Rear floor structure for a motor vehicle

A technology of bottom structure and automobile, applied in the directions of substructure, superstructure, superstructure sub-assembly, etc., can solve the problems affecting the durability and limitation of longitudinal force of longitudinal beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

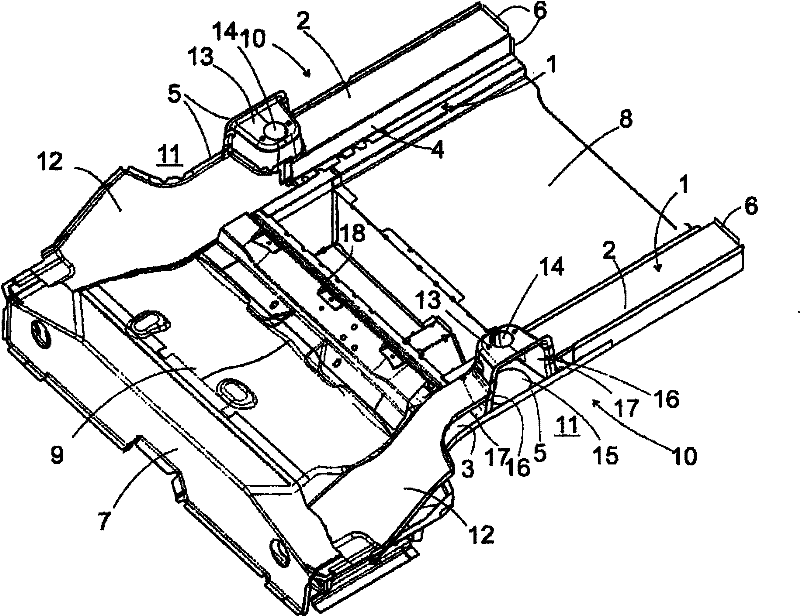

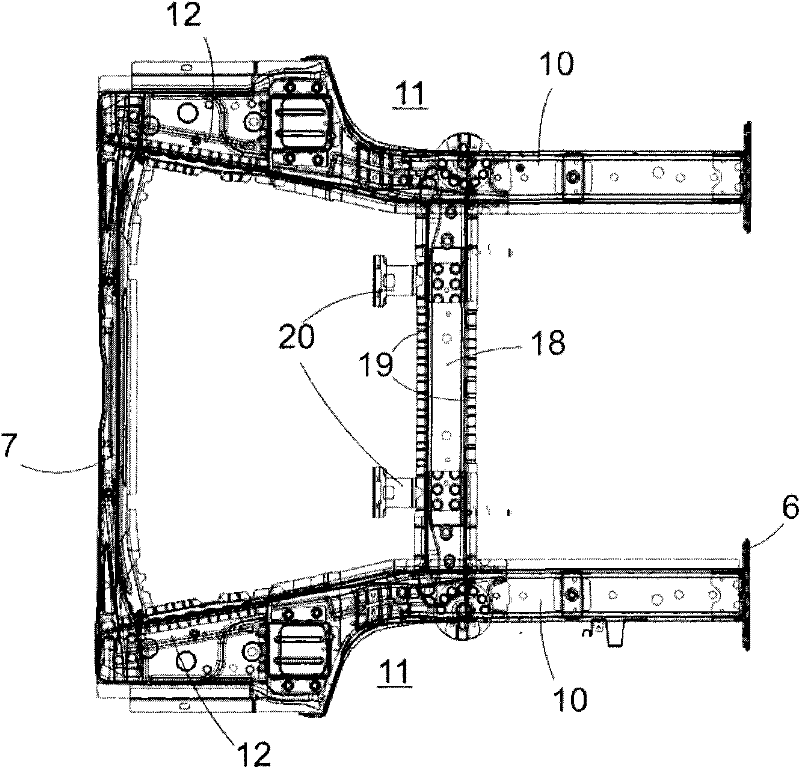

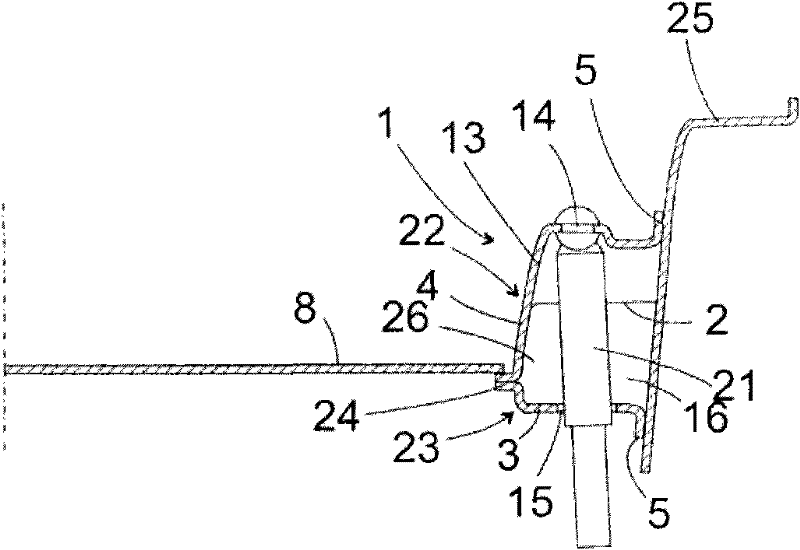

[0021] figure 1 A rear underbody structure for a motor vehicle is shown in perspective view. The side walls of the floor structure are formed by two longitudinal beams 1 . The two side members 1 are profiles with a hat-shaped cross-section that are each open towards the outside of the vehicle. image 3 As can be better seen in , the profile has a substantially horizontal upper wall 2, a lower wall 3, a side wall 4 connecting the walls 2, 3 and a flange forming a hat-shaped cross-section, like the side wall 4 A substantially vertical connecting piece 5 . figure 1 The side members 1 shown each have at their rear ends a flange 6 for fastening a bumper cross member (not shown). The cross member 7 connecting the front ends of the side members 1 to each other is located below the front edge of the rear seat cushions when the vehicle is installed and forms the rear wall of the footwell of the passengers in the rear seat. The rear floor 8 , the pan 35 and the front floor 9 fill th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com