Manufacturing method of rare earth microalloyed weather-resistant bridge steel for alpine regions

A technology of micro-alloying and manufacturing method, applied in the direction of metal rolling, etc., can solve the problem of little research on steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

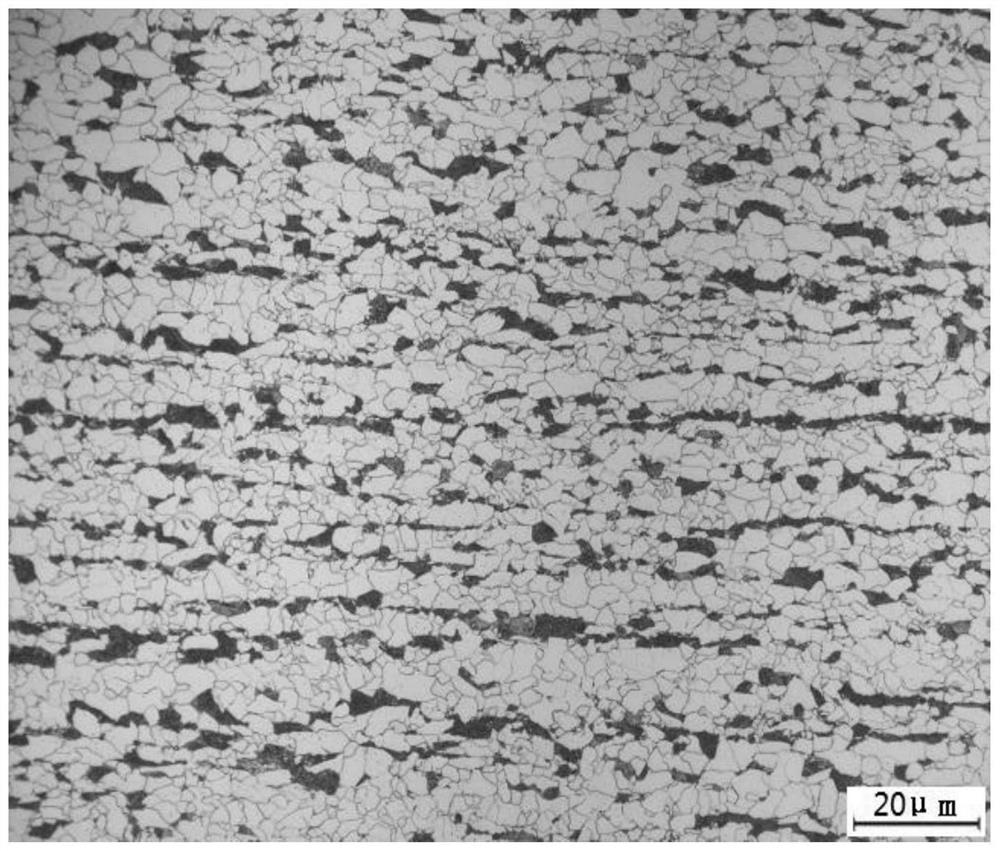

[0030] Q345qD-RE bridge steel plate production process, the composition and mass percentage of steel are: C=0.072, Si=0.32, Mn=1.46, P=0.016, S=0.004, Als=0.022, Nb=0.028, Ti=0.011, Gr =0.027, Mo=0.003, Ni=0.020, Cu=0.020, Ce=0.0200.

[0031] The main process steps and parameters are as follows:

[0032] The molten iron must be pretreated before entering the furnace. After the treatment, the sulfur content of the molten iron is ≤0.010%, and the temperature is ≥1250°C. The slag must be cleaned before the molten iron enters the converter. About 85%, scrap about 15%. Converter end point control C-T coordinated tapping, P≤0.012%, S≤0.015%, strict slag blocking and tapping, tapping time 4-7min, adding alloy at 1 / 5 of tapping, adding alloy at 2 / 5 of tapping, During the tapping process, depending on the oxygen content at the end point, add an appropriate amount of modifier and lime, the oxygen should not be less than 250m, and make appropriate adjustments depending on the loading a...

