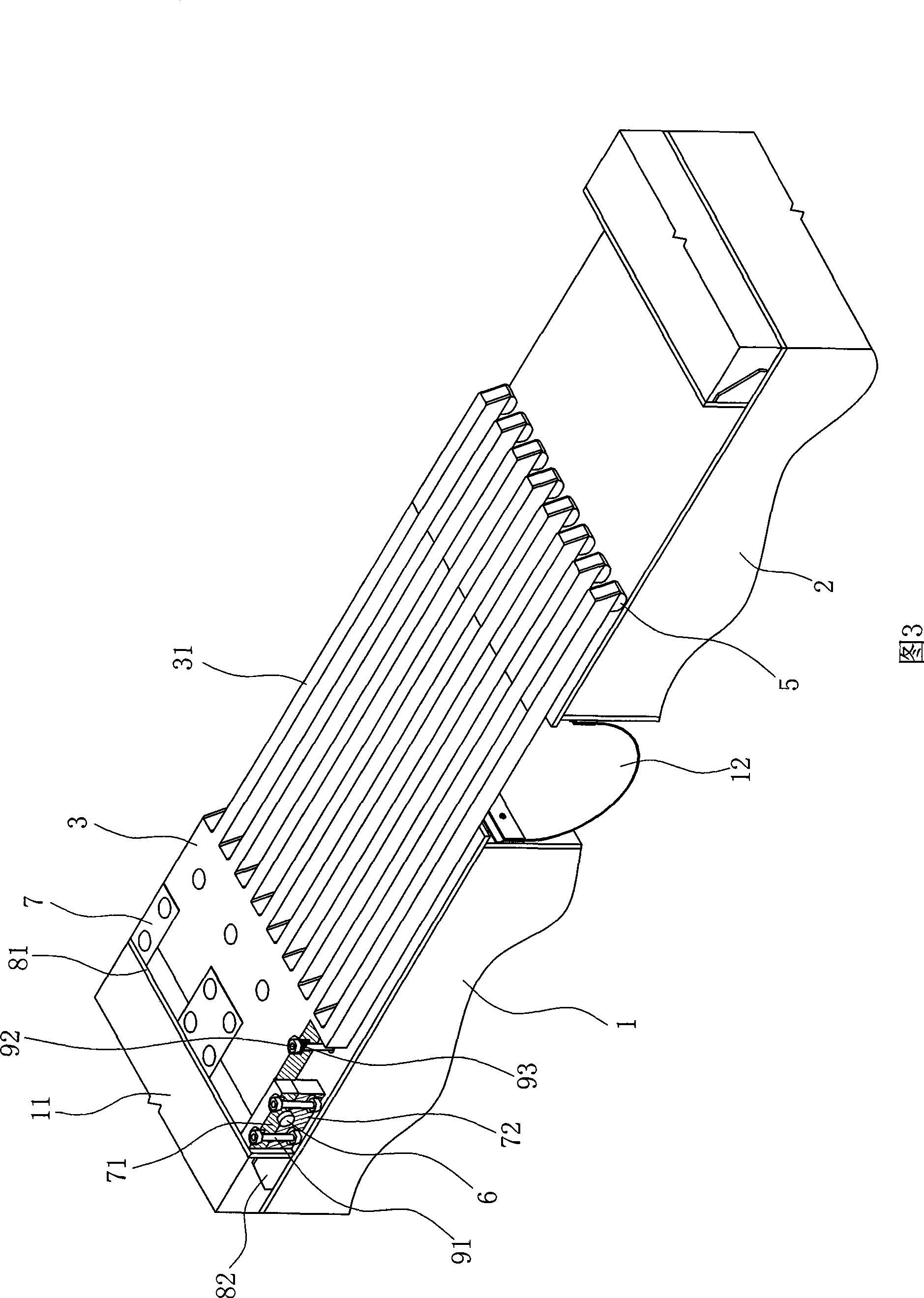

Method and device for bus bar soft connection

InactiveCN101465529AReasonable designSimple structureBus-bar installationClamped/spring connectionsEmbedded systemElectrical conductor

The invention relates to a bus soft connecting method; bus joints in a bus groove are connected by soft conductor materials; the soft conductor materials is connected with the bus joints in a checking way, or is spliced with the bus joints in a close matching way or is fixedly connected with a screw; plug sleeves are fixed at the two ends of the soft conductor materials and are spliced with the bus joints of the bus groove. The bus soft connecting method and the device thereof have reasonable design and simple structure, and can be used in a bus fixation occasion, and can be suitable for the environment of unfixed bus; the application range is wide, and the problem of poor contact among buses is solved; the joint fracture among buses or the change of the contact surfaces is effectively reduced and the normal operation in industrial production is ensured.

Owner:梁波

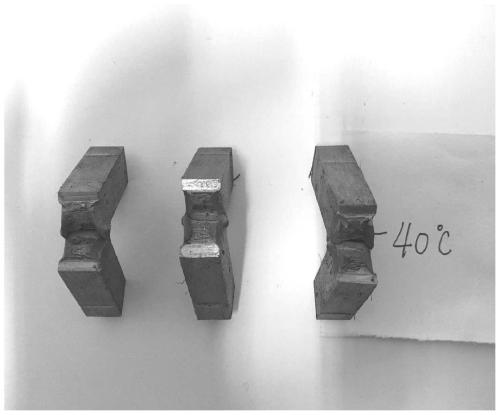

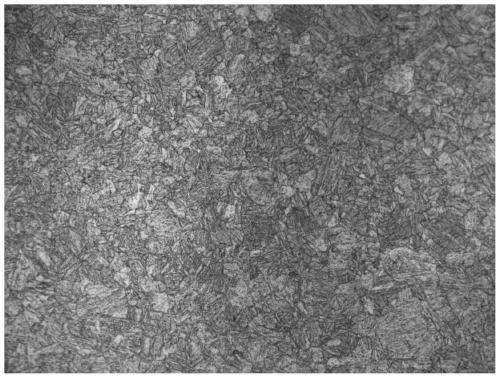

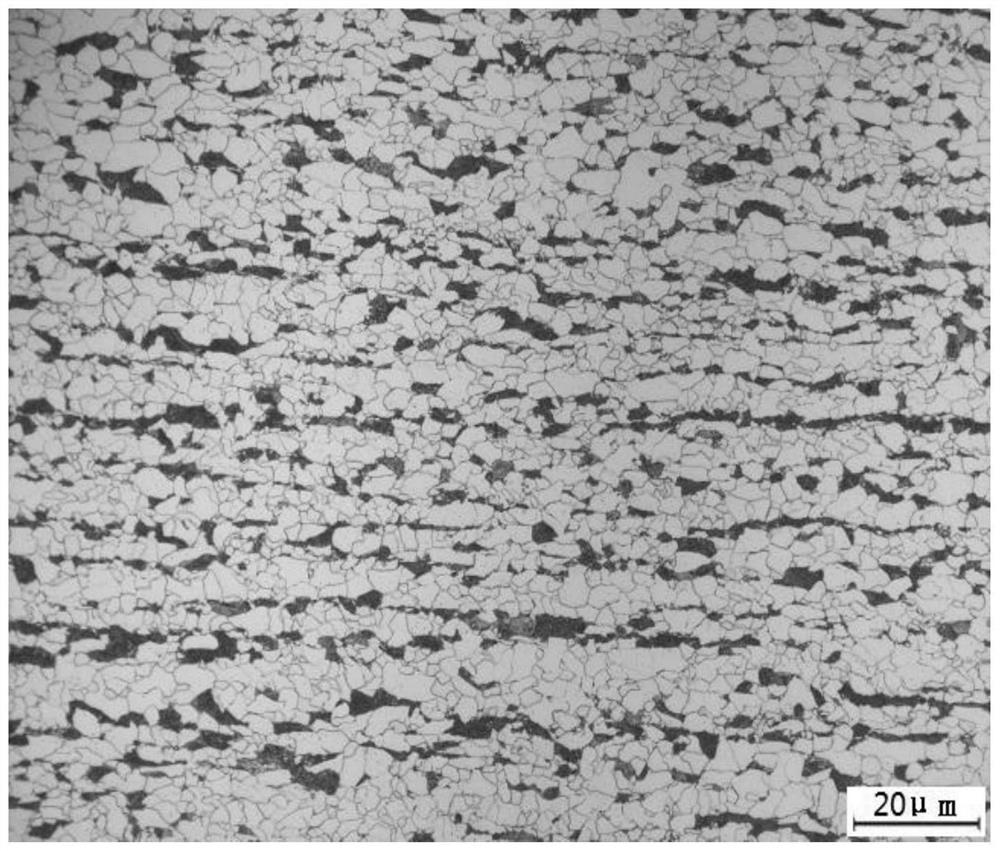

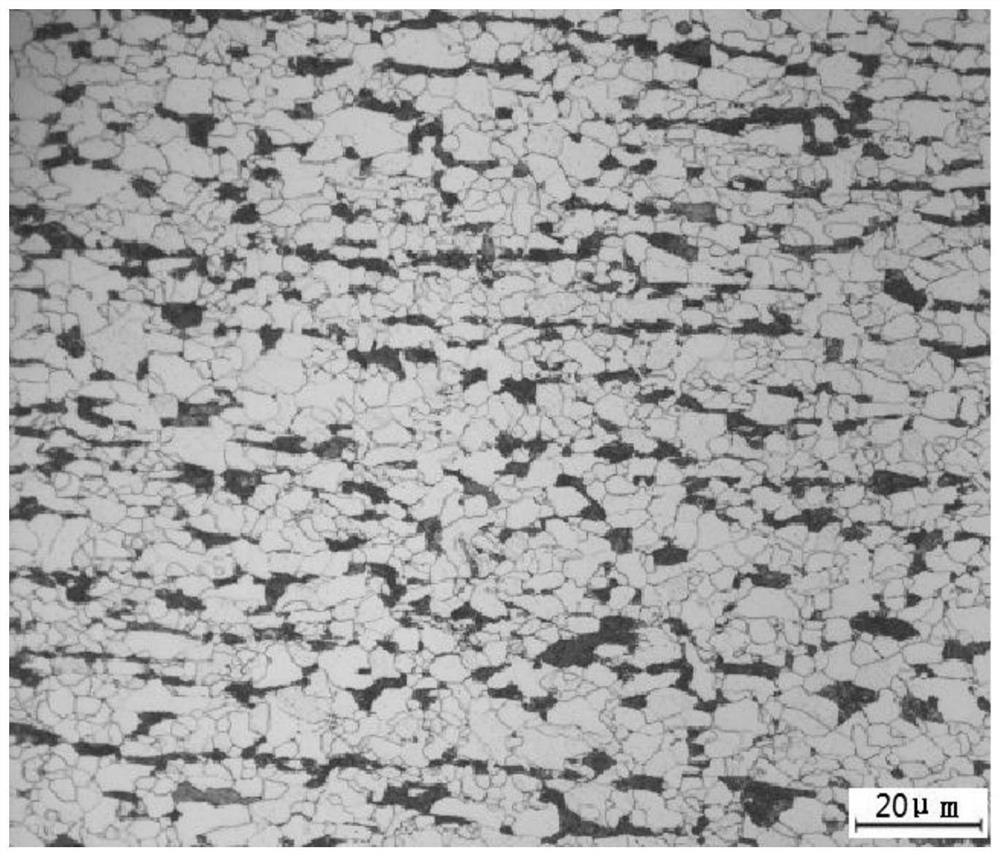

Process for improving rare-earth high-strength steel impact toughness

The invention discloses a process for improving rare-earth high-strength steel impact toughness. The process comprises the following steps of KR desulfurization slagging off, converter smelting, LF refining, RH refining and rare-earth treating, continuous casting, heating, rolling, accelerated cooling and heat treating. According to the process, aiming at the influence on the microstructure of low-alloy high-strength steel in the case that rare-earth exists, a research shows that rare-earth cerium Ce can improve the forms of inclusions and purify grain boundaries, so that the strength of the grain boundaries is improved, the possibility that cracks extend due to the through defects is reduced, and the impact toughness is improved; and addition, the impact toughness can be improved throughrefining austenite grain boundaries, and meanwhile, adding the rare-earth cerium Ce can enable the ductile-brittle transition temperature of the steel to reduce by about 10 DEG C.

Owner:BAOTOU IRON & STEEL GRP

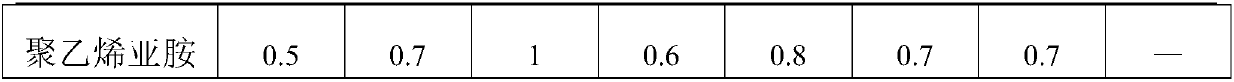

Deodorant plant cat litter and preparing method thereof

InactiveCN109566426AGood sterilization and deodorization effectHigh ammonia uptakeAnimal housingFiberSodium bicarbonate

The invention belongs to the technical field of cat litter, and provides deodorant plant cat litter and a preparing method thereof. The deodorant plant cat litter is prepared from, by weight, 60-70 parts of soybean fibers, 25-35 parts of corn starch, 10-20 parts of sodium bicarbonate, 5-10 parts of zeolite, 4-6 parts of citric acid, 1-3 parts of sodium phenylpropionic acid, 3-7 parts of active carbon, 2-5 parts of ammonium persulfate, 2-4 parts of guar gum, 1-5 parts of a garlic extract, 1-3 parts of tea residues and 0.5-1 part of polyethyleneimine. By means of the deodorant plant cat litter and the preparing method thereof, the technical problem that cat litter in the prior art is poor in antibacterial deodorant effect is solved.

Owner:涿州市浩森再生资源回收有限公司

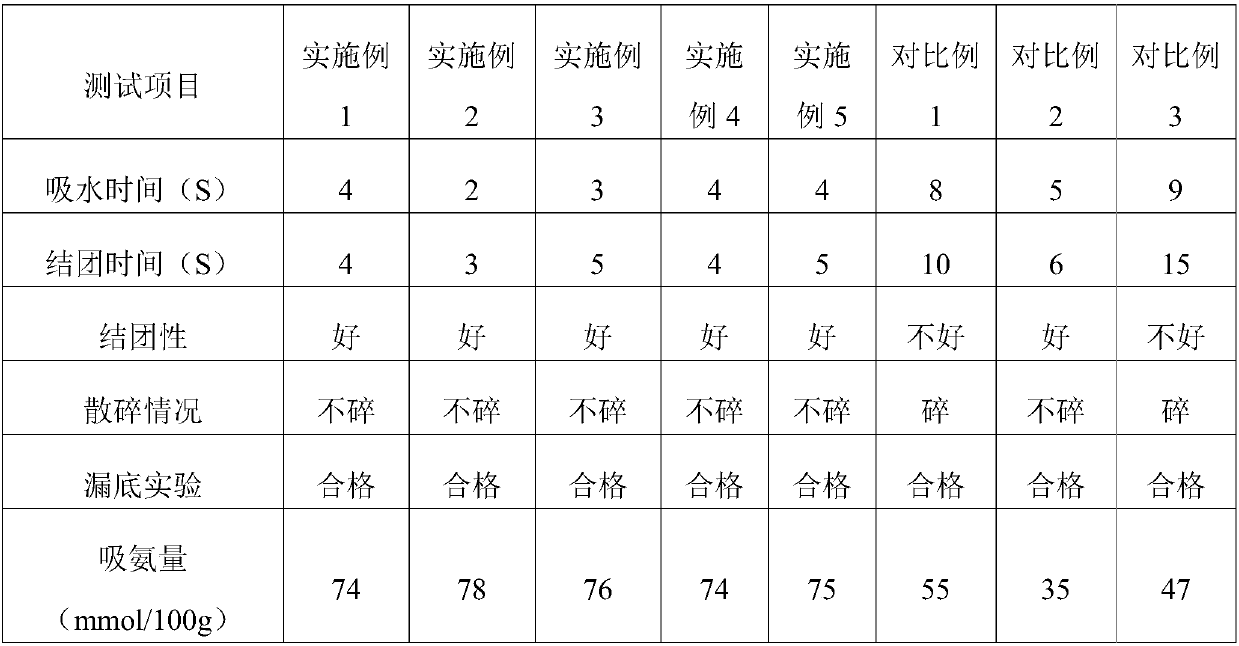

Bridge expansion joint device preventing extra large vertical rotation angle displacement

The invention discloses a bridge expansion joint device for resisting dislocation of an extra large vertical corner, which comprises a first beam body, a second beam body, and a first movable comb-like plate and a second movable comb-like plate. The ends of the first movable comb-like plate and the second movable comb-like plate are provided with comb teeth which are mutually intersected and arranged at intervals. The comb teeth of the first movable comb-like plate and the second movable comb-like plate span the whole bridge expansion joint. Meanwhile, gaps are reserved between the bottoms of the first movable comb-like plate and the second movable comb-like plate and the beam bodies. A slide block is arranged at the bottom of the end of each comb tooth on the first movable comb-like plate and the second movable comb-like plate, and the roots of the first movable comb-like plate and the second movable comb-like plate are rotatably arranged above corresponding beam bodies. When the two beam bodies have vertical corner dislocation, end warping or sinking due to an external force such as loading, the movable comb-like plate on each beam body can rotate correspondingly to the beam body, and each comb tooth is adjusted correspondingly and smoothly, so that each movable comb-like plate keeps smooth, the whole expansion joint device is prevented from being damaged and ensures smooth and safe passing of each vehicle.

Owner:徐斌

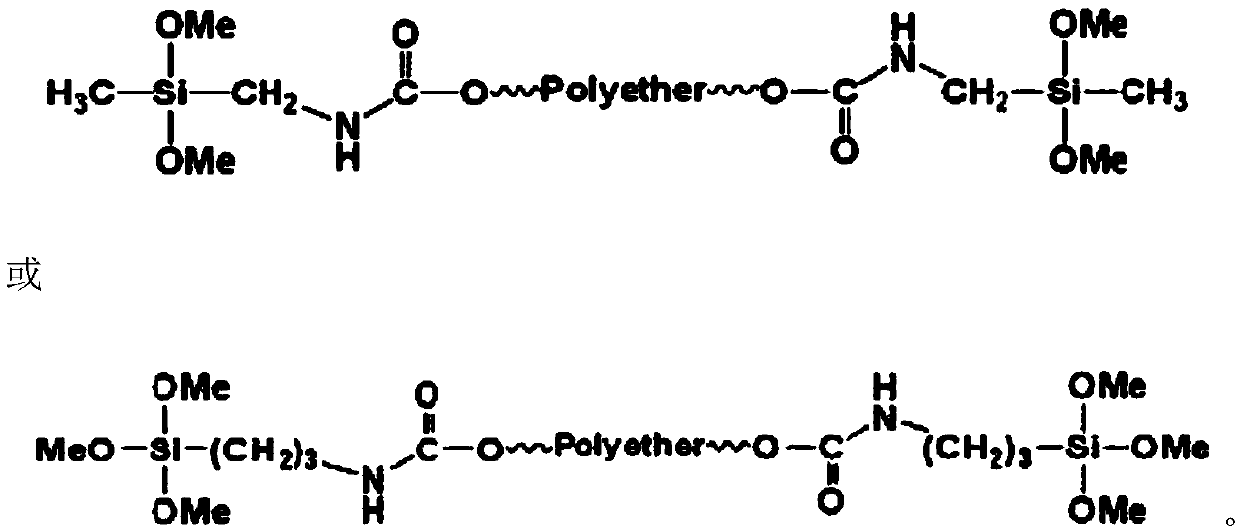

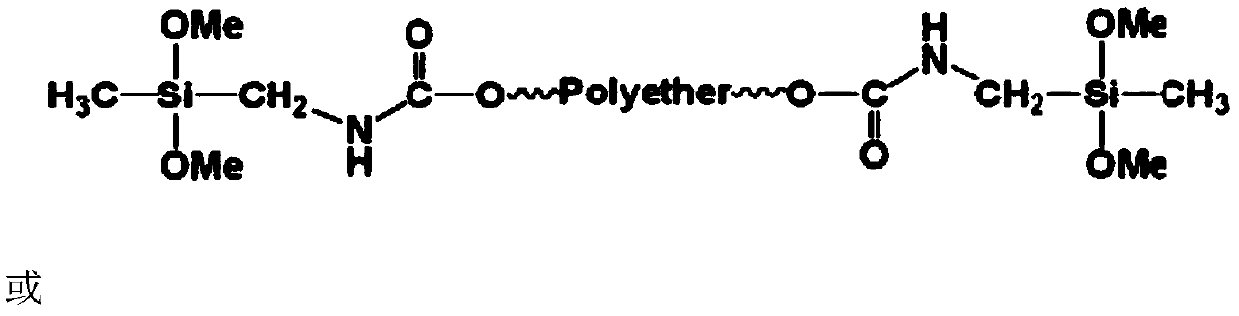

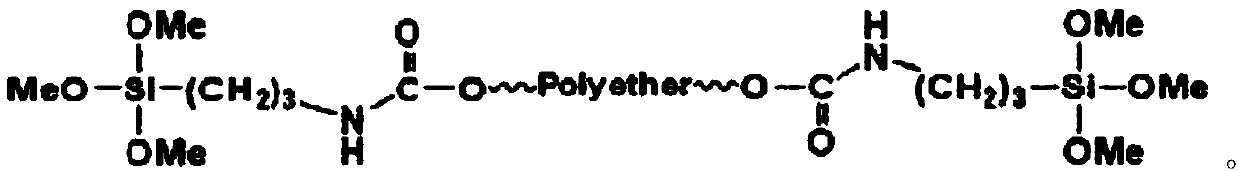

Single-component silane-modified polyether sealant and production method and application thereof

InactiveCN109852317APollution-free corrosionLow VOCNon-macromolecular adhesive additivesMacromolecular adhesive additivesScavengerWeather resistance

The invention provides a single-component silane-modified polyether sealant and a production method and application thereof, and belongs to the field of building sealants. The sealant comprises the following raw materials of, in parts by weight, 20-50 parts of silane-modified polyether resin, 0-15 parts of plasticizer, 30-60 parts of filler, 1-2 parts of thixotropic agent, 0.4-1.5 parts of functional assistant, 0.5-2 parts of moisture scavenger, 0.5-2 parts of bonding accelerator and 0.05-0.5 part of catalyst. The sealant is excellent in weather resistance performance, the phenomena of cracking and efflorescence are not liable to occur, and no pollution is caused for a stone curtain wall.

