Pre-heating spray-hole type static mixer

A technology of static mixers and spray holes, applied in the direction of fluid mixers, mixers, mixing methods, etc., can solve the problems of not realizing preheating, etc., reduce the ammonia slip rate, shorten the mixing distance, and promote uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

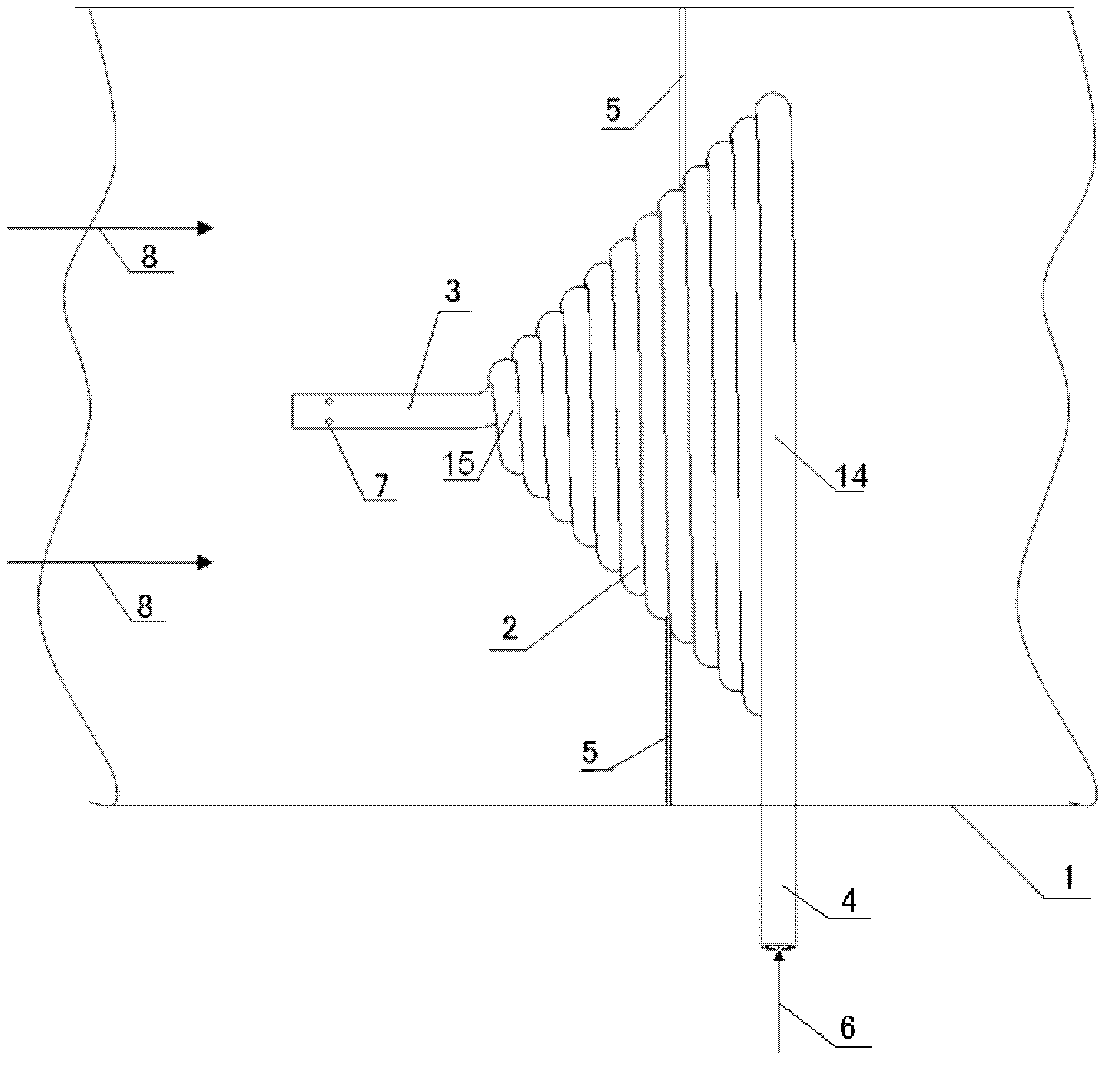

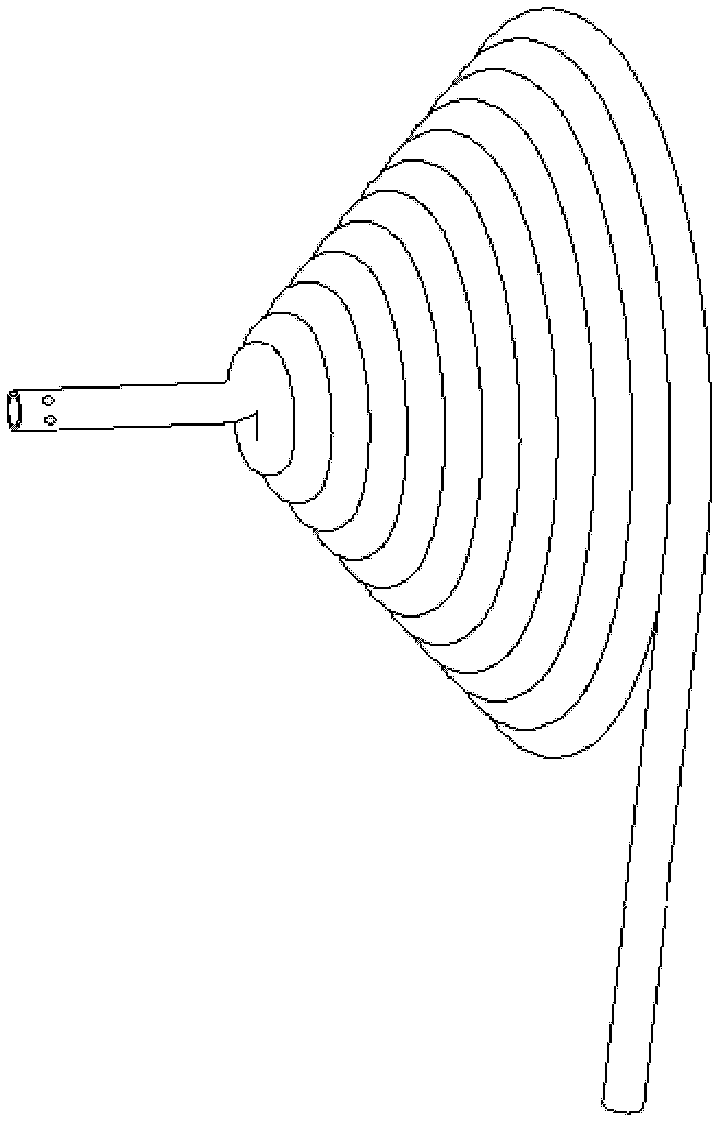

[0033] combine figure 1 and figure 2 , the outer ring port 14 of the preheating pipe is connected to the inlet pipe 4, the inner ring port 15 is connected to the nozzle pipe 3, a ring of nozzle holes 7 is opened on the side wall of the pipe at the closed end of the nozzle pipe 3, and the closed end is arranged at The center of the cross section of the flue 1 is located, and the end face faces the inflow direction of the flue gas 8 . The preheating pipe 2 is fixed to the inner wall of the flue 1 through the support beam 5, and can also be connected to the flange 9 through the support beam 5, such as Figure 9 shown. The preheating tube 2 can be wound into sheets, such as Figure 5 shown, it can also be wound into a tapered shape, such as Image 6 shown. However, no matter what shape of preheating pipe is used, it should be ensured that there is no gap between the spiral center of the preheating pipe 2 and the adjacent spiral pipes, so that the flue gas 8 cannot pass throu...

