PBT composition resistant to cyclic injection molding, preparation method and product thereof

A composition and injection molding technology, applied in the field of engineering plastics, can solve problems such as poor mechanical properties, and achieve the effects of preventing fracture, improving the retention rate of mechanical properties, and reducing degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

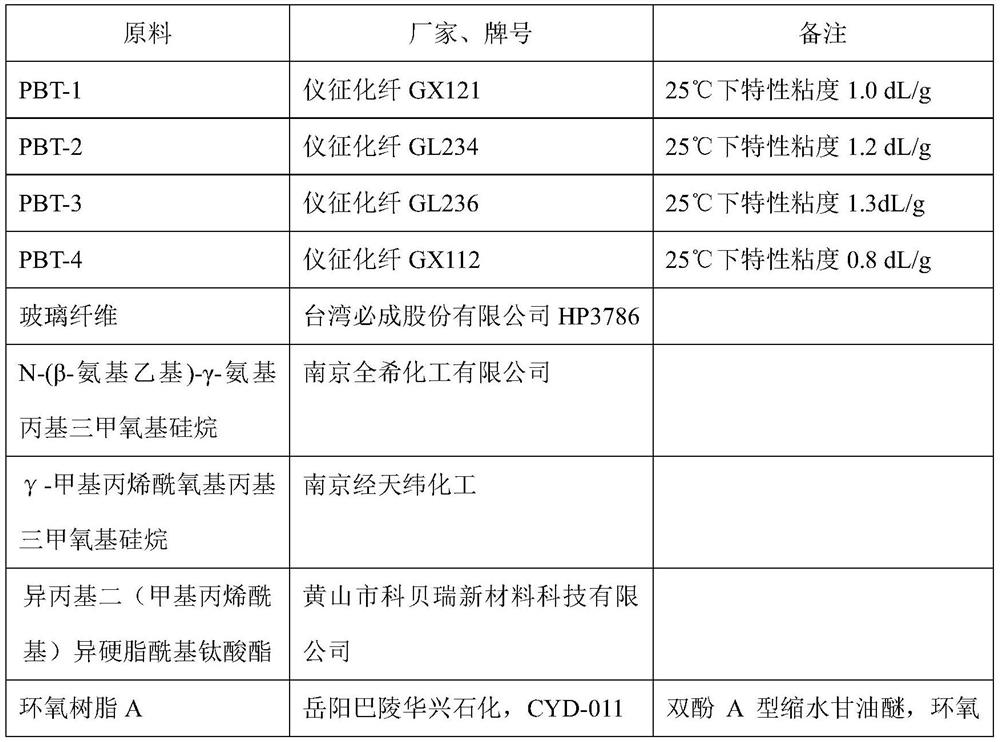

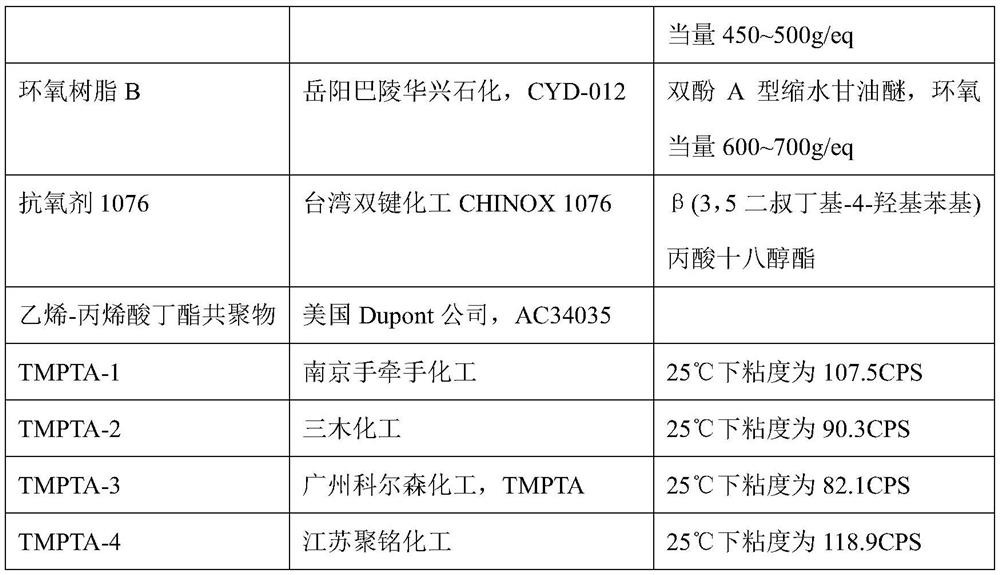

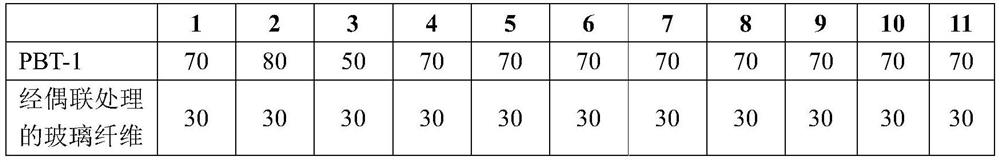

[0051] The content of each component in the PBT compositions of Examples 1-20 is shown in Table 1.

[0052]The preparation method is as follows: the coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, γ-methacryloyloxypropyltrimethoxysilane, isopropylbis(methyl) After blending the acryloyl) isostearoyl titanate according to the weight ratio of 1:2:1, the glass fiber is subjected to a coupling treatment to obtain a coupled-treated glass fiber;

[0053] According to Table 1, PBT, coupled glass fiber or uncoupled glass fiber, epoxy resin, antioxidant, EBA and TMPTA were mixed and added to a twin-screw extruder, and then melted and extruded into pellets. The PBT composition is obtained.

[0054] The temperature of the first zone of the twin-screw extruder from the feeding port to the die head is 200-230°C, the temperature of the second zone is 240-260°C, the temperature of the third zone is 235-255°C, the temperature of the fourth zone is 235-255°C, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com