Al-Fe-B-RE aluminum alloy cable copper aluminum transition terminal and production method thereof

An al-fe-b-re, transition terminal technology, applied in the direction of circuits, electrical components, conductive connections, etc., can solve problems such as potential safety hazards, poor electrical and mechanical creep resistance, quality problems, etc., to achieve Extended life, excellent corrosion resistance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

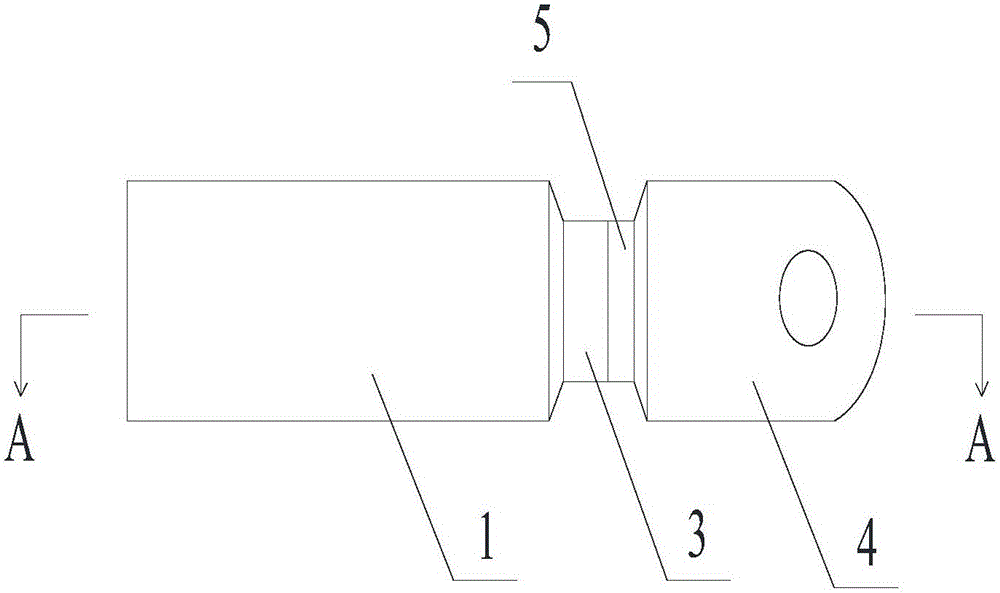

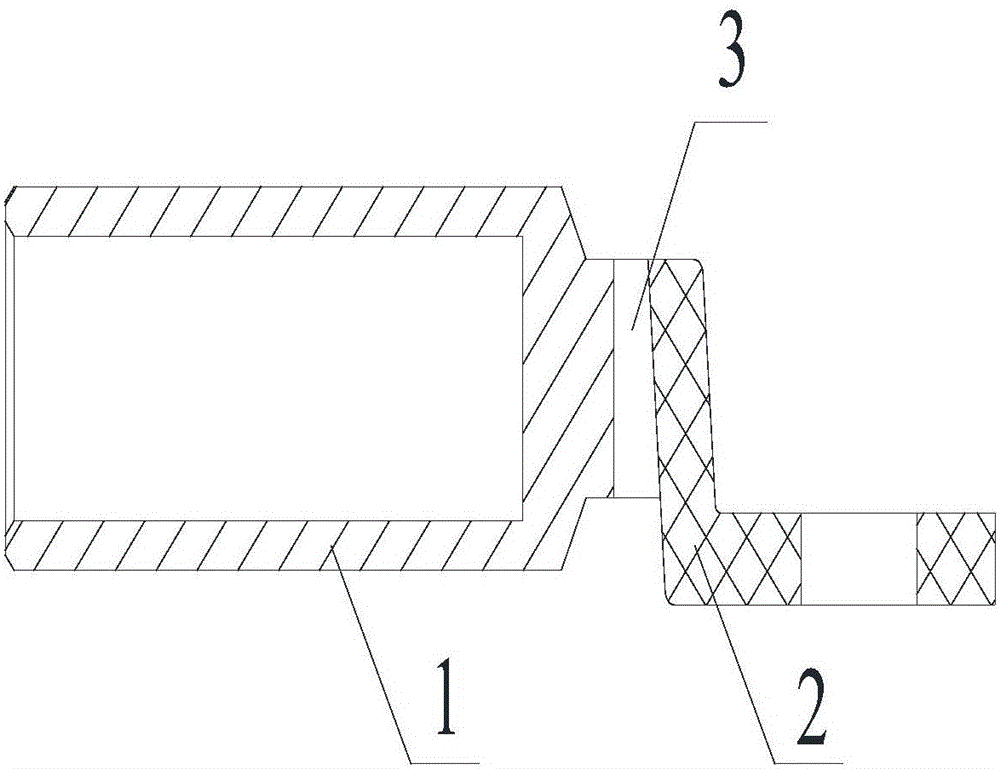

[0043] Such as Figure 1-2 As shown, the Al-Fe-B-RE aluminum alloy cable copper-aluminum transition terminal includes an aluminum alloy connecting pipe 1 connected to the cable conductor, a copper nose 2 connected to the other end of the aluminum alloy connecting pipe 1, and the aluminum alloy connecting pipe 1 is an oil-blocking structure with a built-in conductive paste. The aluminum alloy connecting pipe 1 is provided with an inner connection hole, and the cable conductor is inserted into the inner connection hole. The cross-sectional shape of the inner connection hole is circular, fan-shaped, tile-shaped, or semicircular. shape or a shape corresponding to the section of the cable, the copper lug 2 is L-shaped, including a bottom plate 4 connected to the circuit breaker and a connecting column 5 connected to the bottom plate 4, and the other end of the connecting column 5 is connected to the copper-aluminum transition piece 3 Connection, the connection column 5 and the bott...

Embodiment 2

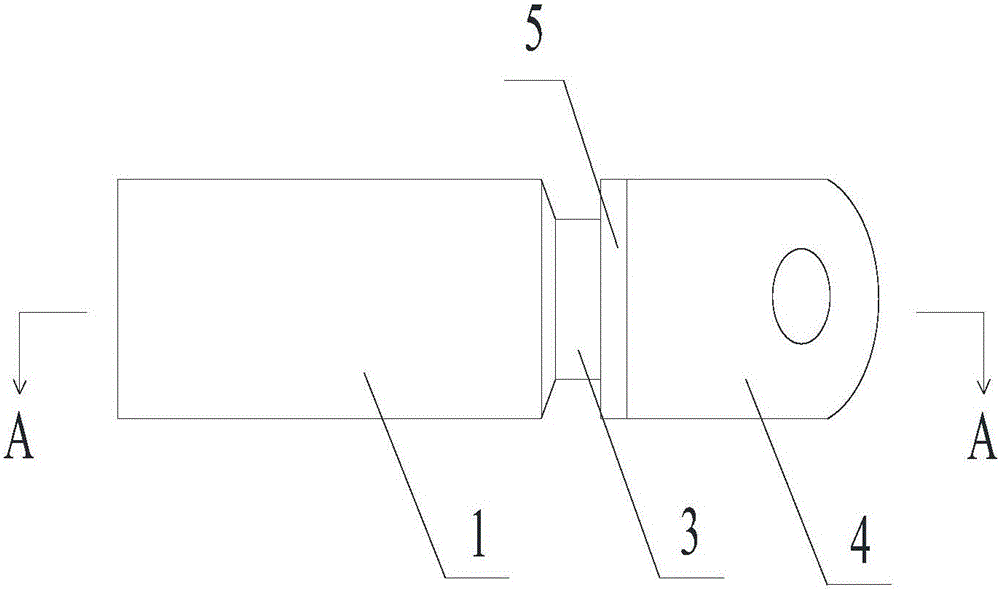

