An intelligent conveying device

An intelligent conveying and conveying device technology, applied in conveyor control devices, conveyors, mechanical conveyors, etc., can solve the problems of large area of conveying equipment, unstable material fixation, and uneven arrangement of materials, so as to meet the The effect of stable conveying process, convenient output and neat material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

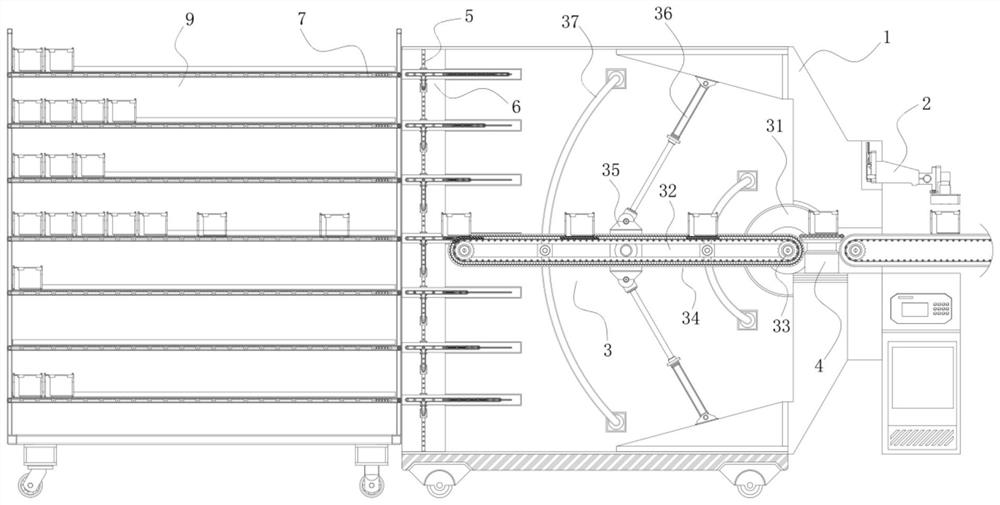

[0042] refer to Figure 1-3 , the present invention provides a technical solution: an intelligent conveying device, which includes:

[0043] Conveying box frame 1, its left side is equipped with front and back parallel dividing plate, is set as transmission chamber between described dividing plate, and longitudinal guide rail-5 is installed on described dividing plate by left side plate wall, and described conveying box A monitor 2 is installed on the right side of the frame 1 to monitor and classify the materials in the feeding device;

[0044] Conveying device one 3 is located in the conveying chamber, and is installed on the front and rear partitions, and directional conveys the materials monitored by the monitor 2;

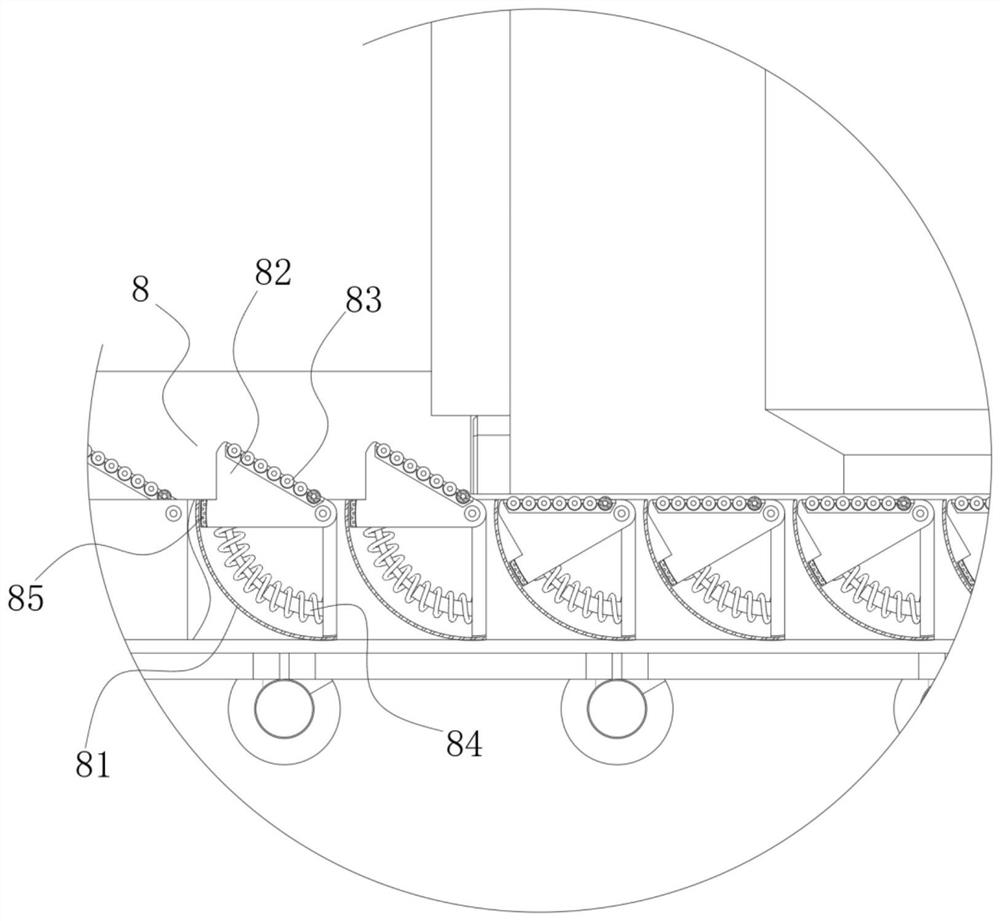

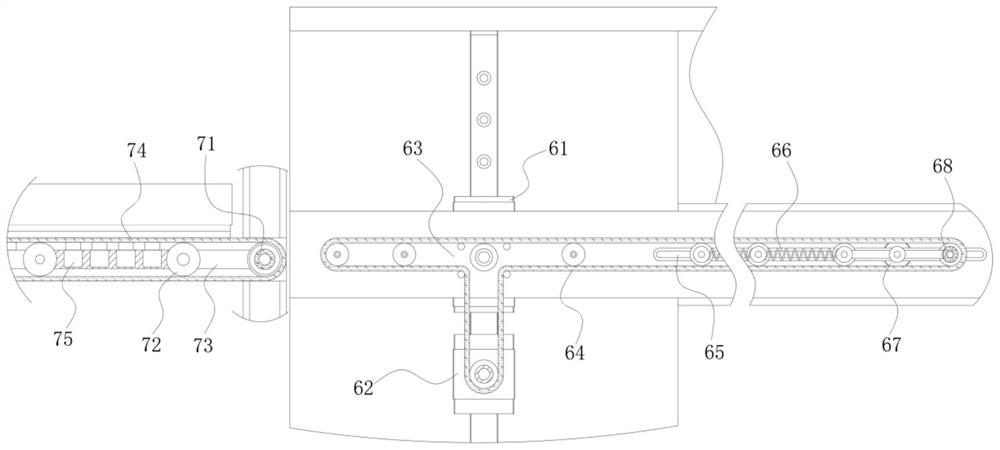

[0045] The conveying device two 6 is configured in multiple groups, installed on the guide rail one 5, and arranged correspondingly to the placement shelf in the display rack 9, and the corresponding conveying device three 7 is installed at the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com