Plate holding apparatus

A technology of clamping equipment and plate clamps, which is applied in printing, printing machines, printing processes, etc., and can solve problems such as damage to the printing plate cylinder and breakage of the printing plate clamping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

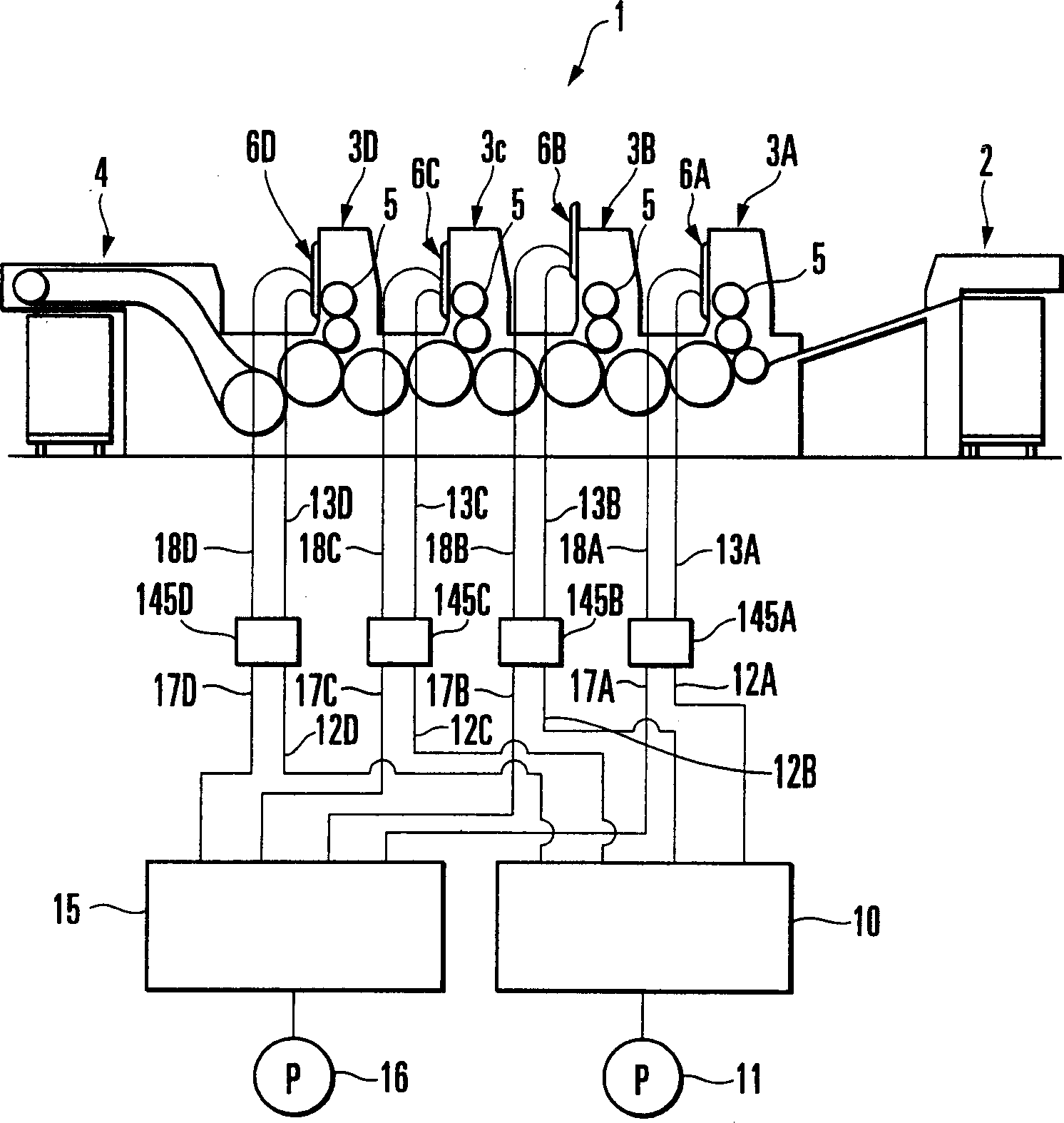

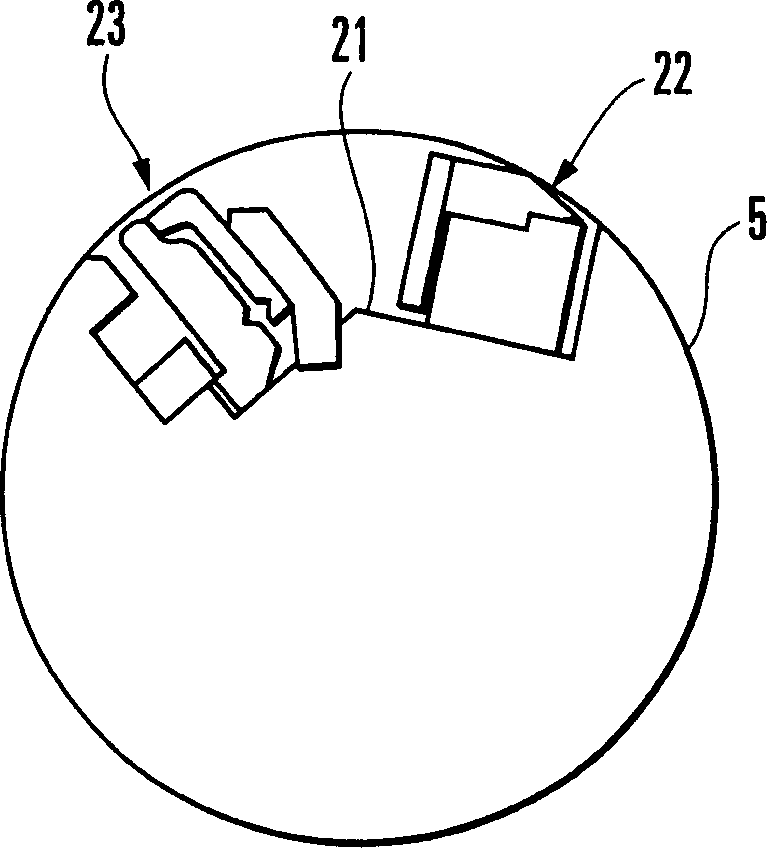

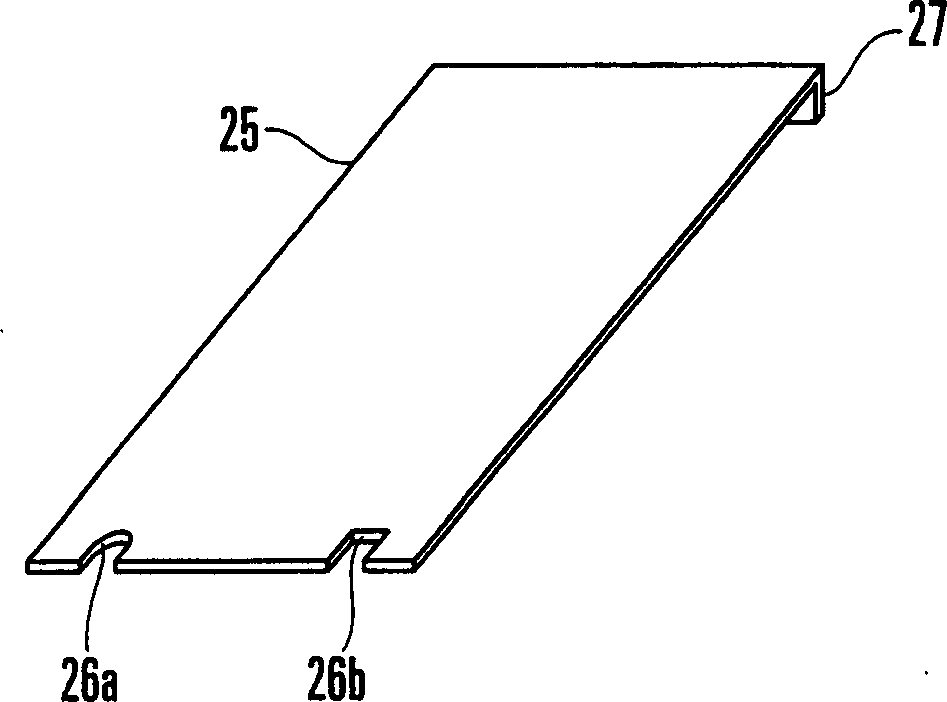

[0041] According to one embodiment of the present invention, reference will be made to Figures 1 to 29 Describe a plate holding device. Such as figure 1 As shown, a sheet-fed rotary printing machine 1 includes a feeder 2 for feeding paper, printing units 3A to 3D for printing four different colors on the incoming paper, and a printing unit for stacking Output unit 4 for paper coming out of printing unit 3D. A plate cylinder 5 is rotatably fixed by a pair of opposing frames, and a printing plate is mounted thereon, and each of the printing units 3A to 3D is equipped with a plate cylinder 5 . Safety covers 6A to 6D are mounted as movable members on output sides of the printing units 3A to 3D, respectively. The safety covers 6A to 6D are respectively supported by the printing units 3A to 3D so that they can be moved vertically by air cylinders 30 . When each safety cover 6A to 6D is moved upward, the safety cover opens the front portion of the corresponding plate cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com