Flame-retardant master batch, preparation method and application thereof

A technology of flame retardant masterbatch and synergistic flame retardant, which is applied in the field of flame retardant masterbatch and its preparation, and can solve the problems of unsatisfactory flame retardant effect and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a preparation method of the flame retardant masterbatch described in the above technical solution, comprising the following steps:

[0063] (1) mixing carrier resin, diphenylphosphine oxide derivatives, antioxidant and synergistic flame retardant to obtain a mixture;

[0064] (2) Granulating the mixture obtained in the step (1) to obtain flame retardant masterbatches.

[0065] The invention mixes carrier resin, diphenylphosphine oxide derivative, antioxidant and synergistic flame retardant to obtain a mixture. In the present invention, there is no special regulation on the mixing operation, as long as the obtained dry raw materials are uniformly mixed.

[0066] In the present invention, the carrier resin, the diphenylphosphine oxide derivative, the antioxidant and the synergistic flame retardant are preferably mixed before the carrier resin, the diphenylphosphine oxide derivative, the antioxidant and the synergistic flame retardant ...

Embodiment 1

[0086] Preparation of compound 1,2-bis(diphenylphosphinoxy)ethane (EDPO) with structure II

[0087]

[0088] Put 200ml of toluene into a single-necked flask with a stirrer, first add 22.6g of diphenylphosphine oxide DPO, then add 15g of NaOH dissolved in aqueous solution, then add 5.5g of dichloroethane, and react at 20°C for 2h, After the reaction is completed, filter with suction, wash with water, and dry at last. Finally, 17.508g of product EDPO was obtained, the yield reached 81.3%, and the phosphorus content was 14.2%.

