Patents

Literature

37results about How to "Barrier corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

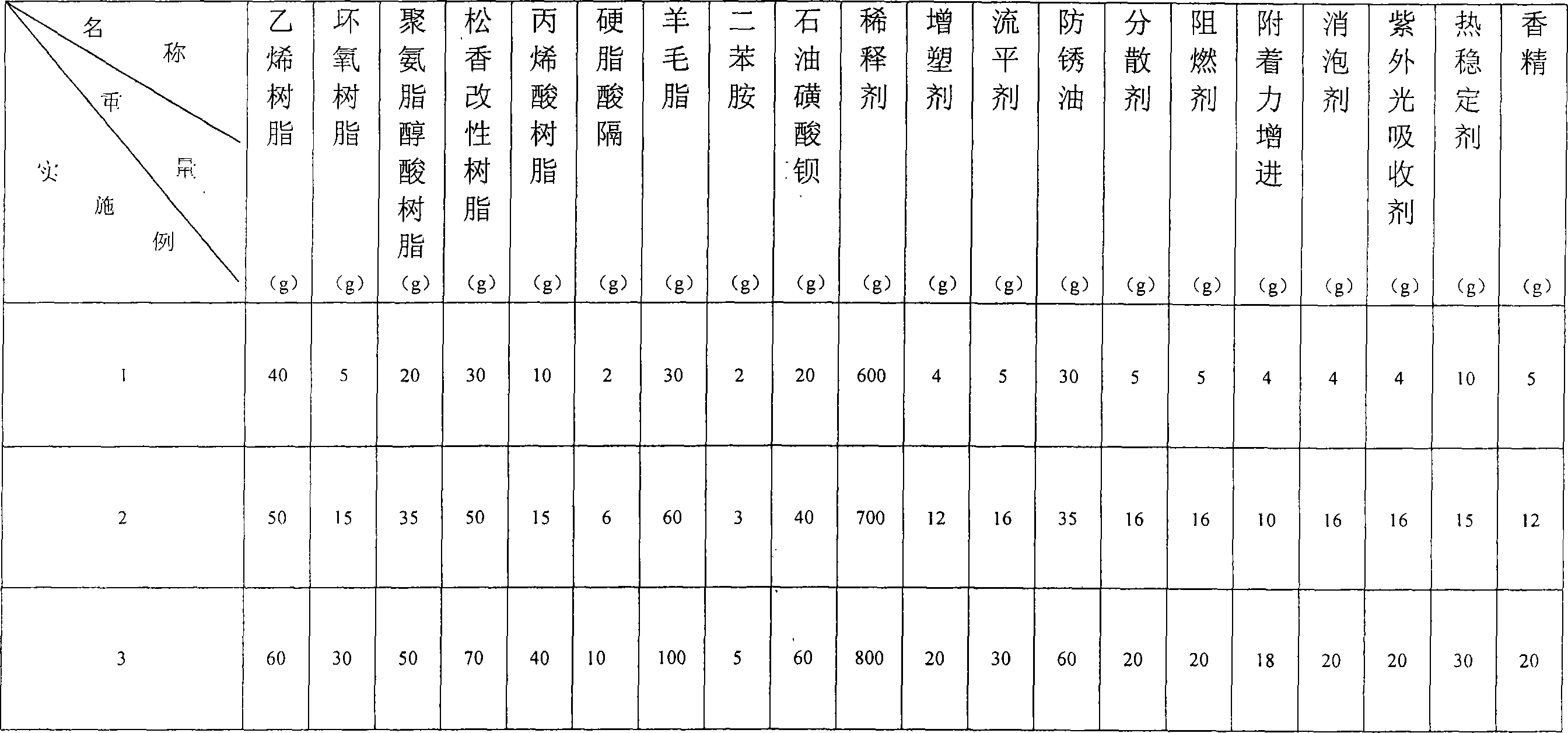

Coating material for high anticorrosive pack, and preparation method

InactiveCN101050329AExcellent physical and chemical propertiesGood chemical resistanceRosin coatingsAnti-corrosive paintsEpoxySolvent

This invention discloses a high-strength antirust packaging paint, which is composed of: ethylene resin, epoxy resin, polyurethane alkyd resin, rosin-modified resin, acrylate resin, cadmium stearate, lanoline, diphenyl amine, barium petroleum sulfonate, essence, antirust oil, plasticizer, heat stabilizer, antirust agent, diluting agent, adhesion promoter, leveling agent, UV absorbent, dispersant, defoamer and flame retardant. The packaging paint can be directly sprayed, soak-coated or brush-coated onto objects with any shape or appearance. A bright and smooth protective film is formed several minutes later. The protective film has high antirust performance, and can be stripped off for recycling.

Owner:郑州博庆环保科技有限公司 +2

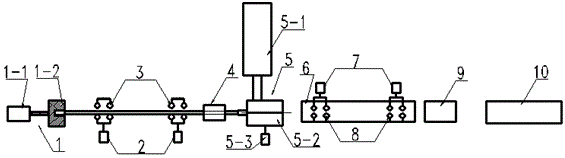

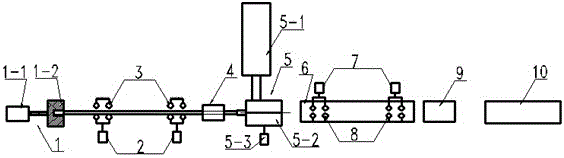

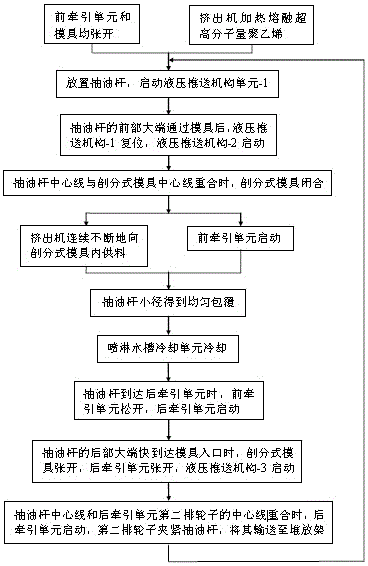

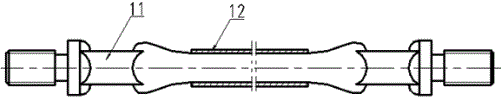

Production equipment of sucker rod continuously coated with ultrahigh molecular weight polyethylene

Owner:BEIJING UNIV OF CHEM TECH

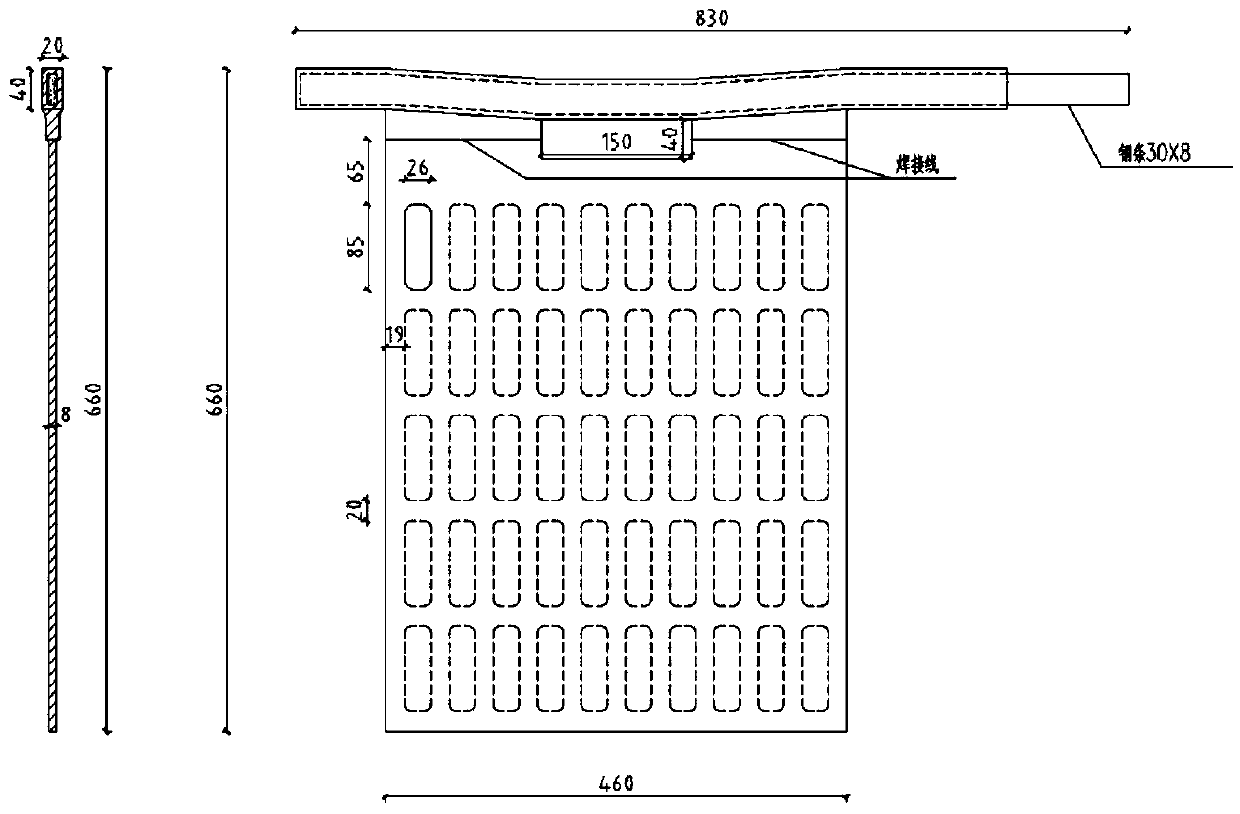

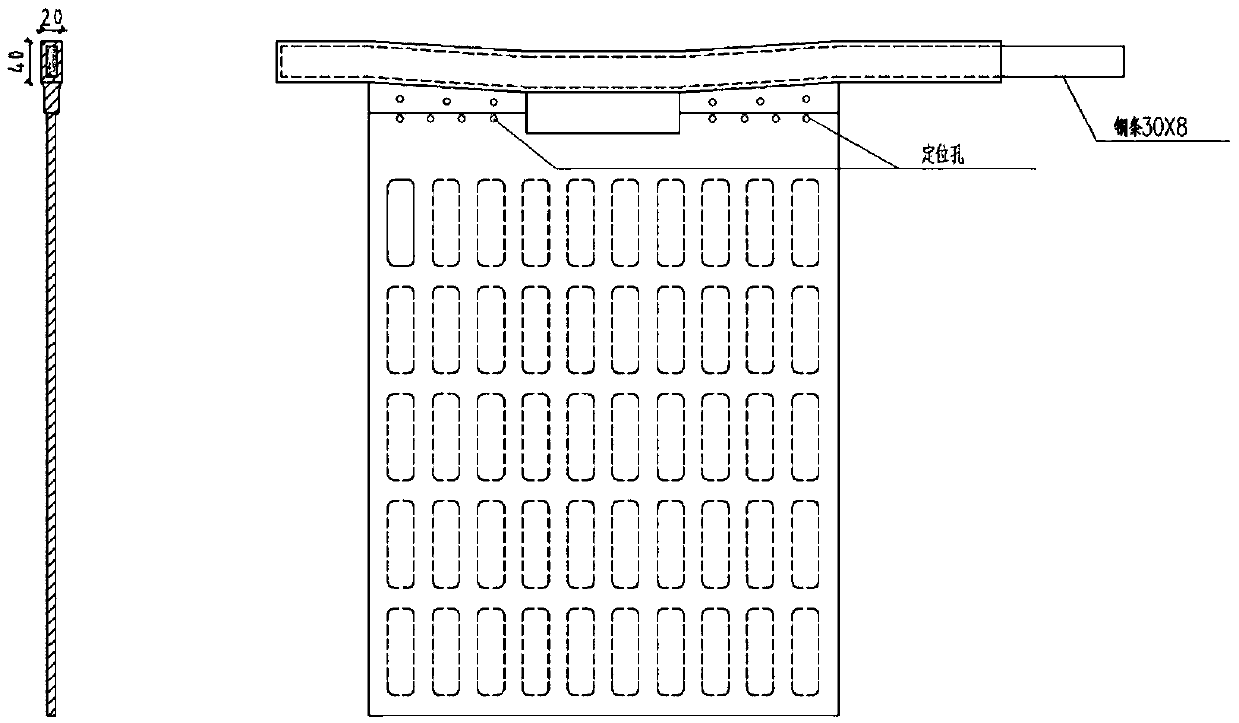

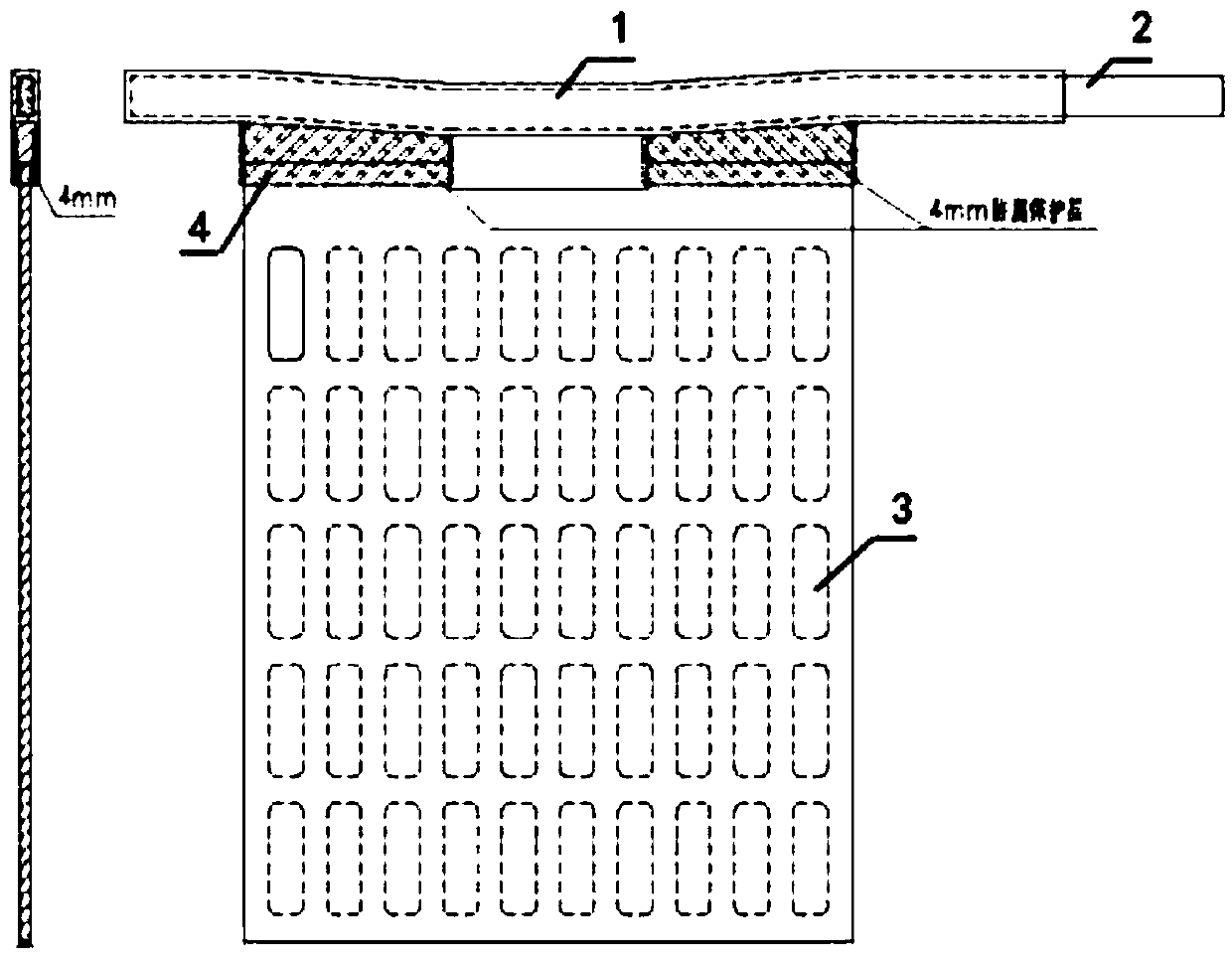

Manufacturing method of electrolytic manganese metal alloy lead-plastic composite anode

InactiveCN103695960AStop breakingBreakage, resulting in product damage preventingPhotography auxillary processesElectrodesElectrolysisManganese

The invention provides a manufacturing method of an electrolytic manganese metal alloy lead-plastic composite anode. The alloy lead-plastic composite anode comprises a conductive rod, a copper bar embedded inside the conductive rod and a male tab at the lower part, wherein the materials for fabricating the male tab comprise the following ingredients (by weight ratio): 0.06-0.10% of silver Ag, 0.1-0.4% of stibium Sb, 1-3% of stannum Sn, 0.3-0.6% of arsenic As, 0.1-0.3% of calcium Ca, 0.1-0.3% of strontium Sr and the balance of lead Pb. By adopting the method, an anode product is mainly prepared by optimizing an alloy element formula, and then a layer of tightly wrapped anti-corrosive protecting coating is formed on the three-item interface (the three-item interface refers to a juncture interface of an electrolyte surface, air and an anode plate) in an injection molding manner. Thus, corrosion to the lead alloy caused by chlorine and fluorine in the electrolyte at the three-item interface can be avoided.

