High temperature-resistant and waterproof coiled material

A waterproof roll material, high temperature resistant technology, applied in the direction of adhesive type, non-polymer adhesive additive, film/sheet adhesive, etc., can solve poor waterproofness, roll material failure, heat resistance Poor and other problems, to achieve the effect of improving heat resistance, adhesive force and heat resistance, improving high temperature resistance, and enhancing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

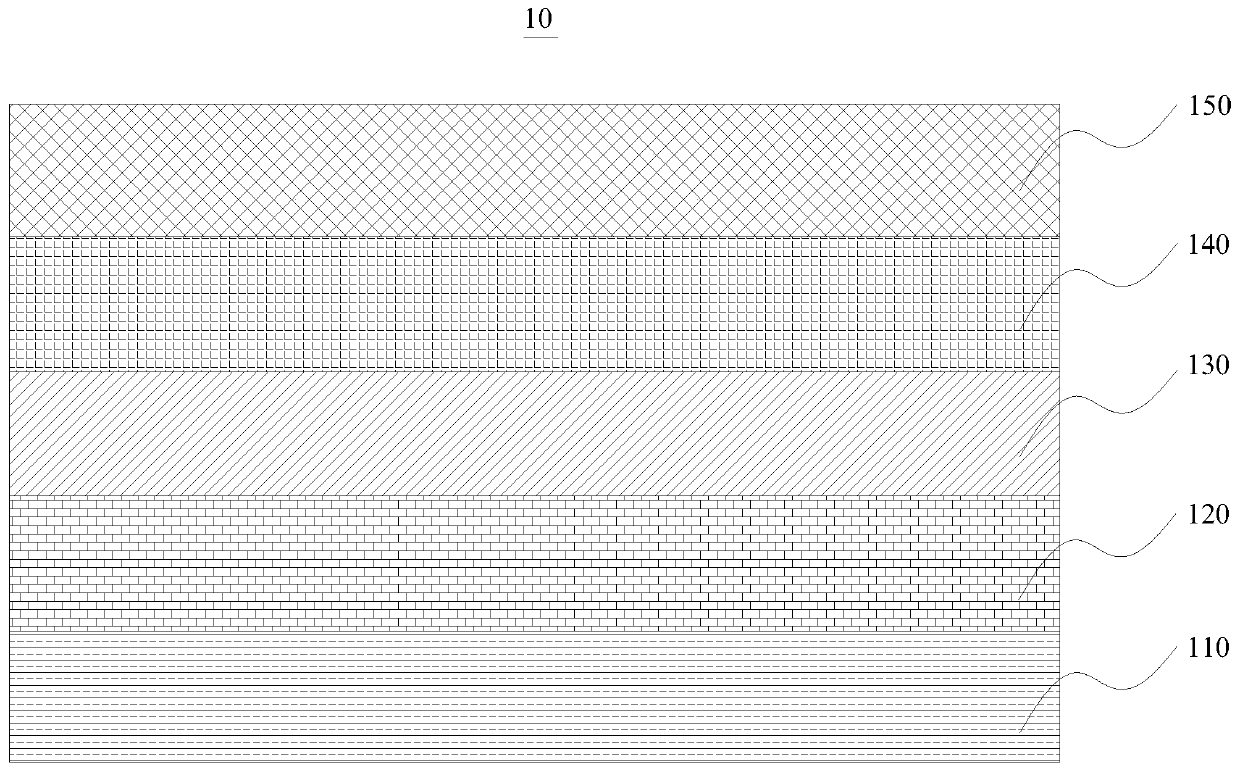

[0030] In order to better describe the above-mentioned high-temperature-resistant waterproof coiled material, so as to better understand the concept of the above-mentioned high-temperature-resistant waterproof coiled material. For an implementation, see figure 1 , a high-temperature-resistant waterproof coiled material 10, comprising a polymer substrate layer 110, a hot-melt adhesive layer 120, a metal foil layer 130, and a heat-resistant butyl adhesive layer 140 that are sequentially stacked; wherein, the heat-resistant butyl The adhesive layer 140 includes the following components by mass: 15-30 parts of plasticizer, 10-40 parts of butyl rubber, 20-50 parts of high-temperature resistant filler, 30-60 parts of tackifying resin, 0.5-2 parts of coupling agent 0.5-2 parts and anti-aging agent. It should be noted that the high-molecular-weight butyl rubber and high-molecular-weight plasticizer are selected for the high-temperature-resistant waterproof coiled material of this emb...

