Manufacturing method of electrolytic manganese metal alloy lead-plastic composite anode

A technology for electrolysis of metal manganese and composite anodes, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve problems such as damage to the service life of lead alloy anodes, and achieve the effect of preventing corrosion and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

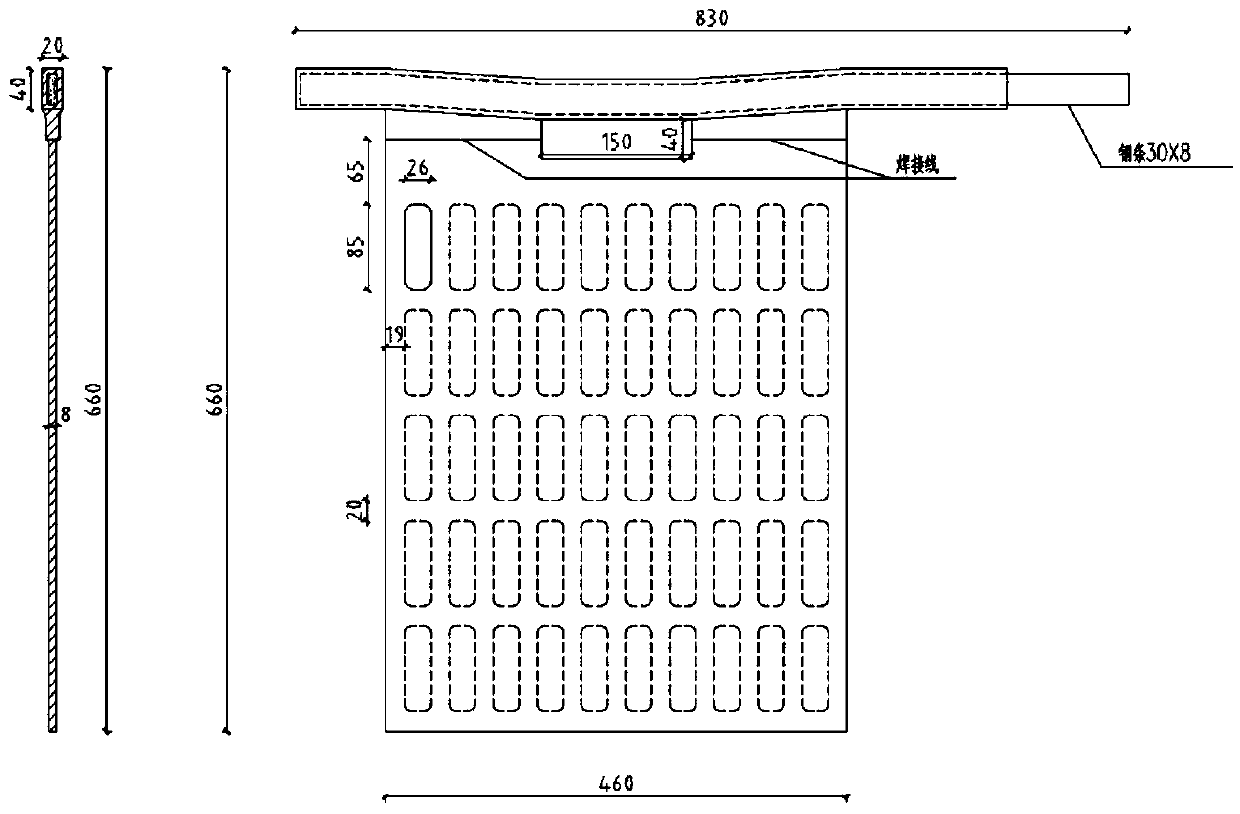

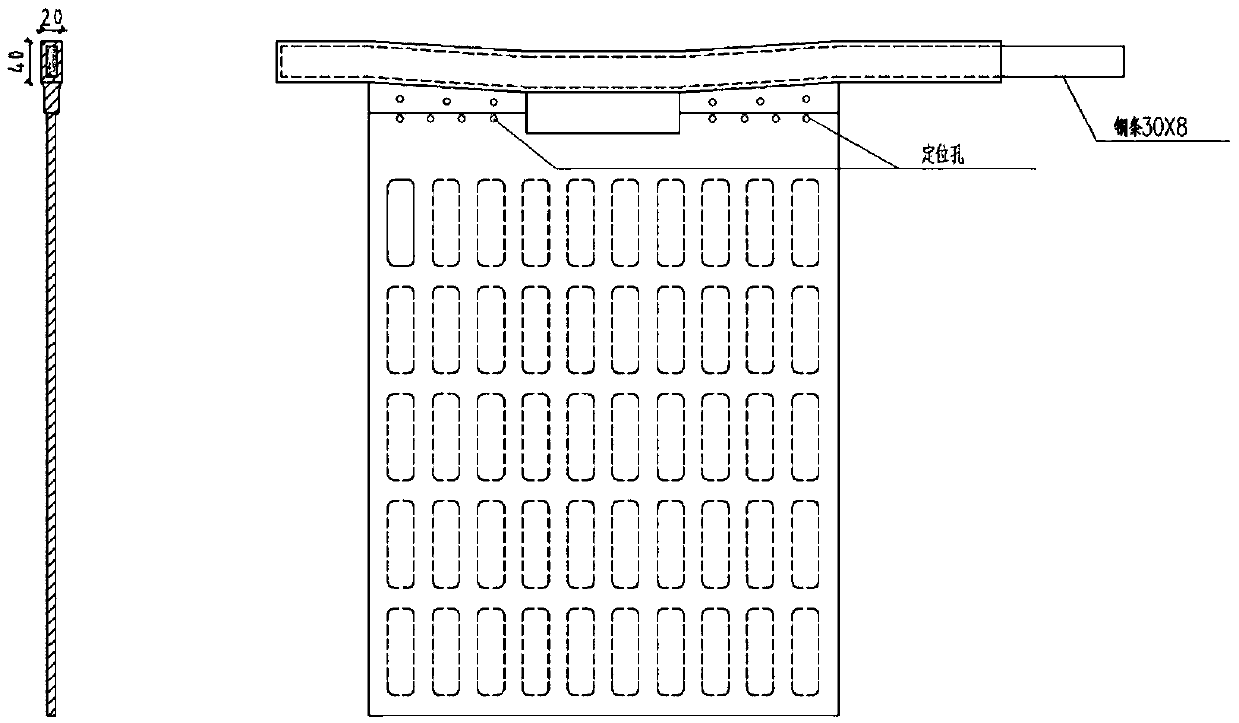

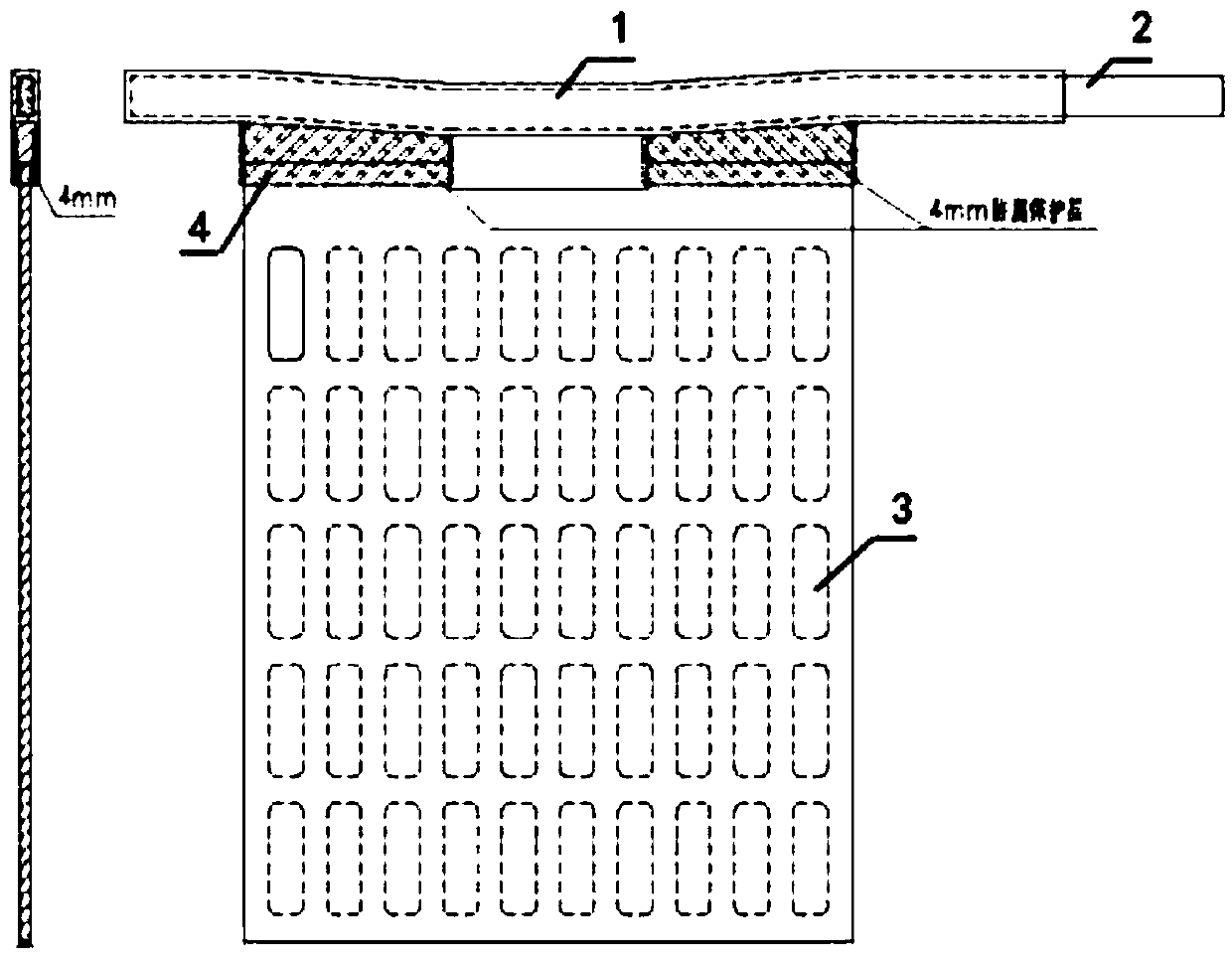

[0032] Such as figure 1 As shown, the present invention provides a method for manufacturing an electrolytic metal-manganese alloy lead-plastic composite anode. The alloy lead-plastic composite anode includes a conductive rod 1, a copper strip 2 in the built-in conductive rod 1 and a lower insert 3, And the anti-corrosion protection layer 4 of three interface wrappings.

[0033] Scheme 1: The materials used to make the insert 3 include the following components (by weight): silver Ag (0.6‰), antimony Sb (1‰), tin Sn (1%), arsenic As (3‰), calcium Ca (1‰), strontium Sr (1‰), and the rest are lead Pb. In terms of processing technology, the change from "casting→rolling→knurling" to "casting→high-pressure rolling→knurling→injection molding" not only increases the density of the anode plate through high-pressure rolling, but also improves the conductivity and reduces the Intergranular corrosion.

[0034] Scheme 2: The materials used to make insert 3 include the following component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com