Owner:申中军

Fluorine nanometer composite modified anticorrosion paint

InactiveCN106398499AImprove compactnessImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolymer science

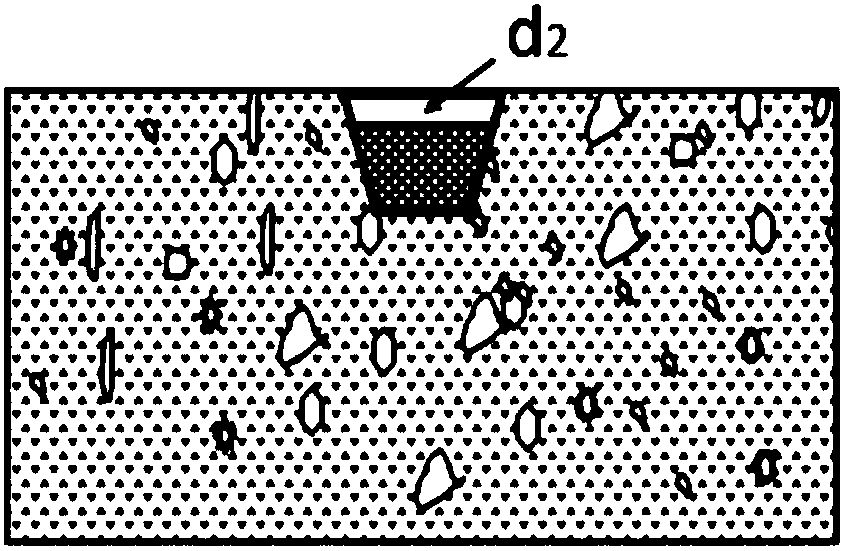

The invention relates to a fluorine nanometer composite modified anticorrosion paint, comprising 32 to 55 parts of waterborne polyurethane emulsion, 28 to 43 parts of epoxy resin, 8 to 15 parts of modified nanometer titanium dioxide, 11 to 19 parts of fluorine polymer, 7 to 14 parts of pigment, 0.3 to 0.8 part of a catalyst triethylamine and 12 to 17 parts of an auxiliary agent. A preparation method for the paint comprises the following steps: step 1, preparing modified nanometer titanium dioxide; step 2, preparation of a fluorine polymer; and step 3, compounding of the anticorrosion paint. According to the invention, the volume-filling density of a carrier is improved through nanometer titanium dioxide, so capillary action is reduced and shielding density is greatly improved; a film structure can be filled with tiny particles of a nano-material, so the density of a film is enhanced, permeability of the film is reduced, and corrosion of water, oxygen and the like to a metal substrate is efficiently blocked; thus, the anticorrosion performance of the paint is improved.

Owner:中国人民解放军空军勤务学院

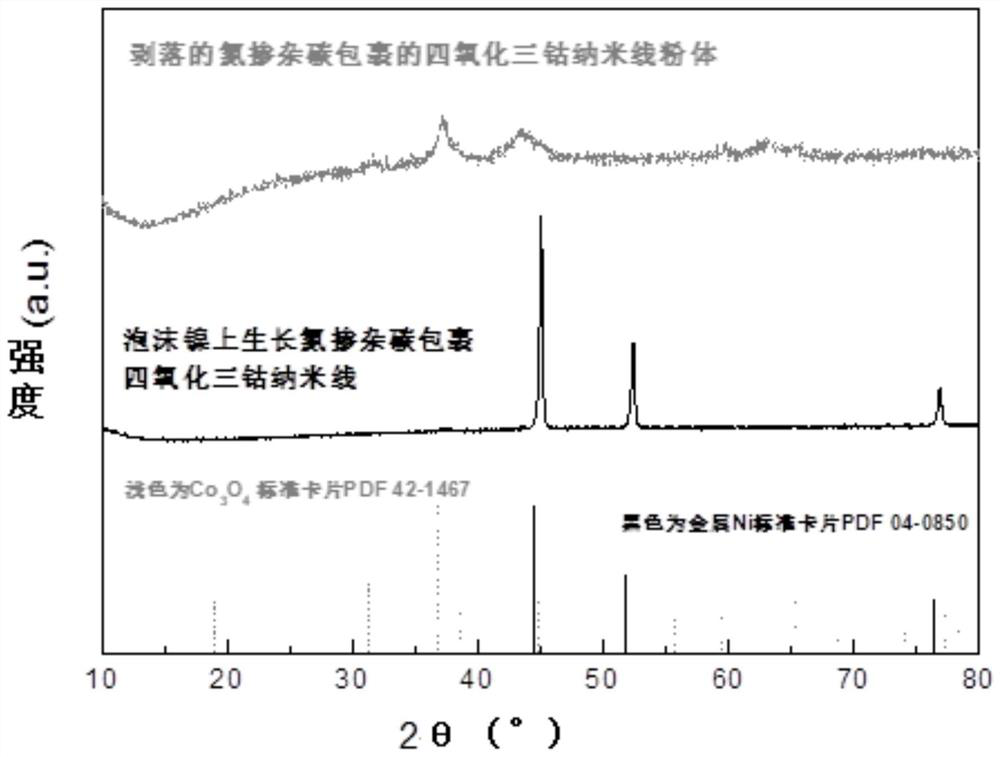

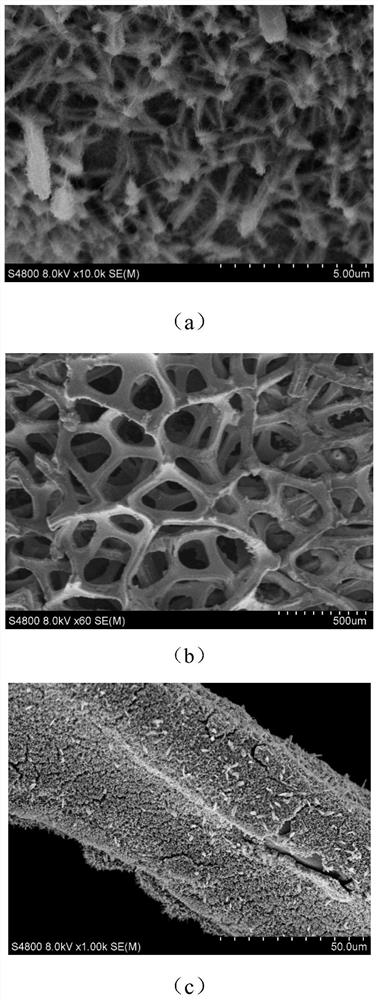

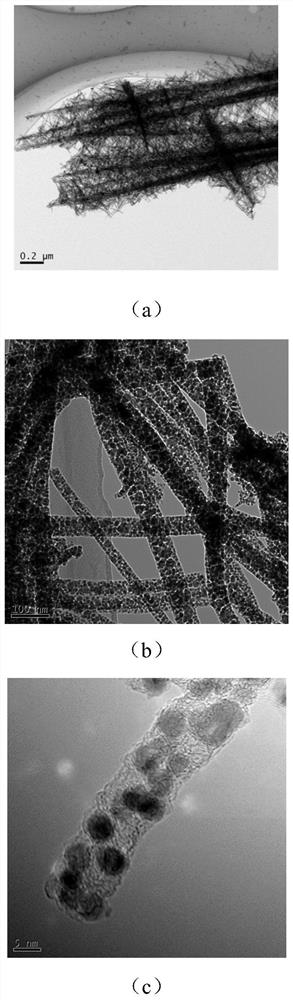

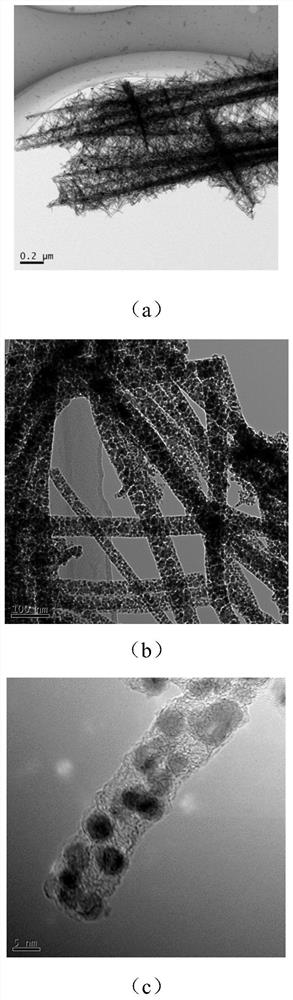

Method for preparing 2, 5-furandicarboxylic acid by electro-catalyzing oxidation of 5-hydroxymethylfurfural and simultaneously electrolyzing water to prepare hydrogen

ActiveCN112538636AImprove toleranceHigh activityCellsPhysical/chemical process catalystsFuranPtru catalyst

The invention discloses a method for preparing 2, 5-furandicarboxylic acid by electro-catalyzing oxidation of 5-hydroxymethylfurfural. An electrolytic tank is adopted for catalytic oxidation; the electrolytic tank is a three-electrode electrolytic tank or a two-electrode electrolytic tank; the adopted anode is an integral electrode; the monolithic electrode comprises a carrier and a catalytic active substance loaded on the carrier; and the catalytic active substance comprises nitrogen-doped carbon nanowires wrapping cobaltosic oxide particles. The method is high in activity and selectivity, and the anode catalyst is high in tolerance to 5-hydroxymethylfurfural.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

