Flame-retardant lyocell fiber and preparation method thereof

A fiber and raw material technology, applied in the field of flame retardant lyocell fiber and its preparation, can solve the problems of lyocell fiber being prone to combustion and the flame retardant performance needs to be improved, and achieves low volatility, improved flame retardant performance, dissolved simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A flame-retardant lyocell fiber, formed by mixing and spinning raw materials containing the following parts by weight: 60 parts of N-methylmorpholine oxide with a mass fraction of 50%; 40 parts of dimethylacetamide with a mass fraction of 50% 6.5 parts of bamboo pulp; 1.5 parts of starch; 1.5 parts of phosphoric acid; 1.5 parts of urea; 1.5 parts of melamine; 1.5 parts of polyphosphate amine;

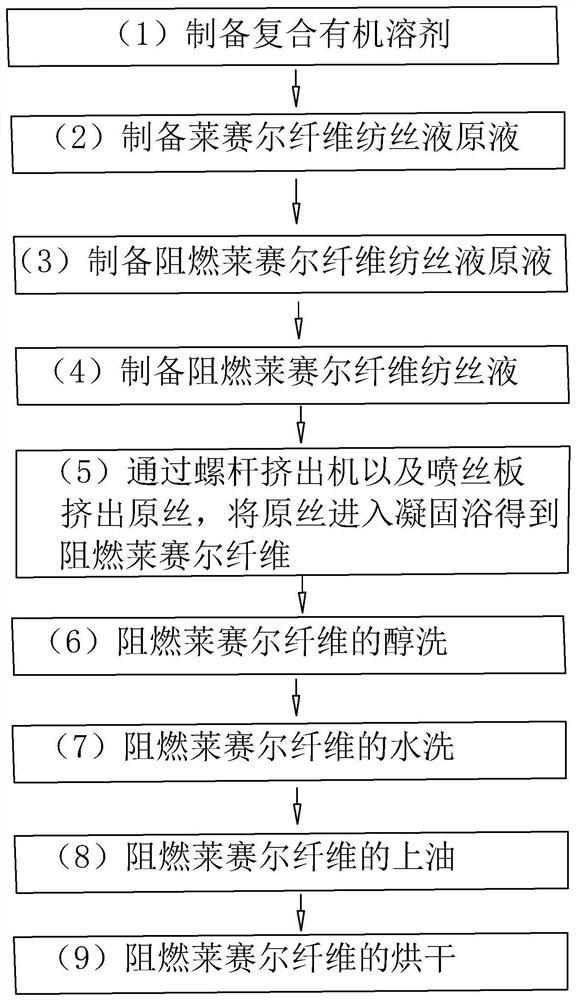

[0058] The manufacture method of flame-retardant lyocell fiber, comprises the following steps:

[0059] (1) the N-methylmorpholine oxide that is 50% by mass fraction and the dimethylacetamide that mass fraction is 50% are that 97KPa and mixing temperature are under the condition of 110 ℃ in absolute vacuum, with 600r / min Stirring speed and negative pressure for 3.5h to obtain a composite organic solvent;

[0060] (2) Add bamboo pulp to the composite organic solvent, and under the conditions of vacuum degree of 97KPa and mixing temperature of 110°C, stir at a stirring speed of 60...

Embodiment 2-5

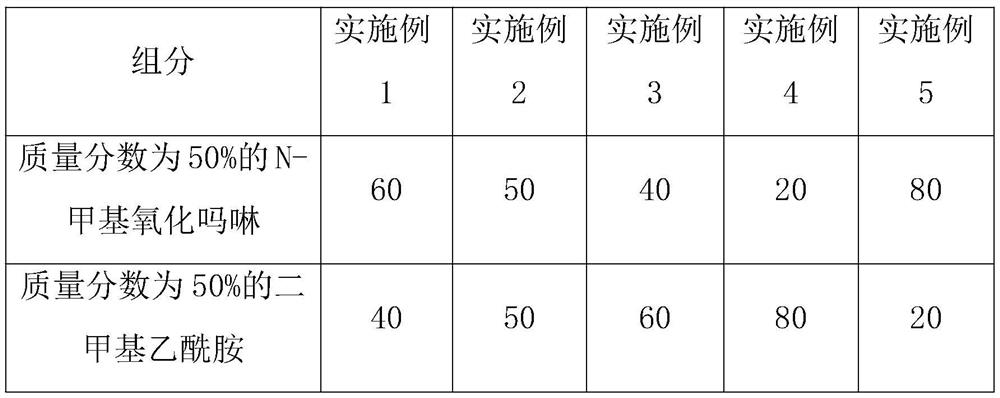

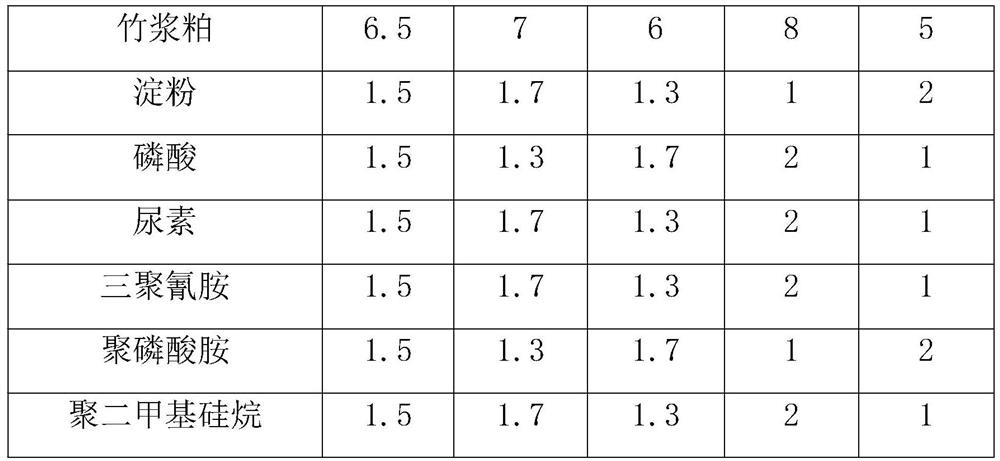

[0070] The difference from Example 1 is that the components of the raw materials and their corresponding parts by weight are different, as shown in Table 2.

[0071] Each raw material and parts by weight thereof in table 2 embodiment 1-5

[0072]

[0073]

Embodiment 6

[0074] Embodiment 6: The difference from Example 1 is that dimethylacetamide with a mass fraction of 50% is not included, and the weight of N-methylmorpholine oxide with a mass fraction of 50% is 100 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com