Embodiment 2

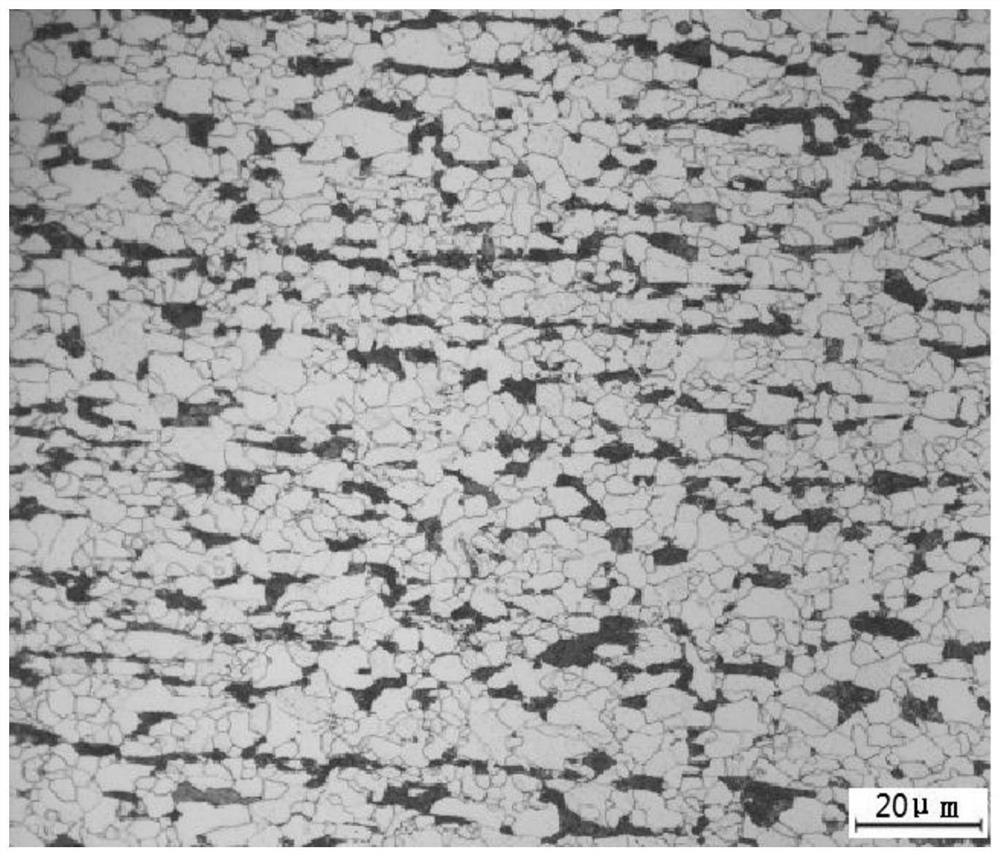

[0043] Q345qD-RE bridge steel plate production process, the composition and mass percentage of steel are: C=0.071, Si=0.32, Mn=1.41, P=0.012, S=0.003, Als=0.023, Nb=0.025, Ti=0.011, Gr =0.028, Mo=0.004, Ni=0.019, Cu=0.016, Ce=0.0370.

[0044] The main process steps and parameters are as follows:

[0045] The molten iron must be pretreated before entering the furnace. After the treatment, the sulfur content of the molten iron is ≤0.010%, and the temperature is ≥1250°C. The slag must be cleaned before the molten iron enters the converter. About 85%, scrap steel about 15%. Converter end point control C-T coordinated tapping, P≤0.012%, S≤0.015%, strict slag blocking and tapping, tapping time 4-7min, adding alloy at 1 / 5 of tapping, adding alloy at 2 / 5 of tapping, During the tapping process, depending on the oxygen content at the end point, add an appropriate amount of modifier and lime, the oxygen should not be less than 250m, and make appropriate adjustments depending on the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com