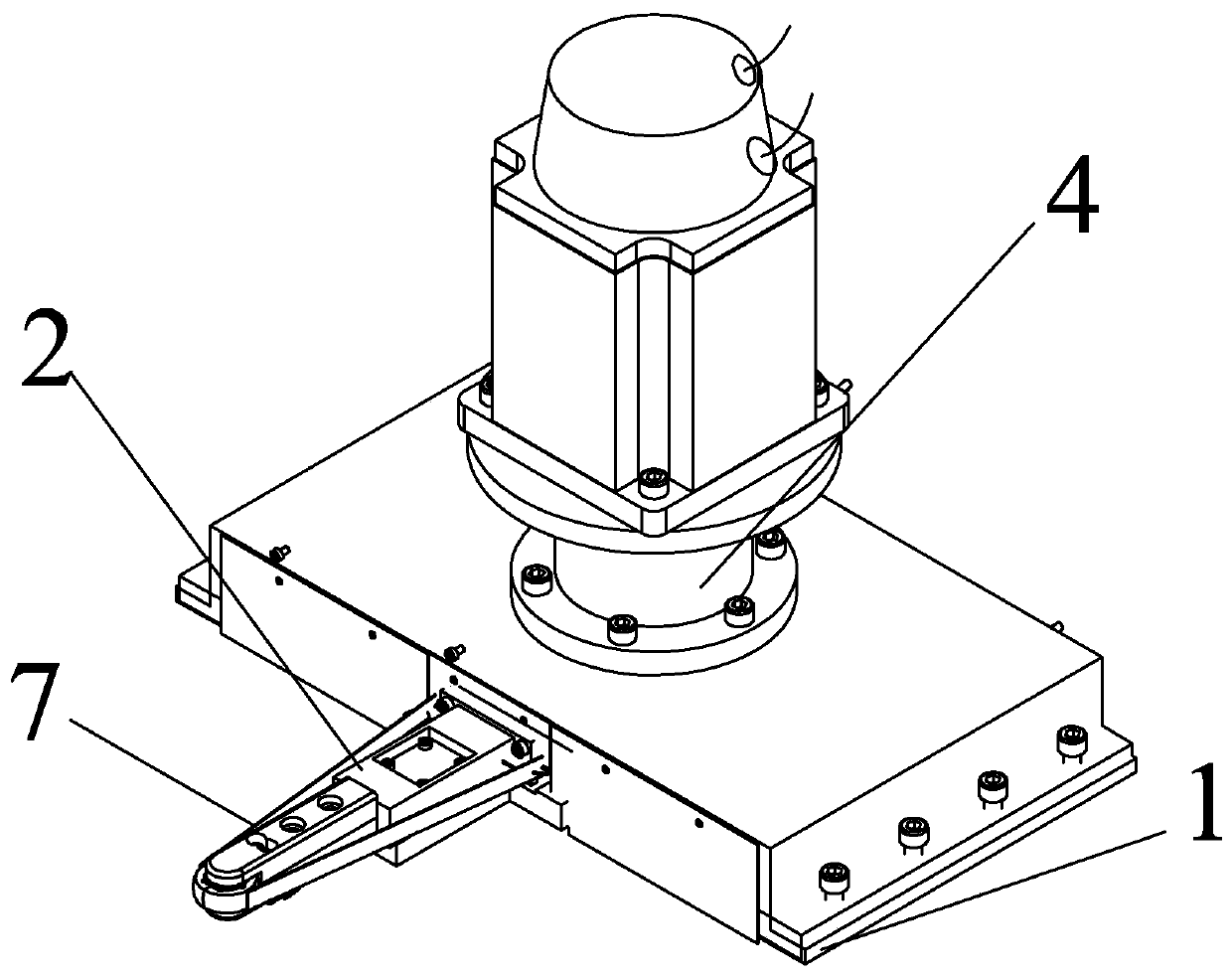

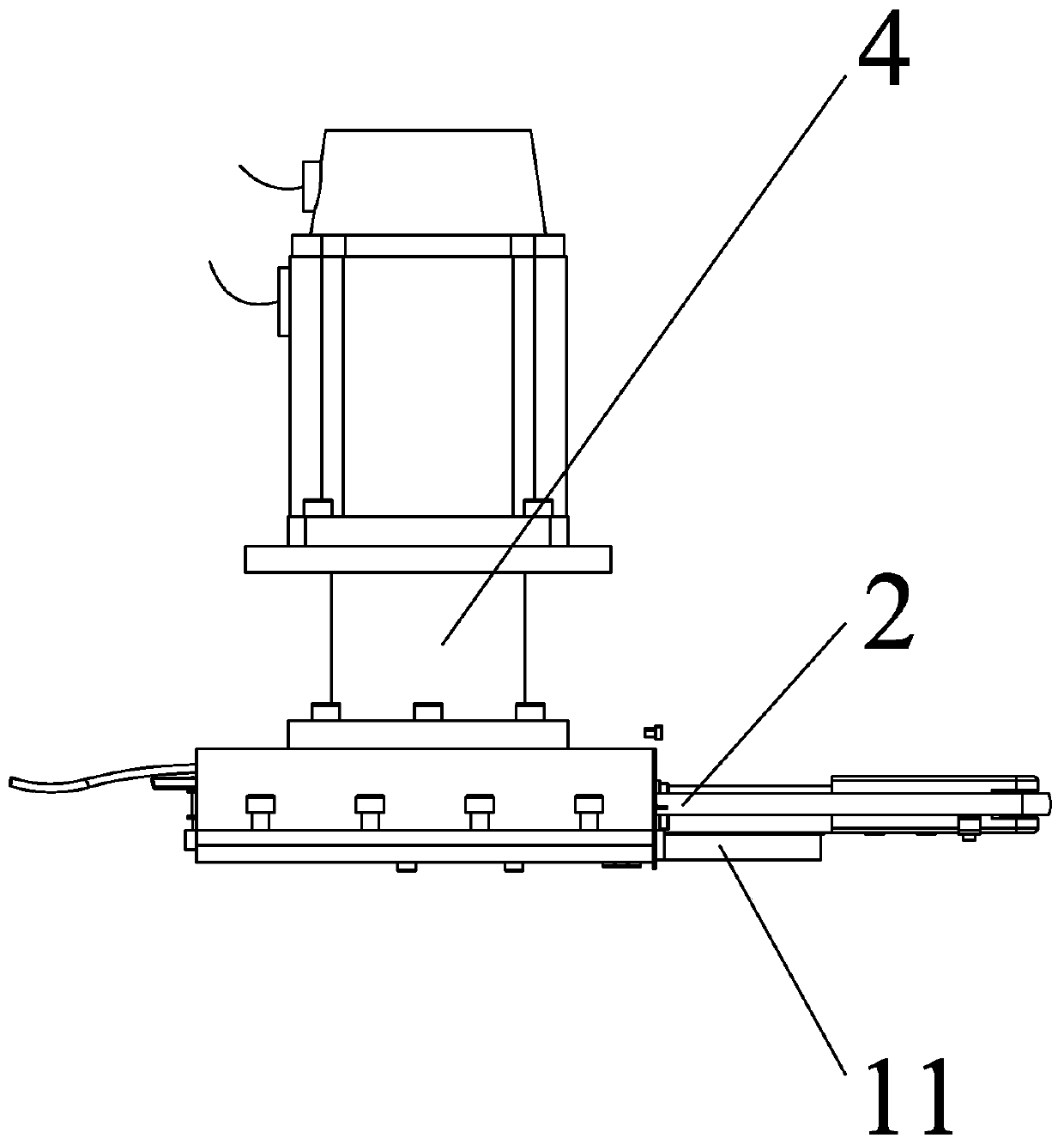

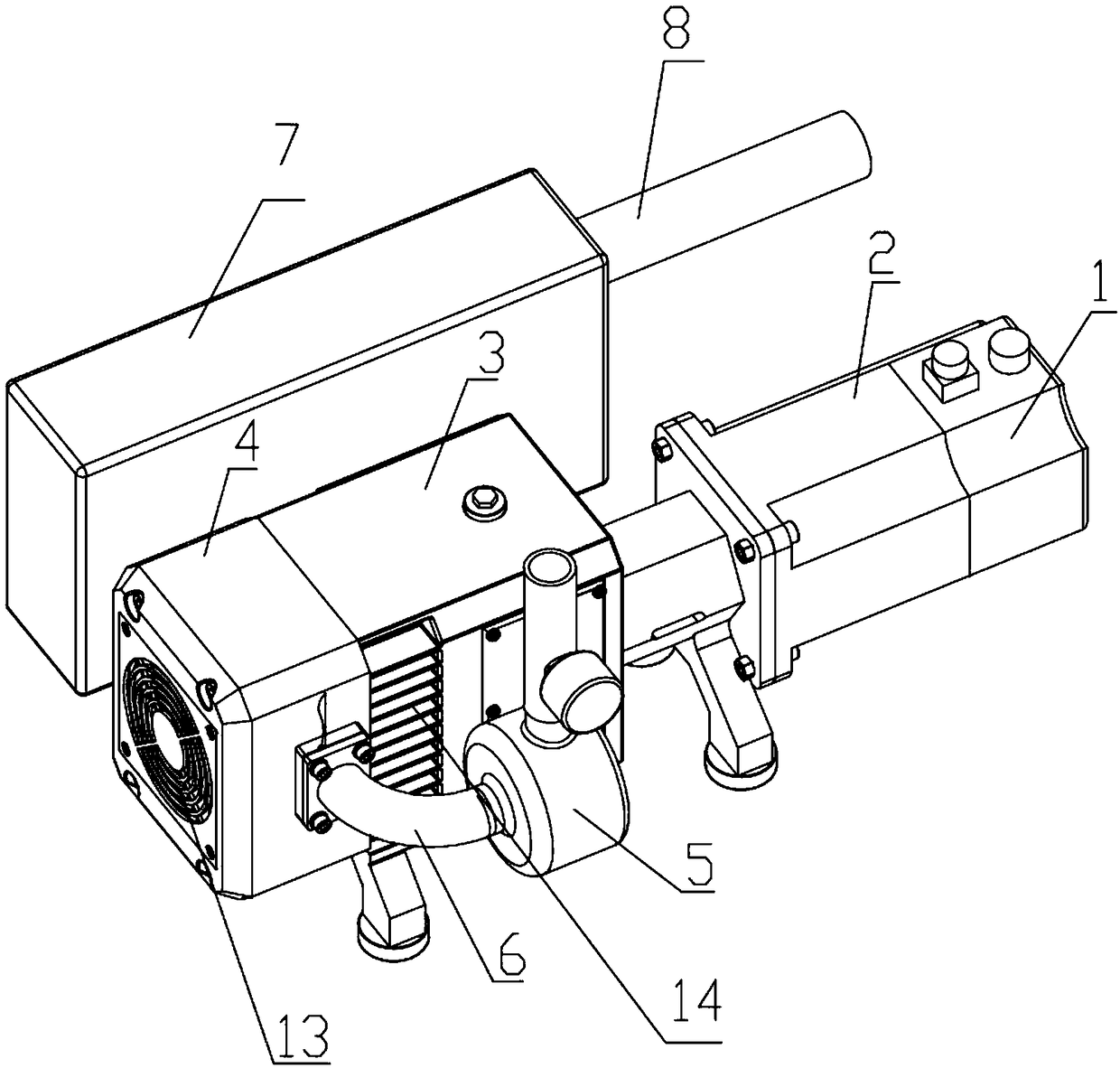

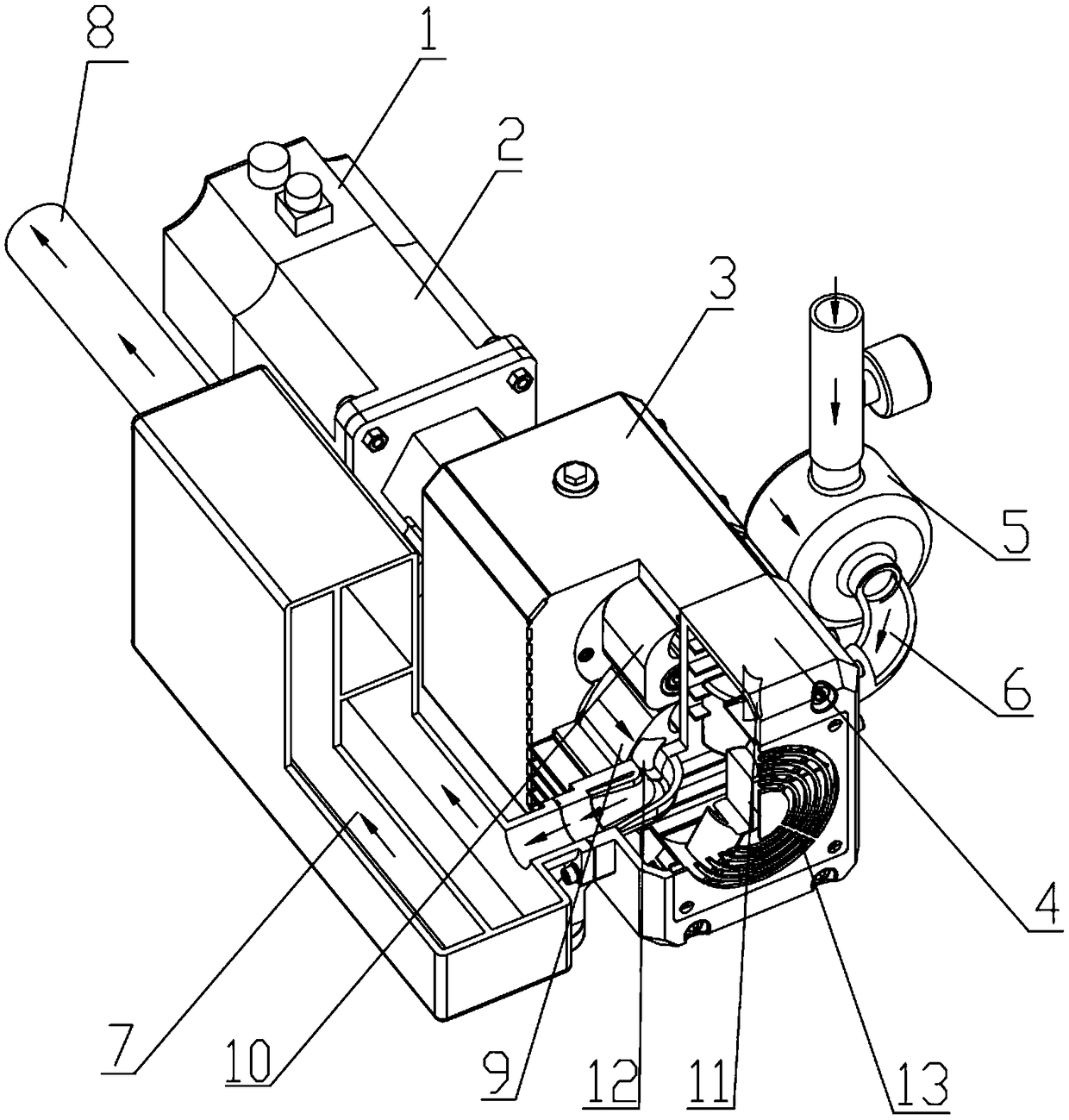

Cantilever wheel belt polishing device with controlled pressure and polishing method

ActiveCN110238729AConstant normal contact pressureControl contact areaOptical surface grinding machinesBelt grinding machinesTarget surfaceContact pressure

The invention provides a cantilever wheel belt polishing device with controlled pressure and a polishing method, belongs to the technical field of ultra-precision processing, and solves the problem that the polishing method in the prior art introduces a certain medium-high frequency error during polishing, so improving the surface precision is difficult, and optical components with large aspect ratio and complex surface cannot be polished effectively, specifically the inner surfaces; meanwhile, the controllable contact pressure polishing device adopts a single contact control method, which cannot effectively polish workpiece with great difference of the target surface. The polishing device provided by the invention comprises a bottom plate, a wheel bar assembly, a drive assembly, a dressing assembly, a polishing belt, a tensioning assembly and a guide idler, is mainly used for ultra-precision machining of optically complex surfaces of hard and brittle materials.

Owner:HARBIN INST OF TECH

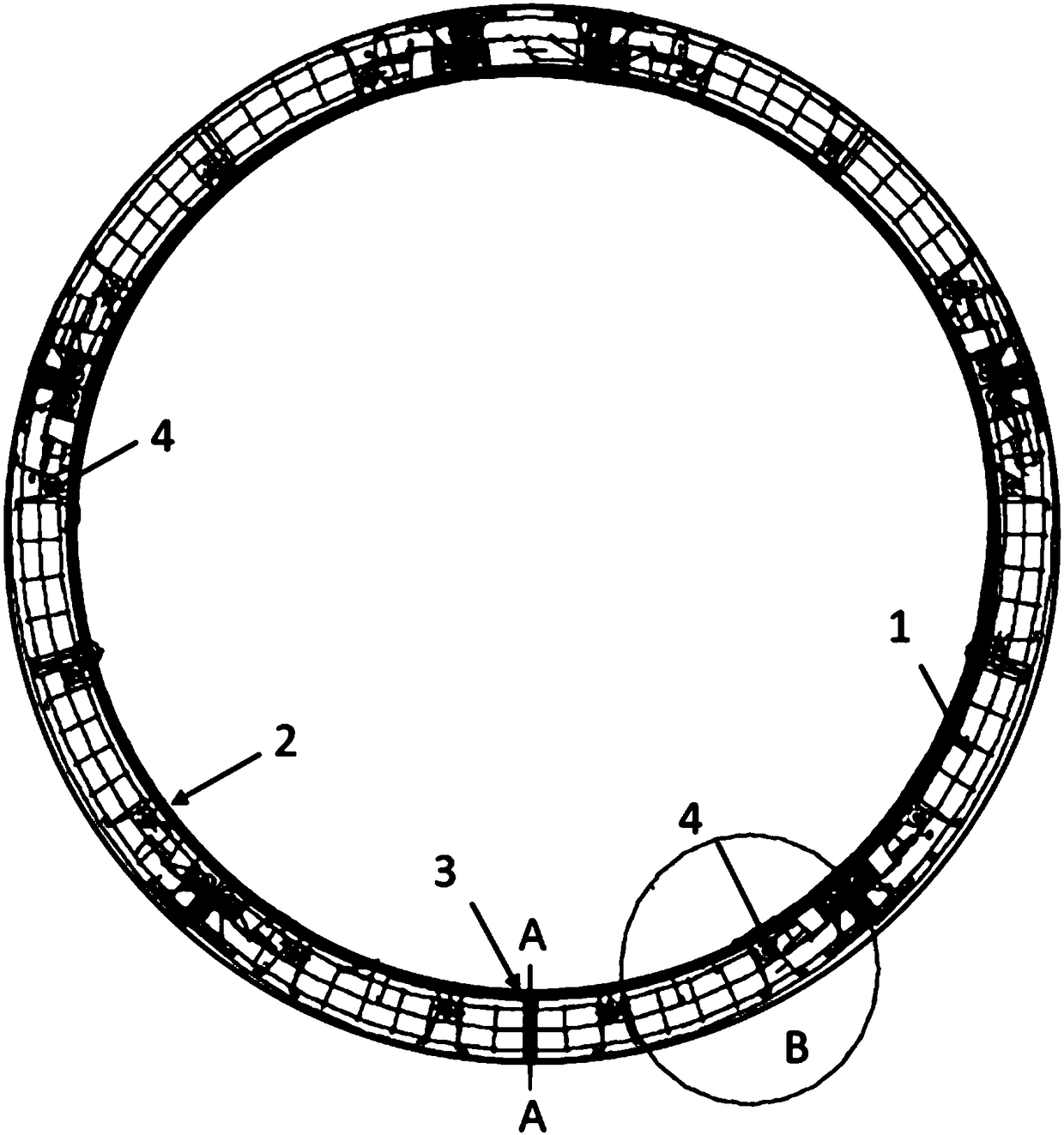

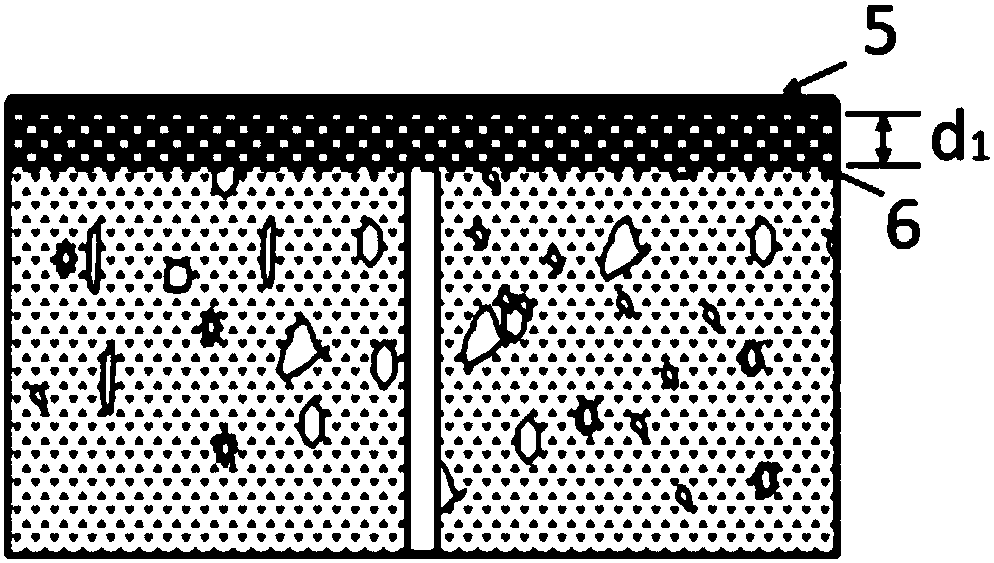

Construction method based on shield method for anti-seepage anticorrosion sewage pipe segment lining

The invention relates to a construction method based on a shield method for an anti-seepage anticorrosion sewage pipe segment lining. The method comprises the following steps that (a) holes in shield segments and gaps between the segments are blocked through epoxy resin; (b) the inner cambered faces of the shield segments are polished to expose inner pores of the shield segments; and (c) polyaniline / epoxy resin mixed coating is sprayed on the inner cambered faces of the shield segments and cured to form protecting coatings. Through the construction steps of epoxy resin blocking, shield segment inner cambered face polishing and protecting coating forming through curing, the construction process is more economical, simpler and rapider, the effective utilized area in pipes is increased, flow resistance of the coatings to sewage is smaller, and the pollution discharge speed is increased. In addition, the protecting coatings have excellent film-forming performance and corrosion resistance and can effectively resist corrosion of acid, alkali and salts in the sewage pipes to the reinforced concrete segments.

Owner:HOHAI UNIV

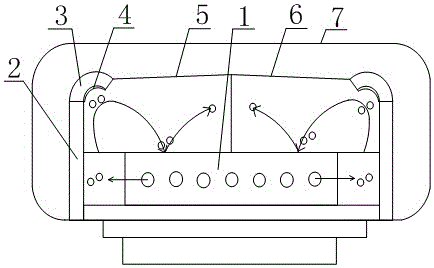

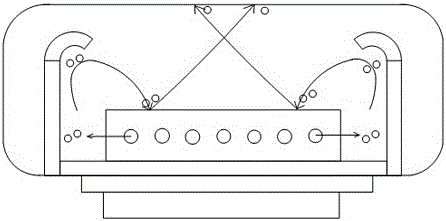

Dry-type claw type vacuum pump

PendingCN108980037ABarrier corrosionCorrosion barrierRotary/oscillating piston combinations for elastic fluidsCorrosion preventionCouplingDrive shaft

The invention discloses a dry-type claw type vacuum pump. The vacuum pump comprises a motor, a coupling, a pump body and a muffler, wherein the pump body comprises a pump shell, an air inflow and outflow shell, a driving shaft, a driven shaft, a driving rotor, a driven rotor, a synchronous gear, a bearing and a dynamic seal, the rear end of the pump shell forms a rotor cavity with the air inflow and outflow shell; the air inflow and outflow shell is provided with an air inlet and an air outlet, which are respectively communicated to the rotor cavity, the air inlet is further connected with anair inflow pipeline, the air outlet is further connected with the muffler, the air inflow pipeline, the air inlet, the rotor cavity, the air outlet and the muffler form a gas pumping passage, and thegas pumping passage forms a WC-DLC superlattice nano-multilayer anticorrosive coating on a surface through a magnetron sputtering process. By the design, the dry-type claw type vacuum pump can be usedfor effectively preventing corrosive gas from corroding the surface of a part.

