Heat-resistant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and heat-resistant technology, which is applied in the field of heat-resistant thermoplastic elastomer and its preparation, and can solve problems such as difficulty in meeting usage requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

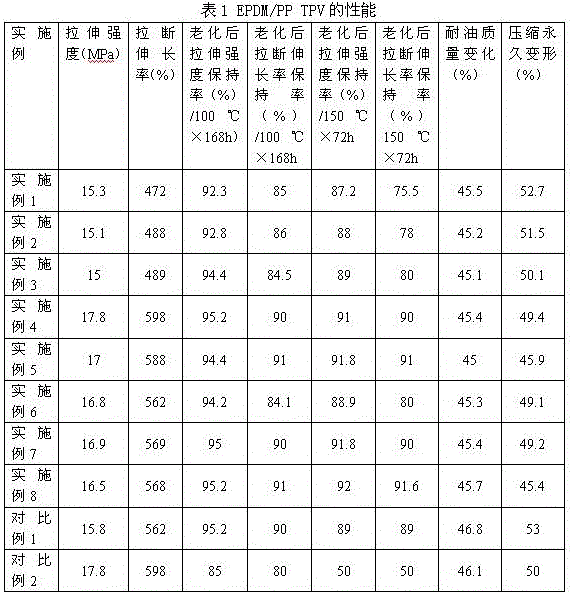

Examples

Embodiment 1

[0015] Embodiment 1 of the present invention: preparation of heat-resistant thermoplastic elastomer, calculated in parts by mass, including 300g of EPDM rubber, 700g of polypropylene, 20g of modified filler, 60g of paraffin oil, 48g of vulcanization system and antioxidant 10101g; the modified filler is modified calcium sulfate whisker, the average diameter of the modified calcium sulfate whisker is 1-10 μm, the average length is 20-200 μm, the average aspect ratio is 10-200, CaSO 4 content ≥ 98%; the composition of the vulcanization system includes 10g of stearic acid, 20g of zinc oxide, 9g of dicumyl peroxide and 9g of triallyl isocyanate.

[0016] The preparation method of the heat-resistant thermoplastic elastomer, according to the quality of the above components, the rubber and the paraffin oil are blended, the vulcanizing agent system is added, after the mixing is uniform, it is placed for 30 minutes, and then polypropylene, antioxidant and The modified filler is mixed ev...

Embodiment 2

[0018] Embodiment 2 of the present invention: preparation of heat-resistant thermoplastic elastomer, calculated in parts by mass, including EPDM rubber 400g, polypropylene 600g, modified filler 50g, paraffin oil 80g, vulcanization system 48g and antioxidant 10103g; the modified filler is modified calcium sulfate whisker, the average diameter of the modified calcium sulfate whisker is 1-10 μm, the average length is 20-200 μm, the average aspect ratio is 10-200, CaSO 4 content ≥ 98%; the composition of the vulcanization system includes 10g of stearic acid, 20g of zinc oxide, 9g of dicumyl peroxide and 9g of triallyl isocyanate.

[0019] The preparation method is the same as in Example 1, but the kneading temperature is 160° C., and the kneading time is 20 minutes.

Embodiment 3

[0020] Embodiment 3 of the present invention: preparation of heat-resistant thermoplastic elastomer, calculated in parts by mass, including EPDM rubber 500g, polypropylene 500g, modified filler 80g, paraffin oil 100g, vulcanization system 48g and antioxidant 10106g; the modified filler is modified calcium sulfate whisker, the average diameter of the modified calcium sulfate whisker is 1-10 μm, the average length is 20-200 μm, the average aspect ratio is 10-200, CaSO 4 content ≥ 98%; the composition of the vulcanization system includes 10g of stearic acid, 20g of zinc oxide, 9g of dicumyl peroxide and 9g of triallyl isocyanate.

[0021] The preparation method is the same as in Example 1, but the kneading temperature is 170° C., and the kneading time is 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com