Owner:GUANGZHOU GLORYSTAR CHEM

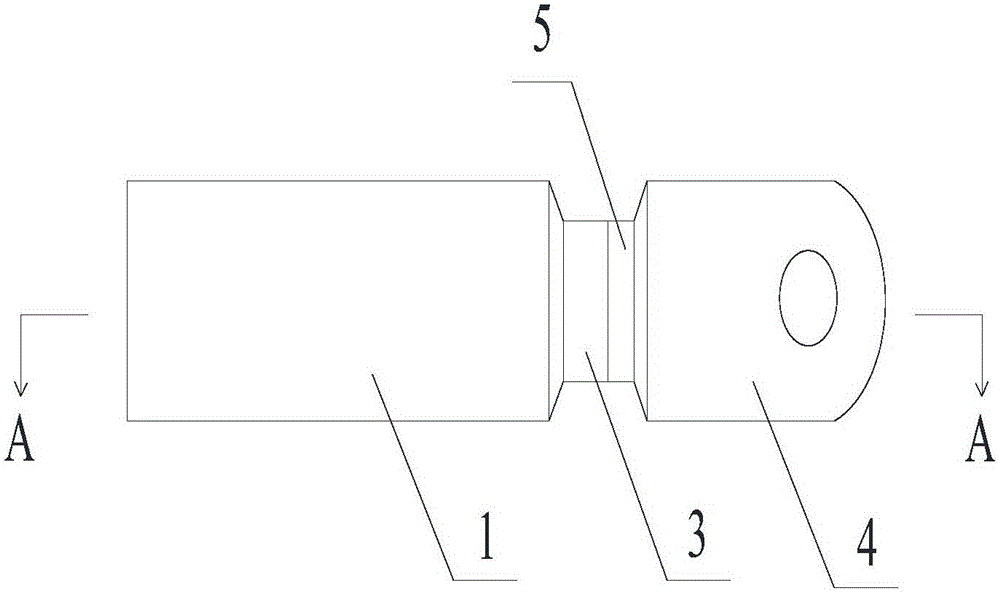

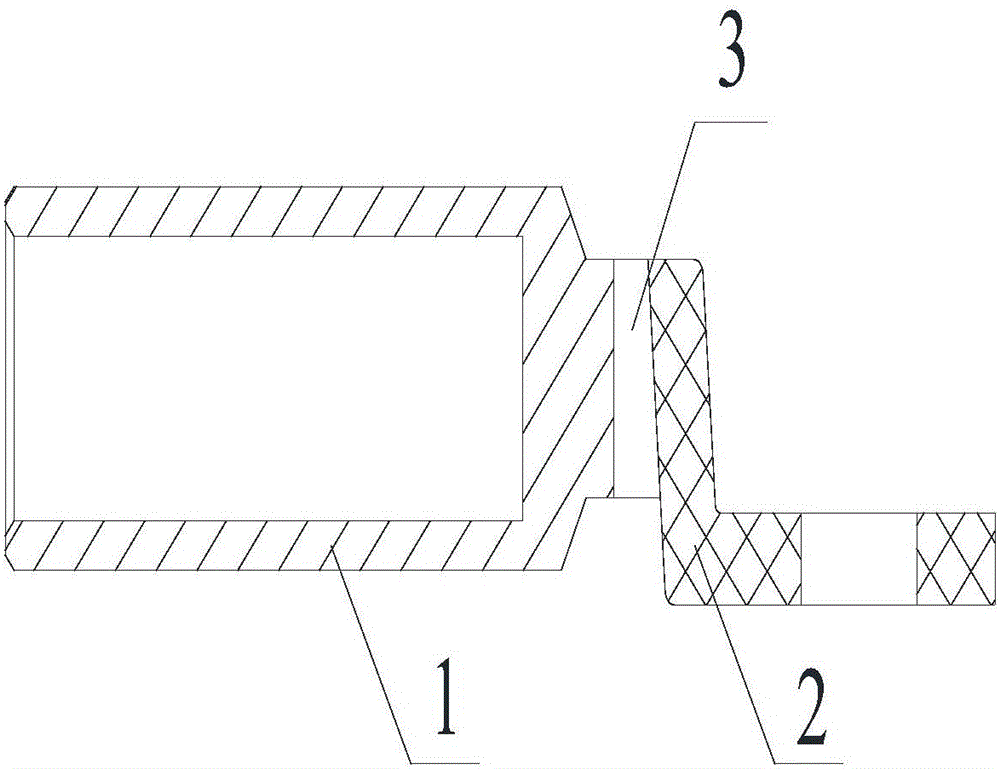

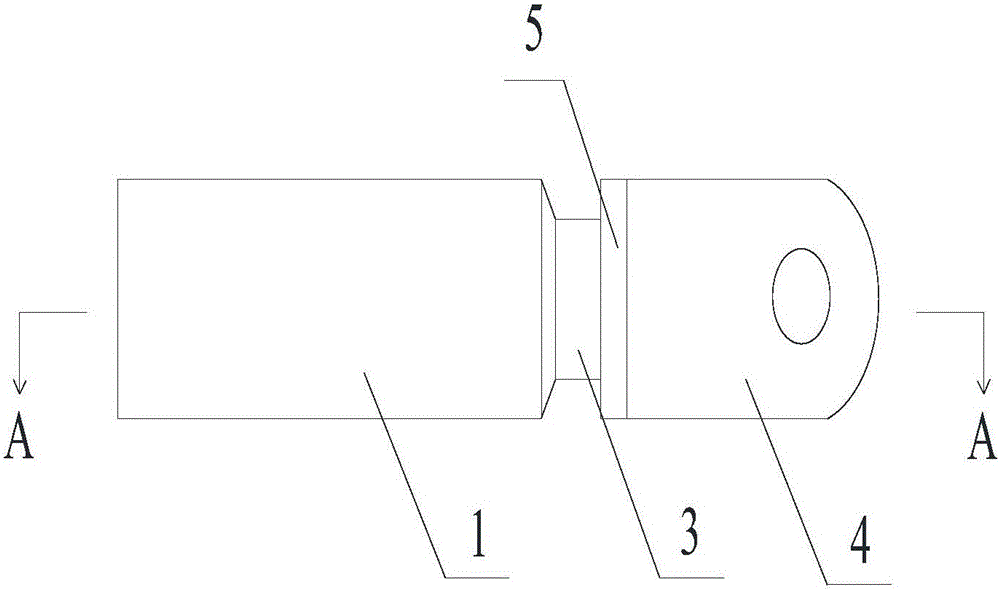

Quick connection joint for plastic pipeline

InactiveCN102654224AOvercome sheddingOvercome the breakPipe connection arrangementsPlastic pipeworkEngineering

The invention provides a quick connection joint for plastic pipeline, relating to a connection structure of the plastic pipeline. The connection joint is made of a hard material, wherein a connection head (1) is a section from one external end to the middle part of the connection joint; a round-about groove (5) is arranged on the outer edge face of the connection head; an opening part stopping ring (2) is arranged on an inner wall (4) at one end inside an end face (6) at one end of the connection joint; clamps which are clamped with the external face of a rubber pipe (8) and are circularly distributed are arranged on the inner wall at one end; and a section from an inner face at the other end to the middle part of the connection joint is a horn opening (9) with a large external part and a small internal part at the other end. The quick connection joint provided by the invention is locked at an end head of the plastic pipeline through a mechanical effect, and forms a tight quick connection structure through the annular-distributed clamps. The quick connection joint ensures the good sealing property due to the specific structural design, so as to achieve rapid, efficient and convenient mounting, dismounting and maintenance. Therefore, the phenomena of releasing, breaking, and water and gas leakage of the pipeline, caused by the conventional connection manner, can be effectively overcome.

Owner:山东鼎鑫矿用新材料有限公司

Multifunctional finishing agent

ActiveCN109457475AImprove antibacterial propertiesImproves UV resistanceHeat resistant fibresVegetal fibresEgg proteinPolyvinyl alcohol

The invention discloses a multifunctional finishing agent which comprises chitosan, sericin, titanium dioxide, hydrosol, aloin, tea polyphenol, quaternary ammonium salt, ethylenediamine tetraacetic dianhydride, polyatomic acid, glucose, hexa (4-amino phenoxy) cyclotriphosphazene, ammonium polyphosphate, guanidine carbonate, graphene oxide, montmorillonoid, magnesium chloride, egg protein, polyvinyl alcohol, coupling agents, acetic acid and solvents. The multifunctional finishing agent is reasonable in formula, and a finished fabric is good in antibacterial property, excellent in flame resistance, soft in hand feeling, resistant to creasing and washable.

Owner:JILIN NORMAL UNIV

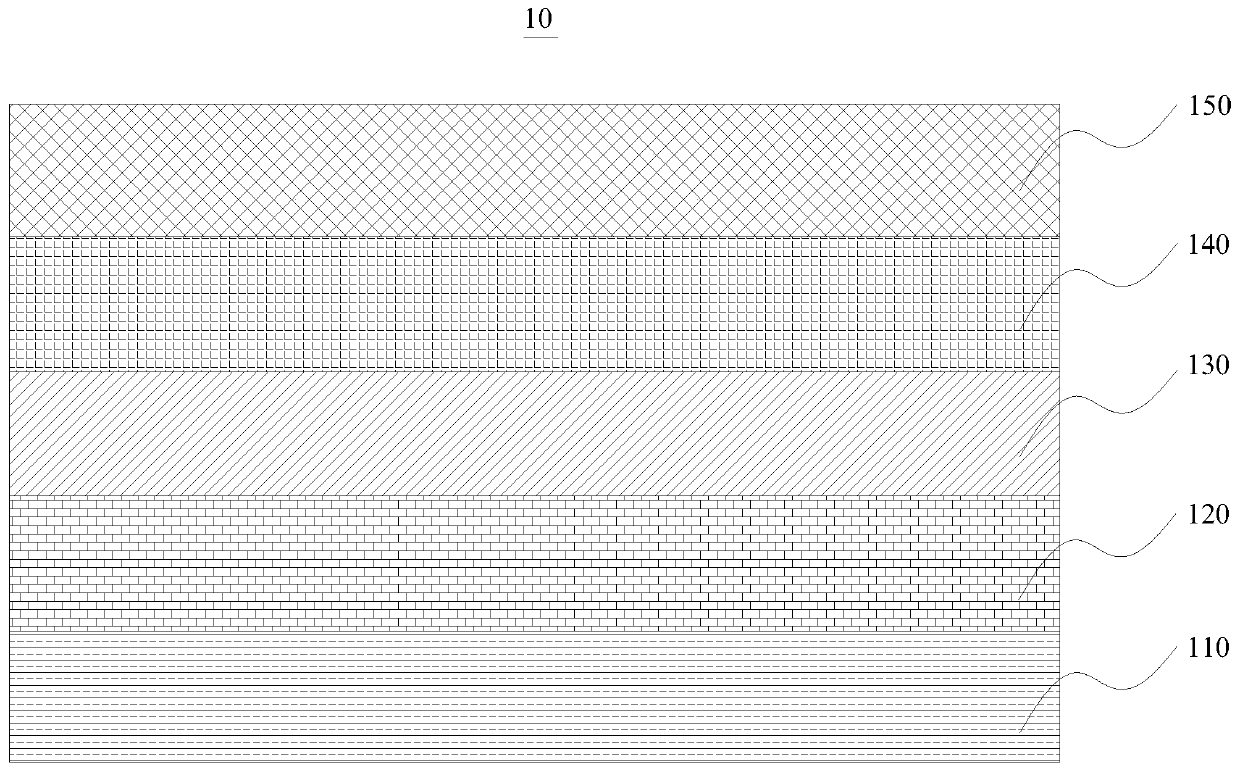

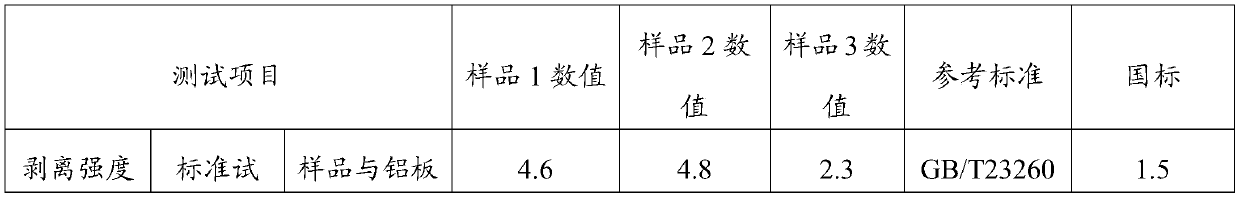

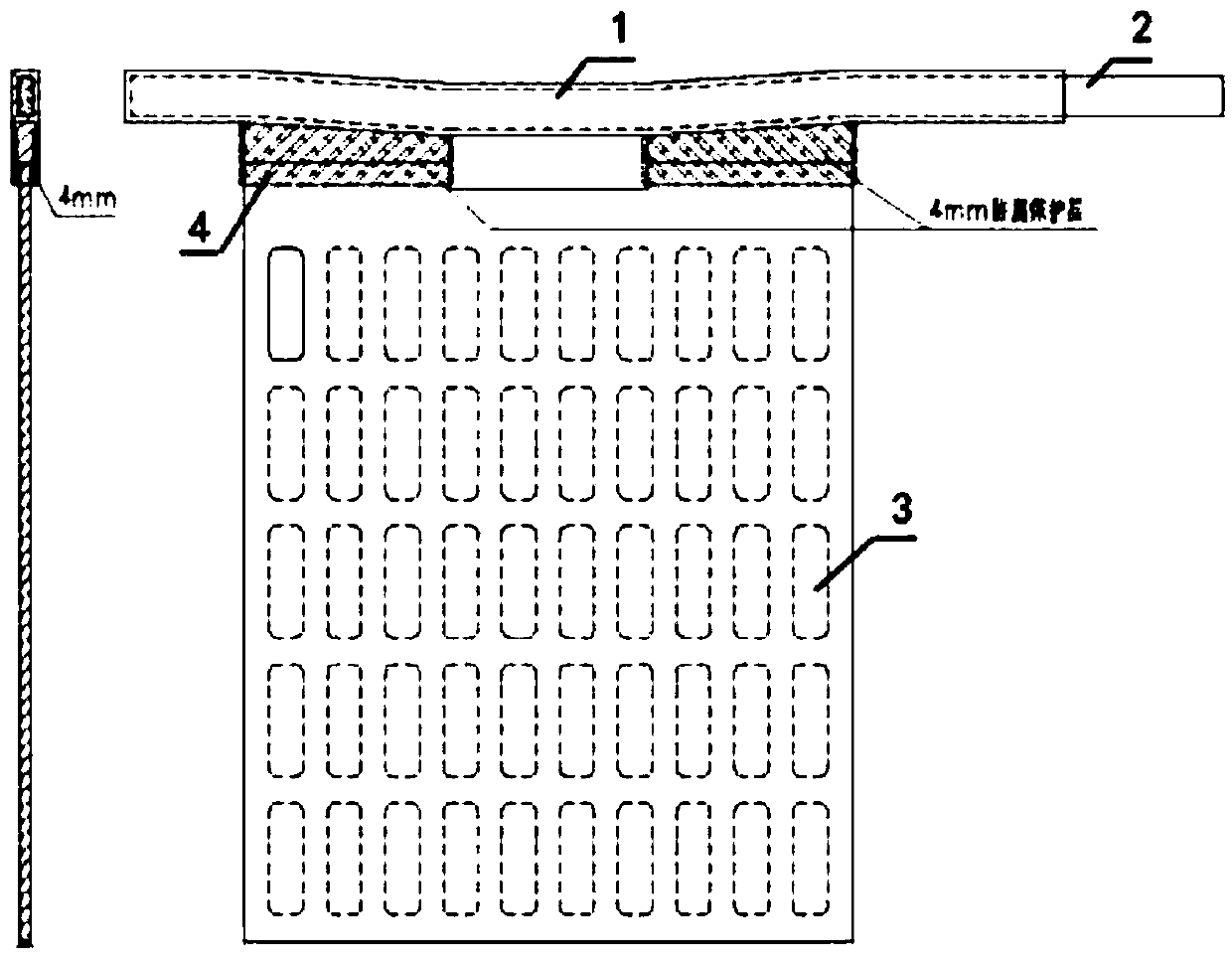

High temperature-resistant and waterproof coiled material

PendingCN110229633AReduce slip rateGood compatibilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMolecular networkPolymer science

The invention relates to the field of waterproof coiled materials, and discloses a high temperature-resistant and waterproof coiled material. The coiled material comprises a polymer substrate layer, ahot melt adhesive layer, a metal foil layer and a heatproof butyl rubber layer which are sequentially laminated, wherein the butyl rubber layer comprises, by mass, 15-30 parts of a plasticizer, 10-40parts of butyl rubber, 20-50 parts of a high temperature-resistant filler, 30-60 parts of a tackifying resin, 0.5-2 parts of a coupling agent and 0.5-2 parts of an anti-aging agent. The high molecular weight butyl rubber and the high molecular weight plasticizer are combined and reacted with the tackifying resin that is compatible with the butyl rubber to form grid-shaped butyl rubber, so the intermolecular slip rate is reduced; and the combination of the coupling agent and the high temperature-resistant filler makes the surface of the high temperature-resistant filler wrapped with an oily group in order to improve the compatibility of the high temperature-resistant filler and the butyl rubber, so that filler particles are uniformly embedded in the molecular network of the grid-shaped butyl rubber, and the deformation and sliding of the butyl rubber molecular net under the action of a high temperature are reduced, thereby the heatproof property of the heatproof butyl rubber layer is improved.