Owner:深圳市泉天下智能装备科技有限公司

A construction method of anti-seepage and anti-corrosion sewage pipeline segment lining based on shield method

Owner:HOHAI UNIV

Rust inhibitor for concrete reinforcement

Owner:CHANGZHOU LANXU CHEM CO LTD

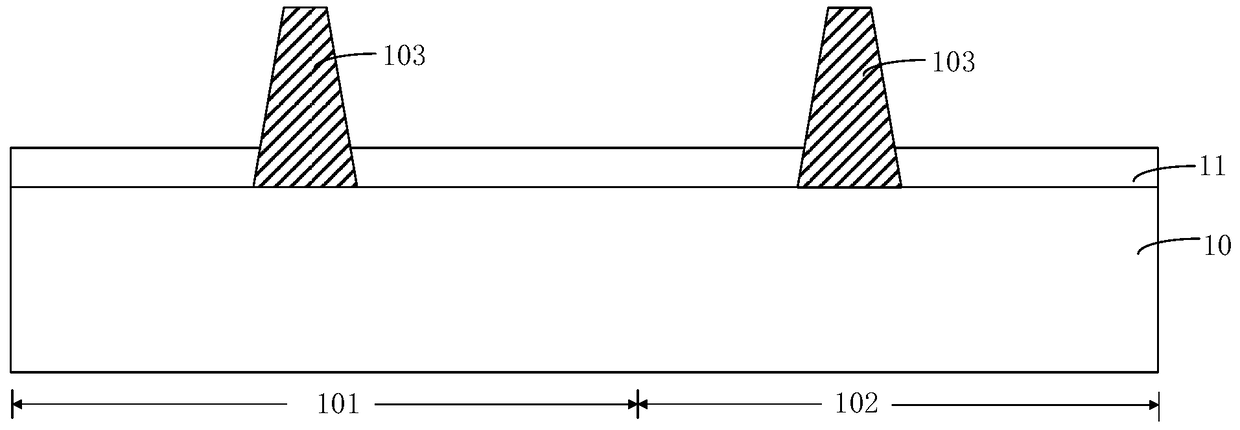

Aluminum-plastic compound film used for anti-pollution polymer lithium-ion power battery and preparation method thereof

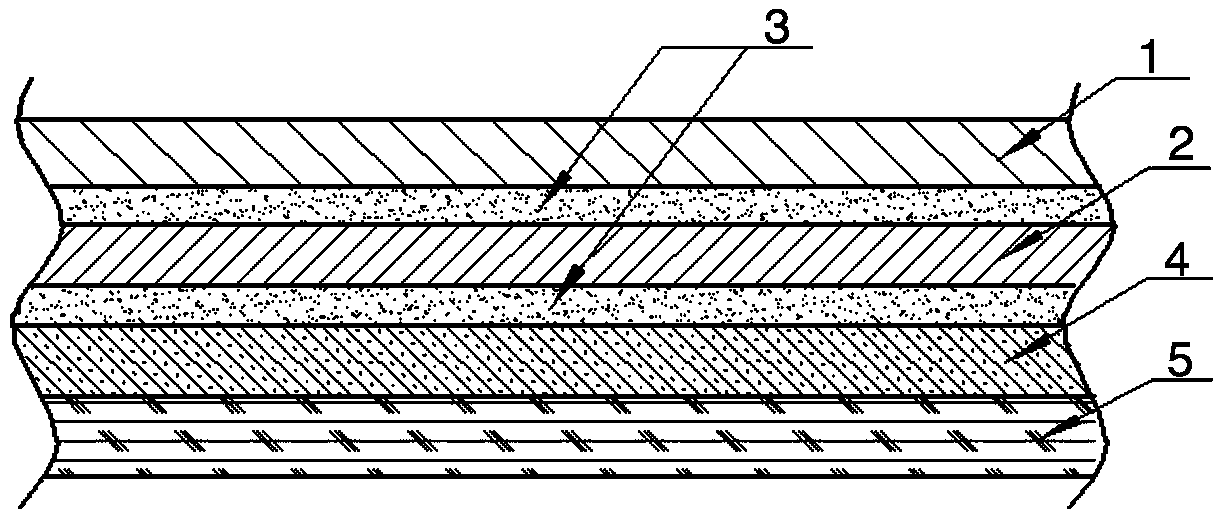

InactiveCN108735921AGood impact resistanceImprove heat resistanceSynthetic resin layered productsJackets/cases materialsPolypropyleneAdhesive

The invention discloses an aluminum-plastic compound film used for an anti-pollution polymer lithium-ion power battery. The aluminum-plastic compound film comprises a polycarbonate film layer, an aluminum foil layer, an acid modified polypropylene layer and a casting polypropylene layer which are arranged from top to bottom in sequence, wherein anti-corrosion layers are arranged on the upper surface and lower surface of the aluminum foil layer respectively; the polycarbonate film layer is hot-pressed and compounded on the upper surface of the aluminum foil layer through a polyurethanes modified adhesive; and the acid modified polypropylene layer and the casting polypropylene layer are hot-pressed and compounded on the lower surface of the aluminum foil layer. Moreover, the invention discloses a preparation method of the aluminum-plastic compound film. When the aluminum-plastic compound film is used for packaging the polymer lithium-ion power battery, the reduction of the aluminum-plastic compound film is controllable, the aluminum-plastic compound film has relatively high heat resistance, cold resistance and strength, micro short circuit is prevented from occurring in the heat-sealing process of the polymer lithium-ion power battery to cause a liquid leakage failure phenomenon, the polymer lithium-ion power battery is high in safety and long in service life after being packaged, the phenomenon of liquid leakage pollution does not occur, and the development of electric automobiles is effectively promoted.

Owner:江苏共巨锂电材料有限公司

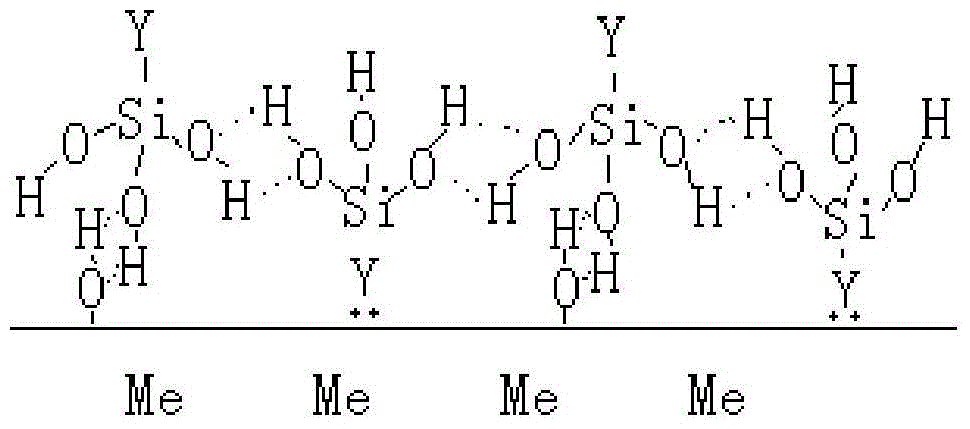

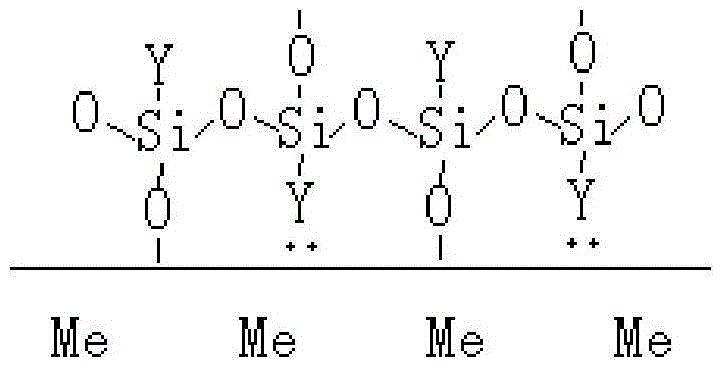

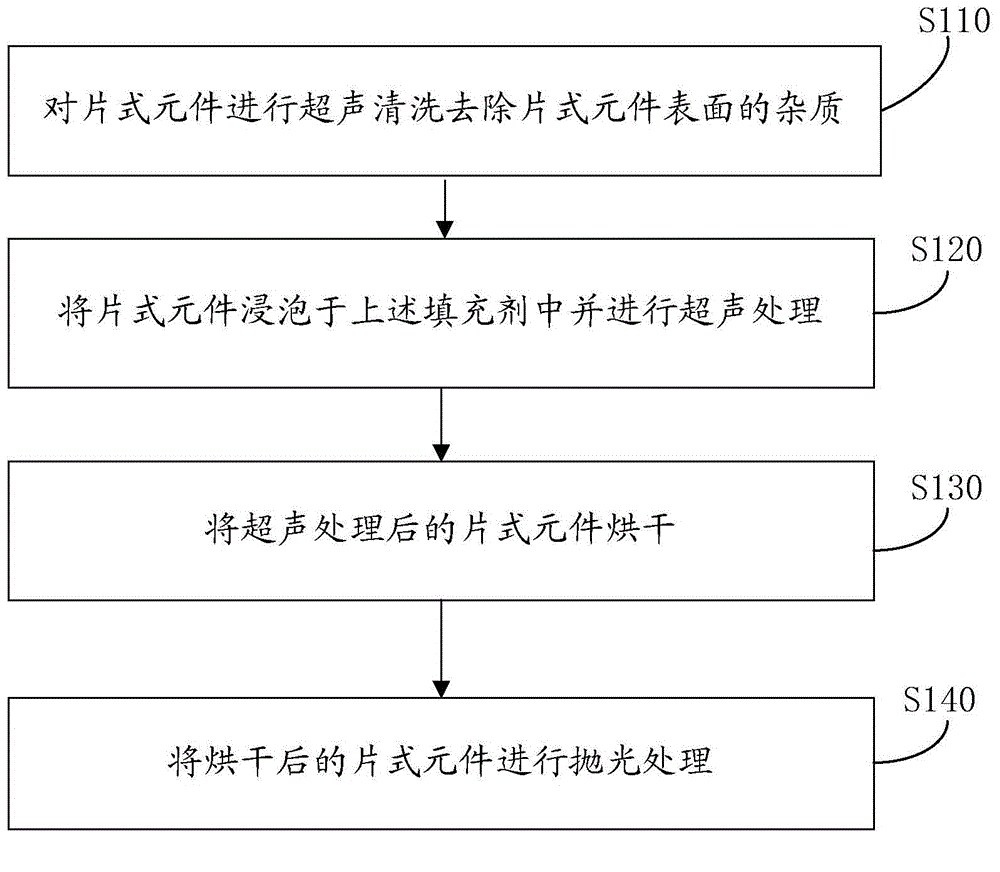

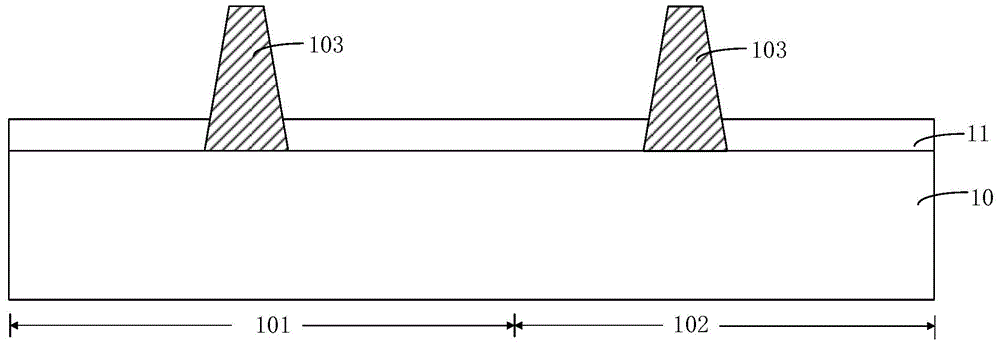

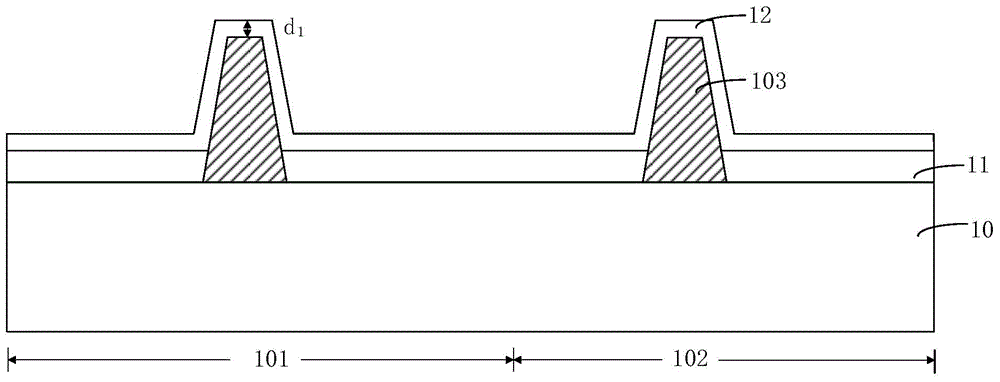

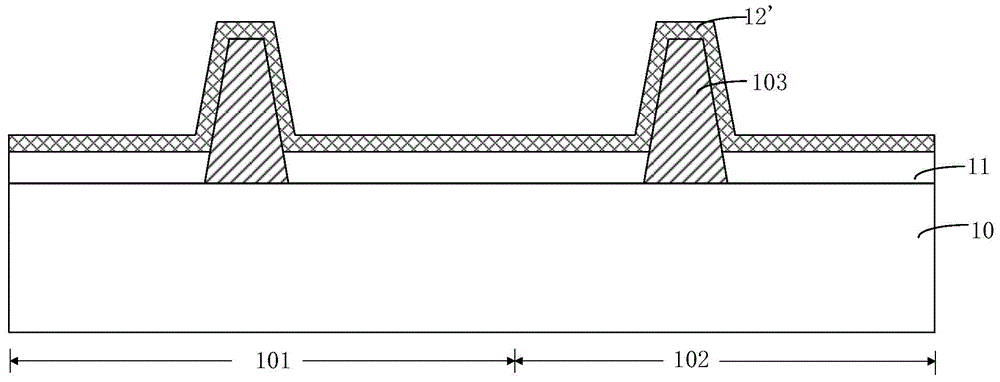

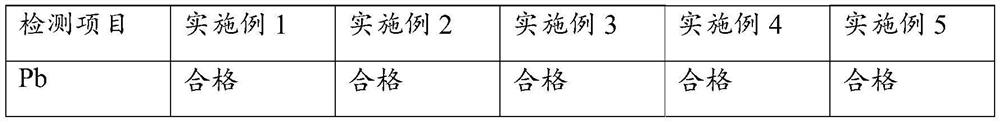

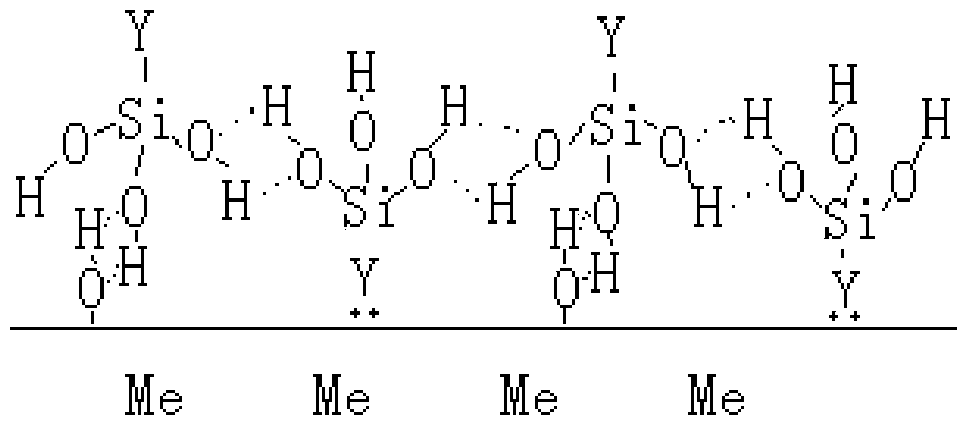

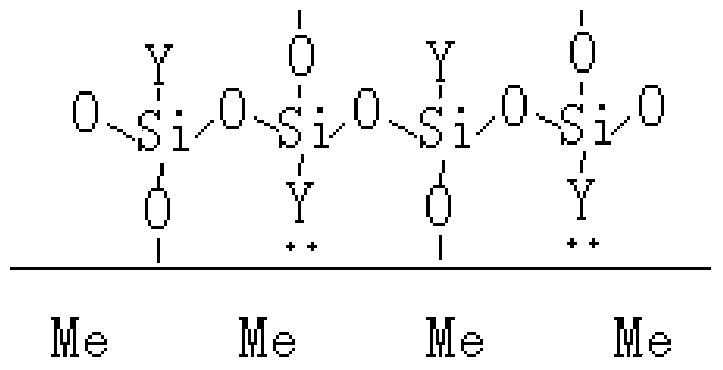

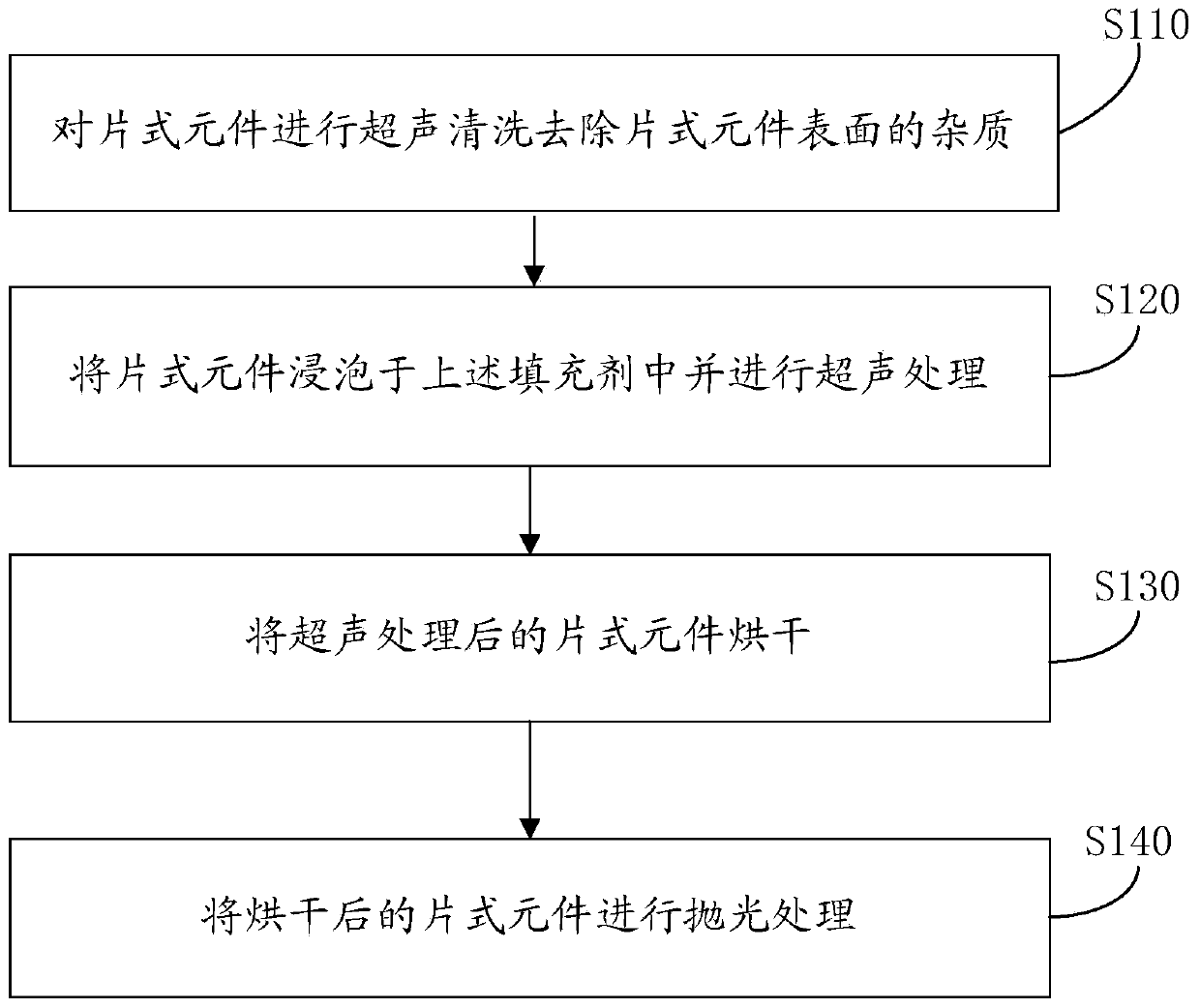

Filling agent and surface treatment method for chip components

ActiveCN104795367AAccelerated corrosionImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesAlcoholCoupling

The invention provides filling agent and a surface treatment method for chip components. The filling agent comprises, by weight, 15 to 30 parts of vinyl silicone coupling agent, 60 to 75 parts of alcohol, 5 to 10 parts of water, and 1 to 5 parts of organic carboxylic acid. The filling agent is capable of sealing micropores in the surface of each chip component.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

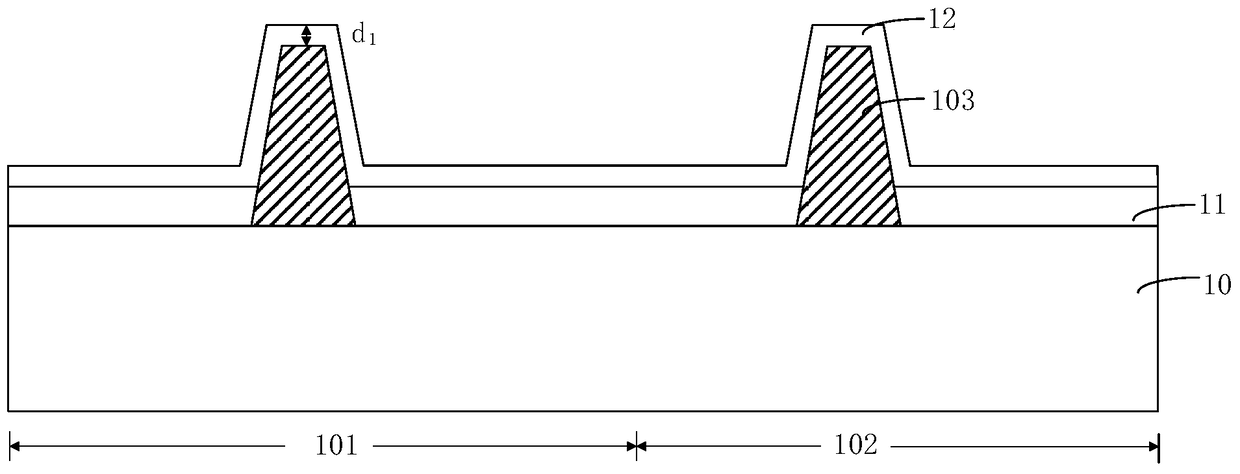

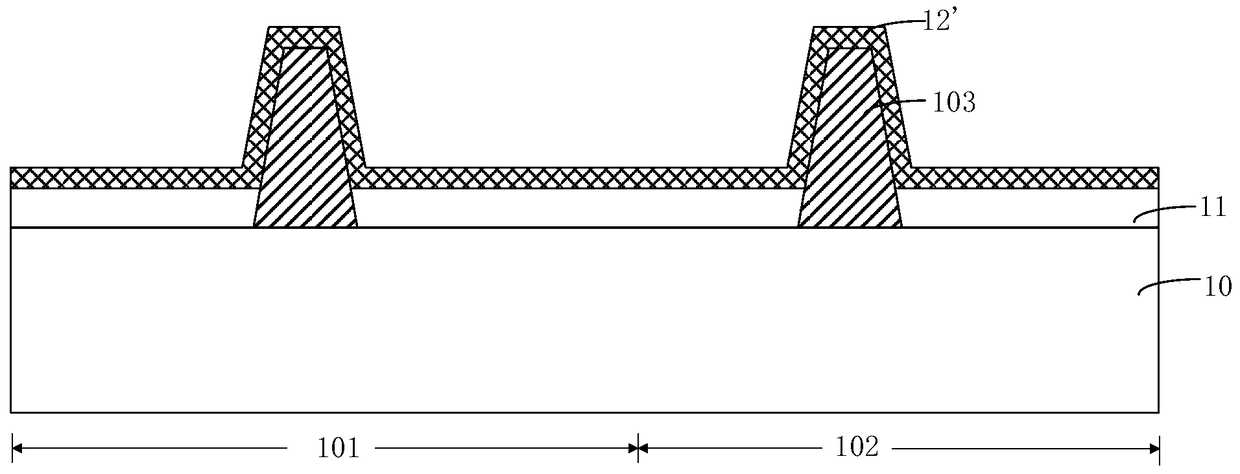

Grid oxidation layer manufacturing method and semiconductor device manufacturing method

ActiveCN105448686AAvoid corrosionImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesOxygen ionsDangling bond

The invention discloses a grid oxidation layer manufacturing method and a semiconductor device manufacturing method. Ozone-containing solution is used for processing a grid oxidation layer before photoetching, and oxygen ions in ozone can be bonded with silicon dangling bonds in the grid oxidation layer. In other words, the oxygen ions in ozone serve as filling atoms which are used for filling the silicon dangling bonds in the grid oxidation layer, thereby enabling the grid oxidation layer to be compact, preventing the inward diffusion of developing solution from causing the corrosion of a trench region of a semiconductor substrate under the grid oxidation layer in a photoetching process, and improving the reliability of a field effect transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

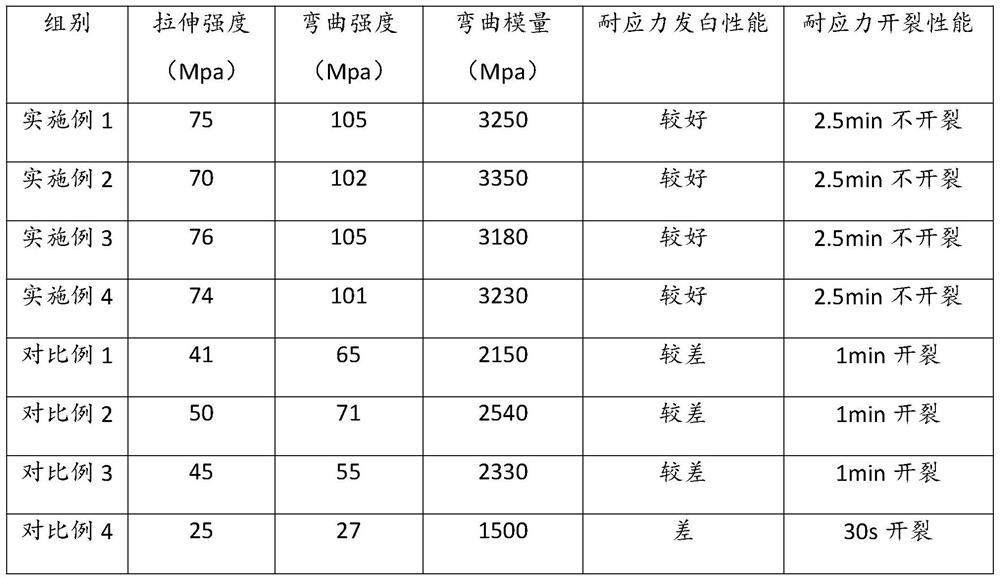

Preparation method of polypropylene film layer for reducing cracks in cold punching process

PendingCN112318843ASlows down or prevents stress whiteningImprove toughnessMacromolecular adhesive additivesGraft polymer adhesivesPolymer scienceCrazing

The invention discloses a preparation method of a polypropylene film layer for reducing cracks in a cold punching process. The preparation method specifically comprises the following steps: (1) respectively and uniformly mixing components contained in a bonding layer, a core layer and a heat sealing layer, and respectively carrying out melting and plasticizing in three extruders to respectively obtain melts of the bonding layer, the core layer and the heat sealing layer; and (2) carrying out three-layer co-extrusion through three extrusion heads of the melt extruder, and enabling materials tobe subjected to casting to a cooling roller to be cooled to form a film comprising the bonding layer, the core layer and the heat sealing layer in sequence. The polypropylene film layer prepared fromthe raw materials according to the ratio is good in mechanical property, has the characteristics of being easy to process and form and the like, particularly, the stress whitening resistance of the material is controlled, and the polypropylene film layer can be used in occasions in which various products requiring materials to keep the appearance under the condition of multiple external forces areformed, and can be used in the field of products with various colors and other modified purposes.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

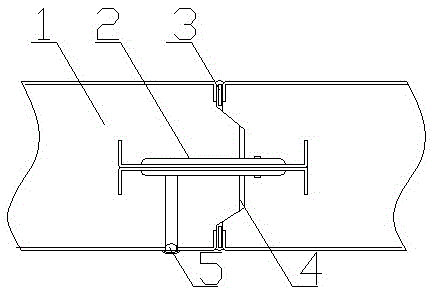

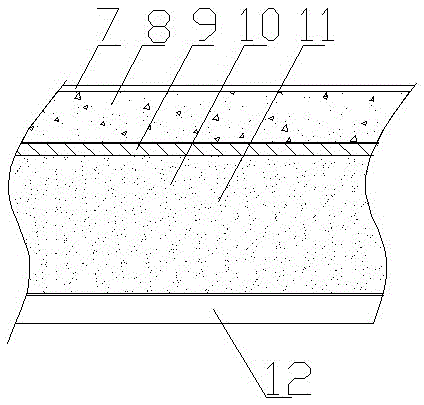

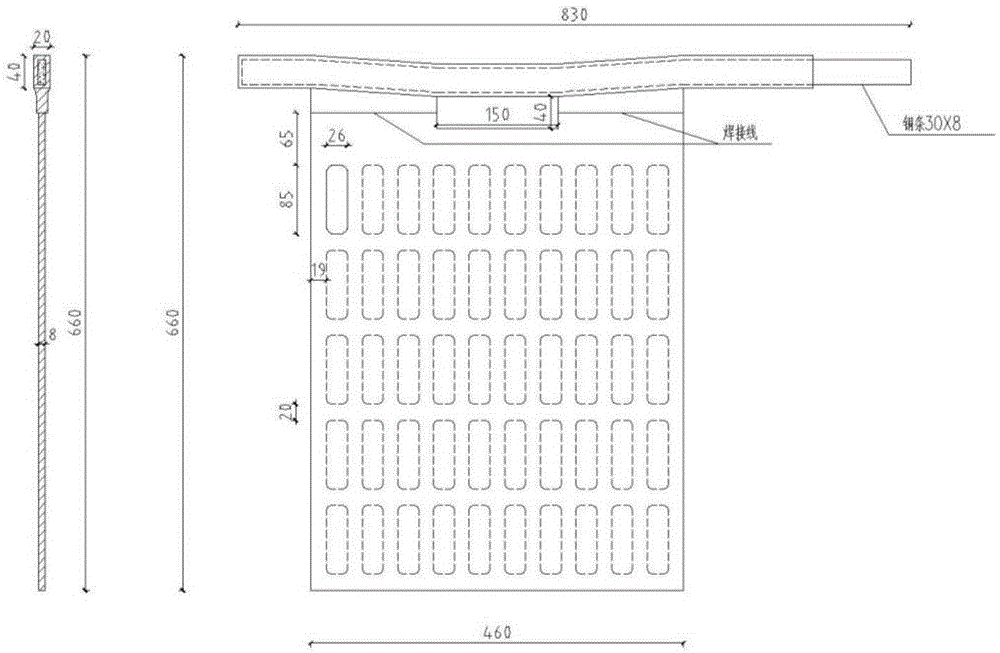

A marine controlled atmosphere vegetable and fruit preservation store

The invention relates to a marine atmosphere control type vegetable and fruit fresh-keeping storehouse which comprises an airtight refrigeratory, a refrigeration drier, a humidifier and a nitrogen making machine. The fresh-keeping storehouse is provided with a storehouse door, a storehouse plates and a door lock, wherein every two adjacent storehouse plates are connected through a locking part, a PVC plug is arranged at the position of a lock hole of each locking part, a silica gel sealing strip is arranged on the seam of the outer surfaces of every two adjacent storehouse plates, and a foaming sealing layer is arranged on the contact surface of every two adjacent storehouse plates. Due to the fact that the silica gel sealing strip is arranged on the connecting surface of every two adjacent storehouse plates and a sealing glue layer is arranged on the connecting seam of every two adjacent storehouse plates, leakage between the storehouse plates is effectively prevented. A wire mesh cement layer, a stainless steel plate layer and a damp-proof plywood layer are sequentially arranged between the storehouse plate on the bottom of the refrigeratory and a deck of a ship, the wire mesh cement layer effectively guarantees the airtightness of the bottom of the refrigeratory, the stainless steel plate layer and the damp-proof plywood layer effectively prevent seawater from corroding the bottom of the refrigeratory, and the service life of the storehouse plates is prolonged.

Owner:JIANGSU JOSUN AIR CONDITIONER

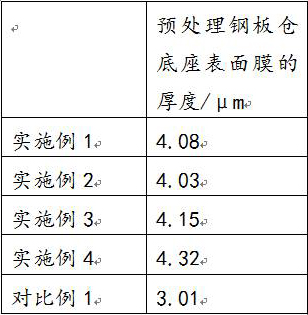

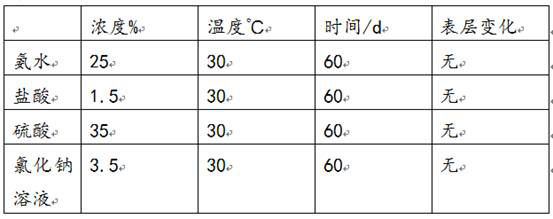

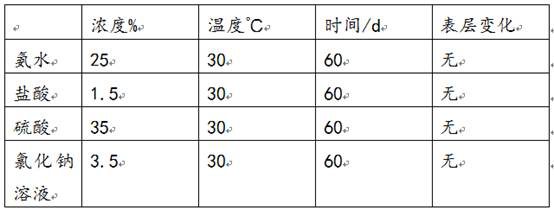

A method for treating the base of a corrosion-resistant steel silo

ActiveCN112143366BBarrier corrosionExtended service lifePretreated surfacesAnti-corrosive paintsSiloCorrosion resistant

Owner:ANHUI FEISONG MASCH TECH CO LTD

A kind of manufacturing method of electrolytic metal-manganese alloy lead-plastic composite anode

InactiveCN103695960BHigh densityBarrier corrosionPhotography auxillary processesElectrodesElectrolysisManganese

The invention provides a manufacturing method of an electrolytic manganese metal alloy lead-plastic composite anode. The alloy lead-plastic composite anode comprises a conductive rod, a copper bar embedded inside the conductive rod and a male tab at the lower part, wherein the materials for fabricating the male tab comprise the following ingredients (by weight ratio): 0.06-0.10% of silver Ag, 0.1-0.4% of stibium Sb, 1-3% of stannum Sn, 0.3-0.6% of arsenic As, 0.1-0.3% of calcium Ca, 0.1-0.3% of strontium Sr and the balance of lead Pb. By adopting the method, an anode product is mainly prepared by optimizing an alloy element formula, and then a layer of tightly wrapped anti-corrosive protecting coating is formed on the three-item interface (the three-item interface refers to a juncture interface of an electrolyte surface, air and an anode plate) in an injection molding manner. Thus, corrosion to the lead alloy caused by chlorine and fluorine in the electrolyte at the three-item interface can be avoided.

