Anti-aging plastic purse net

An anti-aging and plastic technology, applied in the direction of organic chemistry, can solve the problems of plastic fences destroying economy, loss, and affecting the firmness of plastic fences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

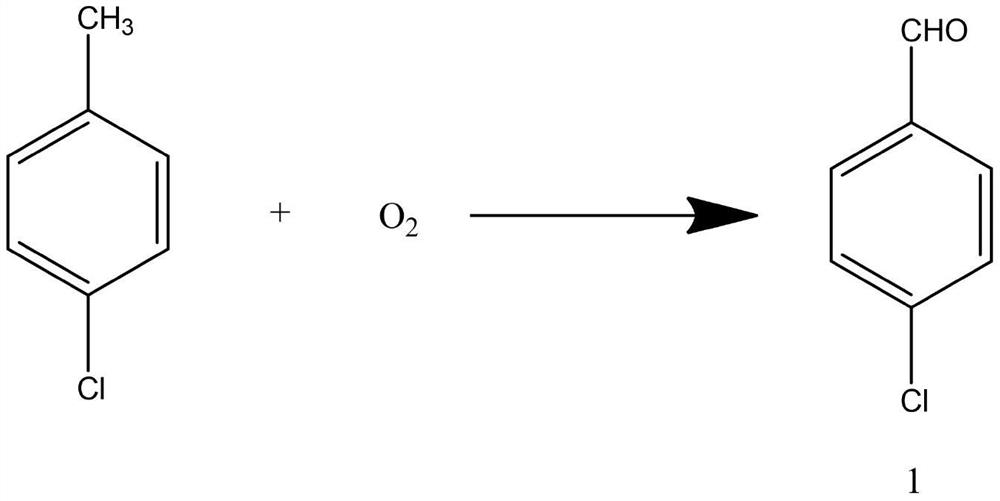

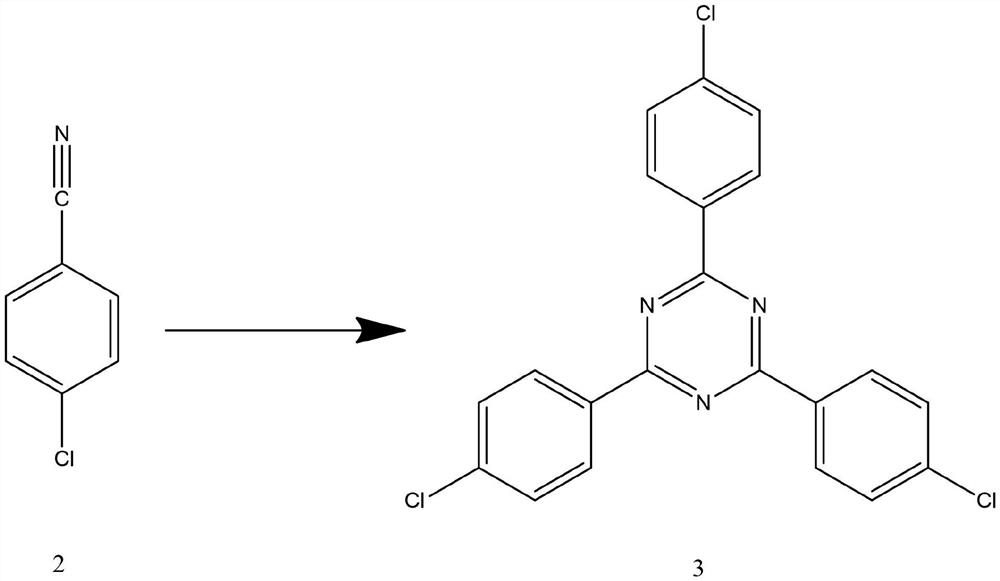

[0046] This embodiment is a preparation method of a high-temperature anti-aging additive, comprising the following steps:

[0047] A1: Add 40mL of acetic acid, 15mL of p-chlorotoluene, and 4.0g of a mixture of cobalt and manganese at a molar ratio of 4:1 to a three-necked flask equipped with a stirrer and an air duct, at a temperature of 90°C and a stirring rate of 200r / Under the condition of 30mL / min, feed oxygen at a rate of 30mL / min while stirring at a constant temperature and reacting with stirring at a constant temperature for 5 hours. After the reaction, it was cooled to room temperature, vacuum filtered, and the filtrate was adjusted to a pH of 1mol / L with sodium hydroxide solution. 8, then extracted twice with dichloromethane, combined the extracts, vacuum filtered, and dried the filtrate to obtain intermediate 1;

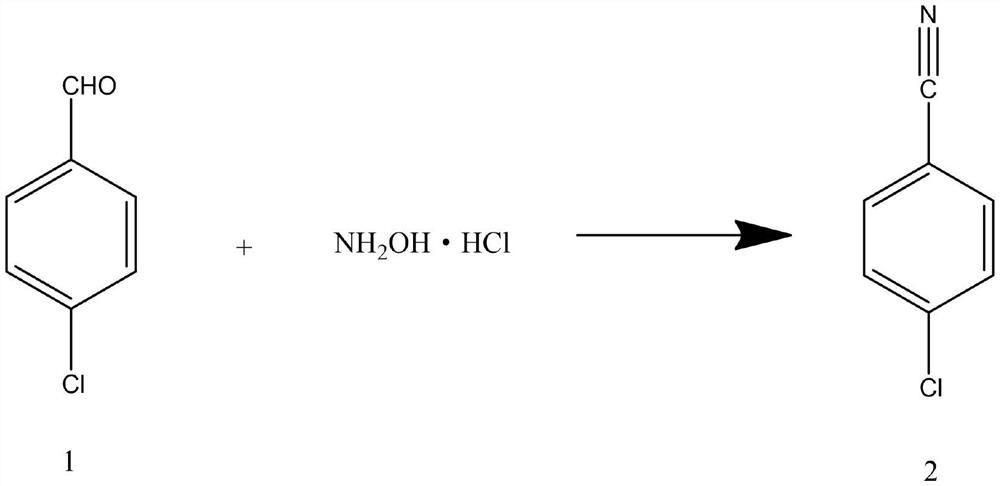

[0048] A2: Add 0.1mol of intermediate 1, 0.12mol of hydroxylamine hydrochloride, 8.12g of anhydrous ferric chloride and 100mL of N, N-dimethylformamide in...

Embodiment 2

[0055] This embodiment is a preparation method of a high-temperature anti-aging additive, comprising the following steps:

[0056] A1: Add 40mL of acetic acid, 15mL of p-chlorotoluene, and 4.0g of a mixture of cobalt and manganese at a molar ratio of 4:1 to a three-necked flask equipped with a stirrer and an air duct, at a temperature of 110°C and a stirring rate of 300r / Under the condition of 30mL / min, feed oxygen at a rate of 30mL / min while stirring and reacting at constant temperature for 6 hours. After the reaction, cool to room temperature, vacuum filter, and adjust the pH of the filtrate to 1mol / L sodium hydroxide solution. 9, and then extracted 3 times with dichloromethane, combined the extracts, vacuum filtered, and dried the filtrate to obtain intermediate 1;

[0057] A2: Add 0.1mol of intermediate 1, 0.12mol of hydroxylamine hydrochloride, 8.12g of anhydrous ferric chloride and 100mL of N, N-dimethylformamide into a three-necked flask equipped with a stirrer and a r...

Embodiment 3

[0064] This embodiment is an anti-aging plastic fence, including the following components in parts by weight:

[0065] 100 parts of polyvinyl chloride, 30 parts of nylon, 10 parts of polyisoprene rubber, 5 parts of nano-titanium dioxide, 0.5 part of chlorinated paraffin and 5 parts of high temperature and anti-aging additives from Example 1;

[0066] The anti-aging plastic fence is prepared by the following steps:

[0067] Step 1: Mix polyvinyl chloride, nylon, polyisoprene rubber, nano-titanium dioxide, chlorinated paraffin and high temperature and anti-aging additives evenly to obtain a mixture;

[0068] Step 2: Add the mixture into the extruder to melt and extrude to obtain an anti-aging mesh rope;

[0069] Step 3: Weaving and forming the anti-aging net rope to obtain the anti-aging plastic fence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com