Magnetic core for antenna, method for producing magnetic core for antenna, and antenna

A magnetic core and antenna technology, applied in the field of magnetic cores for antennas, manufacturing magnetic cores for antennas and antennas, can solve the problems of fragility, property degradation, cracks and other problems of ferrite, and achieve less brittleness and small curvature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

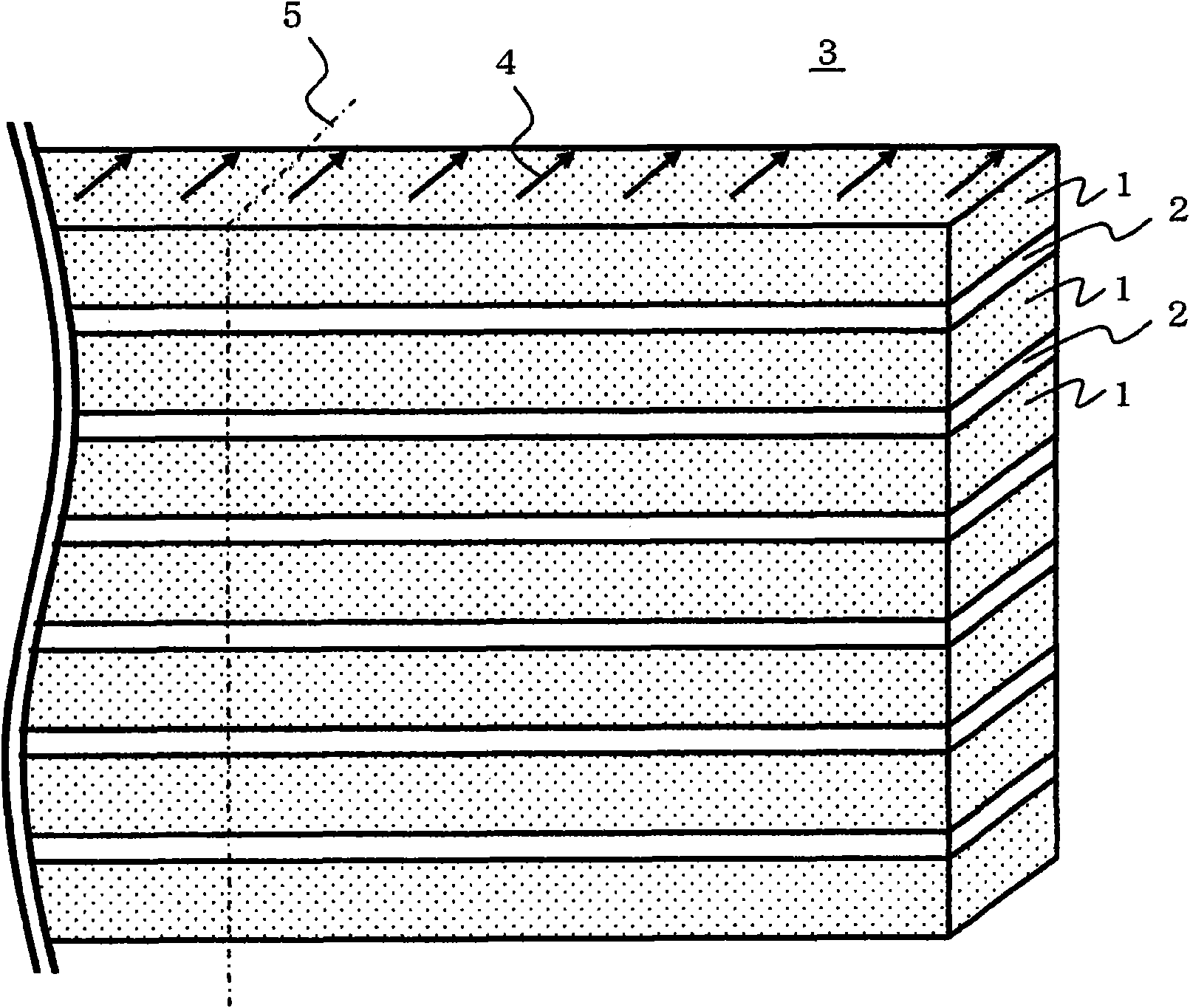

[0065] In the following, reference will be made to figure 1 , 2A and 2B describe a method of manufacturing a magnetic core for an antenna according to the present invention.

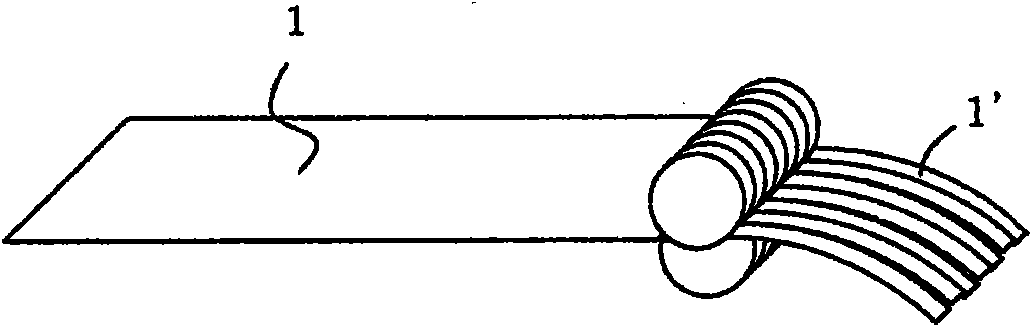

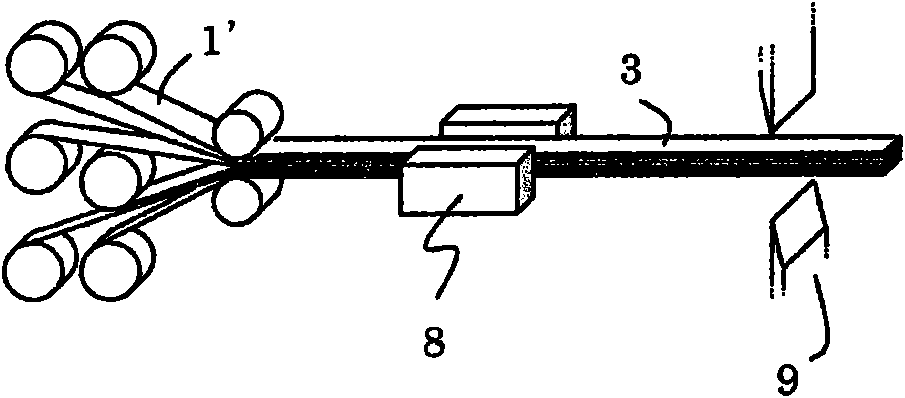

[0066] figure 1 A stack 3 obtained by heat-treating thin metal strips 1 in a magnetic field and stacking thin metal strips 1 through an insulating layer 2 is shown. figure 1 The longitudinal (transverse) direction in is the longitudinal direction of a thin strip obtained by slitting a thin metal strip produced with a hyperquenching roll. A magnetic field is applied in a direction perpendicular to the longitudinal direction, reference numeral 4 designating the direction of the induced magnetic anisotropy. At the time of stacking, for example, thin metal strips 1 are coated with a polyamic acid solution as a precursor of polyimide resin, and pressure-bonded by roll pressing. Thus, the stacking process can be performed in a Roll-to-Roll process, so continuous manufacturing is possible. The laminate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com