Owner:申中军

A kind of billet anti-oxidation coating and spraying method thereof

The invention discloses a casting blank oxidation resisting coating and a spraying method thereof. The casting blank oxidation resisting coating is characterized in that the casting blank oxidation resisting coating is composed of main components including silicon nitride or silicon carbide or silicon nitride plus silicon carbide and iron, and other components including one or more of Al2O3, SiO2, MgO and Cr2O3; the oxidation resisting coating is sprayed at high temperature in a powder electrostatic mode, a double-layer protection structure for a low melting point glass phase and a ceramic phase is formed on the surface of a casting blank in the heating process, oxidation of the casting blank by burner gas and corrosion of the casting blank by the low melting point glass phase can be effectively restrained, and the steel yield is remarkably improved.

Owner:沈阳东大高温材料有限公司

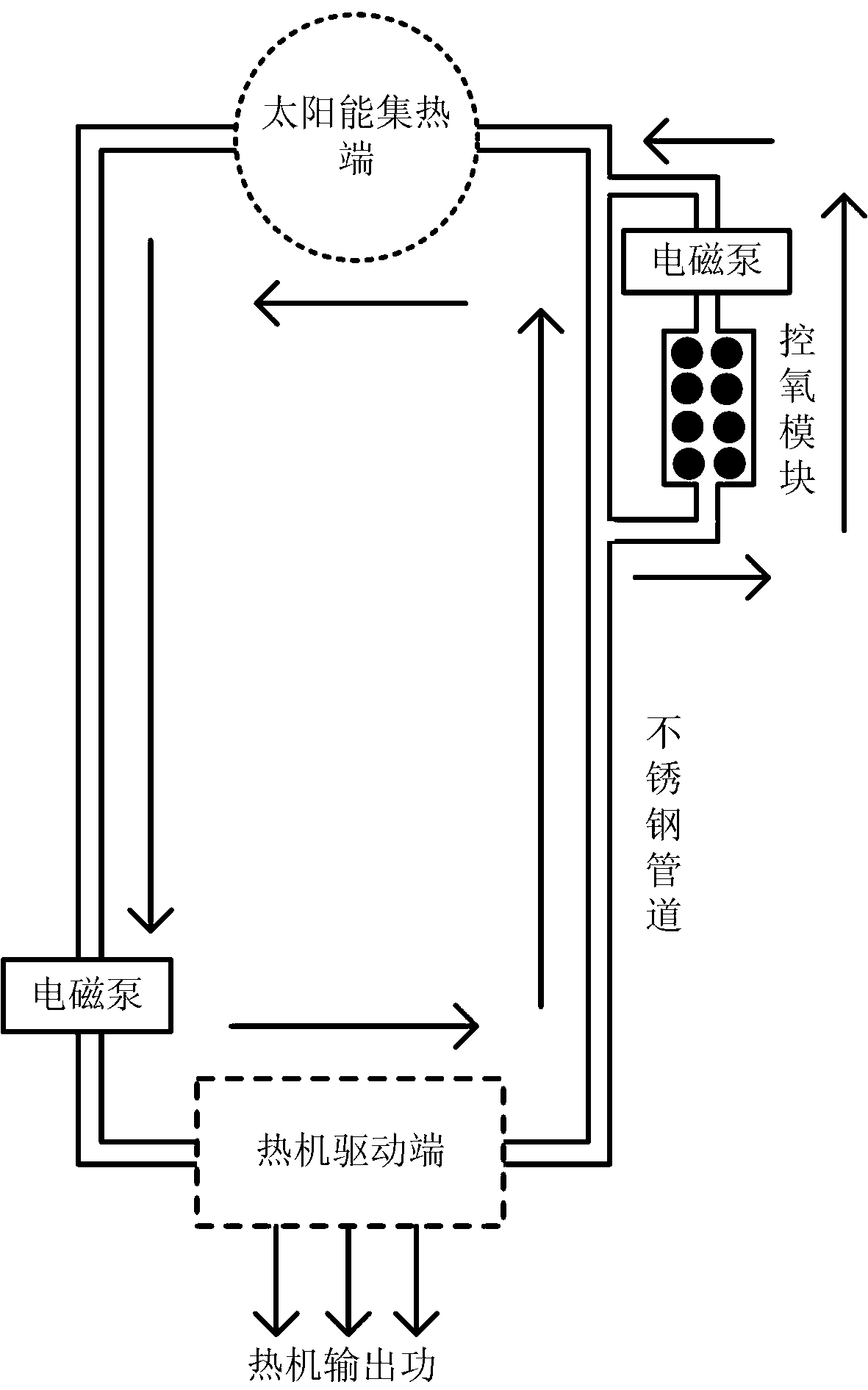

Molten metal compatible with stainless steel and capable of controlling oxygen activity to be 200-300 degrees and technology thereof

InactiveCN110317972AFast dissolutionControl oxygen activitySolar heating energySolar heat storageLiquid metalAlloy

The invention discloses molten metal compatible with stainless steel and capable of controlling the oxygen activity to be 200-300 degrees and a technology thereof. The molten metal is prepared from, by weight, alloys including 0.5-0.8% of Ga, 2.0-3.0% of In, 4.0-6.0% of Pb, 10.0-20.0% of Zn, 4.0-6.0% of Bi, 3.0-5.0% of Cd, 5.0-8.0% of Sb and the balance tin, and oxides for controlling the oxygen activity including 20.0-30.0% of PbO, 3.0-5.0% of MnO, 10.0-20.0% of MgO, 4.0-6.0% of In2O3, 3.0-5.0% of CuO and the balance Fe2O3. The molten metal is adopted in heat collecting and heat transfer modules of a solar energy photo-thermal system, an oxygen control module is adopted for effective control over the oxygen activity, and a layer of dense oxidizing film can be generated on the surface of astainless steel pipeline to restrain the molten metal from corroding a pipeline material. The process is simple, and the effects of enhancing heat transfer and prolonging the service life are quite obvious.

Owner:深圳市兴荣晟物业管理有限公司

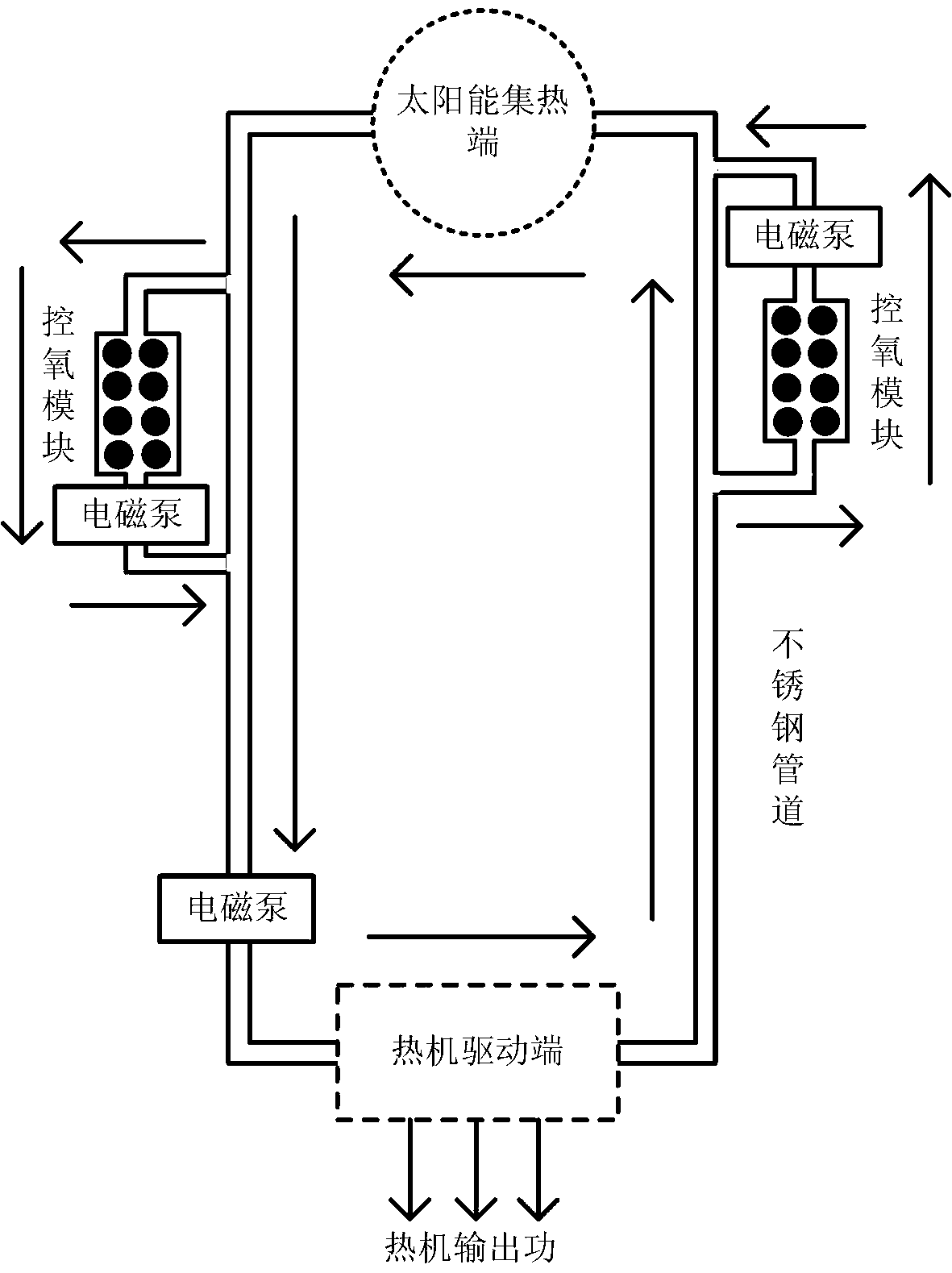

Oxygen-controlled 300-400 DEG C stainless-steel-compatible liquid metal in photothermal field and process thereof

The invention discloses oxygen-controlled 300-400 DEG C stainless-steel-compatible liquid metal in the photothermal field and a process thereof. The alloy compositions include, by weight percent, 1.0-3.0% of In, 10.0-15.0% of Bi, 2.0-3.0% of Mn, 20.0-30.0% of Zn, 10.0-12.0% of Cd, 2.0-5.0% of Pb, 2.0-4.0% of Ga and the balance being Sn, wherein oxygen activity controlled oxide compositions include, by weight, 10.0-20.0% of PbO, 5.0-8.0% of AgO, 2.0-5.0% of Mn, 10.0-20.0% of MgO, 3.0-5.0% of CoO and the balance being Fe2O3. The liquid metal is used in a heat colleting module and a heat transfermodule of a solar photothermal system, an oxygen control module is adopted for controlling the oxygen activity effectively, and a compact layer of oxide film can be formed on the surface of a stainless steel pipeline so as to inhibit erosion of the liquid metal to the pipeline material; and the process is simple, and besides, the effects for improving heat transfer and prolonging the service lifeare quite obvious.

Owner:深圳市兴荣晟物业管理有限公司

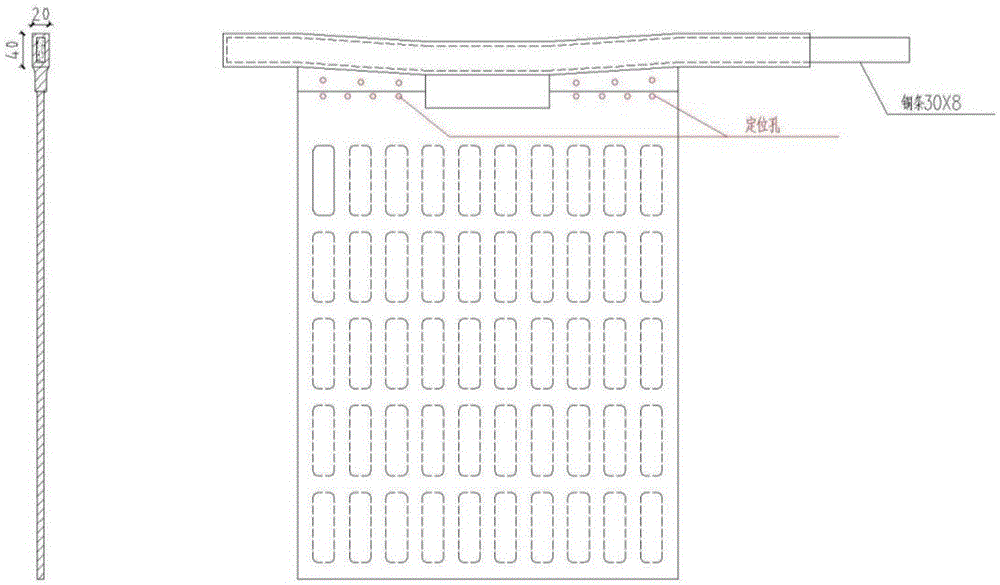

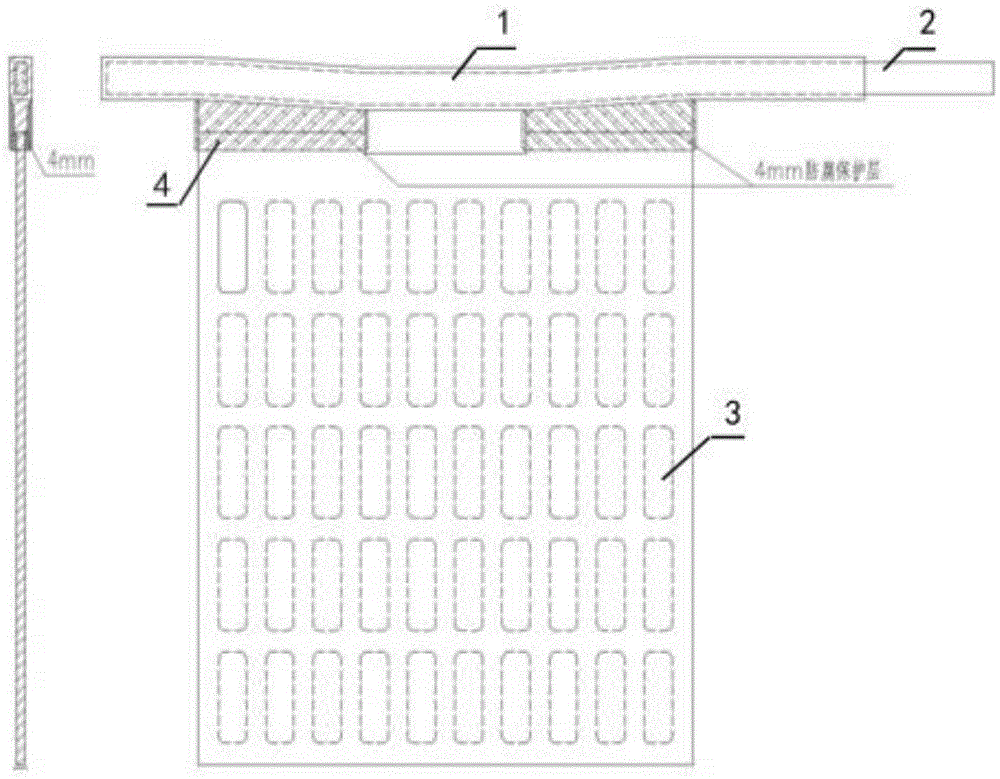

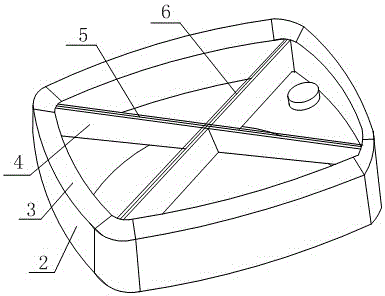

Deep washing and renovating device and washing and renovating method for glass surface of photovoltaic module

InactiveCN113953297AAchieve deep cleaningGood effectDrying gas arrangementsFlexible article cleaningEngineeringStructural engineering

The invention discloses a deep washing and renovating device and washing and renovating method for the glass surface of a photovoltaic module. The deep washing and renovating device comprises a cover body, a groove type washing liquid cavity is formed in the inner side of the cover body, a sealing belt is arranged on the periphery of the washing liquid cavity, a liquid inlet and a liquid outlet are formed in the cover body, and pressure fasteners are arranged on the cover body. The deep washing and renovating method comprises the following steps: preparing of the renovating device; fixing and sealing; washing; flushing; aeration-drying; and coating. Compared with the prior art, the device and method have the advantages that 1, deep washing can be realized, all dirt on the glass surface of the photovoltaic module including a moldy glass substrate can be washed off, and the effect is remarkable; 2, after the photovoltaic module is coated at normal temperature, a protective layer is formed on the surface, the hardness can reach 6H, and then corrosion of water vapor to panel glass is blocked; and 3, the method can be repeatedly adopted for washing, and the optimal power generation efficiency of the module can be achieved during washing each time.