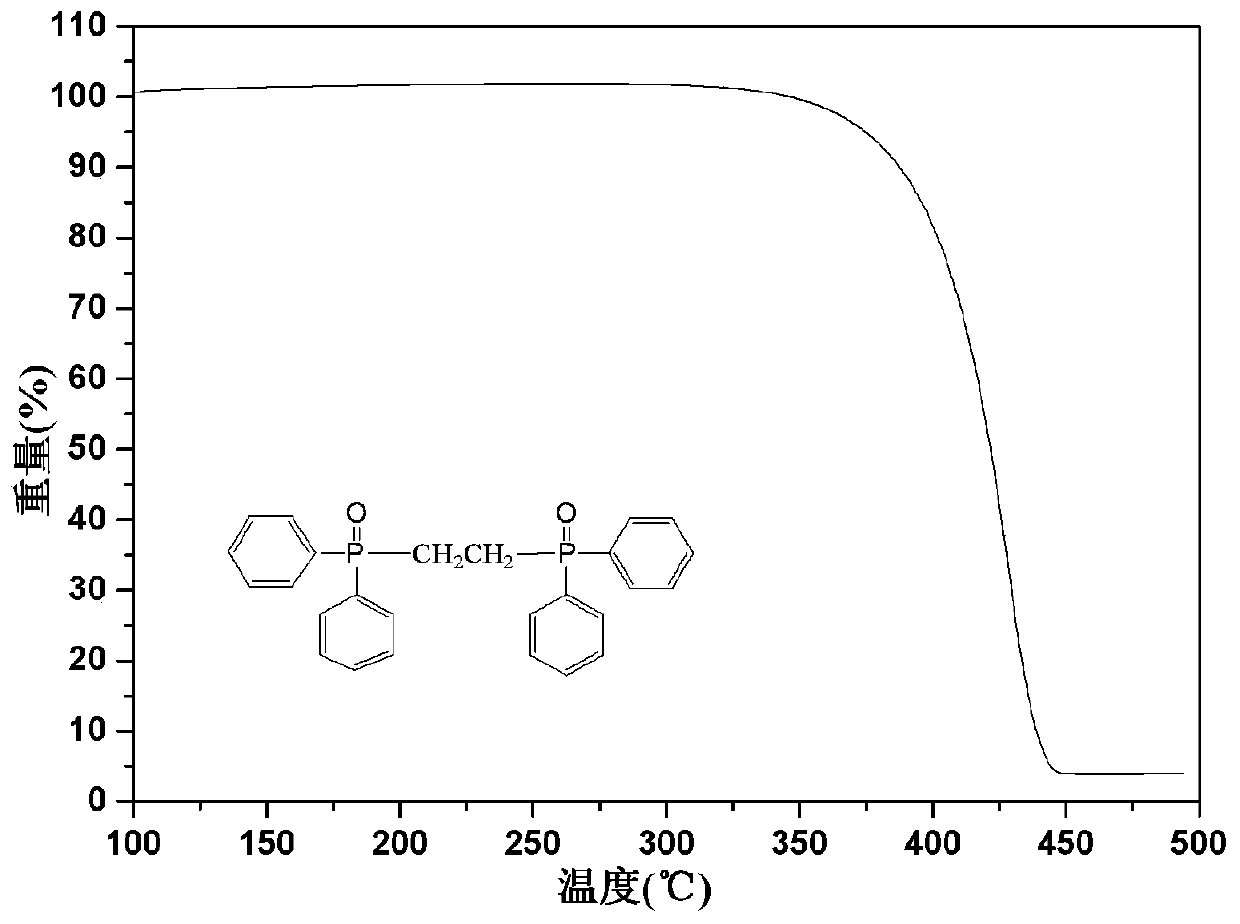

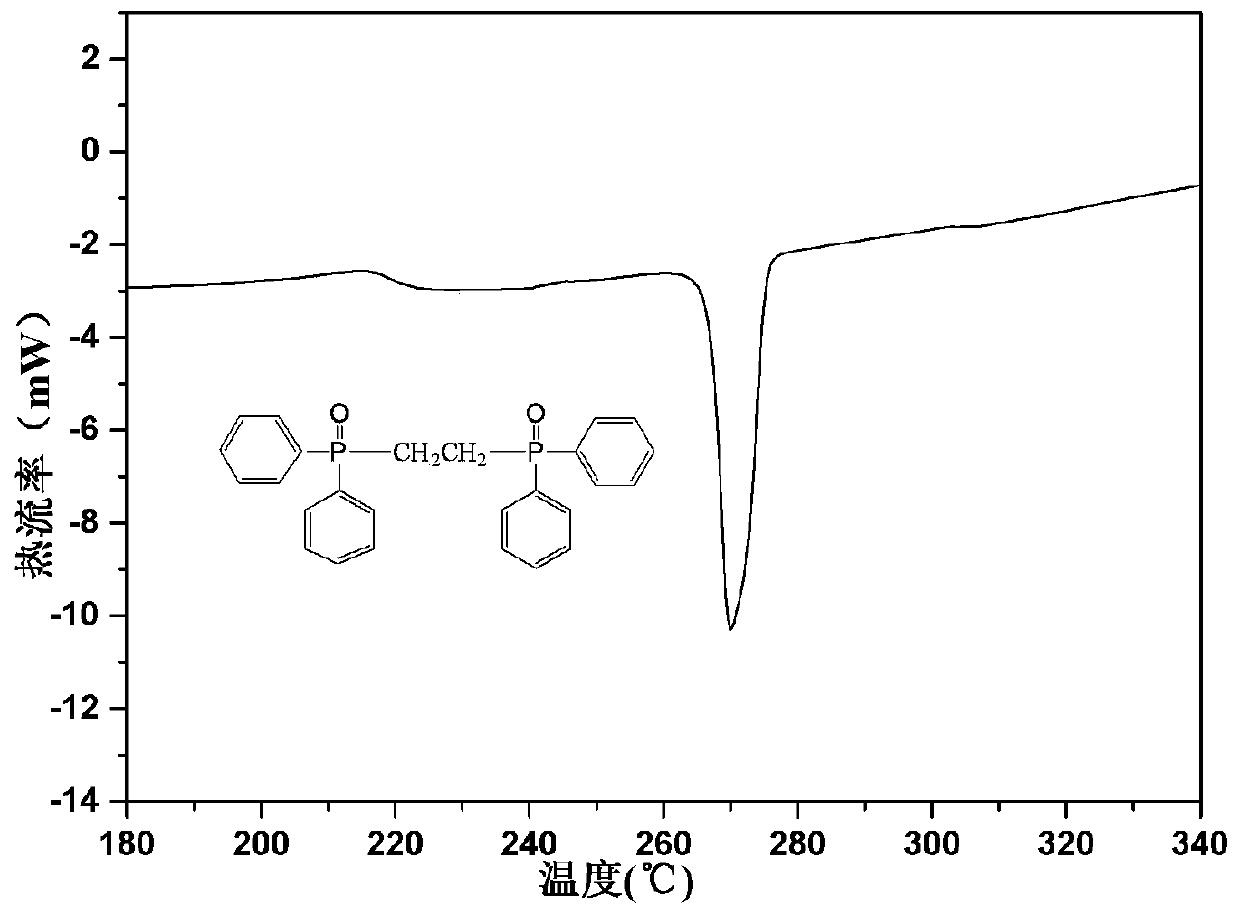

[0089] The TGA test result of the prepared compound EDPO with formula II is shown in figure 1 , its weight loss is 5% at 372.2°C, it has high thermal stability, and the final carbon residue is 3.97%; its DSC melting point test see figure 2 , and its melting point is 272°C.

[0090] Preparation of flame retardant masterbatch FRM-1

[0091] Use blast oven to dry EDPO, PET, antioxidant (1010 and S9228) at 150 ℃ for 3.5h to fully dry, the raw material...