Owner:HUIZHOU NENGHUI CHEM CO LTD

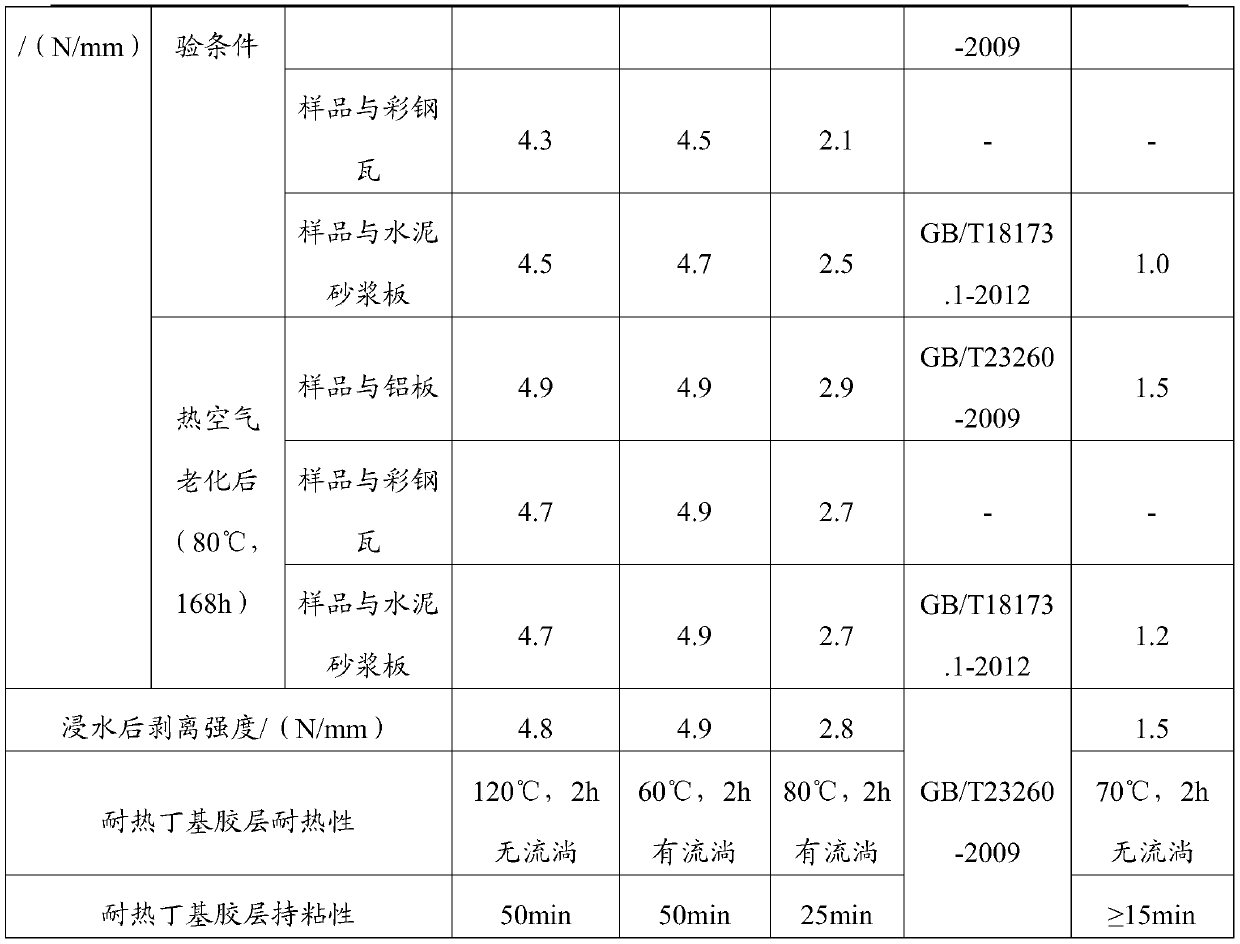

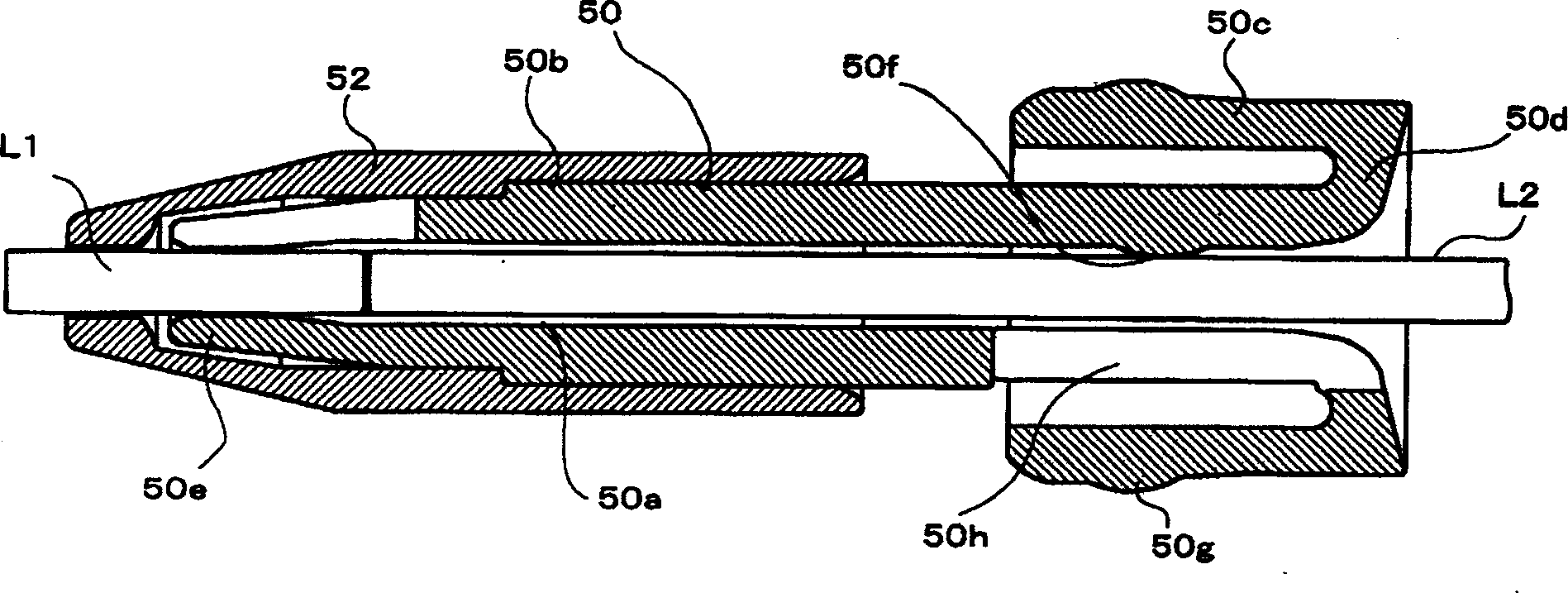

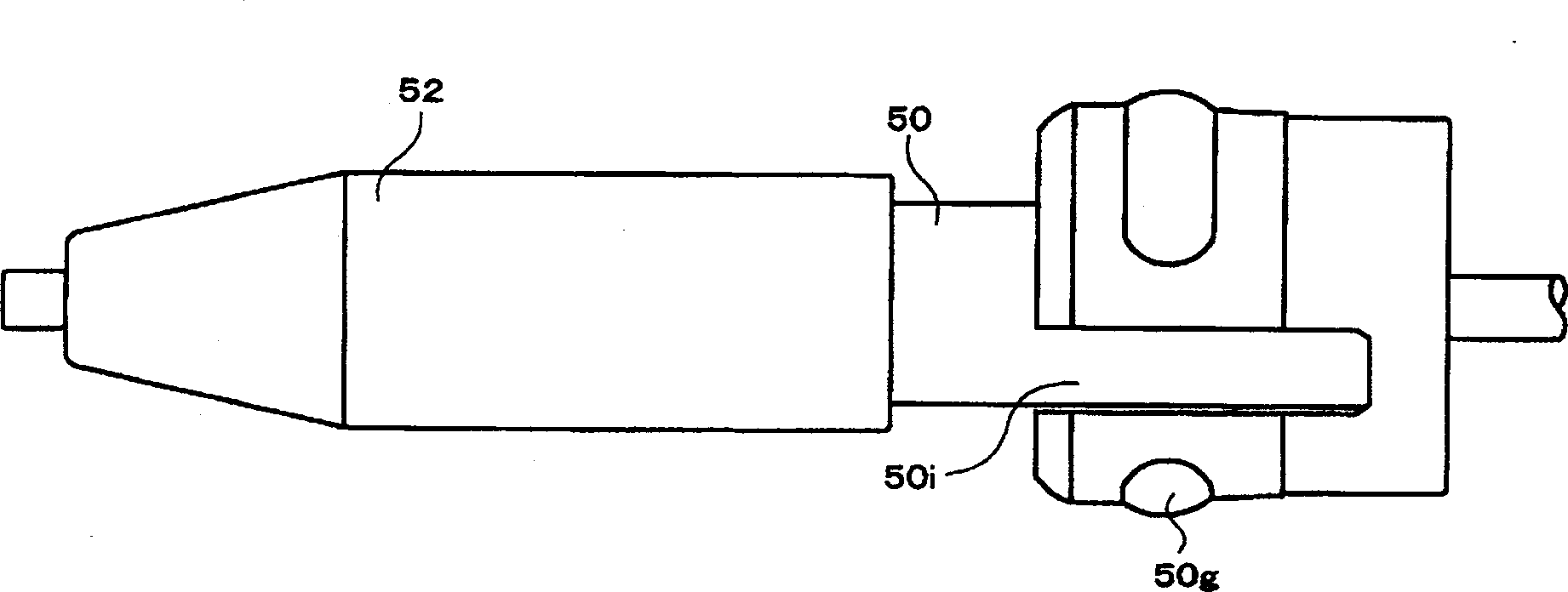

Mechanical propelling pencil

To provide a mechanical pencil, with the residual amount of a lead can be made very small. A slider 50 having a through hole, through which the lead passes, is provided at the side nearer the tip side than a lead delivering mechanism in a barrel so as to form collets 50e, which projects inward radially in order to hold the lead, at the tip part of the slider 50. At the rear end part of the slider 50, ribs 50f, which project radially in order to hold the lead, is formed. A consumed lead L1 is held by the collects 50e and a following lead L2 is held by the ribs 50f.

Owner:KOTOBUKI & CO LTD

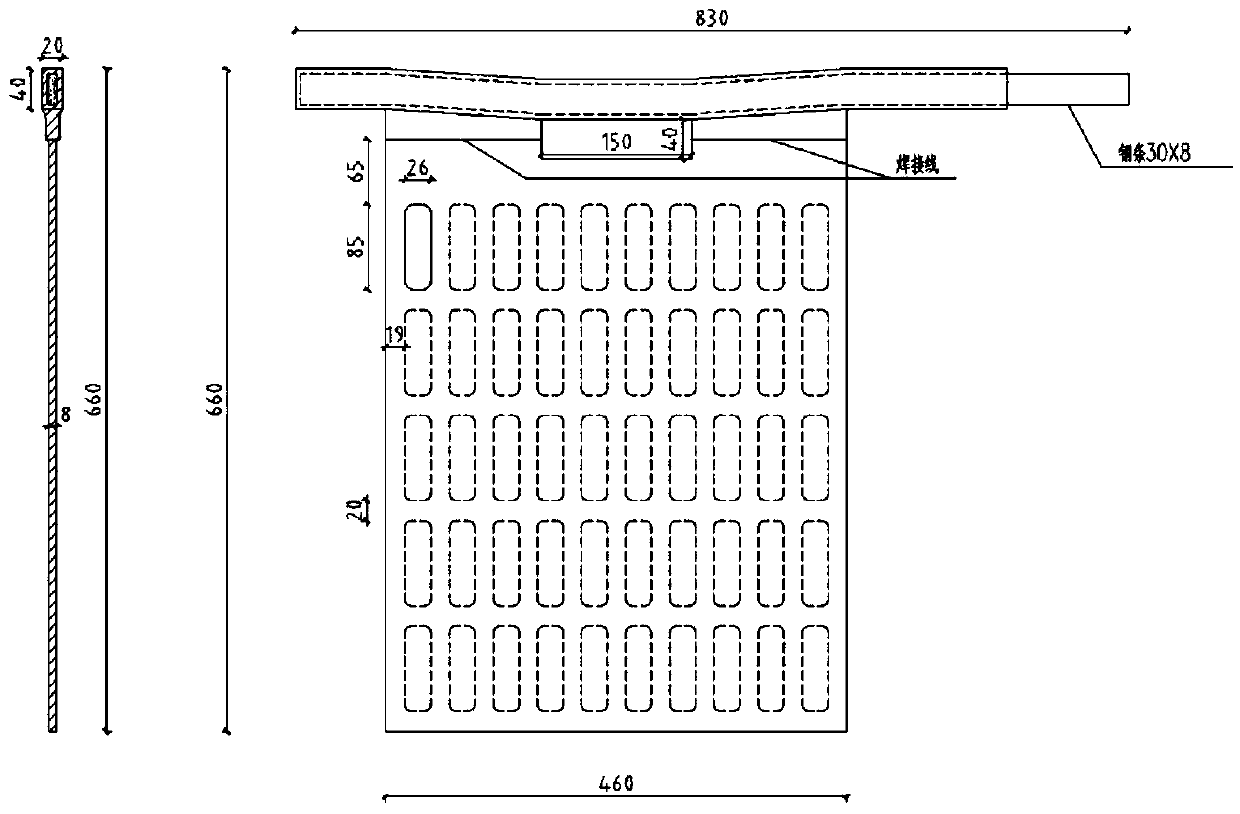

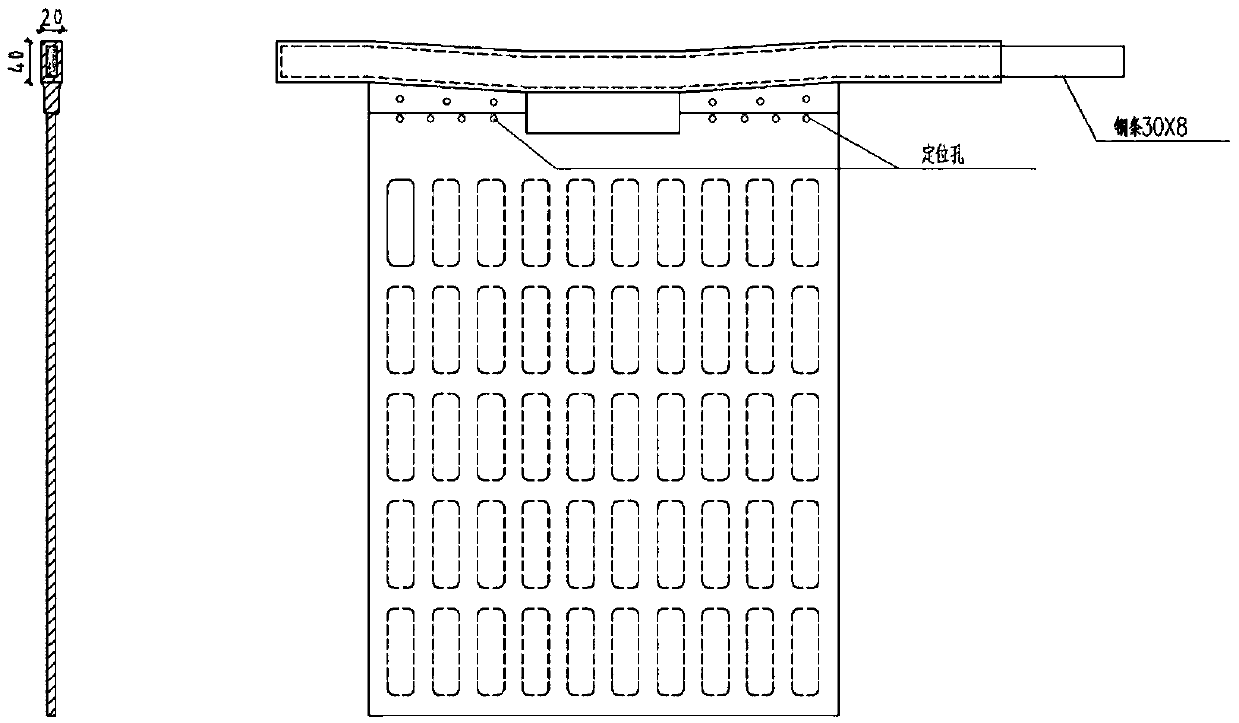

Manufacturing method of electrolytic manganese metal alloy lead-plastic composite anode

InactiveCN103695960AStop breakingBreakage, resulting in product damage preventingPhotography auxillary processesElectrodesElectrolysisManganese

The invention provides a manufacturing method of an electrolytic manganese metal alloy lead-plastic composite anode. The alloy lead-plastic composite anode comprises a conductive rod, a copper bar embedded inside the conductive rod and a male tab at the lower part, wherein the materials for fabricating the male tab comprise the following ingredients (by weight ratio): 0.06-0.10% of silver Ag, 0.1-0.4% of stibium Sb, 1-3% of stannum Sn, 0.3-0.6% of arsenic As, 0.1-0.3% of calcium Ca, 0.1-0.3% of strontium Sr and the balance of lead Pb. By adopting the method, an anode product is mainly prepared by optimizing an alloy element formula, and then a layer of tightly wrapped anti-corrosive protecting coating is formed on the three-item interface (the three-item interface refers to a juncture interface of an electrolyte surface, air and an anode plate) in an injection molding manner. Thus, corrosion to the lead alloy caused by chlorine and fluorine in the electrolyte at the three-item interface can be avoided.

