Method and device for bus bar soft connection

A soft connection and bus joint technology, applied in the direction of busbar installation, cable installation, clamping/spring connection, etc., can solve the problems of unstable input power, unstable bus joint fixing, affecting production and life, etc. Reasonable design, the effect of solving poor contact between busbars and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

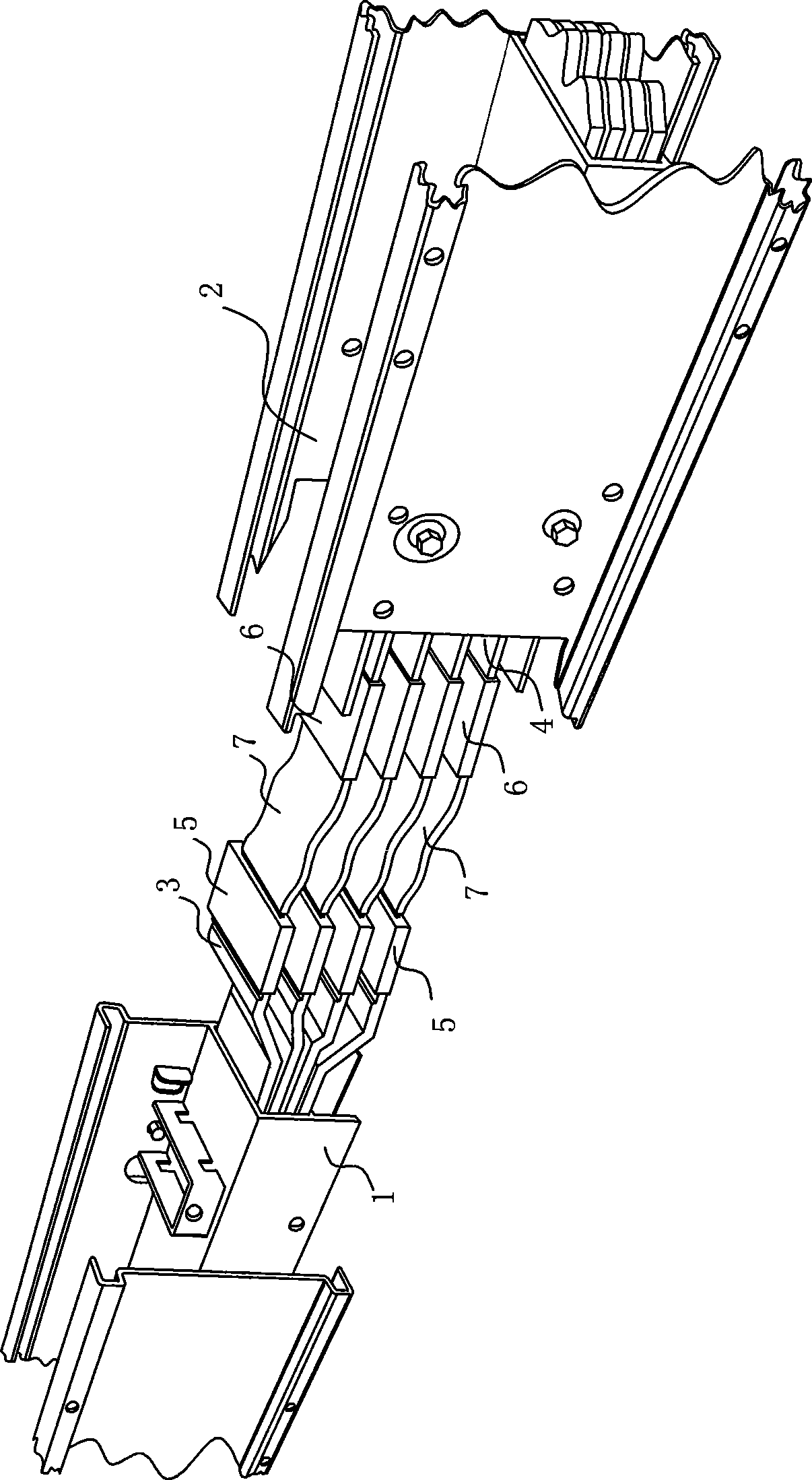

[0014] The method for flexible bus connection of the present invention is to connect the bus joint 3 of the bus duct 1 and the bus joint 4 of the bus duct 2 with a soft conductor material 7 .

Embodiment 2

[0016] The soft connection method of the busbars of the present invention is to fasten and connect the busbar joints 3 of the busway 1 and the busbar joints 4 of the busway 2 with the soft conductor material 7 .

Embodiment 3

[0018] The bus soft connection method of the present invention is that the bus joint 3 of the bus duct 1 and the bus joint 4 of the bus duct 2 are clamped with a soft conductor material 7, or tightly fitted or screwed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com