[0051] Such as Figure 3-4 As shown, the Al-Fe-B-RE aluminum alloy cable copper-aluminum transition terminal includes an aluminum alloy connecting pipe 1 connected to the cable conductor, a copper nose 2 connected to the other end of the aluminum alloy connecting pipe 1, and the aluminum alloy connecting pipe 1 is an oil-blocking structure with a built-in conductive paste. The aluminum alloy connecting pipe 1 is provided with an inner connection hole, and the cable conductor is inserted into the inner connection hole. The cross-sectional shape of the inner connection hole is circular, fan-shaped, tile-shaped, or semicircular. shape or a shape corresponding to the section of the cable, the copper lug 2 is L-shaped, including a bottom plate 4 connected to the circuit breaker and a connecting column 5 connected to the bottom plate 4, and the other end of the connecting column 5 is connected to the copper-aluminum transition piece 3 Connection, the connecting column 5 and the bott...

Embodiment 3

[0058] Such as Figure 5-6 As shown, the Al-Fe-B-RE aluminum alloy cable copper-aluminum transition terminal includes an aluminum alloy connecting pipe 1 connected to the cable conductor, a copper nose 2 connected to the other end of the aluminum alloy connecting pipe 1, and the aluminum alloy connecting pipe 1 is an oil-blocking structure with a built-in conductive paste. The aluminum alloy connecting pipe 1 is provided with an inner connection hole, and the cable conductor is inserted into the inner connection hole. The cross-sectional shape of the inner connection hole is circular, fan-shaped, tile-shaped, or semicircular. shape or a shape corresponding to the section of the cable, the copper lug 2 is L-shaped, including a bottom plate 4 connected to the circuit breaker and a connecting column 5 connected to the bottom plate 4, and the other end of the connecting column 5 is connected to the copper-aluminum transition piece 3 Connection, the connecting column 5 and the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com