Owner:申中军

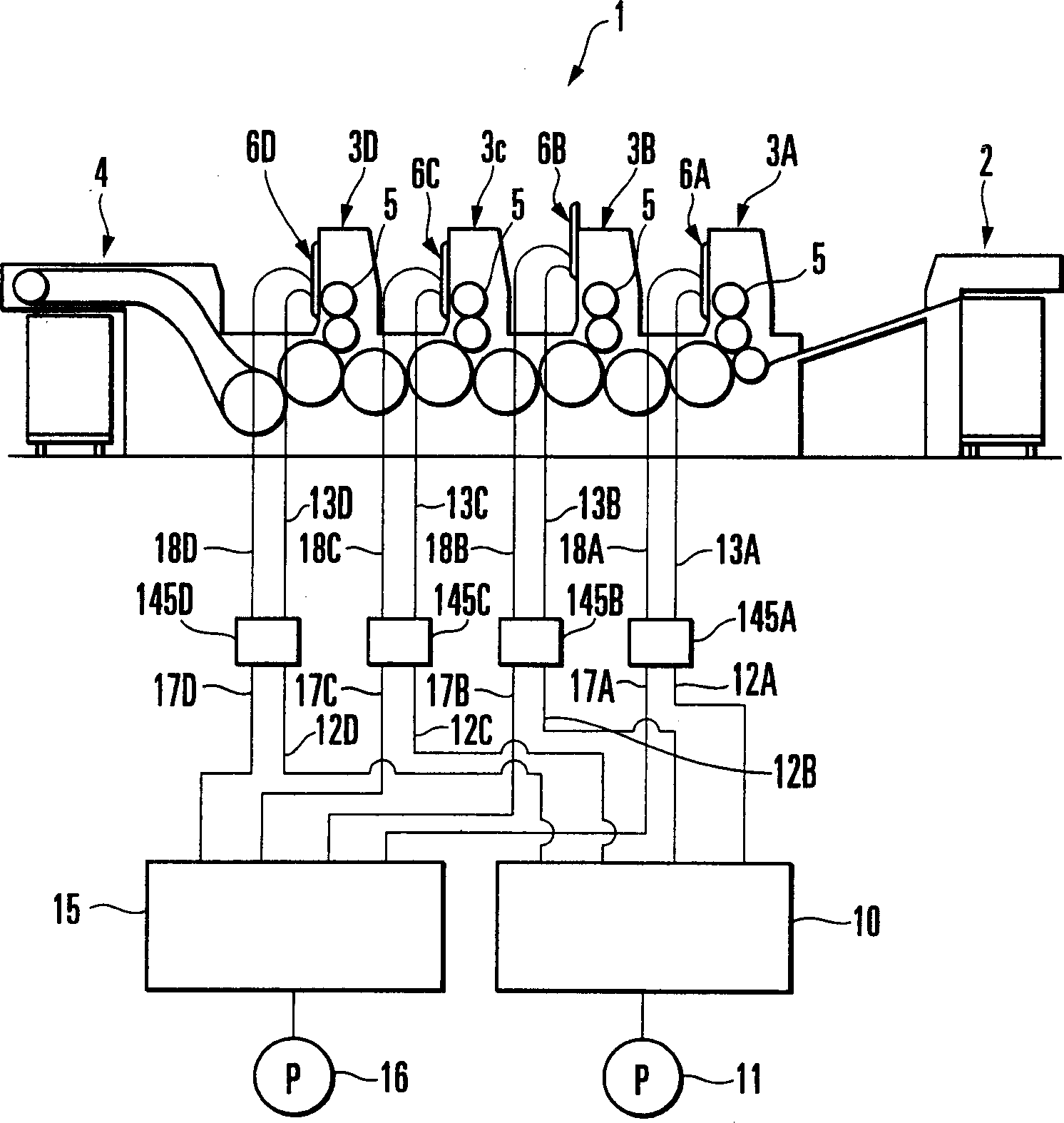

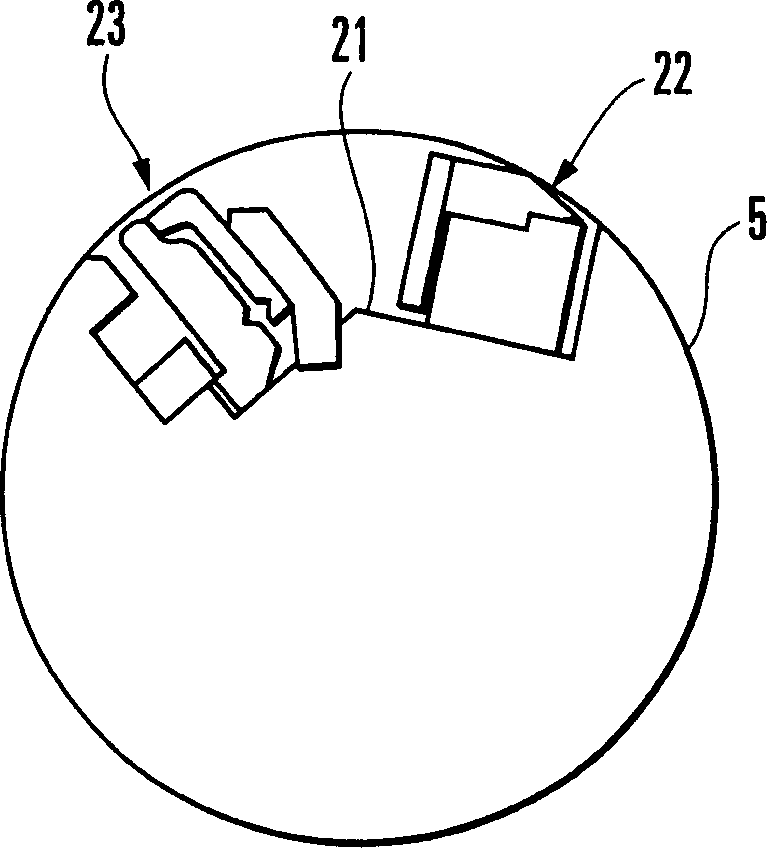

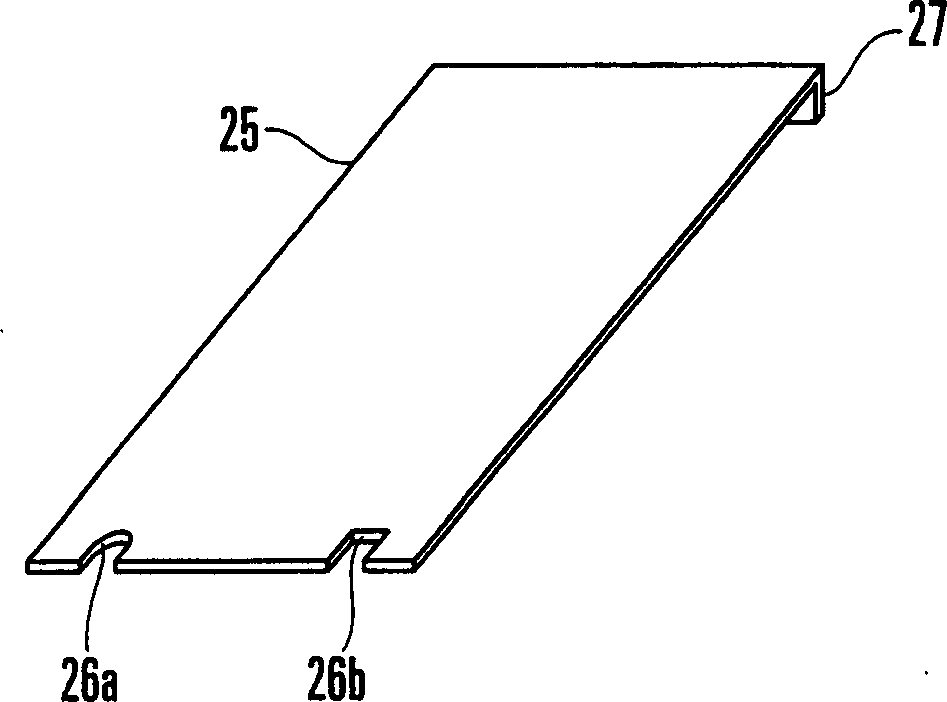

Plate holding apparatus

A plate holding apparatus includes a plate holding device (40A,40B) and an air cylinder (41). The plate holding device holds an old plate (25A) discharged from a plate cylinder (5). The air cylinder (41) moves the plate holding device between the first position of holding the discharged old plate and the second position away from the plate cylinder. The plate holding device includes a support member (42), first (43) and second (44) rotary members, a lever (64), stopper (69), and tensile coil spring (71), and a one-way clutch (45,46). The first rotary member is rotatably, axially supported by the support member. The second rotary member is axially supported by the support member to be movable and rotatable. The lever, stopper, and tensile coil spring move the second rotary member to come into contact with and separate from the first rotary member. When the old plate is held by the first and second rotary members, the one-way clutch allows at least one of the first and second rotary members to rotate in the first direction to disengage the old plate from the plate cylinder, and regulates it from rotating in the second direction opposite to the first direction.

Owner:KOMORI CORP

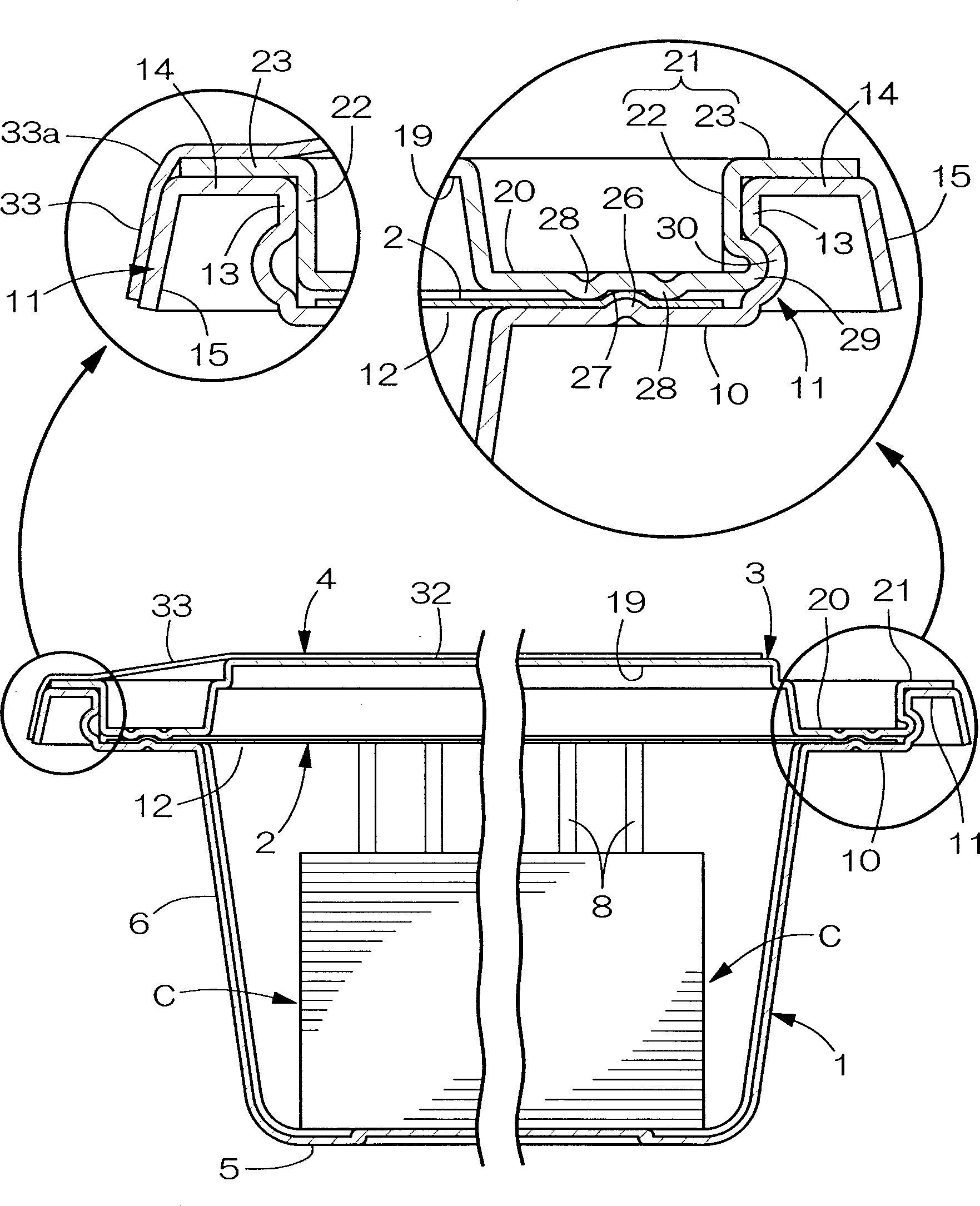

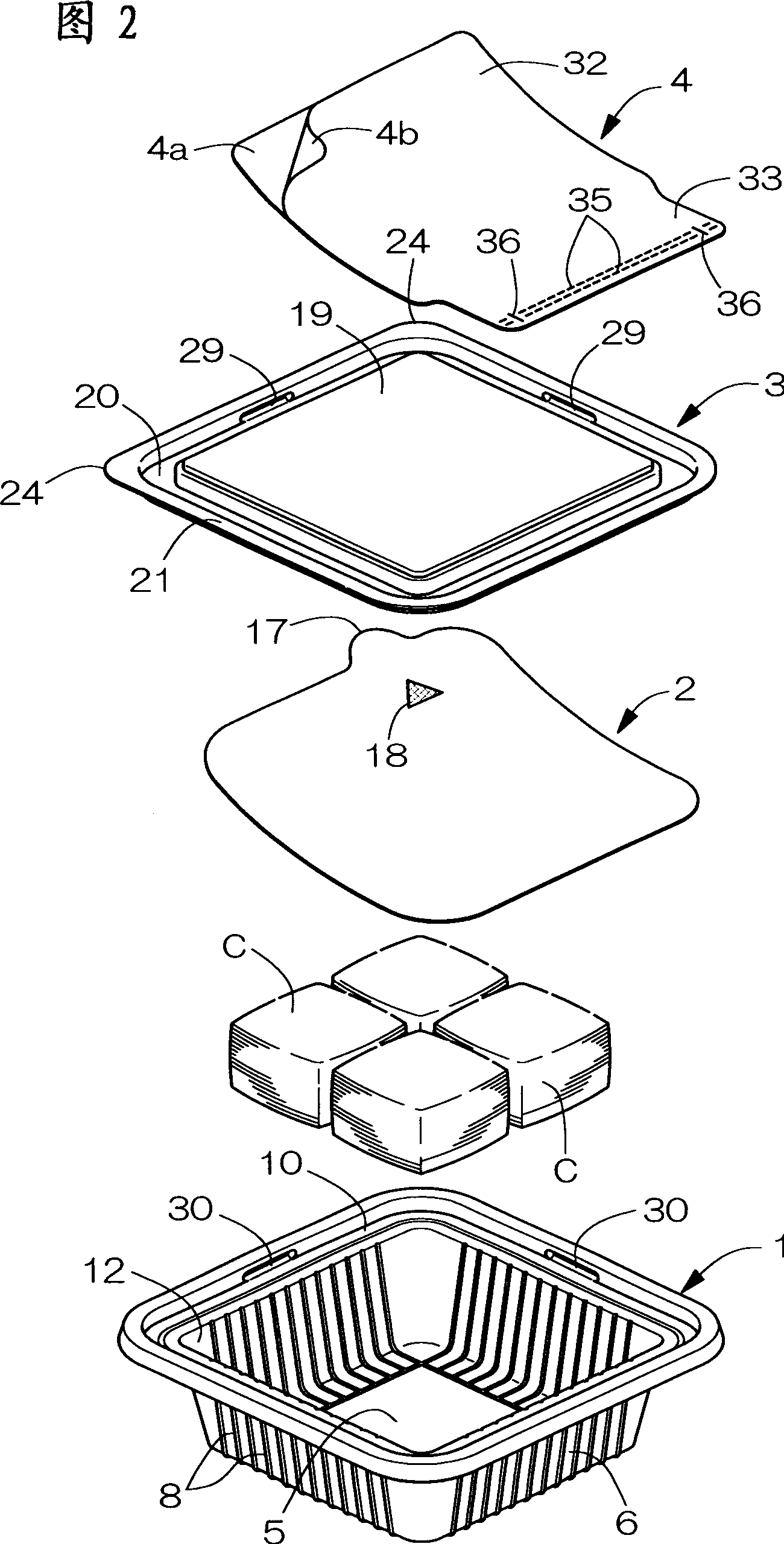

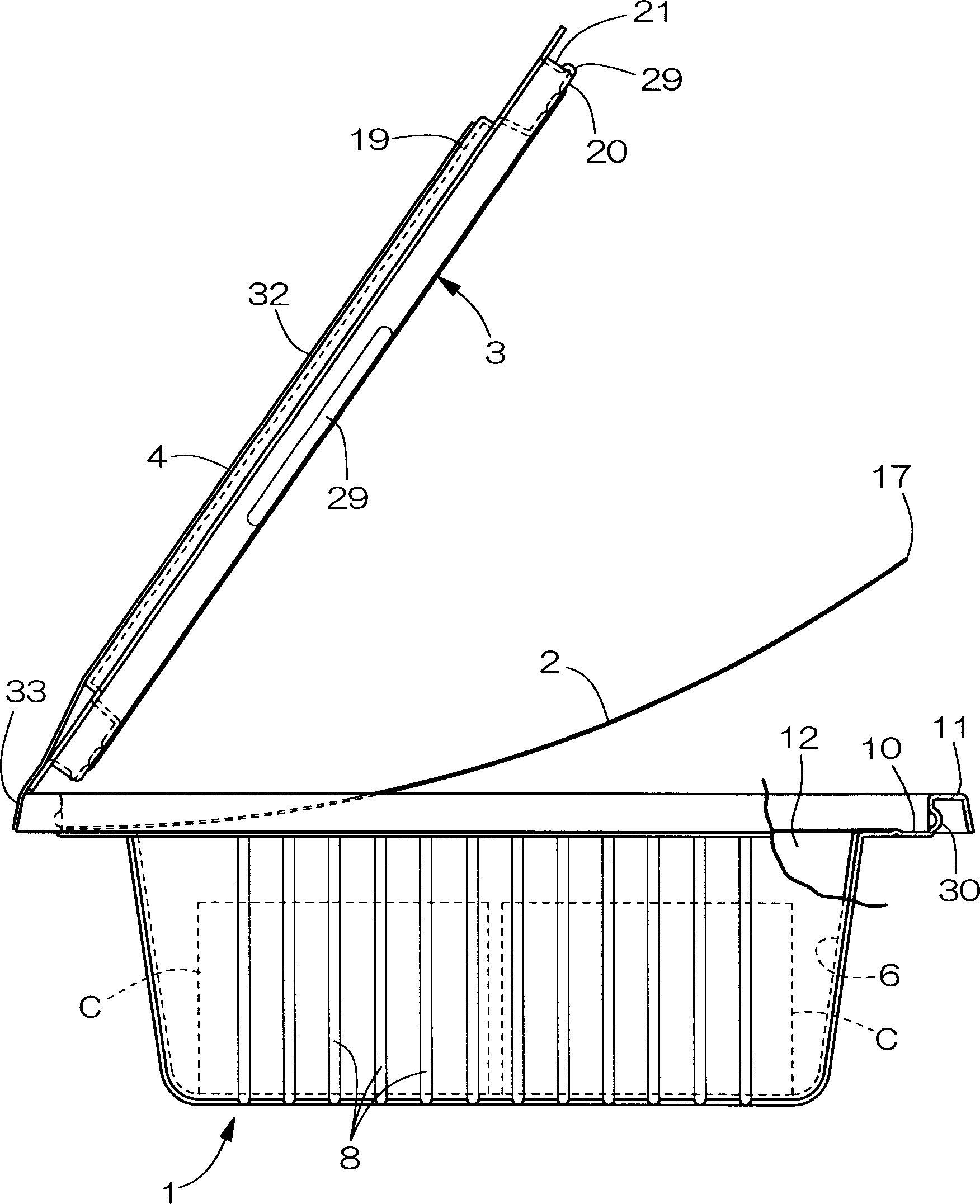

Package container

InactiveCN1448318AOverall structure simplifiedReduce weightStampsClosure with auxillary devicesEngineeringMechanical engineering

A packaging container comprises a container body an upper part opening of which performs as an exit, a seal lid sealing the exit of the container body, and an outer lid openably and closably covering the container body. A commercial label is adhered to an outer surface of the outer lid. The outer lid is attached to the container body openably and closably through the label. The packaging container can store unused pieces of sterilized cotton with a tight seal after a user peels the seal lid, and allows the user to easily and conveniently take out the pieces.

