Cu/Mn-SSZ-39 catalyst, preparation method and application thereof

A -SSZ-39, catalyst technology, applied in the field of Cu/Mn-SSZ-39 catalyst and its preparation, can solve the problems of poor low temperature activity, narrow activity temperature window, etc., and achieves elimination of nitrogen oxides, wide activity temperature window, The effect of excellent SCR activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

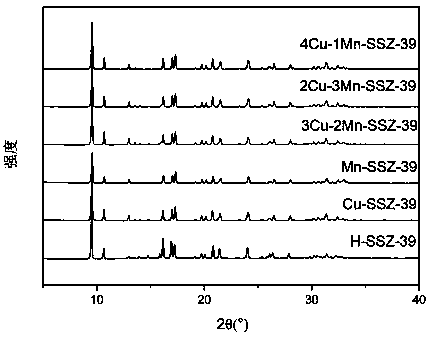

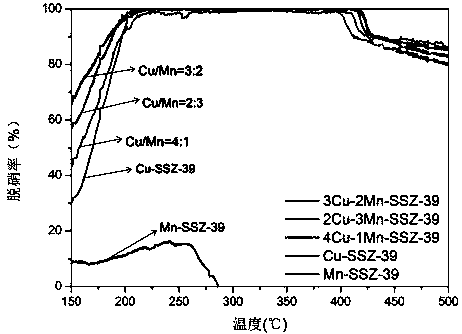

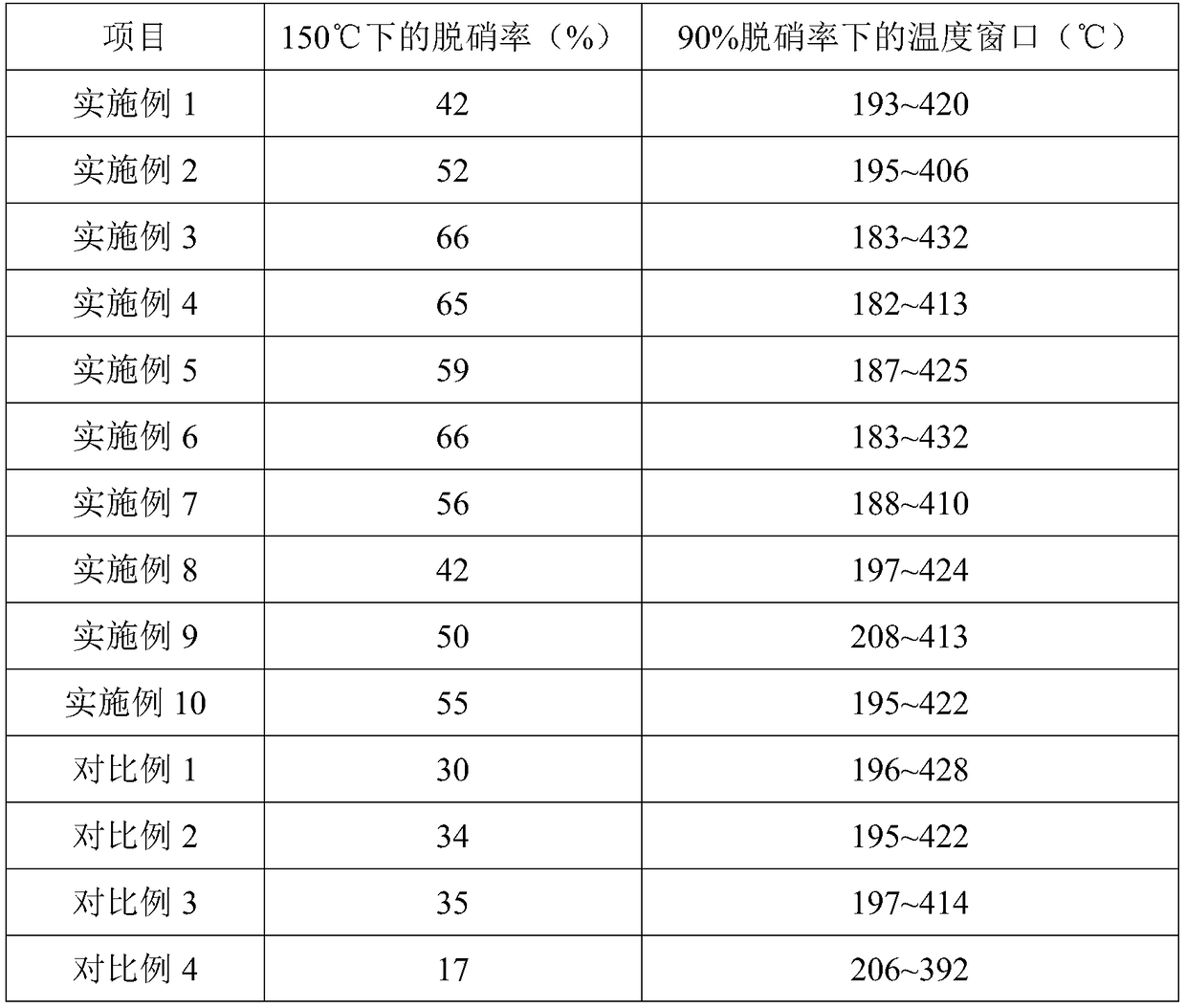

[0036] A Cu / Mn-SSZ-39 catalyst, the catalyst uses H-SSZ-39 molecular sieve as a carrier, the active components are copper and manganese, the loading of the copper is 0.5%, and the loading of the manganese is 0.1%.

Embodiment 2

[0038] A kind of Cu / Mn-SSZ-39 catalyst, described catalyst is carrier with H-SSZ-39 molecular sieve, and active component is copper element and manganese element, and the load capacity of described copper element is 2.3%, the load capacity of manganese element 0.7%.

Embodiment 3

[0040] A Cu / Mn-SSZ-39 catalyst, the catalyst is based on H-SSZ-39 molecular sieve, the active components are copper and manganese, the loading of copper is 1.5%, and the loading of manganese is 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com