Owner:上海达巧康新材料科技有限公司

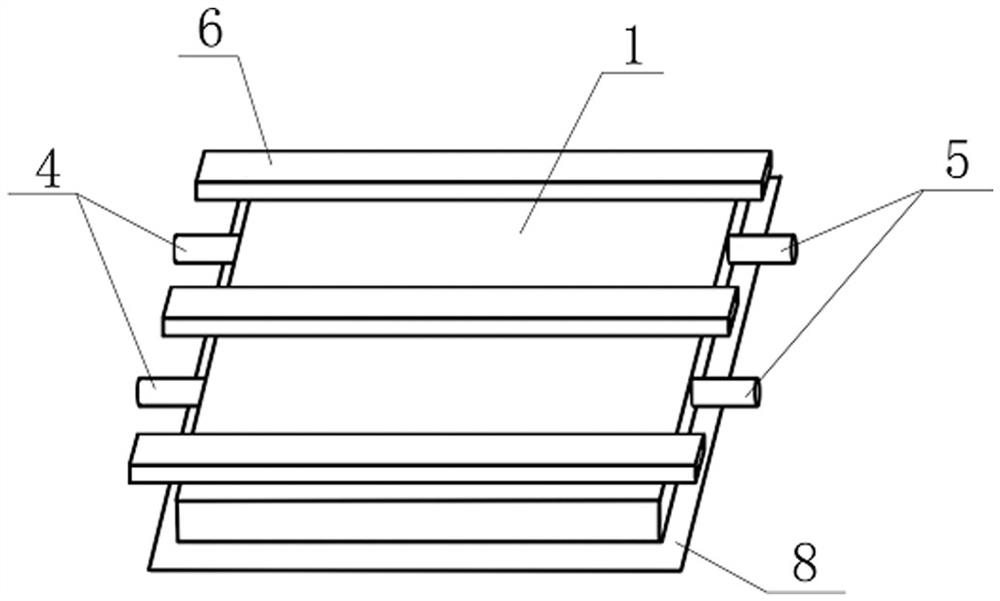

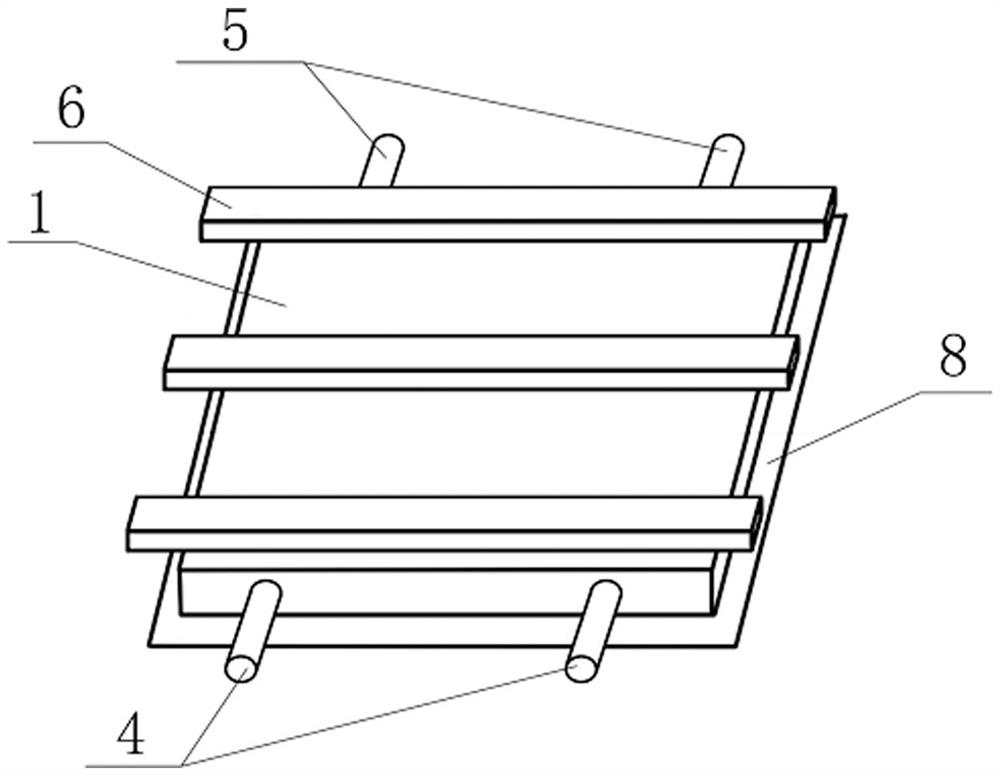

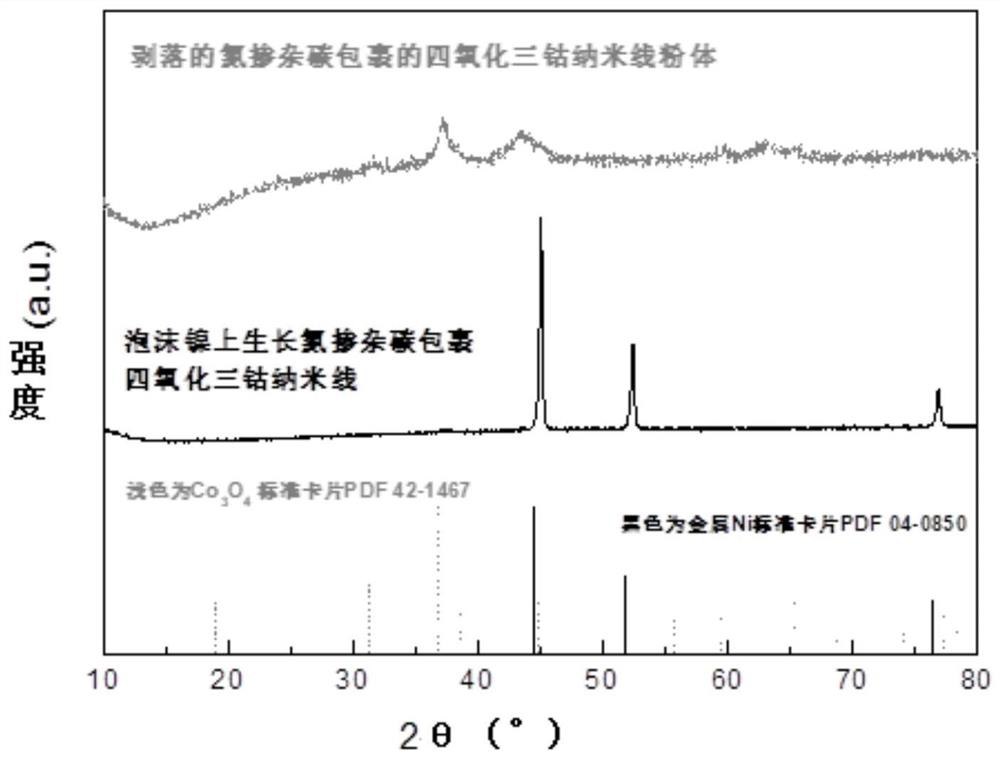

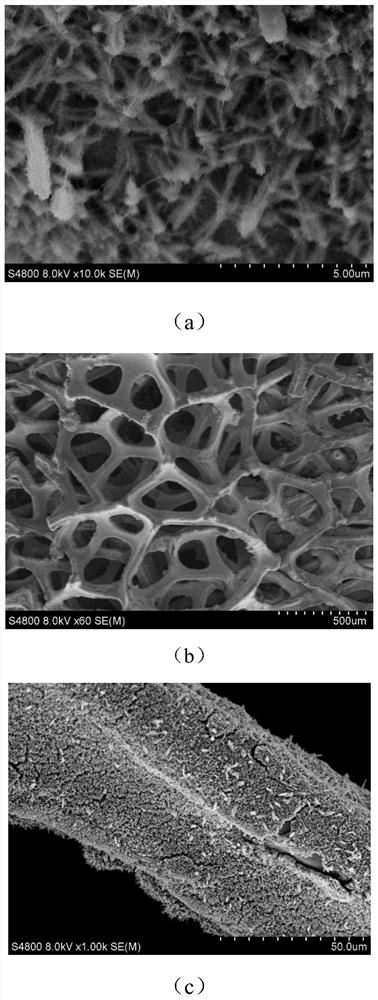

Nitrogen-doped carbon-wrapped tricobalt tetroxide nanowire monolithic catalyst and preparation method thereof

ActiveCN112536055BEasy to prepareRaw materials are easy to getMetal/metal-oxides/metal-hydroxide catalystsCarbon layerPtru catalyst

The present application discloses a monolithic catalyst. The monolithic catalyst includes a carrier and an active material loaded on the carrier; the active material includes nitrogen-doped carbon nanowires wrapping tricobalt tetroxide particles. The application also discloses a preparation method of the monolithic catalyst. The cobalt trioxide nanowires in the monolithic catalyst are wrapped by a nitrogen-doped carbon layer, and the product has good quality, high conductivity and long service life.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

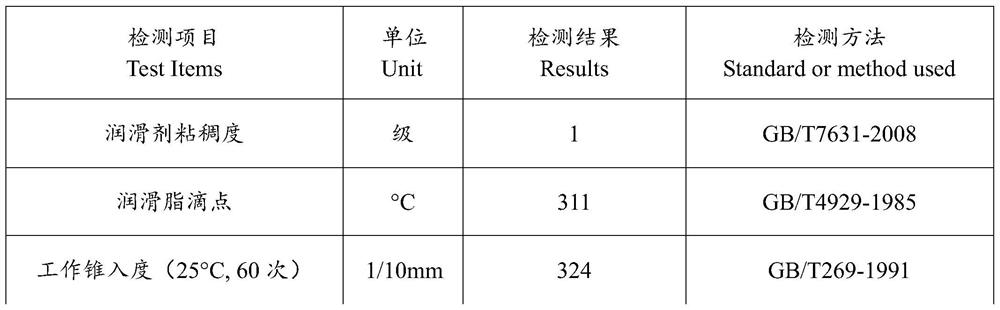

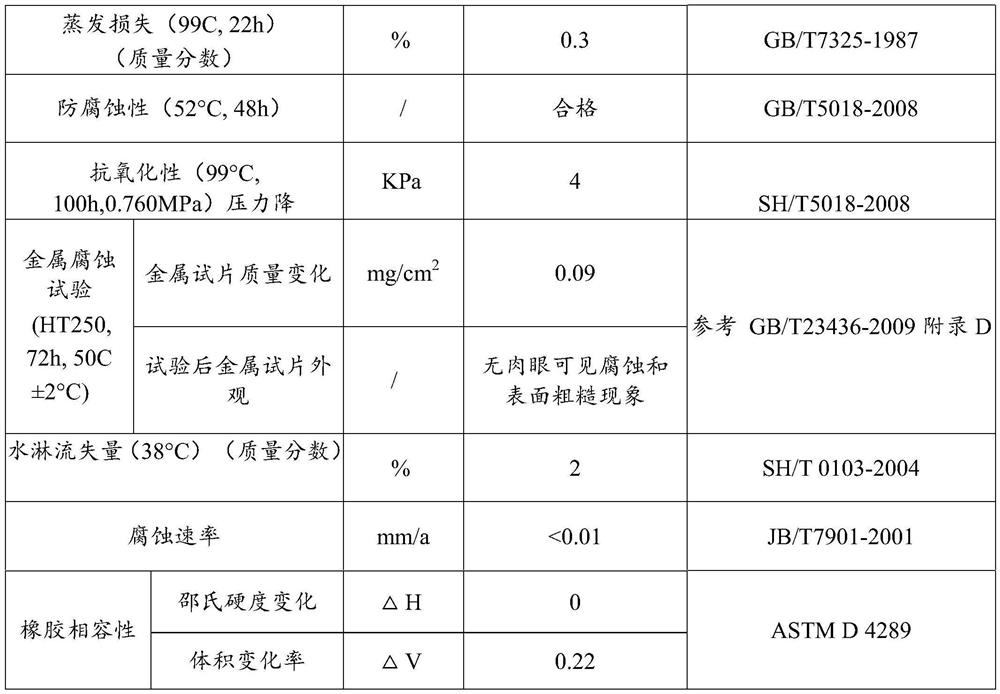

Brake anti-seizure lubricant as well as preparation method and application thereof

PendingCN113583741AAccelerated disengagementBarrier corrosionLubricant compositionButanedioic acidOil separation

The invention discloses a brake anti-seizure lubricant as well as a preparation method and application thereof. The brake anti-seizure lubricant is prepared from the following raw materials: molybdenum dialkyl dithiophosphate, molybdenum dithiocarbamate, dodecenylsuccinic acid, silver aluminum powder, dialkyl diphenylamine, nano silicon dioxide and base oil. Compared with a commercially available brake lubricant, the anti-seizure brake lubricant disclosed by the invention has remarkable progress in steel mesh oil separation and storage pressure oil separation, so that the anti-seizure brake lubricant disclosed by the invention has good colloid stability, is not easy to separate oil in long-term placement and use processes, and has better use performance and longer service life.

Owner:GUANGDONG YUEFU AUTOMOTIVE SUPPLIES

A high heat absorption rate metal pipe wall anti-corrosion and anti-slag wear-resistant ceramic coating

ActiveCN105060909BIncrease heat absorption rateImprove heat exchange capacitySolid componentCeramic coating

The invention discloses a high absorptivity metal pipe wall anti-corrosion and slag resistance wear-resisting ceramic coating, which comprises main components with proportions by weight: silicon carbide 5-15%, brown fused alumina 10-20%, boron nitride 3-8%, boron carbide 2-8%, zirconia 5-10%, potassium titanate 1-3%, chromium oxide 5-10%, iron oxide 5-10%, ball clay 3-10% and high temperature inorganic binder 30-50%, wherein the total weight of the components is 100%. The granularities of all solid components of the high absorptivity metal pipe wall anti-corrosion and slag resistance wear-resisting ceramic coating are less than or equal to 2 microns, parts of components achieve nanometer scales, and the granularities of the parts of components are less than or equal to 100 nanometers. The high absorptivity metal pipe wall anti-corrosion and slag resistance wear-resisting ceramic coating adopts water as solvent, adopts modified high temperature modified inorganic binder as a film forming matter, and determines the addition of the water according to different construction methods, the construction methods comprises a brush coating and a spraying methods, and the volume density of the high absorptivity metal pipe wall anti-corrosion and slag resistance wear-resisting ceramic coating is in 1650-1850kg / m3. The invention discloses a method for making the high absorptivity metal pipe wall anti-corrosion and slag resistance wear-resisting ceramic coating simultaneously.

Owner:夏海清

Filler and Surface Treatment Method of Chip Components

ActiveCN104795367BAccelerated corrosionImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesAlcoholCarboxylic acid