Owner:MEISEI SANSHO

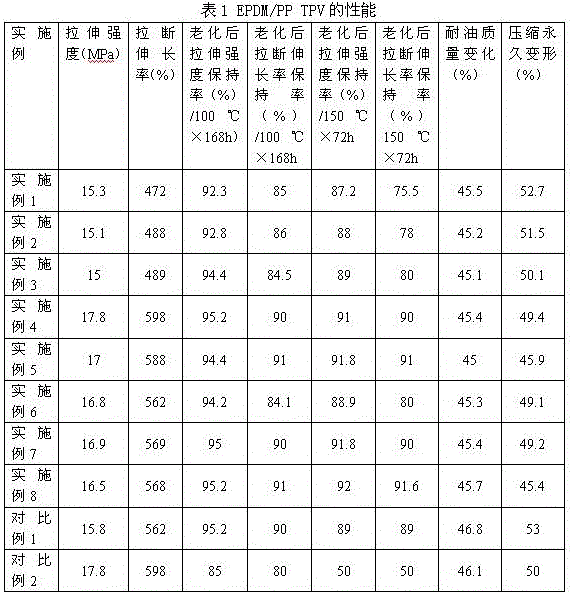

Heat-resistant thermoplastic elastomer and preparation method thereof

The invention discloses a heat-resistant thermoplastic elastomer and a preparation method thereof. According to the preparation method, by virtue of a theory that an antioxidant has relatively more lively hydrogen atoms molecules of EPDM and PP, the hydrogen atoms of the antioxidant can easily react with peroxy radicals generated by a blend molecular chain under heat and oxygen in a thermo-oxidative aging process of an EPDM / PP blend, the chain reaction of free radicals is inhibited, and the cleavage and the oxidative cleavage of the molecular chain are prevented, so that the heat resistance of EPDM / PP TPV is improved, and the aging resistance of EPDM / PP TPV is improved. Calcium sulfate whiskers modified by virtue of a silane coupling agent KH-550 form a 'hard core-soft shell' coating structure with EPDM in the blending process of EPDM / PP, and the disperse state of calcium sulfate has a certain blocking effect to gas during thermo-oxidative aging and impedes the conduction of gas and heat, so that the heat resistance stability of EPDM / PP TPV is improved, and the heat aging resistance of EPDM / PP TPV is meliorated.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

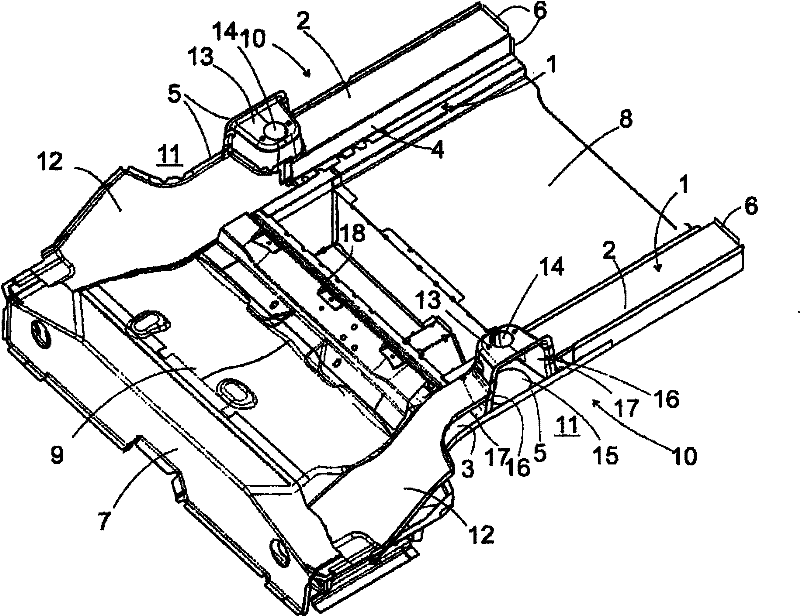

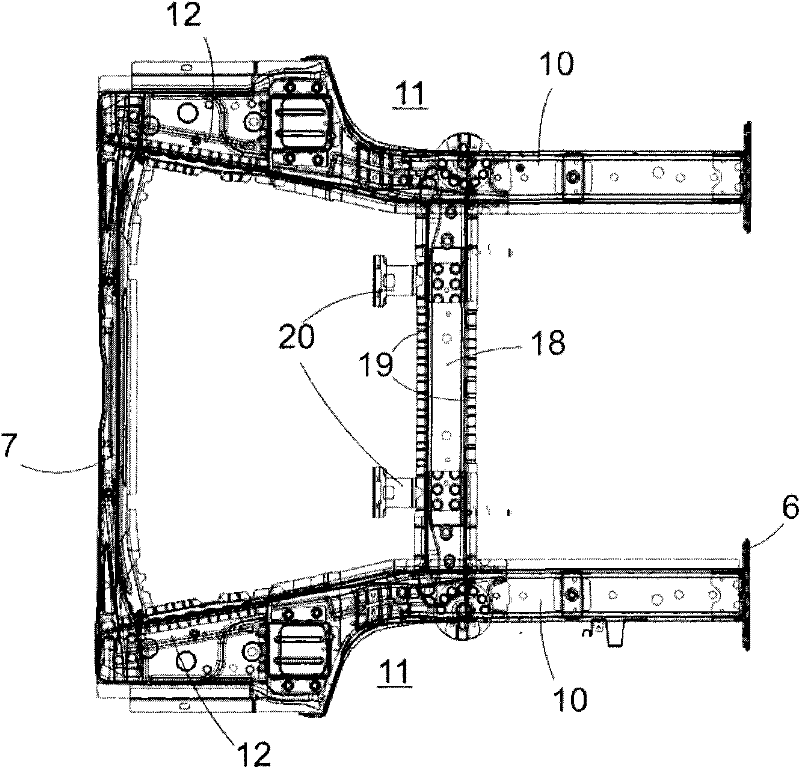

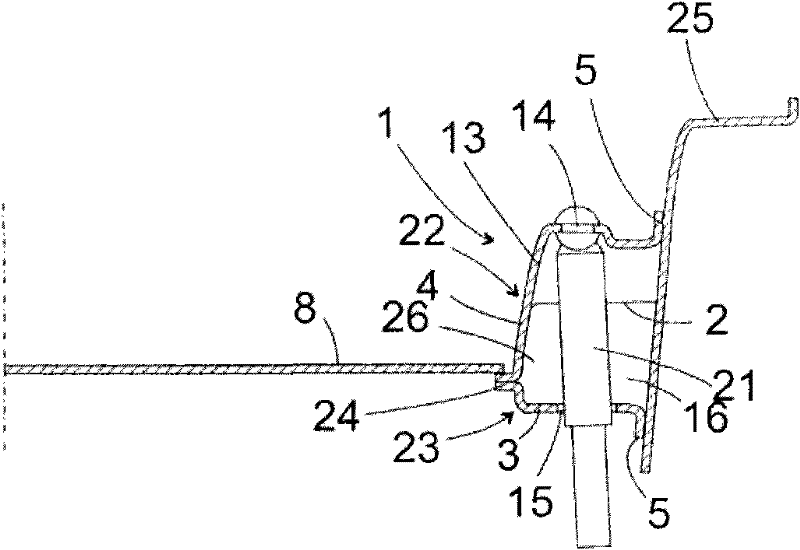

Rear floor structure for a motor vehicle

InactiveCN102530087AReduce curvatureIncrease available spaceUnderstructuresSuperstructure subunitsEngineeringShock absorber

A rear floor structure for a motor vehicle includes, but is not limited to two longitudinal girders extending between rear wheel houses. A downwardly open pocket for receiving a shock absorber is formed in each of the longitudinal girders.

Owner:GM GLOBAL TECH OPERATIONS LLC

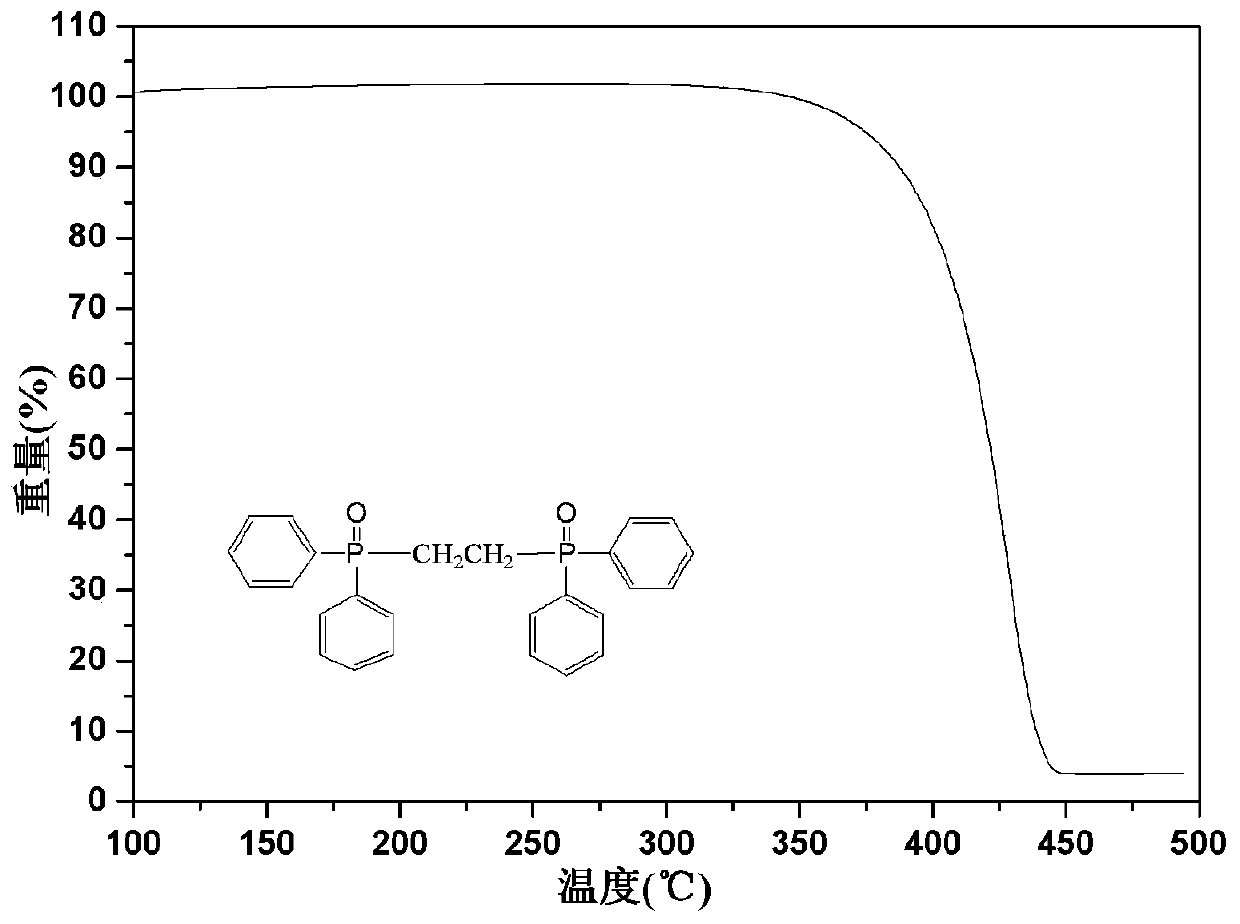

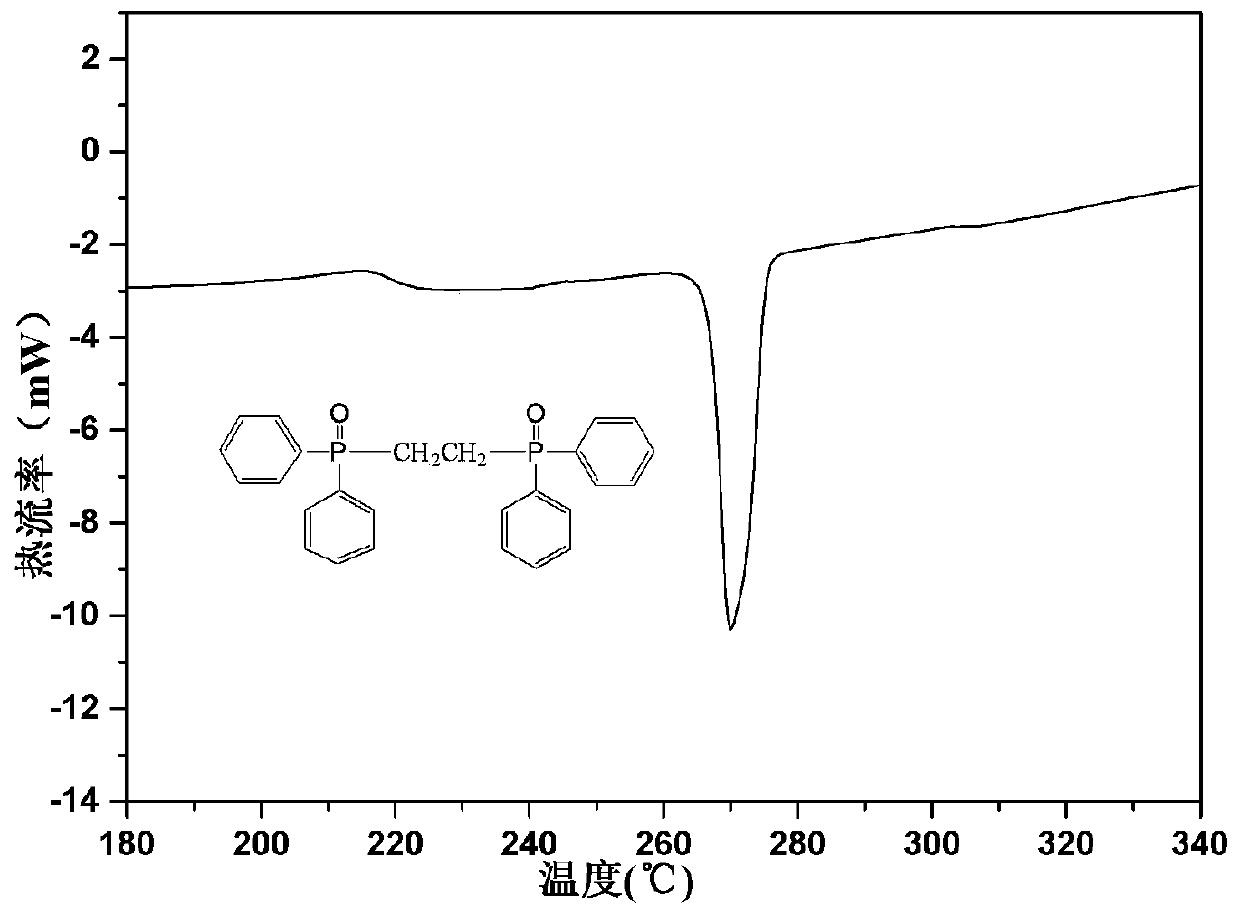

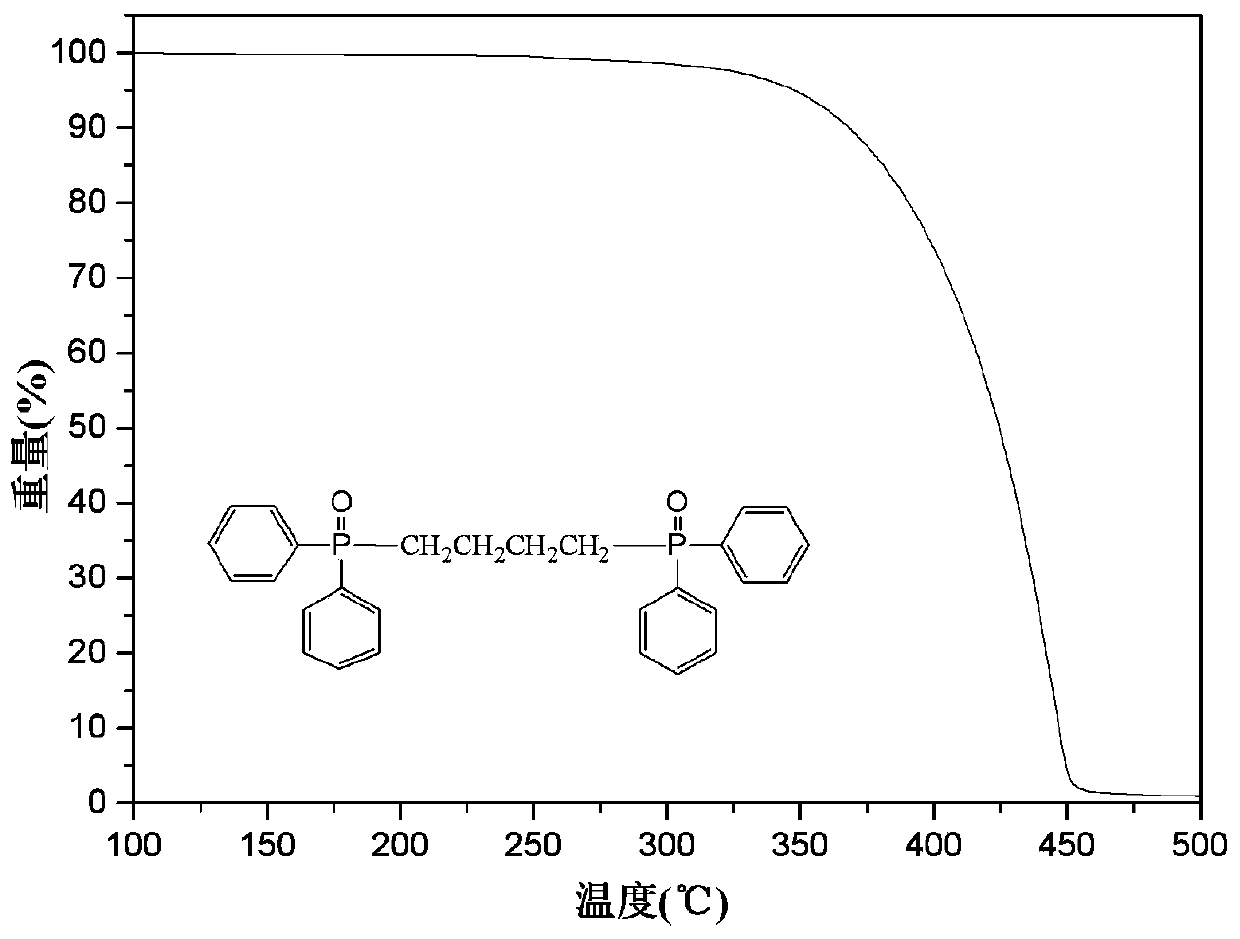

Flame-retardant master batch, preparation method and application thereof

The invention relates to the field of macromolecule materials, and provides a flame-retardant master batch. According to the invention, a diphenyl phosphine oxide derivative with a specific structureand high thermal stability is used as a flame retardant and also has a melting point similar to that of a resin, so that the dispersity of the diphenyl phosphine oxide derivative in a high polymer processing process is improved, and the influence of the flame retardant on melt fluidity is reduced; an antioxidant is used for preventing a macromolecule polymer from becoming sticky, discolored, embrittled or broken due to decomposition; loading of the diphenyl phosphine oxide derivative and the antioxidant is achieved through a carrier resin while the dispersity and the compatibility of the diphenyl phosphine oxide derivative and the antioxidant are improved; and the results of the embodiment show that the flame-retardant master batch provided by the invention shows good compatibility when applied to resin products, and the flame-retardant effect can reach the V-0 level.

Owner:SHANDONG UNIV OF SCI & TECH

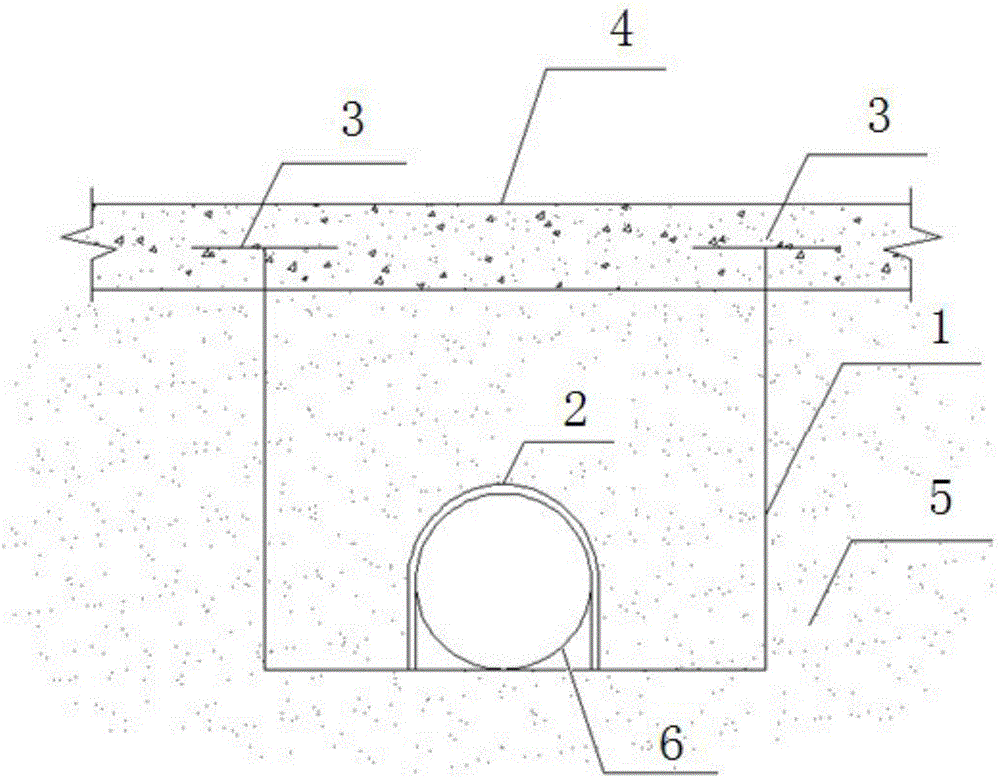

Device for avoiding buried pipeline sedimentation in room subsoil backfill region and construction method

InactiveCN105822831ASimple structureEasy to manufacturePipe laying and repairReinforced concreteRebar

The invention discloses a device for avoiding buried pipeline sedimentation in a room subsoil backfill region and a construction method. The device comprises a pipe hanger. The upper end of the pipe hanger is connected with anchoring components in a concrete ground beam or a reinforced concrete floor. The center of the bottom of the pipe hanger is connected with a U-shaped clamp. The construction method includes the steps of arranging the pipe hanger in a pipeline trench, arranging a pipeline at the bottom of the pipe hanger and fixing the pipeline through the U-shaped clamp, performing a hydraulic test or a closed water test, performing trench backfill, performing floor construction and the like. The device and the construction method have the beneficial effects that defects existing in the prior art are overcome, the stress carrier of the pipeline is changed fundamentally, the problems of pipeline blocking and breakage and the like caused by foundation settlement are eliminated completely, and the safety and normal use of the pipeline are guaranteed, so that construction quality is guaranteed, the economic loss is reduced, and good practicability is achieved.