Embodiment approach 2

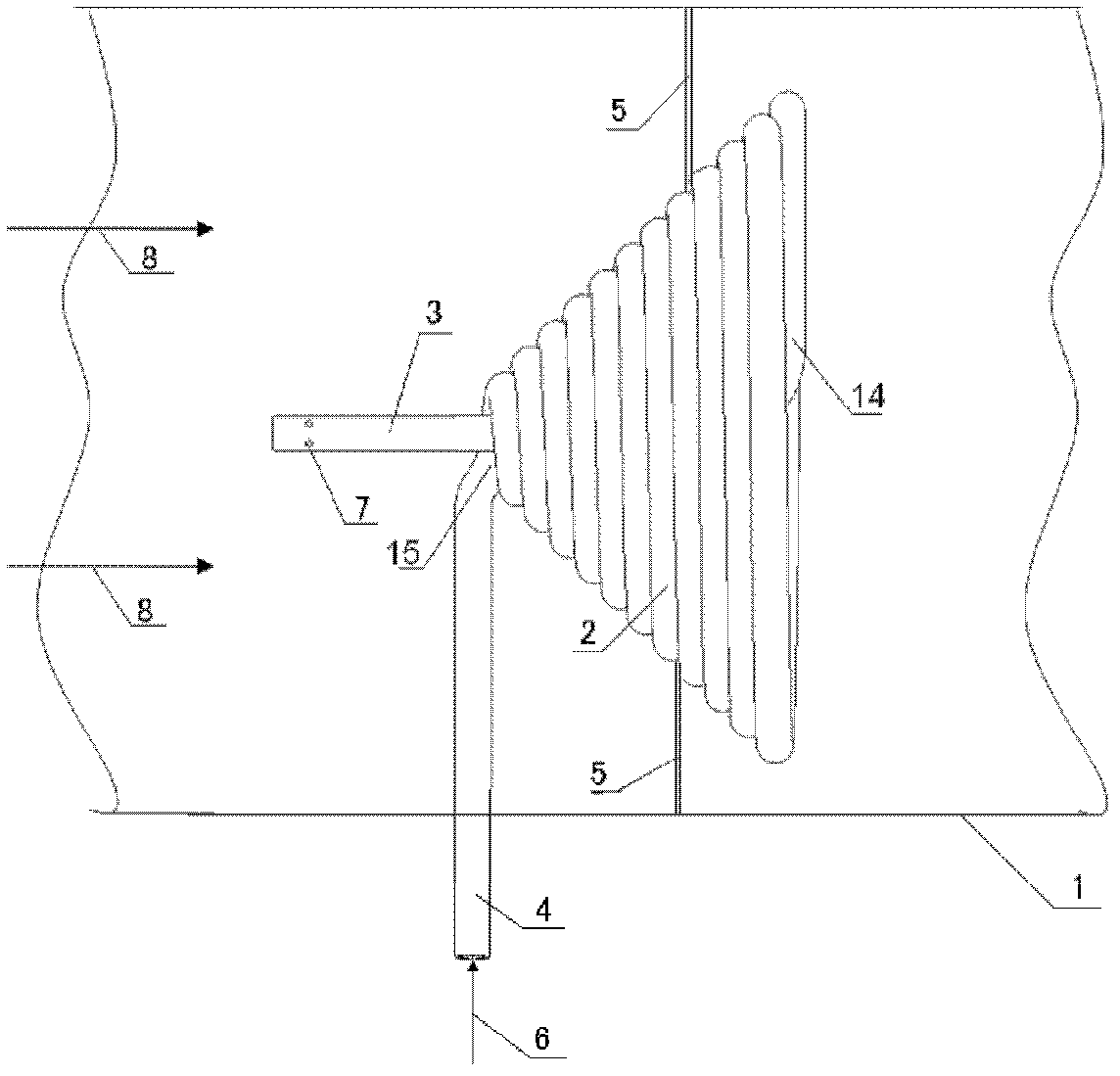

[0034] Embodiment 2: Combining image 3 and Figure 4 The difference from Embodiment 1 is that the outer ring port 14 of the preheating pipe is connected to the nozzle pipe 3 , and the inner ring port 15 is connected to the inlet pipe 4 .

Embodiment approach 3

[0035] Embodiment 3: On the basis of Embodiment 1 and Embodiment 2, after the closed end of the orifice pipe is arranged in the preheating pipe, the end face of the closed end faces or faces away from the inflow direction of the flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com