Embodiment 1

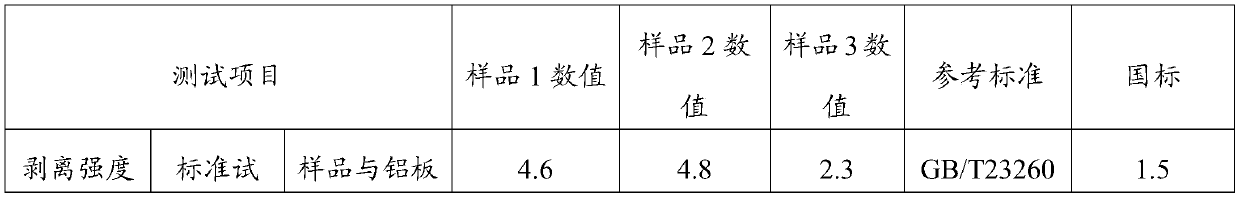

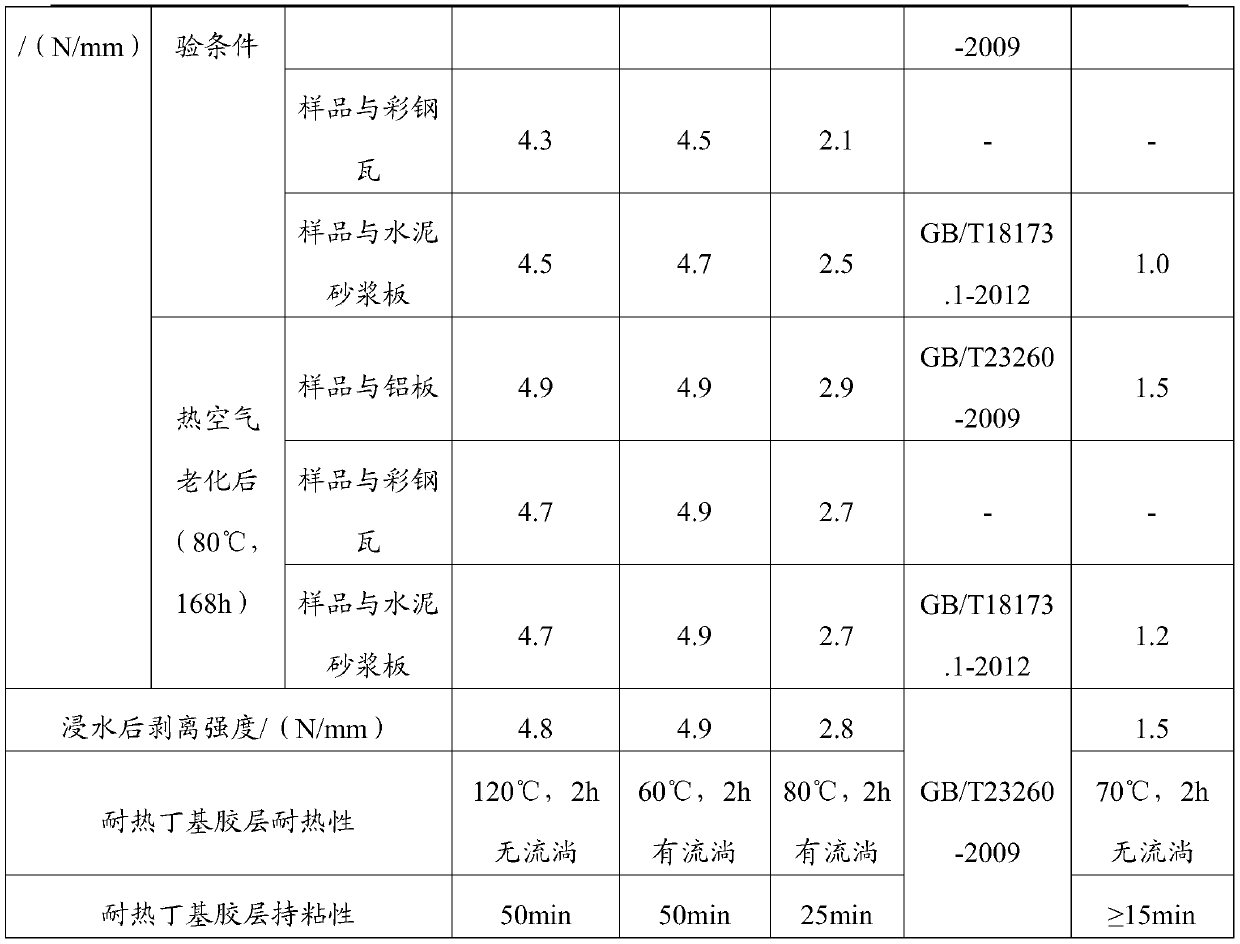

[0055] A high-temperature-resistant waterproof coiled material, comprising a polymer substrate layer, a hot-melt adhesive layer, a metal foil layer and a heat-resistant butyl adhesive layer stacked in sequence; the polymer substrate layer is polyethylene terephthalate ester, the metal foil layer is aluminum foil; wherein, the heat-resistant butyl rubber layer includes the following components in parts by mass: polyisobutylene 15kg, butyl rubber 10kg, calcium carbonate 5kg, mica powder 5kg, titanium dioxide 5kg, diatom 5kg of soil, 15kg of rosin resin, 15kg of terpene resin, 0.5kg of vinyl tris(β-methoxyethoxy)silane and 0.5kg of pentaerythritol of β(3,5-di-tert-butyl-4-hydroxyphenyl)propionate .

Embodiment 2

[0057] A high-temperature-resistant waterproof coiled material, comprising a polymer substrate layer, a hot-melt adhesive layer, a metal foil layer and a heat-resistant butyl adhesive layer stacked in sequence; the polymer substrate layer is polyethylene terephthalate ester, the metal foil layer is aluminum foil; wherein, the heat-resistant butyl rubber layer includes the following components in parts by mass: polyisobutylene 30kg, butyl rubber 40kg, calcium carbonate 15kg, mica powder 15kg, titanium dioxide 10kg, diatom 10kg of soil, 30kg of rosin resin, 30kg of terpene resin, 2kg of vinyl tris(β-methoxyethoxy)silane and 2kg of pentaerythritol of β(3,5-di-tert-butyl-4hydroxyphenyl)propionate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com