Owner:TIANJIN 20 CONSTR

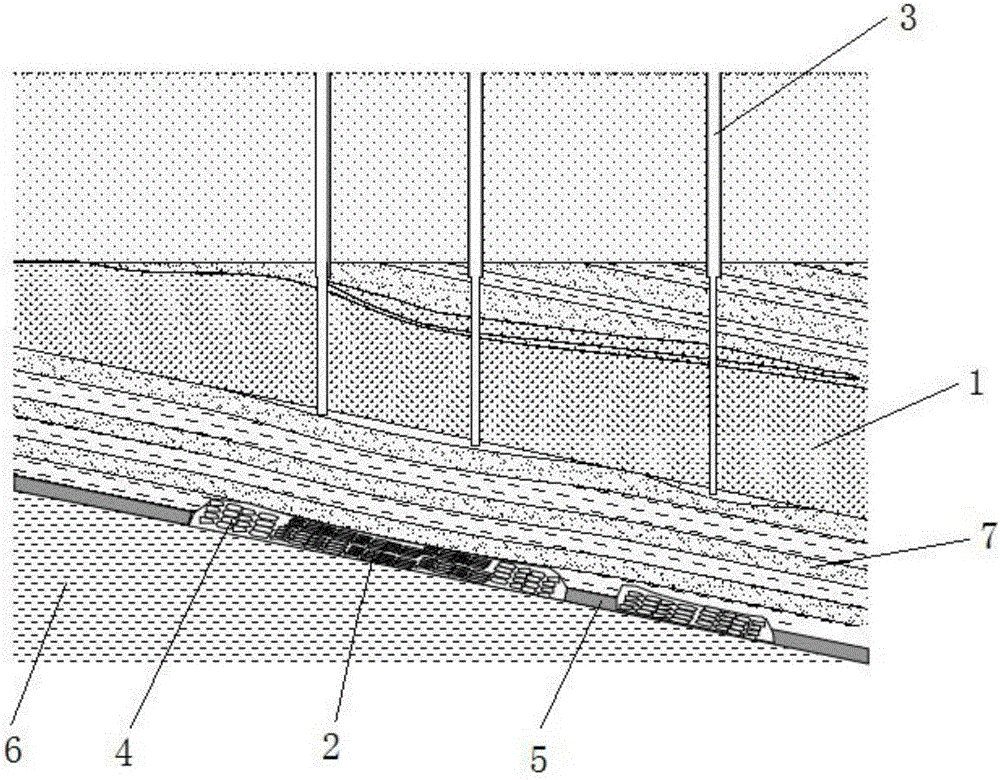

Method for reducing mining vibration energy under hard rock stratum

InactiveCN106593444AAct as an active supportPromote recoveryUnderground miningSurface miningGeomorphologyCoal pillar

Owner:HUABEI MINING GRP +1

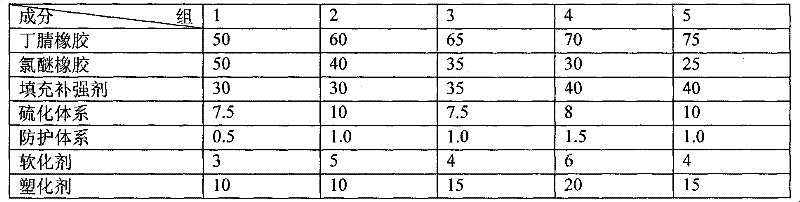

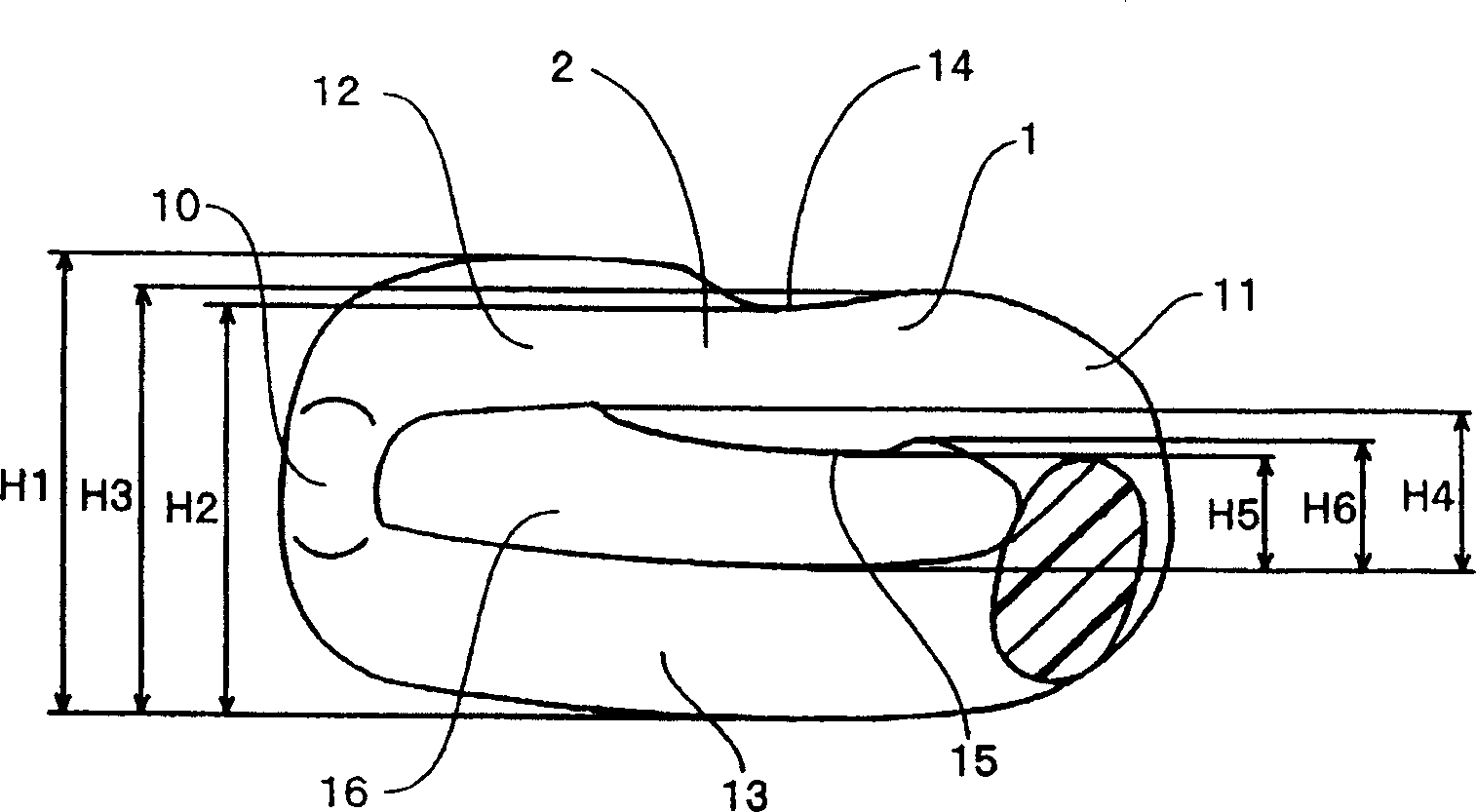

Rubber alloy material of ethanol-resisting gasoline diaphragm of fuel pressure regulator and preparation method of rubber alloy material

The invention provides a rubber alloy material of an ethanol-resisting gasoline diaphragm of a fuel pressure regulator and relates to a preparation method of the rubber alloy material of the ethanol-resisting gasoline diaphragm of the car fuel pressure regulator, which overcome the defects that the diaphragm which is used by the existing car fuel system regulator and takes butadiene-acrylonitrile rubber as a main material does not resist an ethanol solvent, and the cold resistance and the ozone aging resistance of the diaphragm are poor. The rubber alloy material is prepared from the butadiene-acrylonitrile rubber and chlorine ether rubber in an alloying way. The rubber alloy material is composed of the butadiene-acrylonitrile rubber, the chlorine ether rubber, a filling reinforcing agent, a vulcanizing system, a protection system, an activating agent and a plasticizer. The preparation method of the rubber alloy material comprises the following steps of: (1) plastifying; (2) mixing; and (3) vulcanizing and molding. The rubber alloy material of the ethanol-resisting gasoline diaphragm of the fuel pressure regulator, provided by the invention, has excellent oil resistance and solvent resistance and also has the cold resistance and the ozone aging resistance. The preparation method of the rubber alloy material has the advantages of simplicity, easiness in operation and less equipment investment.

Owner:HEILONGJIANG INST OF TECH

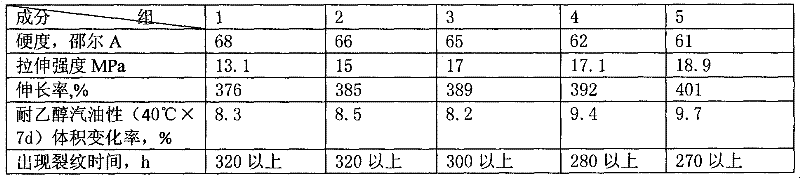

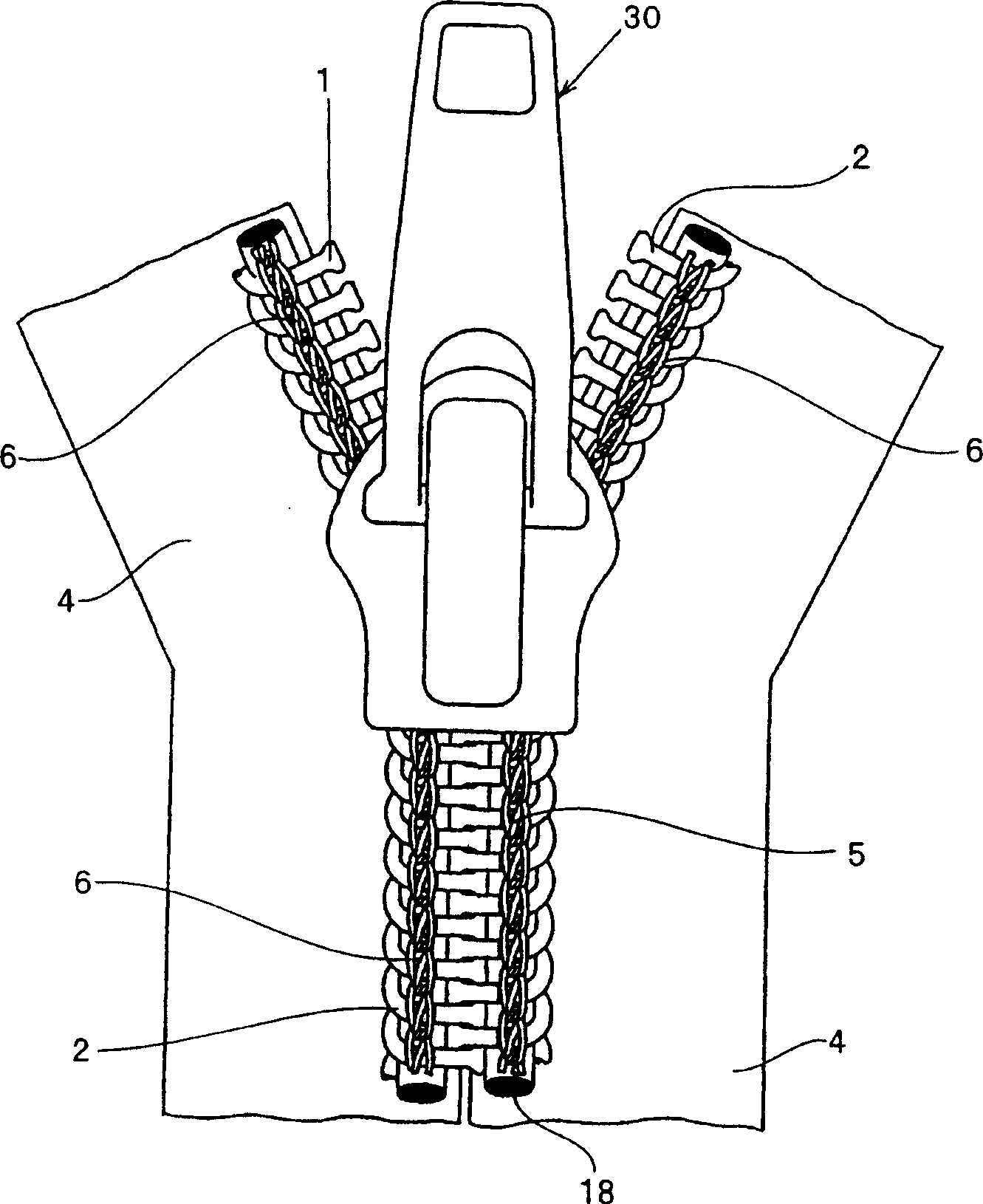

Linear slide fastener

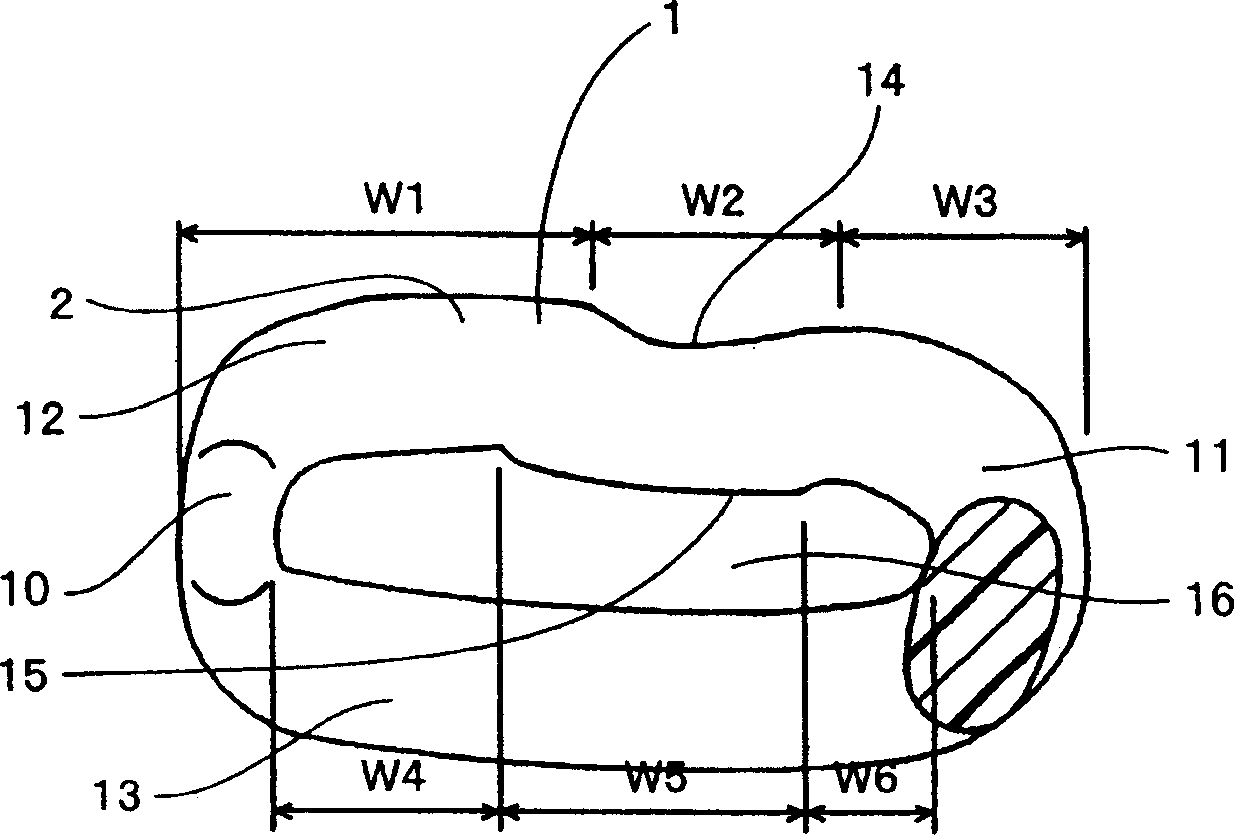

The invention intends to provide a linear slide fastener in which a size of a fastener element is reduced thereby saving resources and achieving a smooth sliding of a slider, wherein a concave portion (14) that accommodates a fixing thread (5) for fixing a fastener tape (4) is provided on a top face of an upper leg portion (12) of a coil-like or zigzag-like linear fastener element (1), when dimensions from a bottom face of a lower leg portion (13) up to a top face of the upper leg portion (12) on a side of a coupling head (10), at the concave portion (14) and on a side of an inverted portion (11) are assumed to be H1, H2 and H3 respectively, a setting condition of H1 > H3 > H2 is satisfied and when dimensions from a bottom face of the upper leg portion (12) to a top face of the lower leg portion (13) within a gap portion (16) on the side of the coupling head (10), at a convex portion (15) and on the side of the inverted portion (11) are assumed to be H4, H5 and H6 respectively, a setting condition of H4 > H6 > H5 is satisfied.

Owner:YKK CORP

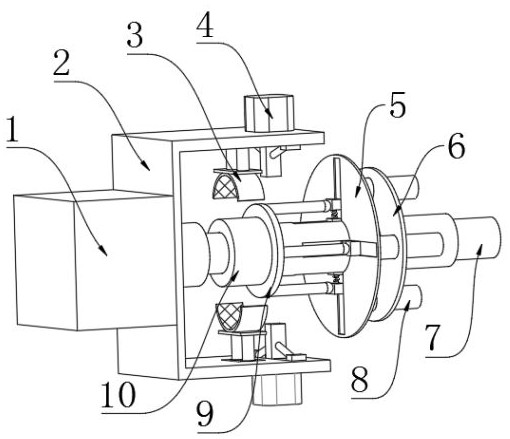

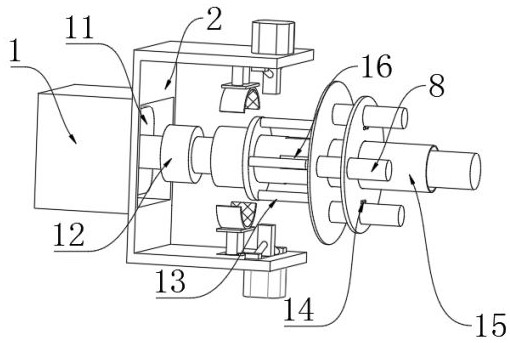

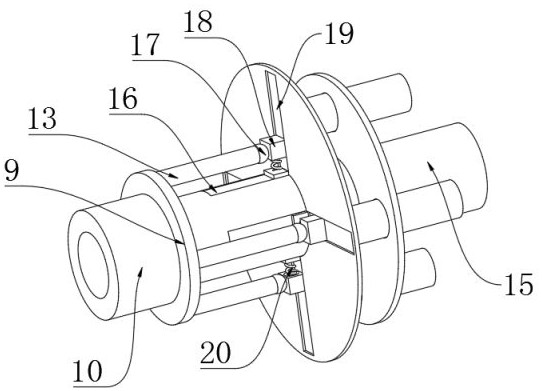

Electric vehicle motor stall protection device and protection method thereof

ActiveCN112910169AReduce wearIncrease flexibilityEmergency protective circuit arrangementsElectric machinesElectric machineryDriving safety

The invention discloses an electric vehicle motor stall protection device and a protection method thereof, and relates to the technical field of motor stall protection. The problems that during motor stall protection, damage to a rotating shaft is large, and follow-up driving safety is affected are solved. The motor stall protection device of the electric vehicle comprises a motor box, and the inner wall of one side of the motor box is connected with a driving motor through bolts; the outer wall of one side of the output shaft of the driving motor is connected with a coupler through bolts. The protection method of the motor stall protection device of the electric vehicle comprises the steps that an electromagnetic groove is powered on, a displacement sensor is started, and the driving motor runs. By arranging a bearing connecting ring, a hollow base, a telescopic spring, a telescopic connecting rod, a fixed connecting plate, an arc-shaped speed reducing plate and a friction layer, the friction layer conducts friction speed reduction on the bearing connecting ring on the driving connecting shaft when the driving motor stalls, and the friction layer on the arc-shaped speed reducing plate is prevented from making direct contact with the driving connecting shaft, so that subsequent driving is prevented from being affected by damage of the driving connecting shaft.