Embodiment 2

[0093] Preparation of compound 1,4-bis(diphenylphosphinoxy)butane (BDPO) with structure III

[0094]

[0095] Put 800ml of toluene into a single-necked flask with a stirrer, first add 118g of diphenylphosphine oxy DPO, then add 70g of NaOH dissolved in aqueous solution, add 35.5g of dichlorobutane, and react for 2 hours at a temperature of 20°C. After the reaction is completed, filter with suction, wash with water, and finally dry to obtain the product BDPO115..8g with a yield of 91% and a phosphorus content of 13.5%.

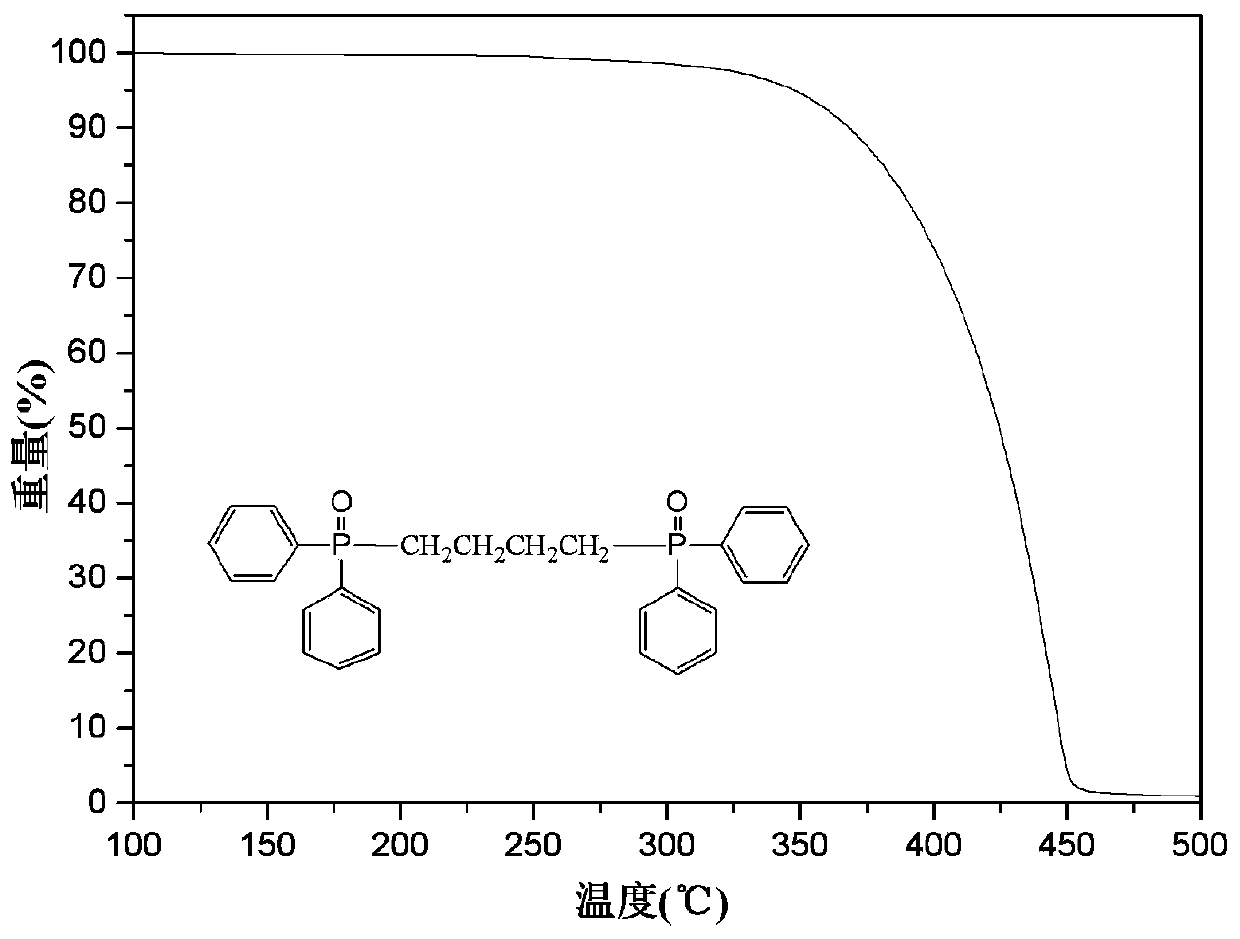

[0096] The TGA test result of the prepared compound BDPO with formula III structure is shown in image 3 , its weight loss is 5% at 347 ° C, it has high thermal stability, and the final carbon residue is 1.2%; its DSC melting point test see Figure 4 , and its melting point is 263°C.

[0097] Preparation of flame retardant masterbatch FRM-2

[0098] BDPO, PET and antioxidant (1010 and S9228) were fully dried at 120°C for 3.5 hours in a blast oven, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com