Mechanical propelling pencil

A technology for mechanical pencils and lead cores, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems of insufficient use of lead cores and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

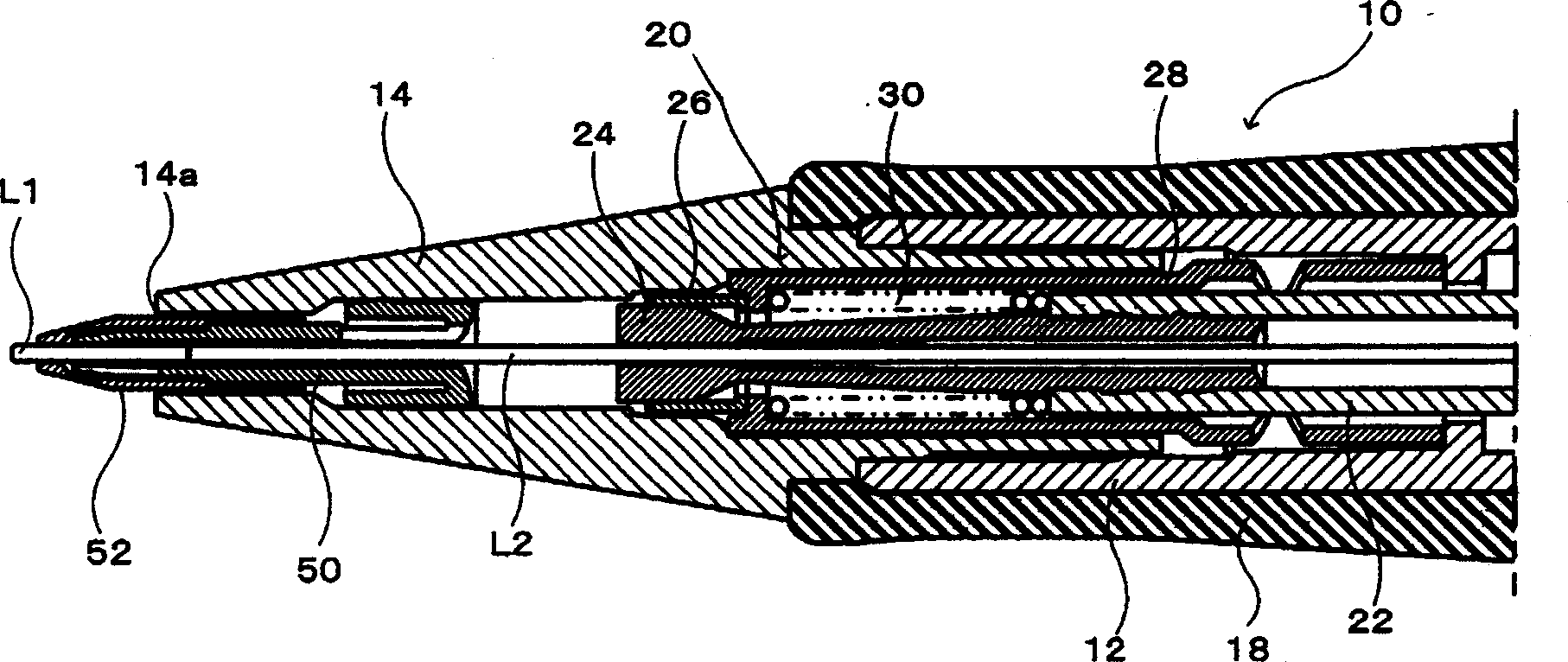

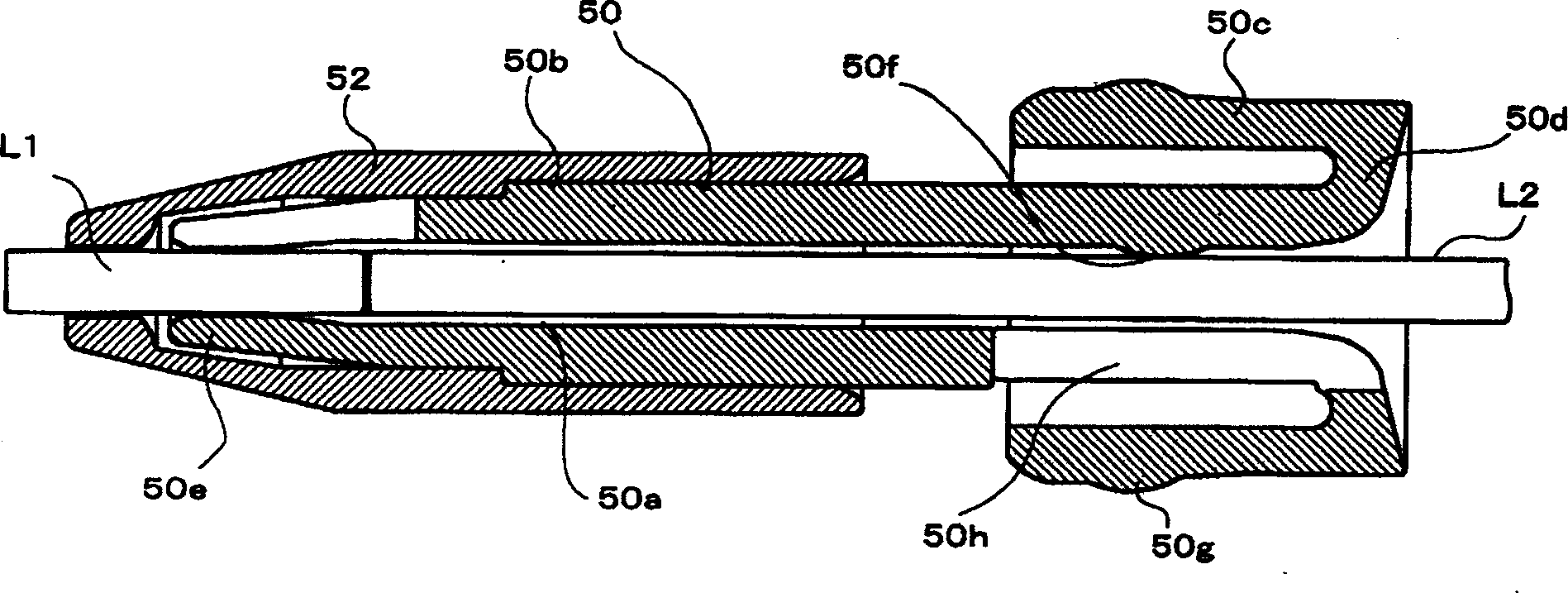

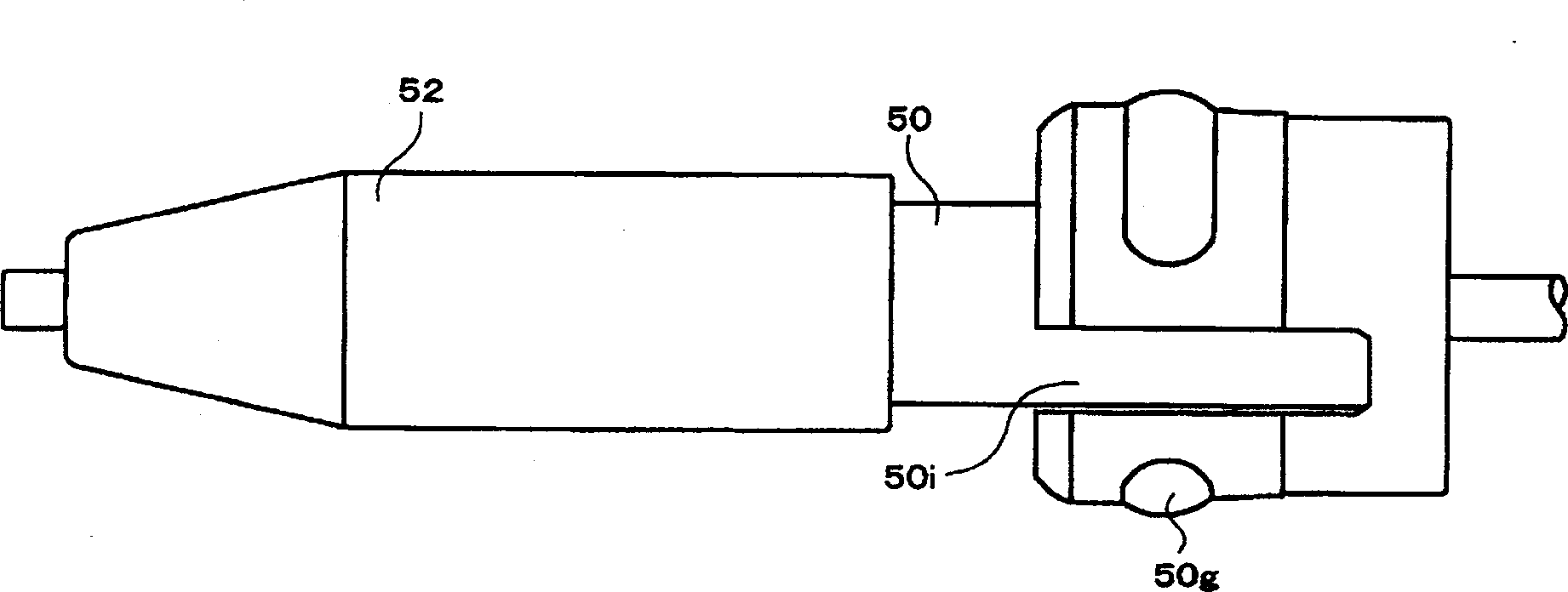

[0015] Embodiments of the present invention will be described below using the drawings. Figure 1 to Figure 3 represent the invention

[0016] Diagram of the implementation form.

[0017] In the figure, the mechanical pencil mainly has a pen holder 10, a core feeding mechanism 20, a core holding part 50 and an operating part (omitted in the figure). The core-feeding mechanism 20 is arranged in the pen holder 10, and is used to clamp the lead and send the lead out; the core-holding part 50 is located at a position more forward than the core-feeding mechanism 20, and is used to maintain the through-through lead, and the operating part is used to Operate the core feeding mechanism to send out the lead core.

[0018] Penholder 10 is made of front axle 12, and the front axle taper end 14 that is threaded with front axle 12 and rear axle (omitted among the figures) constitute; These front axles 12, the front axle cone end 14 and the rear axle also can be made of integral parts, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com