Owner:常州市武进金顺机电有限公司

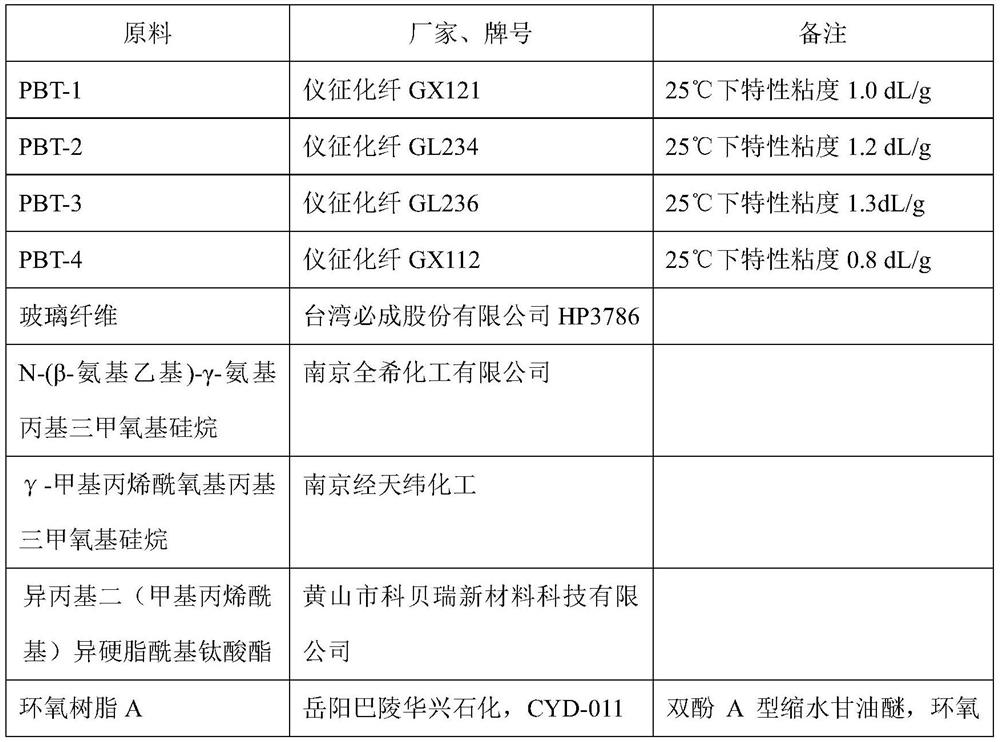

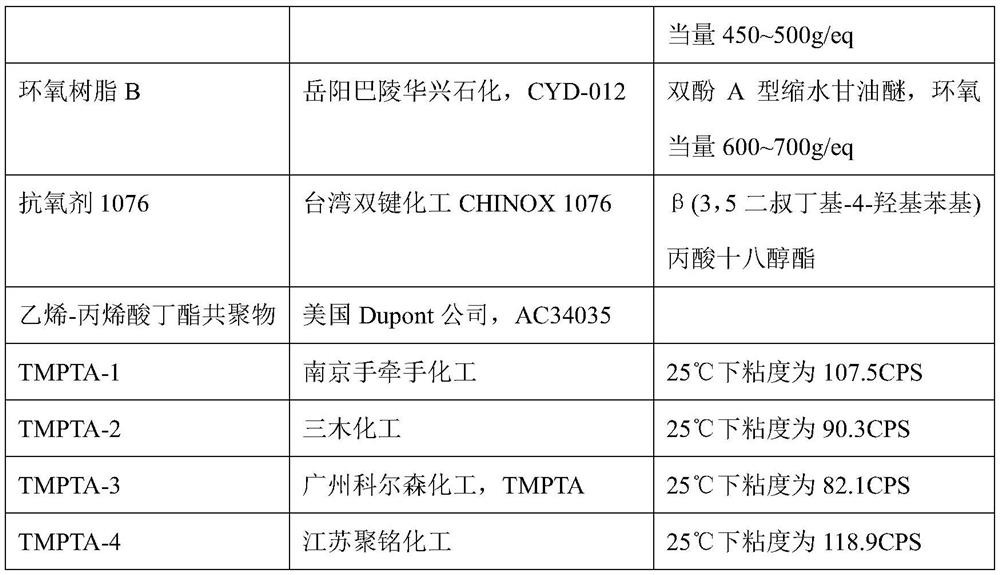

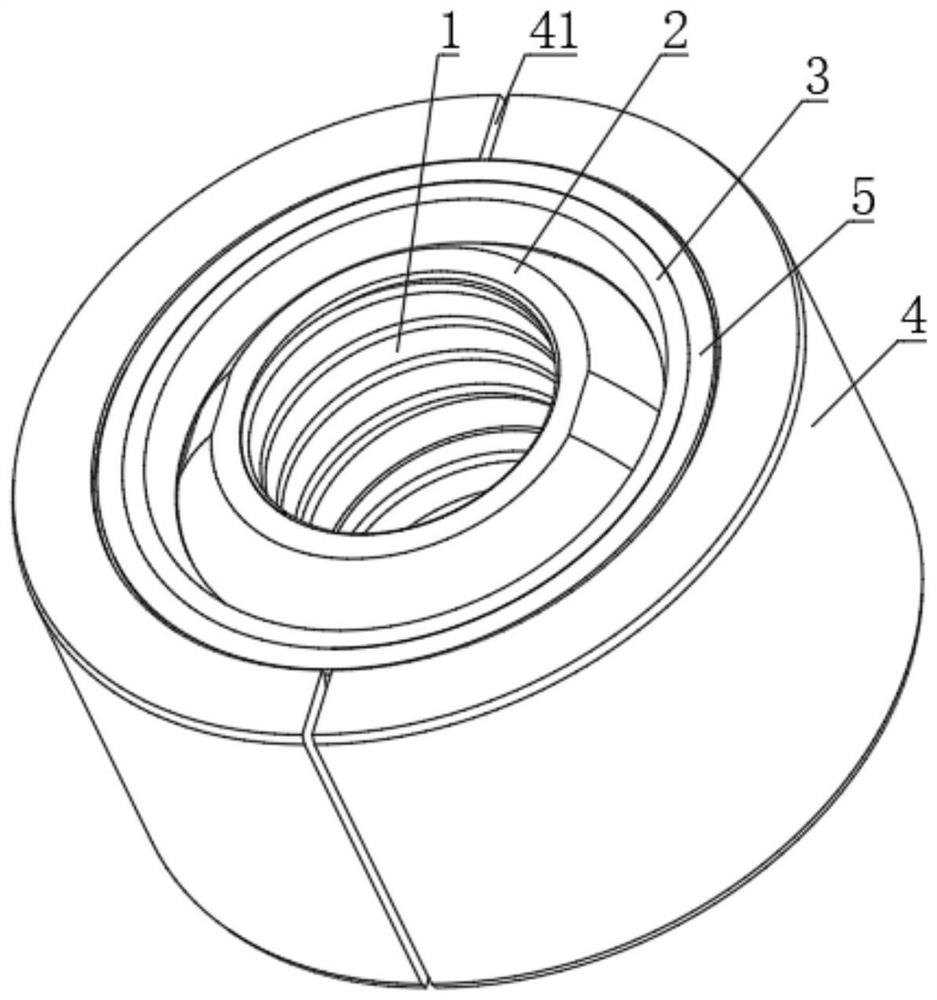

PBT composition resistant to cyclic injection molding, preparation method and product thereof

ActiveCN113583396AHigh retention rate of mechanical propertiesStop breakingPlastic recyclingEpoxyMultiple injection

The invention discloses a PBT composition resistant to cyclic injection molding and a preparation method thereof. The PBT composition resistant to cyclic injection molding is prepared from the following components in parts by weight: 50 to 80 parts of PBT, 10 to 40 parts of glass fiber, 1 to 3 parts of an epoxy resin, 0.1 to 0.3 part of an antioxidant, 2 to 8 parts of an ethylene-butyl acrylate copolymer and 0.5 to 2 parts of trimethylol propane triacrylate. According to the invention, through the synergistic effect of trimethylol propane triacrylate, an ethylene-butyl acrylate copolymer and an epoxy resin, breakage of a PBT molecular chain is effectively prevented, so that the degradation degree of the PBT material in multiple injection molding processes is reduced, and the mechanical property retention rate of the PBT composition after multiple injection molding is further improved; and the mechanical property retention rate of the PBT composition is greater than or equal to 97% after secondary injection molding, the mechanical property retention rate is greater than or equal to 91% after third injection molding, and the PBT composition is suitable for multiple times of cyclic injection molding.

Owner:KINGFA SCI & TECH CO LTD

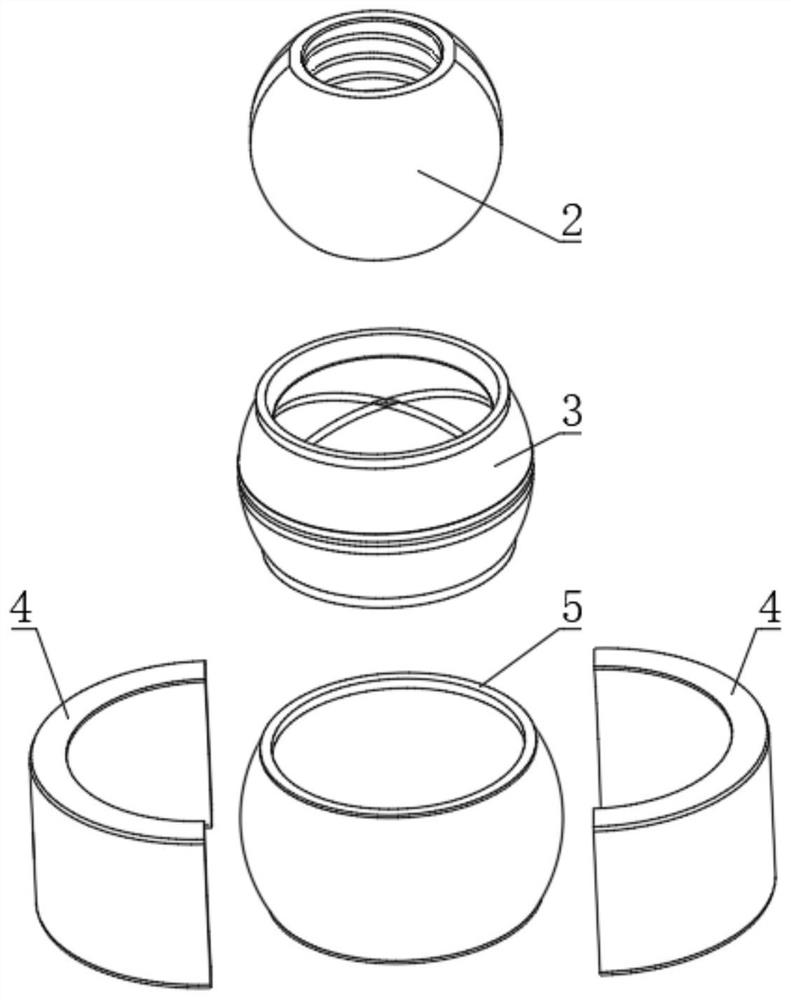

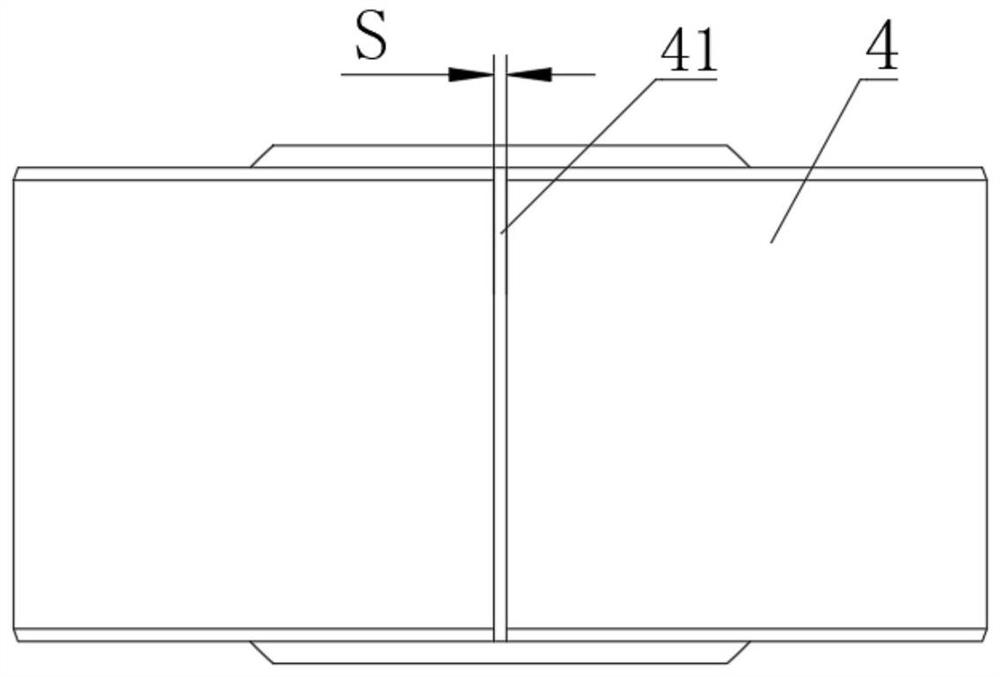

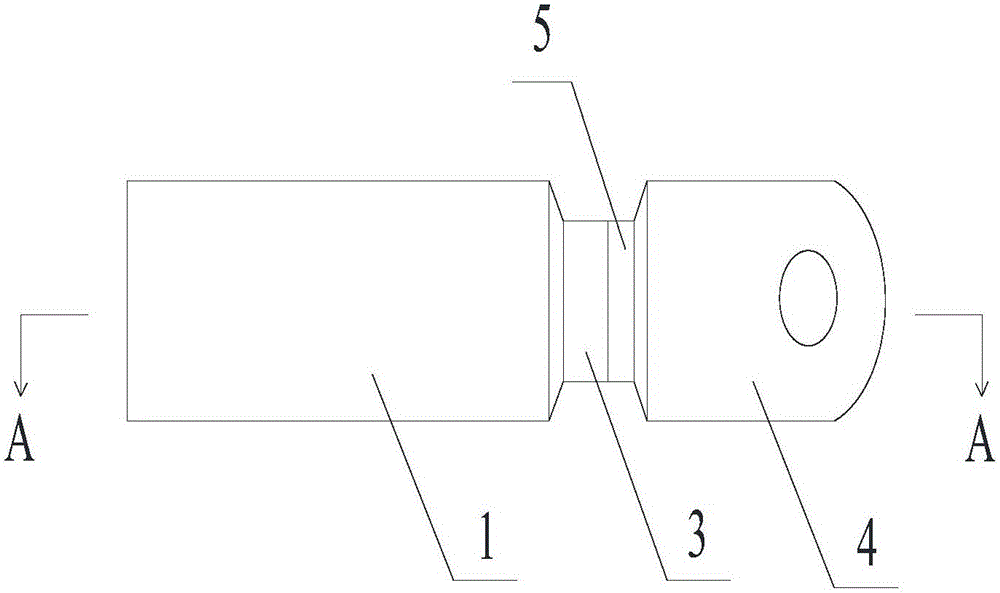

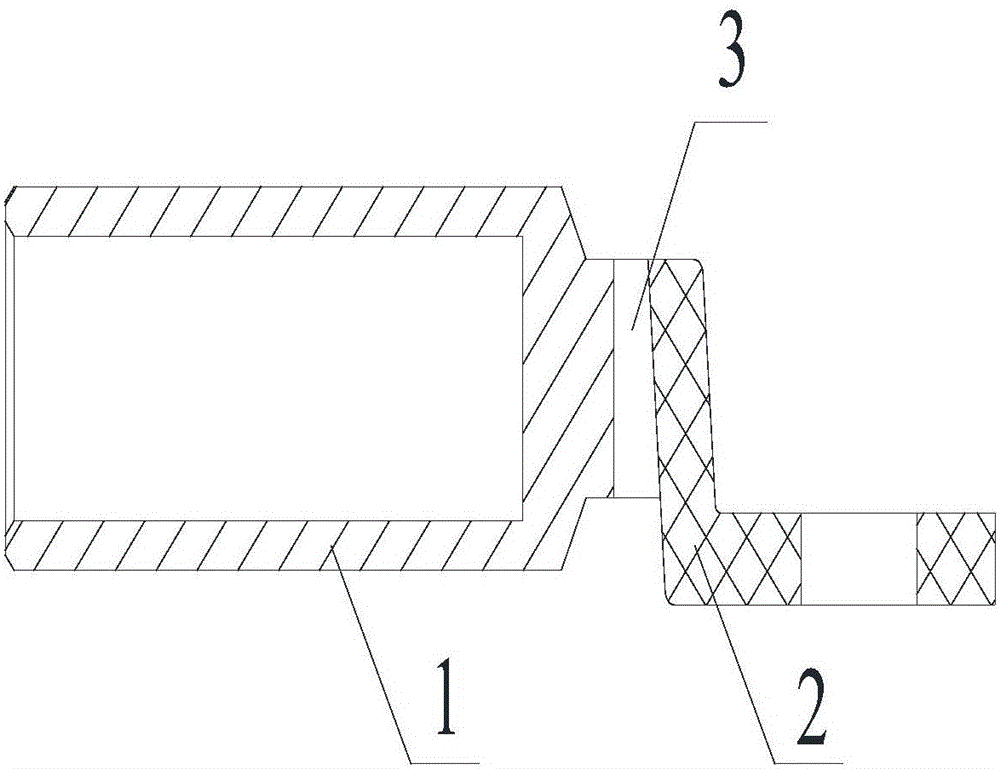

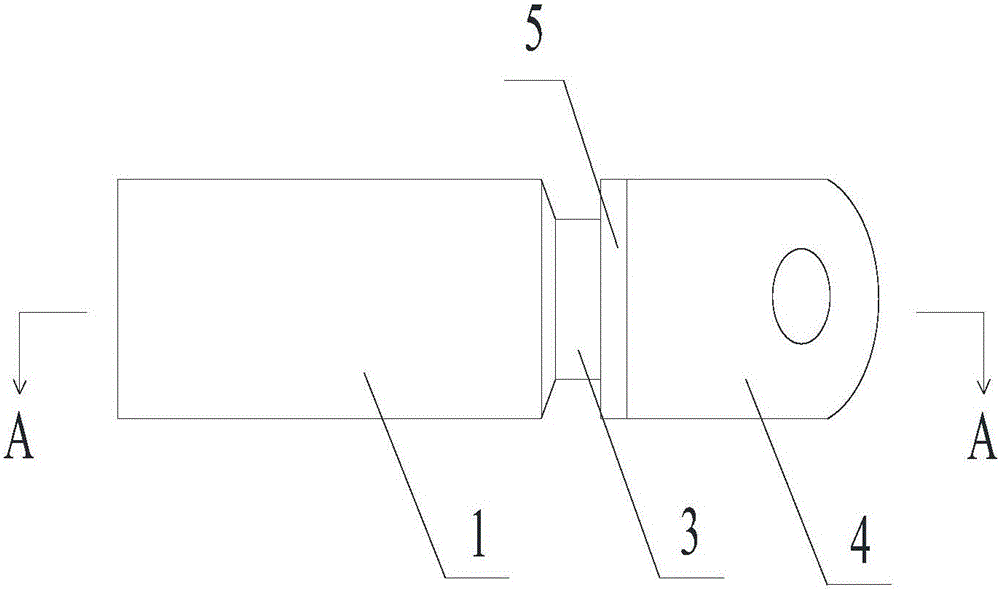

Rigidity-adjustable ball joint and thrust rod assembly

PendingCN112879417AExtended service lifePrevent extrusionPivotal connectionsPivoted suspension armsSuspension (vehicle)Ball joint

The invention discloses a rigidity-adjustable ball joint and thrust rod assembly, and belongs to the technical field of automobile suspension systems. The assembly comprises a thrust rod bracket, a pin shaft, a thrust rod, a ball body, a bearing outer ring and rigidity adjusting sleeves, wherein the ball body is in sliding universal connection with the bearing outer ring; the bearing outer ring is connected with the rigidity adjusting sleeves through an elastic layer; adjusting gaps are formed by the corresponding end faces of the rigidity adjusting sleeves on the two sides; the thrust rod and the rigidity adjusting sleeves are fixedly mounted; and the pin shaft is inserted into a mounting shaft hole and is connected with the thrust rod bracket. Free universal rotation of the thrust rod assembly is achieved through a ball joint, torsion stress of the elastic layer is released, and the elastic layer is only subjected to pressure load; the elastic layer achieves the buffering function of the thrust rod assembly, and the impact load in the force transmission process of the thrust rod is reduced; and the rigidity adjusting sleeves are provided with the adjusting gap, so that rigidity adjustment of the thrust rod assembly is achieved, the reliability of the thrust rod assembly is improved, the service life is prolonged, meanwhile, flexible connection of a suspension system and an axle assembly is achieved, and the comfort of a whole vehicle is improved.