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

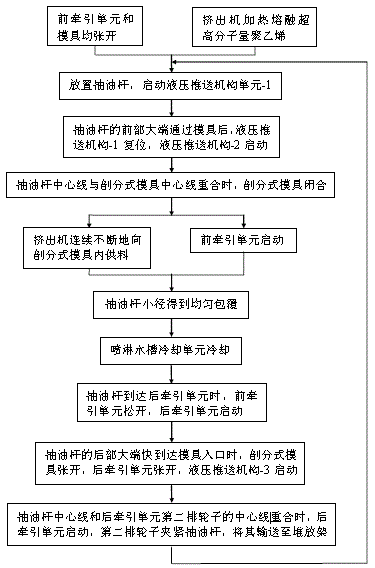

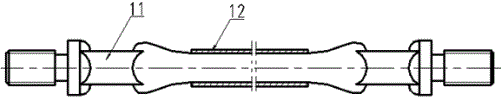

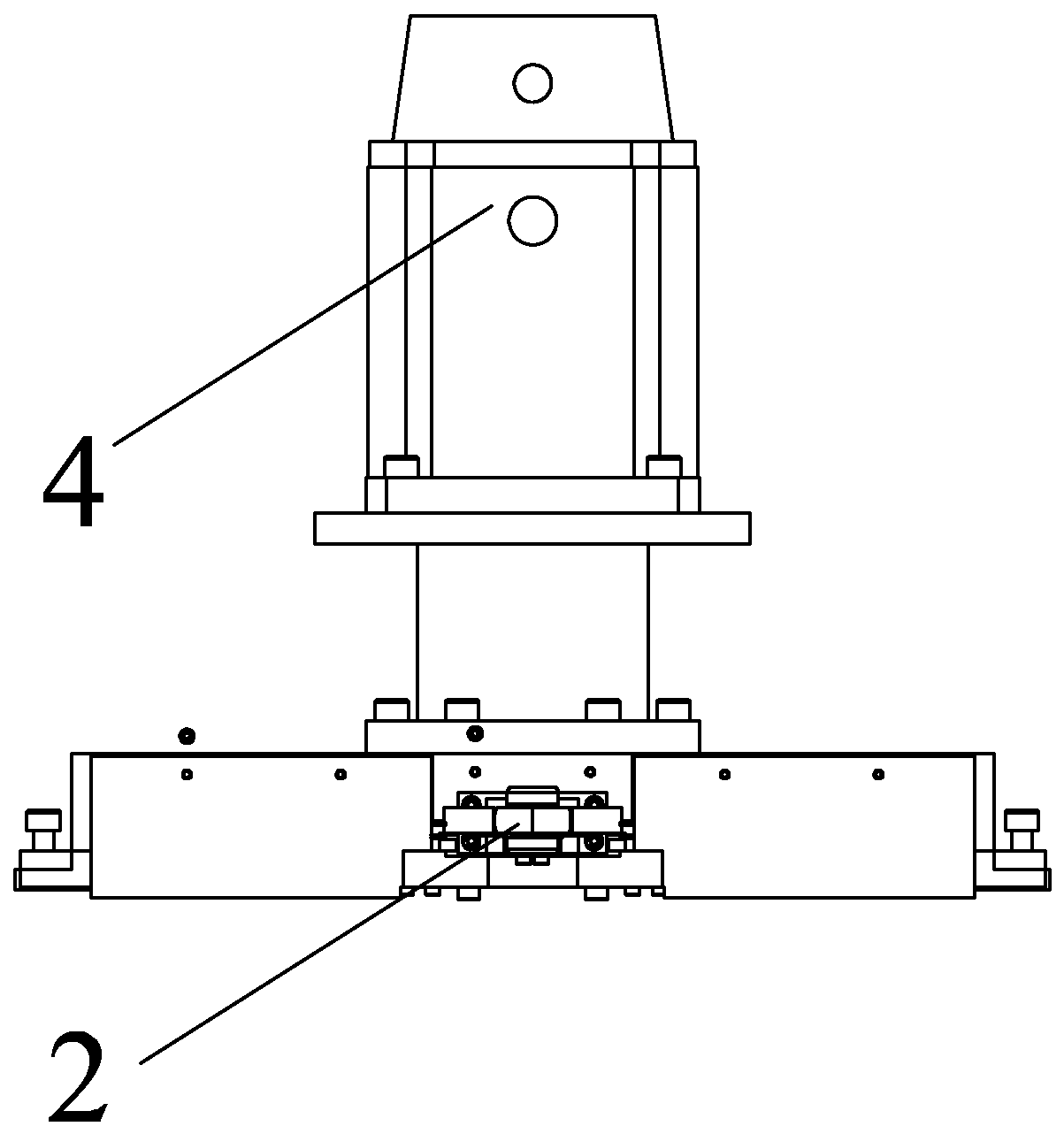

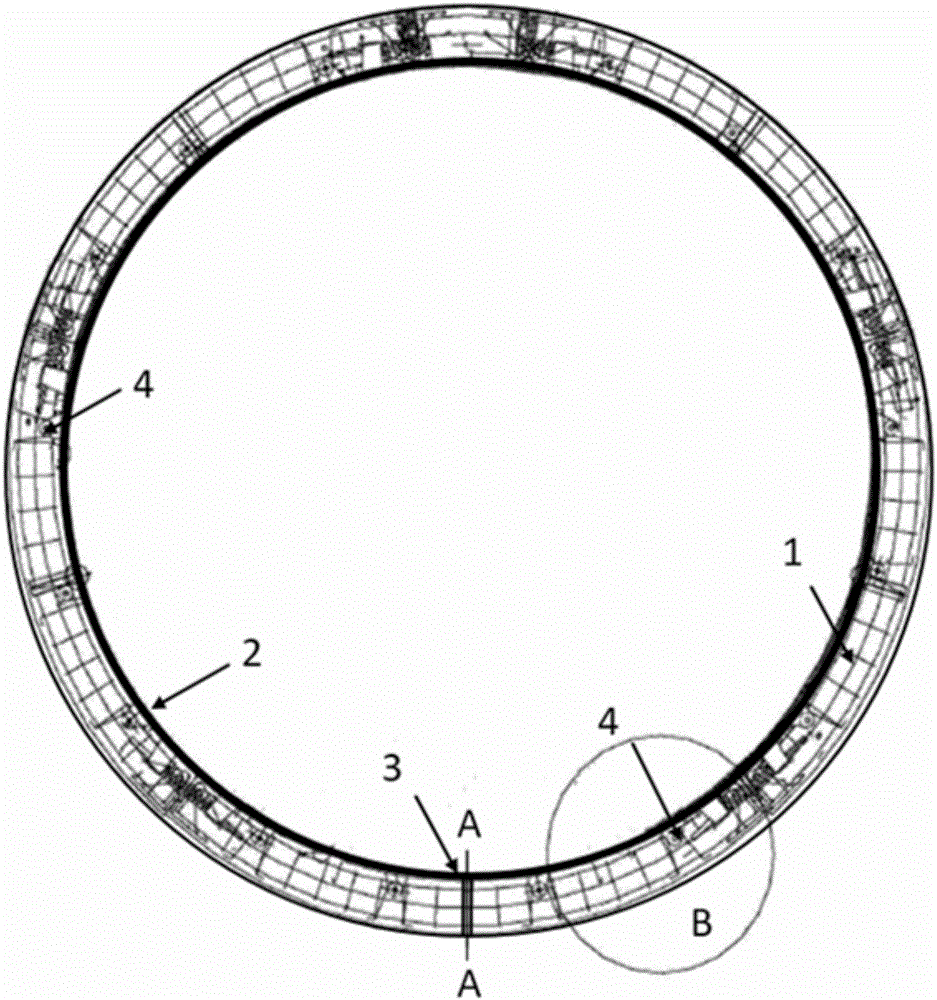

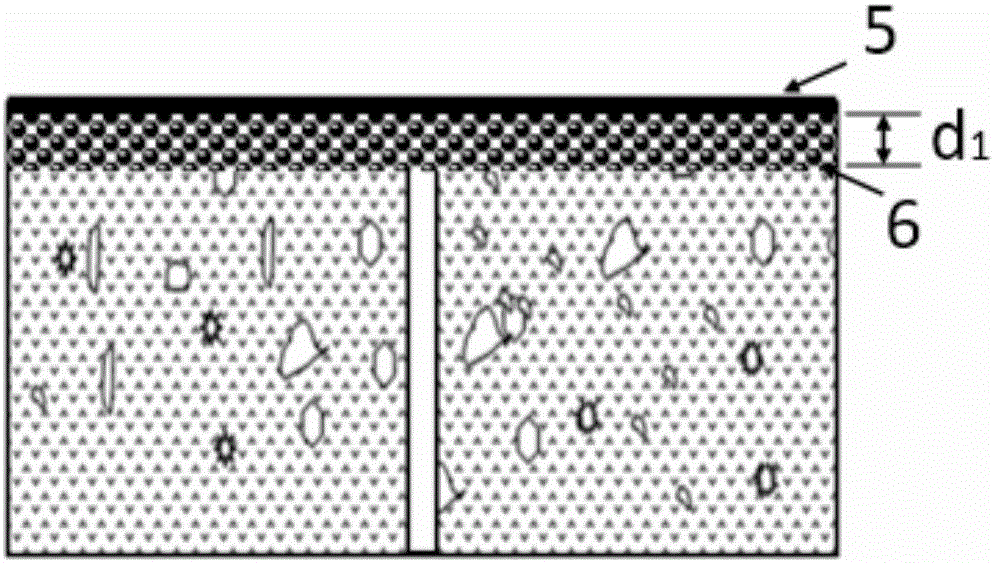

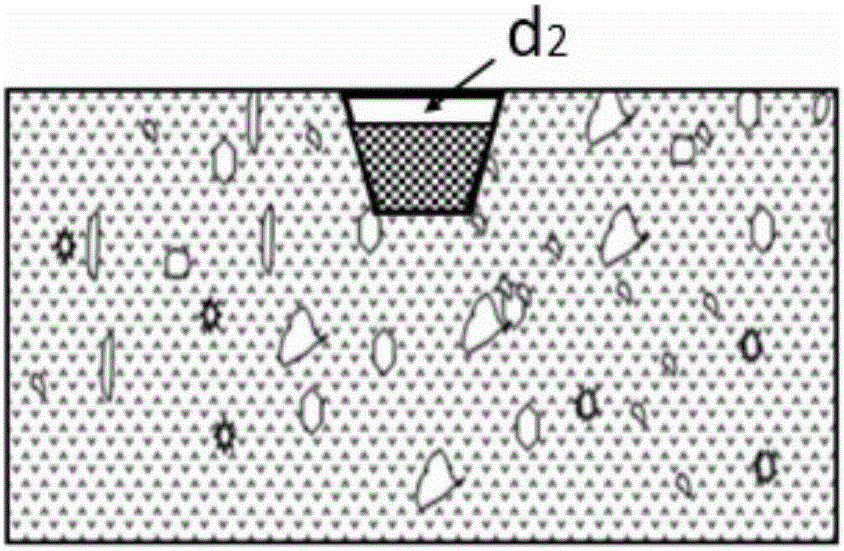

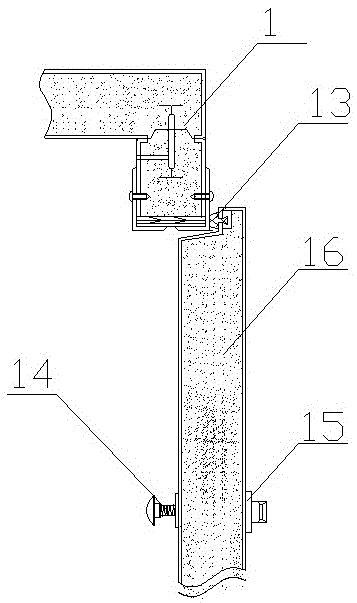

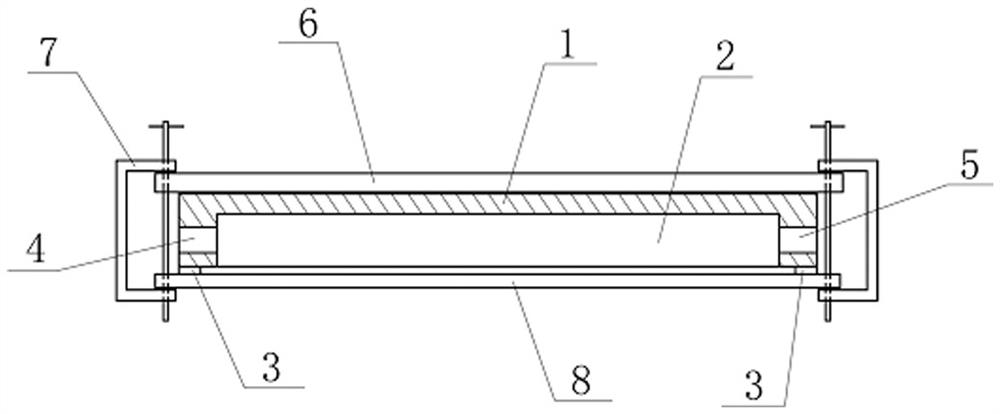

A production equipment for continuously coating ultra-high molecular weight polyethylene on sucker rods

ActiveCN105128302BImprove wear resistanceImprove antifouling performanceState of artAgricultural engineering

The present invention discloses production equipment of a sucker rod continuously coated with ultrahigh molecular weight polyethylene, and the production equipment is prepared by connecting the components of a hydraulic pushing mechanism unit-1, a hydraulic pushing mechanism unit-2, a fixed limit wheel-1, a front tractor unit, an extrusion coating unit, a spray water tank cooling unit, a hydraulic pushing mechanism unit-3, a fixed limit wheel-2, a rear tractor unit and a piling frame in sequence. The extrusion coating unit includes an extruder, a split-type mold and a hydraulic mechanism, after the ultra high molecular weight polyethylene is plasticized and melted in the special extruder, the small diameter part of a standard sucker rod with large diameter two ends and a small diameter middle part is coated with the ultra high molecular weight polyethylene. Compared with the prior art, the small diameter part of the standard sucker rod with larger diameter difference (the maximum and minimum diameter difference may be up to 28.2mm) can be continuously coated, and the coating thickness can be adjusted.

Owner:BEIJING UNIV OF CHEM TECH

Manufacturing method of gate oxide layer and manufacturing method of semiconductor device

ActiveCN105448686BAvoid corrosionImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceOxygen ions

Owner:SEMICON MFG INT (SHANGHAI) CORP

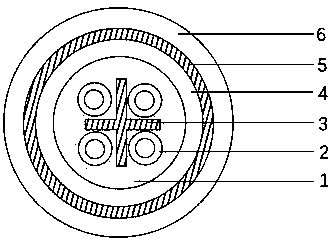

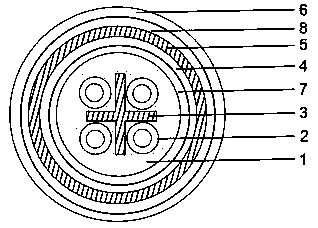

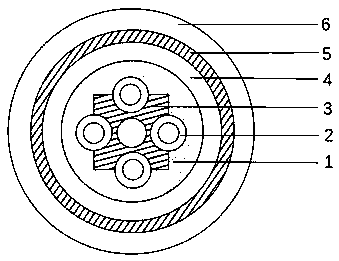

Water-blocking digital communication cable

PendingCN109686489AIncrease plasticity and resistance to stressImprove water resistanceInsulated cablesInsulated conductorsBlocking layerWater block

The invention provides a water-blocking digital communication cable. The water-blocking digital communication cable comprises a separating frame, a plurality of twist pairs, a filling layer, an innersheath layer, a water-blocking layer and an outer sheath layer in sequence from inside to outside. The separating frame is arranged between the twist pairs, and is used for separating the twist pairs.Gaps of the twist pairs are filled with the filling layer, and the twist pairs are coated with the filling layer. The filling layer is used for filling the gaps formed when the twist pairs winding the cable. By adopting the technical scheme, the waterproofness of the digital communication cable is improved, the mechanical strength is good, and the cushioning performance is excellent; and meanwhile, good processability, easy molding forming, high thermal adaptability, high dimensional accuracy, uniform structure and convenient installation are achieved.

Owner:ZHEJIANG HEADWAY COMM EQUIP

Airbags for following cars

InactiveCN104210456BImprove stabilityStrong impactPedestrian/occupant safety arrangementAirbagHigh-temperature corrosion

The invention discloses a safety airbag suitable for a car following, which comprises an airbag cushion, a gas generator and a retainer located between the airbag cushion and the gas generator, and the retainer includes a blocking sill and a downwardly curved bend part, the blocking sill is quadrangular and the two opposite corners of the blocking sill are respectively connected with a first blocking sheet and a second blocking sheet, and both sides of the first blocking sheet and the second blocking sheet are provided with high temperature In the impurity adsorption layer, the curved portion is larger than a quarter arc and smaller than a half arc, which not only has a stable structure, but also can completely block the corrosion of the airbag buffer by high-temperature impurities.

Owner:唐山科骏科技有限公司

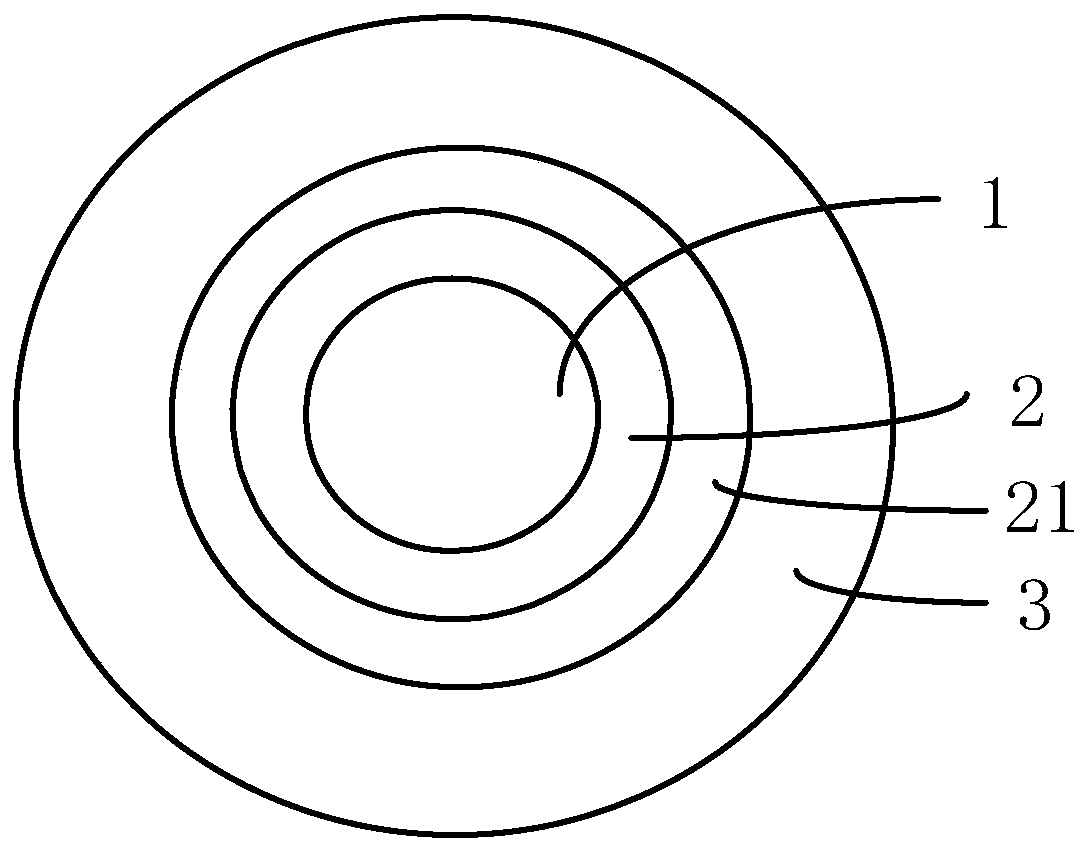

High-temperature oil-proof high numerical aperture optical fiber and preparation method thereof

PendingCN110426778ALarge numerical apertureHigh tensile strengthGlass optical fibreGlass making apparatusBare fiberHigh numerical aperture

The invention relates to a temperature measurement optical fiber, in particular to a high-temperature oil-proof high numerical aperture optical fiber and a preparation method thereof, and mainly solves the problem that an existing temperature measurement optical fiber can not simultaneously meet the requirements of high numerical values, high temperature resistance and oil resistance so as to cause that the existing temperature measurement optical fiber can not meet the temperature measurement use requirements of the transformer winding of the electric power industry. The high-temperature oil-proof high numerical aperture optical fiber comprises a core layer, a coating layer and a protection layer, wherein the core layer, the coating layer and the protection layer are arranged in sequencefrom inside to outside; the core layer is a pure quartz bare fiber; the coating layer comprises one or two high-temperature-resistant coatings; and the protection layer is a high-temperature oil-proofprotection layer.

Owner:西安和其光电科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com