Owner:SINO TRUK JINAN POWER

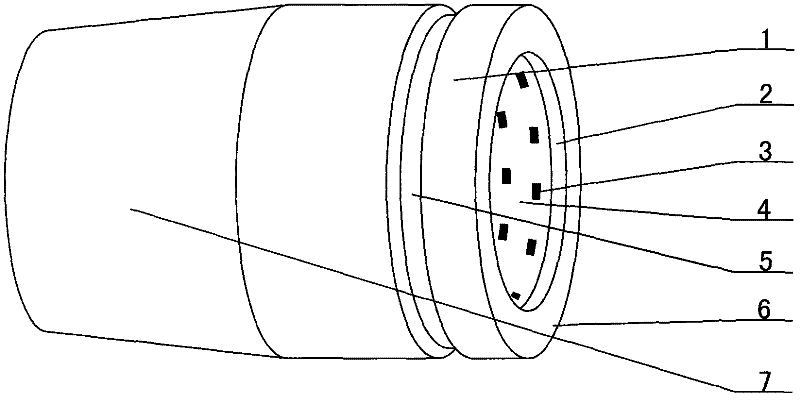

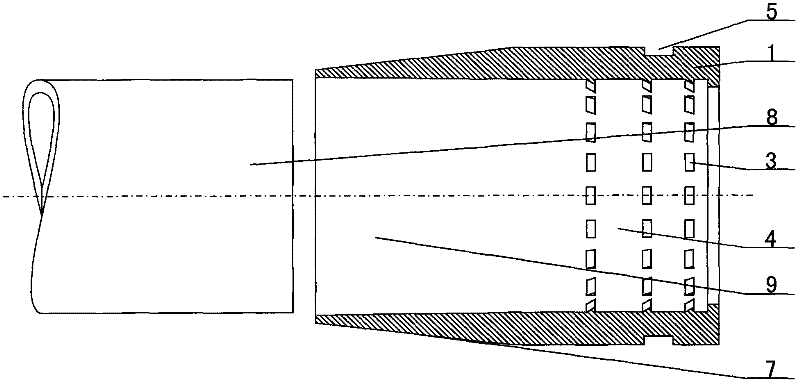

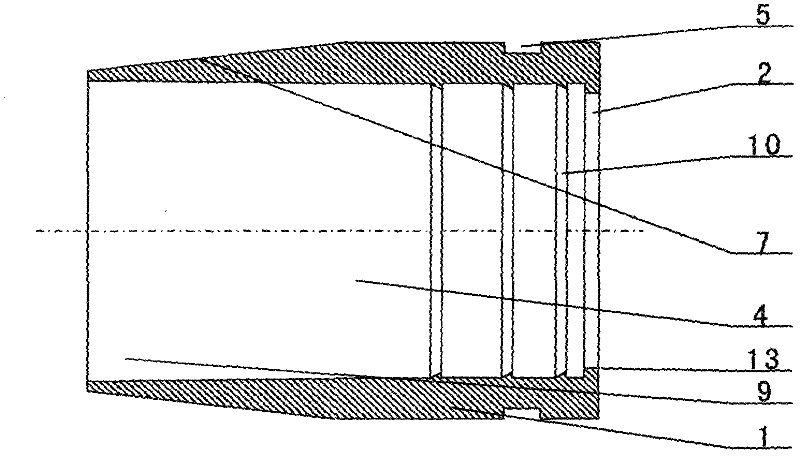

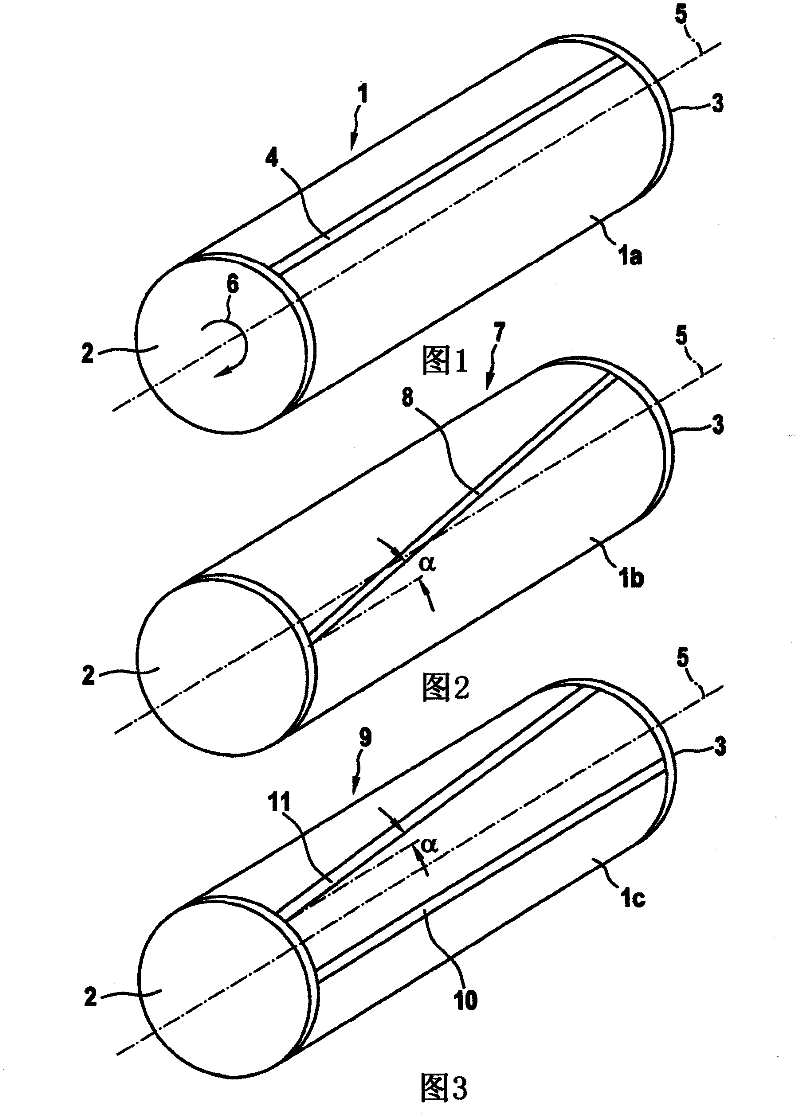

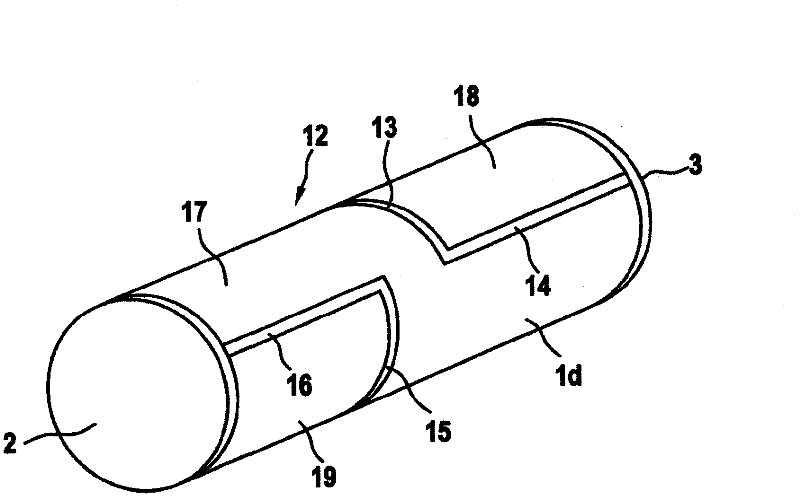

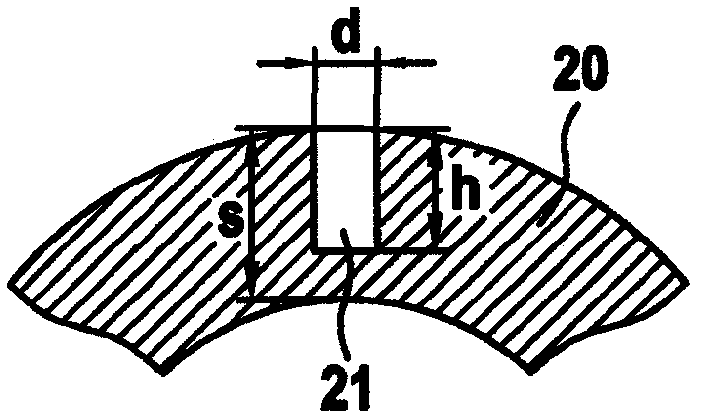

tube target

ActiveCN102272347AReduce stressStop breakingElectric discharge tubesVacuum evaporation coatingMechanical engineeringPhysics

The invention relates to a tube target (50) for sputtering, having a target (46) disposed on a cylindrical carrier tube. Said target (46) is divided into a plurality of segments. The target (46) comprises at least one groove (51 - 54) diagonal to the axis of rotation thereof.

Owner:PROTECH MATERIALS INC

Copper-aluminum transition terminal of Al-Fe-Sr-RE aluminum alloy cable and preparation method thereof

InactiveCN105703111AAddress structural issuesSmooth transitionCoupling contact membersElectrical conductorSolid structure

The invention discloses a copper-aluminum transition terminal of an Al-Fe-Sr-RE aluminum alloy cable, and belongs to the technical field of the copper-aluminum transition terminal. The copper-aluminum transition terminal of the Al-Fe-Sr-RE aluminum alloy cable comprises an aluminum alloy connecting pipe connected with a cable conductor and a copper nose connected with the other end of the aluminum alloy connecting pipe; a copper-aluminum transition part is arranged between the aluminum alloy connecting pipe and the copper nose; and the copper-aluminum transition part is an aluminum alloy in a columnar solid structure. The invention also provides a preparation method of the copper-aluminum transition terminal of the Al-Fe-Sr-RE aluminum alloy cable. The preparation method is simple, and easy to operate; and the prepared copper-aluminum transition terminal is excellent in electrical properties, mechanical properties and creep resistance, also has reliable connectivity under a condition of a constantly changing temperature, is outstanding in thermal stability and electric conductivity and can transit steadily and mildly from the aluminum alloy cable to the connecting pipe and to the copper nose.

Owner:河北欣意电缆有限公司

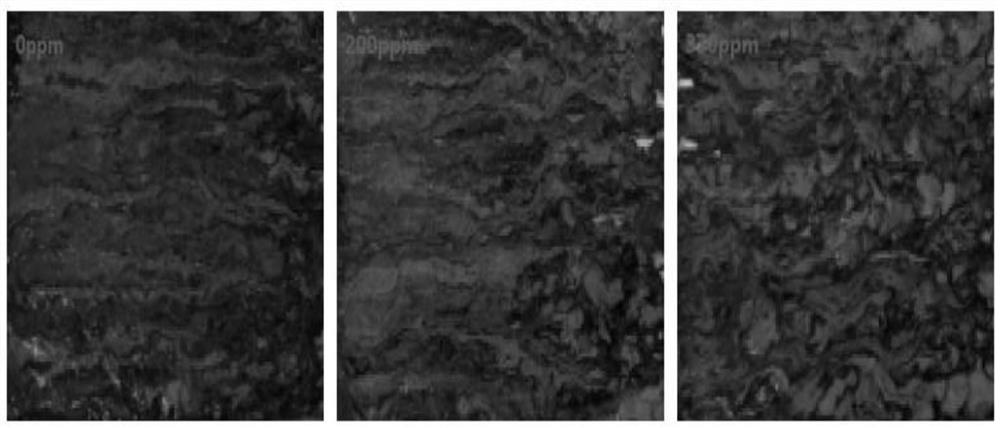

Manufacturing method of rare earth microalloyed weather-resistant bridge steel for alpine regions

InactiveCN113667883ASpread evenlyHigh yieldMetal rolling arrangementsRare-earth elementWeather resistance

The invention discloses a manufacturing method of rare earth microalloyed weather-resistant bridge steel for alpine regions. Compared with the prior art, the method has the advantages that a mode of adding rare earth is different, and by adding rare earth wires containing rare earth cerium Ce in the slab casting process, the defect of low rare earth yield caused by addition of rare earth alloy in the RH refining process is overcome, and the rare earth element yield is greater than 80%; and secondly, the rare earth content of a bridge steel plate is greater than 60 ppm, the low-temperature impact performance of the steel plate is improved through the high rare earth content, weather resistance is improved, and the long-time cognition that only a small amount of rare earth (0-10 ppm) can generate beneficial improvement on the steel plate and on the contrary, addition of a large amount of rare earth can generate inclusions to affect the performance of the steel plate is subverted to a certain extent.

Owner:BAOTOU IRON & STEEL GRP

Non-base cloth flower-absorbing artificial leather and preparation method thereof

ActiveCN109355920ASimplify the suction processRaise the processing temperatureTextiles and paperSurface layerMagnification

The invention relates to a non-base cloth flower-absorbing artificial leather and a preparation method thereof. The preparation method of the non-base cloth flower-sucking artificial leather includesthe following steps: (1) coating a prepared surface layer slurry material on a release papers and drying; (2) coating the prepared foaming layer slurry material on the dried surface layer slurry material and foaming to a specified magnification; (3) coating the prepared back coating slurry material on the foaming layer slurry material after foaming, and then drying until the back coating slurry material is in a molten state, performing flower absorption treatment at this time, stripping the release papers after cooling and shaping, and obtaining the base cloth-free flower absorption artificialleather. The preparation method of the non-base cloth flower-absorbing artificial leather has the advantages of improving the processing temperature of the leather and effectively controlling the adverse phenomena of the leather such as deformation, fracture, paste and the like.

Owner:FUJIAN POLYTECH TECH CO LTD

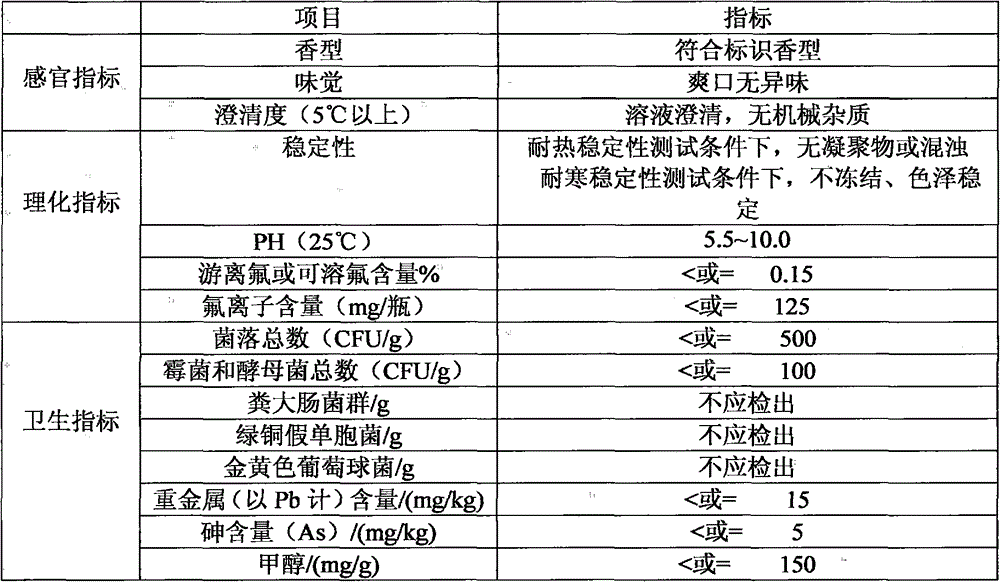

Anti-radiation anti-caries inflammation-diminishing oral preparation

InactiveCN105327337AAlleviate the conditionShorten the duration of the diseaseAntibacterial agentsHydroxy compound active ingredientsOral diseaseOcular inflammation

The invention belongs to technical field of oral pharmaceutical preparations and particularly relates to a multifunctional anti-radiation anti-caries inflammation-diminishing oral pharmaceutical preparation. According to the technical scheme, the anti-radiation anti-caries inflammation-diminishing oral preparation is prepared from, by mass, 0.5%-5% of oltipraz, 0.3%-2% of a recombinant human horny cell growth factor, 0.02%-0.2% of domiphen, 0.02%-0.2% of thymol, 0.02%-0.5% of tinidazole and the balance auxiliary medicines, a freshener, a sweetener, a plasticizer, a disintegrating agent, an algefacient, a stabilizing agent and the like. The anti-radiation anti-caries inflammation-diminishing oral preparation can be made into mouthwash, can be concentrated into spray liquid or can be quickly disintegrated into washing and disinfecting tablets. The anti-radiation anti-caries inflammation-diminishing oral preparation is researched and developed based on pathogenic factors of ionized radiative oral diseases and meets the multi-aspect demands of convenient carrying, prevention and guarantee at ordinary times, emergent treatment and curing in wartime and the like.

Owner:中国人民解放军96617部队

Al-Fe-B-RE aluminum alloy cable copper aluminum transition terminal and production method thereof

InactiveCN105896118ALower resistanceReduce electrical lossContact member manufacturingElectric connection structural associationsElectrical conductorSolid structure

The invention discloses an Al-Fe-B-RE aluminum alloy cable copper aluminum transition terminal belonging to the copper aluminum transition terminal technology field. The Al-Fe-B-RE aluminum alloy cable copper aluminum transition terminal comprises an aluminum alloy connecting pipe connected with a cable conductor and a copper lug connected with the other end of the aluminum alloy connecting pipe. A copper aluminum transition member is disposed between the aluminum alloy connecting pipe and the copper lug, and is an aluminum alloy having a cylindrical solid structure. The invention also provides the production method of the Al-Fe-B-RE aluminum alloy cable copper aluminum transition terminal. The production method is simple, and is easy to operate, the electrical performance, the mechanical performance, and the creep-resistance performance of the produced copper aluminum transition terminal are excellent, and under the condition of the constantly-changing temperature, the reliable connection can be guaranteed, the excellent thermostability and the excellent conductivity are provided, and in addition, the transition from the aluminum alloy cable to the connecting pipe to the copper lug is stable and smooth.

Owner:河北欣意电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com